- DL manuals

- Icom

- Transceiver

- IC-M71

- Instruction Manual

Icom IC-M71 Instruction Manual

TM 10-7360-226-13&P

HEADQUARTERS, DEPARTMENT OF THE ARMY

TECHNICAL MANUAL

OPERATOR’S, UNIT AND DIRECT SUPPORT

OPERATION AND MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS & SPECIAL TOOLS LIST)

FOR

CONTAINERIZED KITCHEN

NSN 7360-01-473-3408

DISTRIBUTION STATEMENT A - Approved forpublic release; distribution is unlimited.

Summary of IC-M71

Page 1

Tm 10-7360-226-13&p headquarters, department of the army technical manual operator’s, unit and direct support operation and maintenance manual (including repair parts & special tools list) for containerized kitchen nsn 7360-01-473-3408 distribution statement a - approved forpublic release; distribut...

Page 2

Tm 10-7360-226-13&p a warning summary this warning summary contains general safety warnings and hazardous materials warnings that must be understood and applied during operation and maintenance of this equipment. Failure to observe these precautions could result in serious injury or death to personn...

Page 3

Tm 10-7360-226-13&p b three person lift the bags of arch frame components weigh approximately 130 lbs (59 kg) each, and the packed light storage box weighs approximately 100 lbs (45.4 kg). Three persons must carry these items, lifting with legs, not back, to prevent injury. Inhalation hazard generat...

Page 4

Tm 10-7360-226-13&p c/d blank heavy object read and understand all instructions in this manual before installing or operating the jacks. Personal injury or property damage can occur if the jacks are improperly installed or operated. Neverallow anyone or any part of your body to be under any portion ...

Page 5

This page intentionally left blank.

Page 6

Tm 10-7360-226-13&p a/b blank list of effective pages/work packages date of issue for the original manual is: original . . . Total number of pages for front and rear matter is 14 and total number of work packages is 55 consisting of the following: page/wp no. *revision no. A – c .......................

Page 7

This page intentionally left blank.

Page 8: Technical Manual

Tm 10-7360-226-13&p i headquarters, department of the army washington, dc technical manual operator’s, unit and direct support operation and maintenance manual (including repair parts & special tools list) for containerized kitchen nsn 7360-01-473-3408 distribution statement a - approved for public ...

Page 9

Tm 10-7360-226-13&p ii table of contents - continued chapter 2 – operator instructions description of operator controls and indicators .........................................................0005 00 operation under usual conditions ......................................................................

Page 10

Tm 10-7360-226-13&p iii/iv blank table of contents – continued chapter 6 – supporting information references.................................................................................................................0031 00 maintenance allocation chart (mac) .......................................

Page 11

This page intentionally left blank.

Page 12

Tm 10-7360-226-13&p v/vi blank how to use this manual this manual contains general information, operating instructions, preventive maintenance checks and services (pmcs), and maintenance/repair instructions for the containerized kitchen (ck). Front matter consists of front cover, warning summary, ti...

Page 13

This page intentionally left blank.

Page 14

Tm 10-7360-226-13&p chapter 1 introductory information with theory of operation.

Page 15

This page intentionally left blank.

Page 16

Tm 10-7360-226-13&p containerized kitchen (ck) 0001 00 general information 0001 00-1 scope equipment covered this technical manual contains instructions for the operation, preventive maintenance, unit and direct support corrective maintenance for the containerized kitchen (ck) and its associated equ...

Page 17

Tm 10-7360-226-13&p containerized kitchen (ck) 0001 00 general information 0001 00-2 purpose of equipment the ck is a mobile, rapidly deployable kitchen that is capable of preparing and serving up to 650 army field menu meals (a-ration, heat and serve ration or any combination) up to three times per...

Page 18

Tm 10-7360-226-13&p containerized kitchen (ck) 0001 00 general information 0001 00-3 these individual warranties vary in terms and conditions. Sfa inc., frederick manufacturing division’s warranty does not apply to these items since typically these individual equipment warranties provide coverage to...

Page 19

Tm 10-7360-226-13&p containerized kitchen (ck) 0001 00 general information 0001 00-4 mtoe modified table of organization and equipment nbc nuclear, biological, and chemical nha next higher assembly nsf national sanitation foundation nsn national stock number od outside diameter pdp power distributio...

Page 20

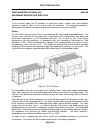

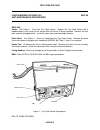

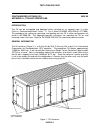

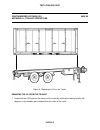

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-1 equipment characteristics, capabilities and features the containerized kitchen is a mobile, self-contained field kitchen configured in an 8-ft by 8-ft by 20-ft international organization for standardizati...

Page 21

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-2 integrated equipment includes a griddle, steam table, cook pot cradles, tray pack heater, and two ovens, all heated by modern burner units (mbus). A permanent fuel distribution system provides fuel to the...

Page 22

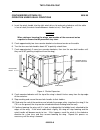

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-3 location and description of major components the ck provides approximately 390 square feet of enclosed floor space. About 30 square feet is used as a mechanical room to house the generator, air conditione...

Page 23

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-4 figure 3. Containerized kitchen, serving side view. Figure 4 shows the cook-equipment interface during meal preparation, and illustrates the area of operation for the five cooks. Each cook has access to t...

Page 24

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-5 refrigerators (2) mobile warming cabinet sink assembly tray pack heater dual oven assembly air conditioners (2) mobile storage cabinet mobile storage cabinet serving tables (2) steam table or cooking rack...

Page 25

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-6 the mechanical room, figure 5, houses the ck’s utility components. These include the generator, air conditioners, ecu controller, mbu converter, electrical distribution panels and ventilation fans. The ge...

Page 26

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-7 the container safety certification plate and system identification plate are located to the left of the personnel access door at the end of the shelter core. These are illustrated in figure 6 and figure 7...

Page 27

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-8 in the transport mode, the ck provides the necessary space, storage area, and tie-downs required to stow all items of the system inside the container. The equipment packout is configured to distribute the...

Page 28

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-9 cook center assembly the cook center assembly, figure 9, houses four mbus over which any two of the following can be placed: the griddle, the steam table and adapter top, or two cook pot cradle adapters a...

Page 29

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-10 figure 10. Cook pot assembly dual oven assembly the dual oven assembly, figure 11, consists of two mbu-fired ovens mounted on a mobile base cabinet. Integral casters allow it to be easily moved between i...

Page 30

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-11 refrigerators two refrigerators provide approximately 58 cubic feet of refrigerated storage. The refrigerators use r-134a refrigerant, which is commercially available, environmentally safe, and non-ozone...

Page 31

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-12 tray pack heater the ck includes a modified tray pack heater which is positioned to the left of the dual oven assembly. The heater connects to the fuel and power lines on the back of the oven base. Gener...

Page 32

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-13 blackout lights figure 13. Lighting fixture layout. The lighting controls, described in detail in wp 0003 00, include switches for operating the lights and for selecting the lighting mode (normal or blac...

Page 33

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-14 air curtain duct from makeup air fan duct to exhaust fan grease cup grease filters figure 14. Cook center exhaust hood. The exhaust hood includes removable, washable, aluminum baffle-type grease filters....

