Carbon monoxide poisoning and fire hazard. Failure to follow safety warnings exactly could result in serious injury, death, and/or property damage. This furnace is not designed for use in mobile homes, trailers or recreational vehicles. ! Electric shock hazard failure to follow safety warnings exact...

2 441 01 2611 06 start--up check sheet (keep this page for future reference) recommended, but not required. Checklist does not apply in canada dealer name: address: business card here city, state(province), zip or postal code: phone: owner name: address: city, state(province), zip or postal code: mo...

3 441 01 2611 06 1. Safe installation requirements fire, explosion, and asphixiation hazard improper adjustment, alteration, service, maintance or installation could cause serious injury, death and/or property damage. Installation or repairs made by unqualified persons could result in hazards to you...

4 441 01 2611 06 frozen water pipe hazard frozen and burst water pipe hazard faiiure to protect against the risk of freezing could result in property damage and/or personal injury. Do not leave your home unattended for long periods during freezing weather without turning off water supply and drainin...

13 1 / 4 28 1 / 2 3 3 / 4 17 1 / 3 2 1 / 4 dimensions and clearances (n8mpn/l) figure 1 drawing is representative, but some models may vary dimensions in inches note: evaporator “a” coil drain pan dimensions may vary from furnace duct opening size. Always consult evaporator specifications for duct s...

Note: evaporator “a” coil drain pan dimensions may vary from furnace duct opening size. Always consult evaporator specifications for duct size requirements. Furnace is designed for bottom return or side return. Return air through back of furnace is not allowed. 17 5 / 16 30 3 / 4 29 1 / 2 2 1 / 4 3 ...

7 441 01 2611 06 typical upflow installation figure 3 25--23--17 vent supply air gas supply return air horizontal if you purchased a multi--position furnace, it can be installed hori- zontally in an attic, basement, crawl space, alcove, or suspended from a ceiling in a basement or utility room in ei...

8 441 01 2611 06 10. Install burner compartment door on furnace with bevel edge at bottom. N8mpn/l, c8mpn/l, h8mpn/l 1. Carefully remove logo from burner compartment door and save it. 2. Turn the logo rightside--up, and install the logo retainer pins into holes in burner compartment door. 3. New lab...

9 441 01 2611 06 figure 7 venter gasket 25--23--52b entry 25--23--52c main line 4. Replace venter gasket (part # 1013540, if needed) to venter assembly with adhesive in the same location as the old one. 5. Rotate venter assembly 90° right or left from original location depending on venting configura...

10 441 01 2611 06 requirements 1. Provide the space with sufficient air for proper combustion and ventilation of flue gases using horizontal or vertical ducts or openings. 2. Figure 8 illustrates how to provide combustion and ventilation air when two permanent openings, one inlet and one outlet, are...

11 441 01 2611 06 indoor combustion air standard and known--air--infiltration rate methods ã nfpa & aga indoor air is permitted for combustion and ventilation, if the standard or known--air--infiltration rate method is used. ! Carbon monoxide poisoning hazard. Failure to supply adequate combustion a...

12 441 01 2611 06 5. Gas vent installation carbon monoxide poisoning, fire and explosion hazard. Failure to properly vent this furnace could result in death, personal injury and/or property damage. Read and follow all instructions in this section. ! Warning install the vent in compliance with codes ...

13 441 01 2611 06 venting and combustion air check note: when an existing category i furnace is removed or re- placed, the original venting system may no longer be sized to prop- erly vent the attached appliances, and to make sure there is adequate combustion air for all appliances, make the fol- lo...

14 441 01 2611 06 6. Horizontal venting category i furnaces with external power venters in order to maintain a category i classification of fan--assisted fur- naces when vented horizontally with sidewall termination, a power venter is required to maintain a negative pressure in the vent- ing system....

A x b v v v v x x air supply inlet v vent terminal area where terminal is not permited a b b b b b c d e f j i l h m k g 25--24--65--2 n v other than direct vent termination clearance figure 10 v v 15 441 01 2611 06 item clearance descriptions canadian installation (1) u.S. Installation (2) a cleara...

16 441 01 2611 06 7. Masonry chimney venting chimney inspection all masonry chimney construction must conform to standard ansi/nfpa 211--2003 and to any state or local codes applicable. The chimney must be in good condition and a complete chimney inspection must be conducted prior to furnace install...

17 441 01 2611 06 chimney is acceptable for use crown condition: missing mortar or brick? Rebuild crown is chimney properly lined with clay tile liner? Yes yes no no yes is liner and top seal in good condition no debris in cleanout? Mortar, tile, metal vent, fuel oil residue? Repair liner or top sea...

18 441 01 2611 06 exterior masonry chimney, fan+nat installations with type--b double--wall vent connectors ã ã ã ã nfpa & aga table a-- combined appliance maximum input rating in thousands of btu per hr vent height (ft) internal area of chimney (sq in.) (ft) 12 19 28 38 6 74 119 178 257 8 80 130 19...

19 441 01 2611 06 vent dampers on any appliance connected to the common vent can cause condensation and corrosion in the venting system. Do not use vent dampers on appliances common vented with this fur- nace. 8. Gas supply and piping carbon monoxide poisoning, fire and explosion hazard. Failure to ...

20 441 01 2611 06 right side gas supply piping (n8mp) gas line can be installed directly to the gas valve through the hole provided in the right side of the cabinet. See figure 12 left side gas supply piping (n8mp) two(2) 90° street elbows or two(2) 90° standard elbows and two(2) close nipples are r...

21 441 01 2611 06 piping with street elbows 1. Assemble the elbows so that the outlet of one(1) elbow is 90° from the inlet of the other. The elbows should be tight enough to be leak proof. An additional 1 / 4 turn will be required at the end of step 2, see figure 13. 2. Screw elbow assembly into ga...

22 441 01 2611 06 9. Electrical wiring electrical shock hazard. Failure to follow safety warnings exactly could result in serious injury, death, and/or property damage. Turn off electrical power at fuse box or service panel before making any electrical connections and ensure a proper ground connecti...

23 441 01 2611 06 fan control the fan control is preset at the factory with on delay of 30 seconds in the heating mode. The blower off timing is preset at 140 sec- onds. If desired, the fan off delay can be reset to obtain the lon- gest delay times while still maintaining comfort levels. See “furnac...

24 441 01 2611 06 · installation of locking-type dampers is recommended in all branches, or in individual ducts to balance system’s air flows. · non--combustible, flexible duct connectors are recom- mended for return and supply connections to furnace. · if air return grille is located close to the f...

25 441 01 2611 06 figure 23 side return filter rack filter 25--23--05--4a 25--23--05--3 filter filter using two filter racks figure 24 filters installed on two sides internal filter in bottom- return installation when installing a bottom--mounted filter inside the furnace, install the filter clips o...

26 441 01 2611 06 burn hazard. The vent may be hot. Failure to install vent shield properly could result in bodily injury. Install vent pipe shield naha002vc as described below. ! Warning vent shield vent shield is required for all downflow installations. The vent must exit out the side of the furna...

27 441 01 2611 06 exploded view of sub--base for furnace only figure 27 t s plenum j k h r l p 1²²²² 2²²²² combustible floor base n hole in floor m setting the base figure 28 subbase insulation wood screw plenum furnace wood floor sub--base for combustible floors -- downflow coil adapter box the sub...

28 441 01 2611 06 removing the knockout panel in the furnace base. Return air con- nection through the side(s) or back of the furnace is not allowed. Duct design design and install air distribution system to comply with air condi- tioning contractors of america manuals or other approved meth- ods