Page 34

Tm 10-7360-226-13&p containerized kitchen (ck) 0002 00 equipment description and data 0002 00-15/16 blank spot cooling and heating of various parts of the food preparation area is controlled by several manually adjustable vent openings in the fixed ceiling duct in the shelter core. The ecu is not de...

Page 35

This page intentionally left blank.

Page 36

Tm 10-7360-226-13&p containerized kitchen (ck) 0003 00 theory of operation 0003 00-1 cooking equipment – mbus operation of the mbus is described in detail in tm 10-7310-281-13&p. The mbus receive fuel through a refueling system which provides fuel to eight locations (five in the cook center and thre...

Page 37

Tm 10-7360-226-13&p containerized kitchen (ck) 0003 00 theory of operation 0003 00-2 process being heated or cooled. From the outlet plenum, the air is distributed throughout the kitchen through fixed ductwork. The ecu provides automatic electrical load control to maximize the amount of available ai...

Page 38

Tm 10-7360-226-13&p containerized kitchen (ck) 0003 00 theory of operation 0003 00-3/4 blank hand sink faucet water heater water pump water hose fitting from fresh water system hand sink quick disconnect covered floor drain flexible drain hose quick disconnect to water reclaim system waste water dra...

Page 39

This page intentionally left blank.

Page 40

Tm 10-7360-226-13&p containerized kitchen (ck) 0004 00 support data for repair parts, special tools, tmde, and support equipment 0004 00-1/2 blank common tools and equipment for common tools and equipment, refer to the modified table of organization and equipment (mtoe), cta 50-970, expendable/durab...

Page 41

This page intentionally left blank.

Page 42

Tm 10-7360-226-13&p chapter 2 operator instructions.

Page 43

This page intentionally left blank.

Page 44

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-1 introduction major controls and indicators for the ck consist of those for the generator, electrical power selection and control, lighting, mbus, hand sink assembly, and cook center venti...

Page 45

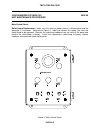

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-2 power distribution panel the power distribution panel (pdp), figure 2, is located on the mechanical room wall in the serving area. The panel houses the circuit breakers that control the d...

Page 46

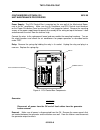

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-3 main control panel the main control panel (mcp), figure 3, is located in the food preparation area, on the wall to the right of the personnel access door. It houses the controls and indic...

Page 47

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-4 generator power available off external power available external power on generator power on on off on off normal blackout interior lighting lighting mode emergency light system power sele...

Page 48

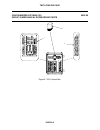

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-5 mbu power on off figure 4. Mbu power switch. Mbu converter the mbu converter, figure 5, is mounted on the wall in the mechanical room, and has the following controls and indicators: • mai...

Page 49

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-6 power converter on off power 90-132v ac 47-63 hz outpu t a outpu t b 26 v dc 600w continuous 1 2 3 4 power cord figure 5. Mbu converter. Mbu control panel each mbu has an integral control...

Page 50

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-7 total hours run warm up fueling/fuel low fuel voltage service start power stop fuel operation 1. Press power button. 2. Turn burner control to high (start) position. 3. Press start button...

Page 51

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-8 figure 7. Appliance control box. Cook center ventilation the cook center exhaust hood intake and exhaust fans are controlled together by a single wall- mounted, rotary speed-control switc...

Page 52

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-9 figure 8. Cook center ventilation control switch. Mobile warming cabinet the controls and indicators for the mobile warming cabinet (figure 9) are located at the bottom front of the unit ...

Page 53

Tm 10-7360-226-13&p containerized kitchen (ck) 0005 00 description of operator controls and indicators 0005 00-10 refrigerators each refrigerator is controlled by a thermostat (figure 10) located on the inside back wall of the unit. Rotating the knob clockwise lowers the temperature setting (makes t...

Page 54

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-1 initial setup: ck packed out maintenance level personnel required operator/crew four (plus one supervisor) general when the ck arrives at the deployment site, all equipment necessary for setup and opera...

Page 55

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-2 unpacking the mechanical room before beginning to set up the ck, unpack the mechanical room as described below. The room is at the end of the container with the double doors. As items are removed, place...

Page 56

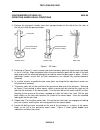

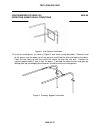

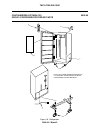

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-3 4. Retrieve the jack/winch handles from their storage location on the side of the rifle rack, to the left just inside the personnel door. Figure 1. Ck jacks. 5. Referring to figure 2, insert a corner ja...

Page 57

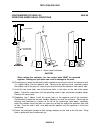

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-4 extension/ base plate jack body figure 2. Corner jack installation. Caution when raising the container, the two corner jacks must be operated together. Raising one jack alone can result in damage to the...

Page 58

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-5 leveling the container on the trailer 1. Locate the two bullseye levels mounted on the ends of the container, in recesses in the corner blocks. One is to the left of the personnel access door, and the o...

Page 59

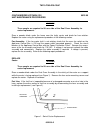

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-6 4. Insert the winch handle into the right winch drive slot and crank clockwise until the cable is free of slack (the winch handle becomes harder to turn). See figure 4. When raising or lowering the wing...

Page 60

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-7 caution do not move loads onto the wing until the wing jacks are installed. 12. Adjust each wing jack by screwing its base completely in. Align a set of holes in the jack with the bracket on the wing. I...

Page 61

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-8 table 1. Contents of shelter frame bags. Component qty roof arch 5 “t” vertical (left side) 1 “t” vertical (right side) 1 “x” vertical 3 arch spacer 3 (prep side) 2 (serving side) adjustable spacer (2 s...

Page 62

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-9 figure 7. Arch frame inserted into arch cups. 7. Pushing lightly on the end of the assembly to hold it in the header cup, swing the assembly (keeping corner below fabric cover) until the vertical bottom...

Page 63

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-10 figure 8. Arch spacer installation. 12. Install a curved spacer, as shown in figure 9, over each serving wing door. Place one end of the spacer near the down-turn of the roof arch and lift up the other...

Page 64

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-11 fabric erection – food preparation wing note the wing floor must be level with the center core floor to ensure a correct fit for the roof arches. 1. Unstrap the two refrigerators, unlock their casters,...

Page 65

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-12 figure 10. Adjustable spacer. Mechanical room setup 1. If the ck is mounted on a trailer, install the platform to provide a safe standing area for setting up the mechanical room. Hook one edge of the p...

Page 66

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-13 figure 11. Awning installation. 4. Retrieve the generator exhaust elbow pipe from its storage location to the right of the generator. Insert the open end of the pipe down through the opening in the awn...

Page 67

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-14 11. Locate the ends of the two clear plastic air conditioner condensation drain hoses. Position them so the condensation drains outside of the mechanical room. 12. Retrieve the mbu fuel can adapter fro...

Page 68

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-15 4. Connect the other end of the grounding cable to the grounding terminal on the power entrance panel. Ensure that the connection is tight. Energizing the ck from the onboard generator the following pr...

Page 69

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-16 off on off on off normal blackout interior lighting lighting mode emergency light generator power available external power available external power on generator power on system power selection e-stop f...

Page 70

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-17 do not attempt to connect an energized cable to the power entrance panel. 2. Ensure that external power is turned off at its source, then connect the cable at the power entrance panel. 3. Connect the o...

Page 71

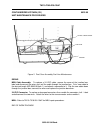

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-18 food preparation area serving area shelter core (top view) white light white light blackout light oven assy 24 vdc white light blackout light appliance control box mechanical room mobile warming cabine...

Page 72

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-19 7. Uncoil the water heater and water pump power cables from the back of the sink assembly and temporarily drape them across the top of the assembly. 8. Roll up the window flap behind the sink location ...

Page 73

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-20 22. Remove the heater fan assembly from inside the tray pack heater and mount it in its bracket on the back of the unit. Route the exhaust pipe through its penetration in the shelter wall, orienting th...

Page 74

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-21 31. Remove the cook pot cradle adapters stored in the blanket from the cook center and store them under the tables. Remove the moving blanket and set it aside in a convenient location. 32. Remove the r...

Page 75

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-22 ceiling light installation in the event of lamp breakage, be careful in removing glass fragments and white phosphorous dust that may be dispersed from the fixture. Handling glass fragments or inhaling ...

Page 76

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-23 water and drain system startup the water supply hose, internal drain hose, and external drain hose should already be connected as described earlier in this work package. Fill the water system as follow...

Page 77

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-24 kitchen operation generator a detailed description of generator operation is provided in tm 9-6115-642-10. Modern burner units a detailed description of mbu operation is provided in tm 10-7310-281-13&p...

Page 78

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-25 kitchen packout and preparation for transport introduction the iso expandable shelter serves as the primary container for the ck. Upon completion of an operational deployment, the ck is packed for tran...

Page 79

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-26 preparation for packout before beginning packout, prepare the ck as follows. Except as noted, these steps may be performed simultaneously or in any convenient order. Ensure that all ck components have ...

Page 80

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-27 table 2. Loose item packout list. Item qty packout location fire extinguisher 4 wall brackets ground rod assembly 1 brackets inside the left door of the mechanical room wing jack 8 on top of stair/ladd...

Page 81

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-28 table 2. Loose item packout list – continued item qty packout location ladle, 8-ounce, 12-inch handle 4 shelf under the ovens measuring cup, 4-quart 2 shelf under the right oven measuring set, spoons 2...

Page 82

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-29 referring to figure 16, pack out the cook center as follows: 1. Pack the mbus, griddle and grease pan in place. 2. Place the moving blanket over the griddle. Place the cook pot cradle adapters on the b...

Page 83

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-30 do not use one of the water supply hoses to drain the tray pack heater. They are for potable water use and could become contaminated. 3. If the tray pack heater must be drained, roll it to the area of ...

Page 84

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-31 mobile warming cabinet 1. Unplug the power cord, coil it, and hang it from the holder on the back of the unit. 2. Place all the baking pans except one on the bottom slides. 3. Place the cutting boards ...

Page 85

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-32 food preparation wing closure 1. Close and secure the windows in the food preparation wing. 2. Retrieve any ratchet straps and rubber straps still hanging in the food preparation wing and place them in...

Page 86

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-33 refrigerator tie-down 1. Place the long ends of three ratchet straps in the tie-down provisions for the first refrigerator. 2. Referring to figure 15, position the right-hand hinged refrigerator with i...

Page 87

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-34 when raising or lowering the wings, one member of the crew must act as a spotter to ensure that all personnel stay clear. 8. Winch up the wing using the right winch. When the wing is approximately half...

Page 88

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-35 2. Unbuckle the awning from both doors and lay it up out of the way. 3. Remove the awning support bar from the brackets on the doors. Slip the straps from the generator, air conditioner, and exhaust fa...

Page 89

Tm 10-7360-226-13&p containerized kitchen (ck) 0006 00 operation under usual conditions 0006 00-36 19. Place the wing jacks, with their base plates to the left, on top of the stair/ladders. Slide the tops of the jacks under the air conditioner and secure the jacks to the stair/ladders using two shor...

Page 90

Tm 10-7360-226-13&p containerized kitchen (ck) 0007 00 operation under unusual conditions 0007 00-1 initial setup: kitchen set up and operating maintenance level personnel required operator/crew four (plus one supervisor) general this work package provides instructions for operating the ck under unu...

Page 91

Tm 10-7360-226-13&p containerized kitchen (ck) 0007 00 operation under unusual conditions 0007 00-2 operation in snow, ice, or extreme cold in extreme cold, do not touch metal parts with bare hands. Severe skin damage may result. Note fluorescent lights may be slow to light at very low temperatures....

Page 92

Tm 10-7360-226-13&p containerized kitchen (ck) 0007 00 operation under unusual conditions 0007 00-3 draining the water system if freezing conditions are possible while the ck is packed for transport, or the kitchen is to be left set up but unheated during possible freezing conditions, drain the wate...

Page 93

Tm 10-7360-226-13&p containerized kitchen (ck) 0007 00 operation under unusual conditions 0007 00-4 emergency procedures operation during blackout conditions meal preparation and serving can be conducted during blackout conditions. Kitchen doors should be opened only as necessary, and should be clos...

Page 94

Tm 10-7360-226-13&p chapter 3 troubleshooting procedures.

Page 95

This page intentionally left blank.

Page 96

Tm 10-7360-226-13&p containerized kitchen (ck) 0008 00 introduction 0008 00-1/2 blank malfunction/symptom index the malfunction/symptom index (wp 0009 00) is a quick reference for finding troubleshooting procedures. Associated with each symptom name is a work package sequence number representing the...

Page 97

This page intentionally left blank.

Page 98

Tm 10-7360-226-13&p containerized kitchen (ck) 0009 00 malfunction/symptom index 0009 00-1/2 blank malfunction/symptom troubleshooting procedure electrical system no power to kitchen – external source ...........................................................Wp 0010 00 no power to kitchen – generat...

Page 99

This page intentionally left blank.

Page 100

Tm 10-7360-226-13&p containerized kitchen (ck) 0010 00 troubleshooting procedures (electrical system) 0010 00-1 this work package covers: electrical system initial setup: kitchen set up maintenance level operator/crew electrical system malfunctions table 1. Troubleshooting procedures (electrical sys...

Page 101

Tm 10-7360-226-13&p containerized kitchen (ck) 0010 00 troubleshooting procedures (electrical system) 0010 00-2 table 1. Troubleshooting procedures (electrical system) – continued malfunction test or inspection corrective action ensure that the generator power control circuit breaker (power entrance...

Page 102

Tm 10-7360-226-13&p containerized kitchen (ck) 0010 00 troubleshooting procedures (electrical system) 0010 00-3/4 blank table 1. Troubleshooting procedures (electrical system) - continued malfunction test or inspection corrective action check generator fuel level refill fuel tank check for dirty fue...

Page 103

This page intentionally left blank.

Page 104

Tm 10-7360-226-13&p containerized kitchen (ck) 0011 00 troubleshooting procedures (modern burner unit) 0011 00-1 this work package covers: modern burner unit (mbu) initial setup: ck set up maintenance level operator/crew modern burner unit (mbu) malfunctions table 1. Troubleshooting procedures (mbu)...

Page 105

Tm 10-7360-226-13&p containerized kitchen (ck) 0011 00 troubleshooting procedures (modern burner unit) 0011 00-2 table 1. Troubleshooting procedures (modern burner unit) – continued malfunction test or inspection corrective action mbu is in cook center start right-side mbu first mbu is in oven assem...

Page 106

Tm 10-7360-226-13&p containerized kitchen (ck) 0012 00 troubleshooting procedures (environmental control unit) 0012 00-1/2 blank this work package covers: environmental control unit (ecu) initial setup: ck set up maintenance level operator/crew environmental control system malfunctions table 1. Trou...

Page 107

This page intentionally left blank.

Page 108

Tm 10-7360-226-13&p containerized kitchen (ck) 0013 00 troubleshooting procedures (hand sink assembly) 0013 00-1 this work package covers: hand sink assembly initial setup: ck set up maintenance level operator/crew hand sink assembly malfunctions table 1. Troubleshooting procedures (hand sink assemb...

Page 109

Tm 10-7360-226-13&p containerized kitchen (ck) 0013 00 troubleshooting procedures (hand sink assembly) 0013 00-2 table 1. Troubleshooting procedures (hand sink assembly) - continued malfunction test or inspection corrective action notify unit maintenance no hot water water heater plugged in check/pl...

Page 110

Tm 10-7360-226-13&p containerized kitchen (ck) 0014 00 troubleshooting procedures (kitchen appliances) 0014 00-1 this work package covers kitchen appliances initial setup: ck set up maintenance level operator/crew kitchen appliance malfunctions table 1. Troubleshooting procedures (kitchen appliances...

Page 111

Tm 10-7360-226-13&p containerized kitchen (ck) 0014 00 troubleshooting procedures (kitchen appliances) 0014 00-2 table 1. Troubleshooting procedures (kitchen appliances) - continued malfunction test or inspection corrective action tray pack heater fan does not work heater fan power cord plugged in c...

Page 112

Tm 10-7360-226-13&p chapter 4 operator/unit maintenance procedures.

Page 113

This page intentionally left blank.

Page 114

Tm 10-7360-226-13&p containerized kitchen (ck) 0015 00 service upon receipt 0015 00-1/2 blank this work package covers: unpacking, inspection initial setup: ck packed out maintenance level operator/crew unpacking the ck is shipped with all components and equipment packed inside the iso container. To...

Page 115

This page intentionally left blank.

Page 116

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services (pmcs) 0016 00-1 this work package covers: introduction, preventive maintenance checks and services (pmcs) procedures initial setup: ck set up maintenance level operator/crew introduction preventive mai...

Page 117

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services (pmcs) 0016 00-2 lubrication the only component of the ck requiring scheduled lubrication is the generator set. Refer to lo 9-6115-642-12 and tm 9-6115-642-10 for lubrication procedures. The container w...

Page 118

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-3 this section covers: before operation preventive maintenance checks and services (pmcs) initial setup: kitchen set up for operation maintenance level: operator/crew table 1. Before operation p...

Page 119

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-4 table 1. Before operation pmcs for ck - continued item no. Interval man- hour item to be checked or serviced procedure equipment not ready/ available if: inspect ratchet straps for fraying, cu...

Page 120

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-5 table 1. Before operation pmcs for ck - continued item no. Interval man- hour item to be checked or serviced procedure equipment not ready/ available if: inspect oven fan for damage, missing o...

Page 121

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-6 table 1. Before operation pmcs for ck - continued item no. Interval man- hour item to be checked or serviced procedure equipment not ready/ available if: inspect prep/serving tables and drawer...

Page 122

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-7 this section covers: during operation preventive maintenance checks and services (pmcs) initial setup: kitchen set up/operating maintenance level: operator/crew table 2. During operation pmcs ...

Page 123

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-8 table 2. During operation pmcs for ck – continued item no. Interval man- hour item to be checked or serviced procedure equipment not ready/ available if: 6 during refrigerators inspect door fo...

Page 124

Tm 10-7360-226-13&p containerized kitchen (ck) 0016 00 preventive maintenance checks and services 0016 00-9/10 blank this section covers: after operation preventive maintenance checks and services (pmcs) initial setup: kitchen set up/not operating maintenance level: operator/crew table 3. After oper...

Page 125

This page intentionally left blank.

Page 126

Tm 10-7360-226-13&p containerized kitchen (ck) 0017 00 unit maintenance procedures 0017 00-1 shelter assembly this section covers: inspect, test, replace, repair initial setup: ck set up for operation maintenance level unit tools and special tools tool kit, general mechanic's (wp 0052 00, table 1, i...

Page 127

Tm 10-7360-226-13&p containerized kitchen (ck) 0017 00 unit maintenance procedures 0017 00-2 if the winch assembly cable is not binding, the winch assembly can be removed following the replacement procedure in the next section. After the winch assembly has been removed from the shelter, remove the h...

Page 128

Tm 10-7360-226-13&p containerized kitchen (ck) 0017 00 unit maintenance procedures 0017 00-3 to install a new cable, feed the end of the cable opposite the ferrule through the hole from inside the mechanical room. Avoid twisting and kinking the cable. Feed the end of the cable through the tube at th...

Page 129

Tm 10-7360-226-13&p containerized kitchen (ck) 0017 00 unit maintenance procedures 0017 00-4 repair fabric repair, outside surface or awning: to repair a tear in the outer fabric or awning, use the fabric repair kit. Cut a patch of at least a one-inch greater size than the tear in all directions. Ro...

Page 130

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-1 mechanical room this section covers: inspect, test, replace initial setup: ck set up for operation maintenance level unit tools and special tools tool kit, general mechanic's (wp 0052 00, table 1, item 1) ge...

Page 131

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-2 if the 24 vdc at the mbu converter is correct, check the 24 vdc wiring to the kitchen area. Electrical power: see power entrance panel: wp 0026 00 cook center fan assemblies: rotate the fan control knob on t...

Page 132

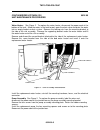

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-3 remove the access panels of both air conditioners. Set the ecu mode switch in the operating area for high cool. Monitor ecu operation by noting the leds as shown in figure 1. Led configuration is also shown ...

Page 133

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-4 figure 3. Air conditioner terminal boards. Generator set: refer to the troubleshooting procedures in tm 9-6115-642-24 to test the generator set. Replace before servicing any component of the mechanical room,...

Page 134

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-5 exhaust fan: turn off and lock or tag intake/exhaust fan circuit breakers #2 and #4 on the power distribution panel. Remove and retain the four mounting bolts on the exhaust duct and remove the fan assembly....

Page 135

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-6 power supply: the ecu control box is mounted on the rear wall of the mechanical room, next to the air conditioners. Make sure the air conditioner and ecu control circuit breakers on the power distribution pa...

Page 136

Tm 10-7360-226-13&p containerized kitchen (ck) 0018 00 unit maintenance procedures 0018 00-7/8 blank remove the flexible exhaust pipe at the top of the generator. Remove and retain the hold down plates at the base of the generator. Leave the exhaust plenum attached the top of the generator. A forkli...

Page 137

This page intentionally left blank.

Page 138

Tm 10-7360-226-13&p containerized kitchen (ck) 0019 00 unit maintenance procedures 0019 00-1 cook center this section covers: inspect, test, replace, repair initial setup: ck set up for operation maintenance level unit tools and special tools tool kit, general mechanic's (wp 0052 00, table 1, item 1...

Page 139

Tm 10-7360-226-13&p containerized kitchen (ck) 0019 00 unit maintenance procedures 0019 00-2 the problem. Remove the power connector at the mbu and check for 24 vdc. If voltage is present, recheck the procedures in the mbu manual. If 24 vdc is not present, remove the access cover on the 24 vdc elbow...

Page 140

Tm 10-7360-226-13&p containerized kitchen (ck) 0019 00 unit maintenance procedures 0019 00-3/4 blank attach a connector to it. Slip the new cable down through the cook center frame and junction box. Attach the wire nuts and reassemble the junction box cover. Mbu: refer to tm 10-7310-281-13&p for mbu...

Page 141

This page intentionally left blank.

Page 142

Tm 10-7360-226-13&p containerized kitchen (ck) 0020 00 unit maintenance procedures 0020 00-1 dual oven assembly this section covers: inspect, test, replace, repair initial setup: ck set up for operation power cable, fuel line disconnected maintenance level unit tools and special tools tool kit, gene...

Page 143

Tm 10-7360-226-13&p containerized kitchen (ck) 0020 00 unit maintenance procedures 0020 00-2 three people are required to lift one side of the dual oven assembly for caster replacement . Place a wooden block under the frame near the faulty caster and check for free rotation. Replace the caster using...

Page 144

Tm 10-7360-226-13&p containerized kitchen (ck) 0020 00 unit maintenance procedures 0020 00-3/4 blank figure 2. Dual oven assembly fuel line maintenance. Repair mbu cable assembly: to replace a 24 vdc cable, remove the cover of the junction box, label and disconnect the wires and pull the cable throu...

Page 145

This page intentionally left blank.

Page 146

Tm 10-7360-226-13&p containerized kitchen (ck) 0021 00 unit maintenance procedures 0021 00-1 mobile warming cabinet this section covers: inspect, test, replace initial setup: ck set up for operation warming cabinet operational maintenance level unit tools and special tools tool kit, general mechanic...

Page 147

Tm 10-7360-226-13&p containerized kitchen (ck) 0021 00 unit maintenance procedures 0021 00-2 if insufficient warming of the cabinet is noted, visually check the door seals and gasket for warpage or deteriorated condition of the seals. If the warming oven is on, it may be possible to detect a deterio...

Page 148

Tm 10-7360-226-13&p containerized kitchen (ck) 0021 00 unit maintenance procedures 0021 00-3 door seal: refer to figure 2. Remove and retain the five door seal mounting screws and the door seal retaining strip. Install the new door seal using retained hardware. On power metro hm15lw figure 2. Mobile...

Page 149

Tm 10-7360-226-13&p containerized kitchen (ck) 0021 00 unit maintenance procedures 0021 00-4 power cord: label and disconnect the power cord wires. Using pliers, squeeze the strain relief from inside and push out. Slip the replacement power cord through the strain relief and then through the mountin...

Page 150

Tm 10-7360-226-13&p containerized kitchen (ck) 0022 00 unit maintenance procedures 0022 00-1 refrigerator this section covers: inspect, test, replace initial setup: ck set up for operation refrigerator power cord unplugged maintenance level unit tools and special tools tool kit, general mechanic's (...

Page 151

Tm 10-7360-226-13&p containerized kitchen (ck) 0022 00 unit maintenance procedures 0022 00-2 perimeter of the door and by visually inspecting the entire gasket for hardness, cuts and a deteriorated condition. Casters: attempt moving therefrigerator with the casters unlocked. It should move freely wi...

Page 152

Tm 10-7360-226-13&p containerized kitchen (ck) 0022 00 unit maintenance procedures 0022 00-3/4 blank caster: see figure 2.To replace a front caster, unsnap and remove the grille at the bottom of the refrigerator, then remove the drip pan. To replace a rear caster, remove the access cover at the bott...

Page 153

This page intentionally left blank.

Page 154

Tm 10-7360-226-13&p containerized kitchen (ck) 0023 00 unit maintenance procedures 0023 00-1 tray pack heater this section covers: inspect, test, replace initial setup: ck set up for operation heater fan assembly unplugged maintenance level unit tools and special tools tool kit, general mechanic's (...

Page 155

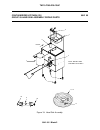

Tm 10-7360-226-13&p containerized kitchen (ck) 0023 00 unit maintenance procedures 0023 00-2 replace caster: see figure 1. Drain the tray pack heater. Support the tray pack heater with a wooden block in the vicinity of the caster while the caster is being replaced. Remove the four bolts and the dama...

Page 156

Tm 10-7360-226-13&p containerized kitchen (ck) 0024 00 unit maintenance procedures 0024 00-1 hand sink assembly this section covers: inspect, test, replace initial setup: ck set up for operations water pump and water heater connected to the appliance control box water supply hose connected drain hos...

Page 157

Tm 10-7360-226-13&p containerized kitchen (ck) 0024 00 unit maintenance procedures 0024 00-2 test pump assembly: run faucet water into the sink. The pump should run periodically. Check the pump assembly by temporarily connecting the pump assembly power cord to the appliance control box and check for...

Page 158

Tm 10-7360-226-13&p containerized kitchen (ck) 0024 00 unit maintenance procedures 0024 00-3 water heater: see figure 2. To replace the water heater, disconnect the power cord at the bottom of the tank. Allow the water in the tank to cool, open the drain valve and drain the water into an empty bucke...

Page 159

Tm 10-7360-226-13&p containerized kitchen (ck) 0024 00 unit maintenance procedures 0024 00-4 faucet: to replace the faucet, disconnect the hot and cold water supply lines under the sink. Remove the nuts and washers from the faucet pipes and remove the faucet. Insert a replacement faucet and reassemb...

Page 160

Tm 10-7360-226-13&p containerized kitchen (ck) 0025 00 unit maintenance procedures 0025 00-1/2 blank mobile storage cabinets this section covers: inspect, test, repair initial setup: ck set up for operation maintenance level unit tools and special tools tool kit, general mechanic's (wp 0052 00, tabl...

Page 161

This page intentionally left blank.

Page 162

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-1 electrical system this section covers inspect, test, replace initial setup ck set up for operation external power disconnected, generator shut down maintenance level unit tools and special tools tool kit, ge...

Page 163

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-2 power distribution panel: using a multimeter, check the power voltage on both sides of the applicable circuit breaker in the off position and on position. Follow the circuit diagrams in wp 0054 00 to check c...

Page 164

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-3 ground terminal: make sure all power is turned off at the main control panel. Referring to figure 1, disconnect the source power plug at the power entrance panel and attach plug cover. Remove the mounting ha...

Page 165

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-4 figure 2. Appliance control box. 1 input power 2 intake/exhaust fan 3 input power 4 intake/exhaust fan 5 input power 6 heater 7 refrigerator 1 8 heater 9 refrigerator 2 10 heater 11 mbu converter 12 convenie...

Page 166

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-5 main control panel: switch/lamp replacement: make sure the external power source is disconnected and the generator is shut down. Referring to figure 4, label and remove the spade lugs from the switch/lamp to...

Page 167

Tm 10-7360-226-13&p containerized kitchen (ck) 0026 00 unit maintenance procedures 0026 00-6 lighting fixtures permanently mounted fixture ballast replacement: turn off lighting system circuit breaker #19 on the power distribution panel. Referring to figure 5, remove the connectors at the fixture, t...

Page 168

Tm 10-7360-226-13&p chapter 5 direct support maintenance procedures.

Page 169

This page intentionally left blank.

Page 170

Tm 10-7360-226-13&p containerized kitchen (ck) 0027 00 direct support maintenance procedures 0027 00 - 1/2 blank cook center this work package covers: inspect, repair initial setup kitchen set up, cook center not operating maintenance level direct support tools and special tools tool kit, general me...

Page 171

This page intentionally left blank.

Page 172

Tm 10-7360-226-13&p containerized kitchen (ck) 0028 00 direct support maintenance procedures 0028 00 - 1/2 blank dual oven assembly this work package covers: inspect, repair initial setup ovens shut down and cool maintenance level direct support tools and special tools tool kit, general mechanic’s (...

Page 173

This page intentionally left blank.

Page 174

Tm 10-7360-226-13&p containerized kitchen (ck) 0029 00 direct support maintenance procedures 0029 00 - 1/2 blank tray pack heater this work package covers: inspect, repair initial setup tray pack heater shut down, cool, drained maintenance level direct support tools and special tools tool kit, gener...

Page 175

This page intentionally left blank.

Page 176

Tm 10-7360-226-13&p containerized kitchen (ck) 0030 00 direct support maintenance procedures 0030 00 - 1 shelter assembly/mechanical room this work package covers: inspect, repair initial setup ck set up air conditioner removed (for air conditioner repair) maintenance level direct support tools and ...

Page 177

Tm 10-7360-226-13&p containerized kitchen (ck) 0030 00 direct support maintenance procedures 0030 00-2 assemble the blower wheel to the shaft of the replacement blower motor. Tighten the set screw on the flat of the shaft. Assemble the motor mount onto the assembly cover. Tighten nuts. Ensure the bl...

Page 178

Chapter 6 supporting information.

Page 179

This page intentionally left blank.

Page 180

Tm 10-7360-226-13&p containerized kitchen (ck) 0031 00 references 0031 00-1 scope this work package lists field manuals, forms, technical manuals, pamphlets and miscellaneous publications that are referenced in this manual or are otherwise applicable to the operation and maintenance of the ck. Field...

Page 181

Tm 10-7360-226-13&p containerized kitchen (ck) 0031 00 references 0031 00-2 pamphlets functional user’s manual for the army maintenance management system (tamms) ................................................ Da pam 738-750 miscellaneous publications occupational and environmental health food serv...

Page 182

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-1 introduction this work package provides the maintenance allocation chart (mac) for the ck, excluding the government-furnished equipment (gfe). Refer to tm 10-7310-281-13&p for the mac and other mainte...

Page 183

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-2 3. Service. Operations required periodically to keep an item in proper operating condition; e.G., to clean (includes decontaminate, when required), to preserve, to drain, to paint, or to replenish fue...

Page 184

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-3 10. Overhaul. That maintenance effort (service/action) prescribed to restore an item to a completely serviceable/operational condition as required by maintenance standards in appropriate technical pub...

Page 185

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-4 note the “l” maintenance level is not included in column (4) of the mac. Functions to this level are identified by a work time figure in the “h” column of column (4), and an associated reference code ...

Page 186

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-5 maintenance allocation chart for ck table 1. Mac for ck (4) maintenance level unit ds gs depot (1) group no. (2) component/ assembly (3) maintenance function c o f h d (5) tools and equipment referenc...

Page 187

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-6 table 1. Mac for ck – continued. (4) maintenance level unit ds gs depot (1) group no. (2) component/ assembly (3) maintenance function c o f h d (5) tools and equipment reference code (6) remarks code...

Page 188

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-7 table 1. Mac for ck – continued. (4) maintenance level unit ds gs depot (1) group no. (2) component/ assembly (3) maintenance function c o f h d (5) tools and equipment reference code (6) remarks code...

Page 189

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-8 table 1. Mac for ck – continued. (4) maintenance level unit ds gs depot (1) group no. (2) component/ assembly (3) maintenance function c o f h d (5) tools and equipment reference code (6) remarks code...

Page 190

Tm 10-7360-226-13&p containerized kitchen (ck) 0032 00 maintenance allocation chart (mac) 0032 00-9/10 blank tools and test equipment for ck table 2. Tools and test equipment for ck. Tool or test equipment reference code maintenance level nomenclature national stock number tool number 1 o tool kit, ...

Page 191

This page intentionally left blank.

Page 192

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-1 scope this repair parts & special tools list (rpstl) lists and authorizes spares and repair parts; special tools; special test, measurement, and diagnostic equipment (tmde); and other s...

Page 193

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-2 source code maintenance code recoverability code xx xx x 1 st two positions: how to get an item. 3 rd position: who can install, replace, or use the item 4 th position: who can do compl...

Page 194

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-3 source code application/explanation ao – assembled by unit/avum level af – assembled by ds/avim level ah – assembled by gs level al – assembled by sfa ad – assembled by depot items with...

Page 195

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-4 source code application/explanation h general support maintenance can remove, replace, and use the item. L specialized repair activity can remove, replace, and use the item. D depot can...

Page 196

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-5 recoverability code. Recoverability codes are assigned to items to indicate the disposition action on unserviceable items. The recoverability code is shown in the fifth position of the ...

Page 197

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-6 description and usable on code (uoc) (column (6)). This column includes the following information: 1. The federal item name, and when required, a minimum description to identify the ite...

Page 198

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-7 special information uoc. The uoc appears in the lower left corner of the description column heading. Usable on codes are shown as “uoc: . . .” in the description column (justified left)...

Page 199

Tm 10-7360-226-13&p containerized kitchen (ck) 0033 00 introduction to repair parts & special tools list 0033 00-8 how to locate repair parts 1. When nsns or p/ns are not known. First. Using the table of contents, determine the assembly group to which the item belongs. This is necessary since figure...

Page 200

This page intentionally left blank.

Page 201

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-1 blank/2 figure 1. Container. 1 3 4 4 2 5 6.

Page 202

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 01 shelter assembly figure 1 container 1 paozz 80298 50389344 kicker, side ..................

Page 203

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-4 figure 2. Winch/cable assembly. 1 2.

Page 204

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-5 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 01 shelter assembly figure 2 winch/cable assembly 1 pbozz 80298 50389296 assembly, winch d...

Page 205

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-6 figure 3. Jacks. 1 2 3 4 wing jack corner jack screw jack 5.

Page 206

Tm 10-7360-226-13&p containerized kitchen (ck) 0034 00 group 01 shelter repair parts 0034 00-7/8 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 01 shelter assembly figure 3 jacks 1 paozz 80298 50389341 pin, shear, corner jack ...

Page 207

This page intentionally left blank.

Page 208

This page intentionally left blank.

Page 209

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-1 blank/2 figure 4. Exhaust pipe assembly. 3 1 2.

Page 210

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 02 mechanical room figure 4 exhaust pipe assembly 1 paozz 0u5n7 47012265 elbow, ex...

Page 211

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-4 figure 5. Ecu control box. 1 2 3.

Page 212

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-5 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 02 mechanical room figure 5 ecu control box 1 paozz 0u5n7 47013014 board, ecu cont...

Page 213

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-6 figure 6. Ecu mode switch assembly. 1 2.

Page 214

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-7 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 02 mechanical room figure 6 ecu mode switch assembly 1 paozz 02929 hs13-z switch, ...

Page 215

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-8 figure 7. Air conditioner. 2 3 4 5 6 1 2 - 5.

Page 216

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-9 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 02 mechanical room figure 7 air conditioner 1 pbfzz 0u5n7 47011034 air conditioner...

Page 217

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-10 figure 8. Intake and exhaust fan installation 1 1 2 3 2.

Page 218

Tm 10-7360-226-13&p containerized kitchen (ck) 0035 00 group 02 mechanical room repair parts 0035 00-11/12 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 02 mechanical room figure 8 intake and exhaust fan installation 1 paozz ...

Page 219

This page intentionally left blank.

Page 220

This page intentionally left blank.

Page 221

Tm 10-7360-226-13&p containerized kitchen (ck) 0036 00 group 03 cook center repair parts 0036 00-1 blank/2 1 1 1 1 2 3 4 4 5 6 6 6 6 7 7 7 7 8 7 figure 9. Fuel line assembly..

Page 222

Tm 10-7360-226-13&p containerized kitchen (ck) 0036 00 group 03 cook center repair parts 0036 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 03 cook center figure 9 fuel line assembly 1 paozz 0u5n7 47012152-1 hose assembly, fue...

Page 223

Tm 10-7360-226-13&p containerized kitchen (ck) 0036 00 group 03 cook center repair parts 0036 00-1 blank/4 figure 10. 24 vdc power cable assembly. 1 2 2 2 2 2 3 3 3 4 4.

Page 224

Tm 10-7360-226-13&p containerized kitchen (ck) 0036 00 group 03 cook center repair parts 0036 00-5/6 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 03 cook center figure 10 24vdc power cable assembly 1 paozz 5935-01-116-3615 9...

Page 225

This page intentionally left blank.

Page 226

This page intentionally left blank.

Page 227

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-1 blank/2 figure 11. Oven base assembly. 2 2 front 1 1 1 1.

Page 228

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 05 dual oven assembly figure 11 oven base assembly 1 pbozz 39428 2370t11 caster...

Page 229

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-4 figure 12. Oven fan assembly. 1 2.

Page 230

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-5 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 05 dual oven assembly figure 12 oven fan assembly 1 paozz 25795 4c727 blower......

Page 231

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-6 figure 13. Fuel line assembly. 1 2 3 4 5 6 7 5 7.

Page 232

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-7 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 05 dual oven assembly figure 13 fuel line assembly 1 paozz 0u5n7 47012152-5 hos...

Page 233

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-8 figure 14. 24 vdc power cable assembly. 2 1 1 1 3 3.

Page 234

Tm 10-7360-226-13&p containerized kitchen (ck) 0037 00 group 05 dual oven assembly repair parts 0037 00-9/10 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 05 dual oven assembly figure 14 24 vdc power cable assembly 1 paozz 59...

Page 235

This page intentionally left blank.

Page 236

This page intentionally left blank.

Page 237

Tm 10-7360-226-13&p containerized kitchen (ck) 0038 00 group 06 mobile warming cabinet repair parts 0038 00-1 blank/2 on power metro hm15lw figure 15. Mobile warming cabinet. 4 6 8 5 7 3 4 - 8 1 2 10 9.

Page 238

Tm 10-7360-226-13&p containerized kitchen (ck) 0038 00 group 06 mobile warming cabinet repair parts 0038 00-3/4 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 06 mobile warming cabinet figure 15 mobile warming cabinet 1 pbozz ...

Page 239

This page intentionally left blank.

Page 240

This page intentionally left blank.

Page 241

Tm 10-7360-226-13&p containerized kitchen (ck) 0039 00 group 07 refrigerator repair parts 0039 00-1 blank/2 figure 16. Refrigerator. 1 2 3 4 note: left-hand-hinged refrigerator illustrated. Repair parts for right- hand-hinged unit are identical. 7 6 5.

Page 242

Tm 10-7360-226-13&p containerized kitchen (ck) 0039 00 group 07 refrigerator repair parts 0039 00-3/ 4 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 07 refrigerators figure 16 refrigerator 1 pbozz 9r633 18202-002 caster, swiv...

Page 243

This page intentionally left blank.

Page 244

This page intentionally left blank.

Page 245

Tm 10-7360-226-13&p containerized kitchen (ck) 0040 00 group 08 tray pack heater repair parts 0040 00-1 blank/2 front figure 17. Tray pack heater 2 3 1.

Page 246

Tm 10-7360-226-13&p containerized kitchen (ck) 0040 00 group 08 tray pack heater repair parts 0040 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 08 tray pack heater figure 17 tray pack heater 1 pbozz 39428 9908t18 caster, swiv...

Page 247

Tm 10-7360-226-13&p containerized kitchen (ck) 0040 00 group 08 tray pack heater repair parts 0040 00-4 figure 18. Heater fan assembly. 1 2.

Page 248

Tm 10-7360-226-13&p containerized kitchen (ck) 0040 00 group 08 tray pack heater repair parts 0040 00-5/6 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 08 tray pack heater figure 18 heater fan assembly 1 paozz 0ld16 a128 blow...

Page 249

This page intentionally left blank.

Page 250

This page intentionally left blank.

Page 251

Tm 10-7360-226-13&p containerized kitchen (ck) 0041 00 group 09 hand sink assembly repair parts 0041 00-1 blank/2 figure 19. Hand sink assembly. 1 2 3 4 5 6 7 8 front 9 10 10 11, 12 13 note: water lines omitted for clarity.

Page 252

Tm 10-7360-226-13&p containerized kitchen (ck) 0041 00 group 09 hand sink assembly repair parts 0041 00-3/4 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 09 hand sink assembly figure 19 hand sink assembly 1 pbozz 39428 22785t...

Page 253

This page intentionally left blank.

Page 254

This page intentionally left blank.

Page 255

Tm 10-7360-226-13&p containerized kitchen (ck) 0042 00 group 10 mobile storage cabinet repair parts 0042 00-1 blank/2 figure 20. Mobile storage cabinet. 1 1 2 3.

Page 256

Tm 10-7360-226-13&p containerized kitchen (ck) 0042 00 group 10 mobile storage cabinet repair parts 0042 00-3/4 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 10 mobile storage cabinets figure 20 mobile storage cabinet 1 pbozz...

Page 257

This page intentionally left blank.

Page 258

This page intentionally left blank.

Page 259

Tm 10-7360-226-13&p containerized kitchen (ck) 0043 00 group 11 prep/serving table repair parts 0043 00-1 blank/2 figure 21. Prep/serving table. 1 2.

Page 260

Tm 10-7360-226-13&p containerized kitchen (ck) 0043 00 group 11 prep/serving table repair parts 0043 00-3/4 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 11 prep/serving tables figure 21 prep/serving table 1 pbozz 0u5n7 47011...

Page 261

This page intentionally left blank.

Page 262

This page intentionally left blank.

Page 263

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-1 blank/2 figure 22. Power entrance panel. 1 2 3 4 5 6 2.

Page 264

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-3 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 22 power entrance panel 1 paozz 097m6 dpa63-vo2 cont...

Page 265

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-4 3 5 1 2 4 1 7 1 6 figure 23. Power distribution panel. (blank) (blank) (blank) (blank).

Page 266

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-5 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 23 power distribution panel 1 paozz 5925-00-984-2163...

Page 267

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-6 figure 24. Main control panel. 1 2 2 6 5 3 3 4 4 6 7 8 9 10

Page 268

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-7 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 24 main control panel 1 paozz 5930-01-302-9739 0et52...

Page 269

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-8 figure 25. Appliance control box. 1 2 3 7 6 4 5.

Page 270

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-9 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 25 appliance control box 1 paozz 097m6 hbl11sp switc...

Page 271

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-10 figure 26. Mbu power switch assembly. 1 2.

Page 272

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-11 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 26 mbu power switch assembly 1 paozz 097m6 hbl11sp ...

Page 273

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-12 figure 27. Ceiling light – fixed. 1 2 3 (clear), 4 (red) 5 6.

Page 274

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-13 (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 27 ceiling light - fixed 1 paozz 097m6 f40cw/rs/wm ...

Page 275

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-14 figure 28. Ceiling light – removable. 4 (clear), 5 (red) 1 2 6 3.

Page 276

Tm 10-7360-226-13&p containerized kitchen (ck) 0044 00 group 12 electrical system repair parts 0044 00-15/16 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 12 electrical system figure 28 ceiling light - removable 1 paozz 097m6...

Page 277

This page intentionally left blank.

Page 278

Tm 10-7360-226-13&p containerized kitchen (ck) 0045 00 group 99 bulk material repair parts 0045 00-1/2 blank (1) item no. (2) smr code (3) nsn (4) cagec (5) part number (6) description and usable on code (uoc) (7) qty group 99 bulk material figure bulk 1 paozz 097m6 85022 cord, type sjoow, 2 conduct...

Page 279

This page intentionally left blank.

Page 280

Tm 10-7360-226-13&p containerized kitchen (ck) 0046 00 special tools list 0046 00-1/2 blank no special tools are required to maintain the containerized kitchen..

Page 281

This page intentionally left blank.

Page 282

Tm 10-7360-226-13&p containerized kitchen (ck) 0047 00 national stock number index 0047 00-1/2 blank stock number fig. Item 5935-00-321-8295 10 2 14 1 5925-00-728-1969 23 7 4730-00-795-6959 9 7 13 6 5925-00-936-3933 23 4 5925-00-983-5666 23 5 5925-00-984-2163 23 1 5925-01-018-3041 23 2 5925-01-056-5...

Page 283

This page intentionally left blank.

Page 284

Tm 10-7360-226-13&p containerized kitchen (ck) 0048 00 part number index 0048 00-1 part number fig. Item 1450a2119 7 3 1452-1531 7 2 1452-1541 7 1 1468a3029 7 4 1468a3129 7 5 1626k31 27 3 28 4 1626k4red 27 4 28 5 16830-000 16 5 17465-000 16 6 17963-000 16 4 18202-001 16 2 18202-002 16 1 2088-594-154...

Page 285

Tm 10-7360-226-13&p containerized kitchen (ck) 0048 00 part number index 0048 00-2 part number fig. Item hbl11sp 24 9 hbl11sp 25 1 26 1 hbl22sp 24 8 hs13-z 6 1 lk-2490 19 8 m-i-wh6u3ss 19 7 ms3106f16-11p 10 1 13 2 ms3106f16-11s 10 2 13 1 n3030b 22 5 ps-6000 27 6 p-sdc-2-hk 9 8 13 7 qob110 23 6 qob11...

Page 286

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item (coei) and basic issue items (bii) lists 0049 00-1 introduction scope this work package lists the components of end item (coei) and basic issue items (bii) for the ck to help you inventory items for safe and efficient oper...

Page 287

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-2 components of end item (coei) list table 1. Components of end item list. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m ...

Page 288

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-3 table 1. Components of end item list. – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 6 base rac...

Page 289

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-4 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 11 cabinet,...

Page 290

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-5 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 15 cook pot...

Page 291

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-6 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 21 grease c...

Page 292

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-7 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 26 heater, ...

Page 293

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-8 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 32 6545-00-...

Page 294

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-9 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 38 rail, pl...

Page 295

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-10 table 1. Components of end item list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 44 stair a...

Page 296

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-11 basic issue items (bii) list table 2. Basic issue items list. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rq...

Page 297

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-12 table 2. Basic issue items list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 7 7330-00-272-2...

Page 298

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-13 table 2. Basic issue items list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 16 7340-00-197-...

Page 299

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-14 table 2. Basic issue items list – continued. (1) illus number (2) national stock number (3) description, (cagec) and part number (4) usable on code (5) u/m (6) qty rqr 25 7330-00-238-...

Page 300

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-15 operator's unit and direct support operation and maintenance manual including repair parts & special tools list for containerized kitchen nsn 7360-01-473-3408 distribution statement a...

Page 301

Tm 10-7360-226-13&p containerized kitchen (ck) 0049 00 components of end item and basic issue items lists 0049 00-16 table 2. Basic issue items list – continued. 36 technical manual tm 10-7310-281-13&p ea 1 37 2030-01-168-9371 tie-down, rubber, 28 in. (39428) 3891t16 ea 15 38 tie-down, rubber, 35 in...

Page 302

Tm 10-7360-226-13&p containerized kitchen (ck) 0050 00 additional authorization list (aal) 0050 00-1/2 blank introduction scope this work package lists additional items you are authorized for the support of the ck. Explanation of columns in the aal column (1) – national stock number (nsn). Identifie...

Page 303

This page intentionally left blank.

Page 304

Tm 10-7360-226-13&p containerized kitchen (ck) 0051 00 expendable and durable items list 0051 00-1/2 blank introduction scope this work package lists expendable and durable items that you will need to operate and maintain the ck. This list is for information only and is not authority to requisition ...

Page 305

This page intentionally left blank.

Page 306

Tm 10-7360-226-13&p containerized kitchen (ck) 0052 00 tool identification list 0052 00-1/2 blank introduction scope this work package lists all common tools and supplements and special tools/fixtures needed to maintain the ck. Explanation of columns in the tool identification list column (1) – item...

Page 307

This page intentionally left blank.

Page 308

Tm 10-7360-226-13&p containerized kitchen (ck) 0053 00 mandatory replacement parts 0053 00-1/2 blank refer to tm 10-7310-281-13&p for mandatory replacement parts for the mbus. The only mandatory replacement part for the generator is the oil filter. Refer to lo 9-6115-642- 12 for replacement informat...

Page 309

This page intentionally left blank.

Page 310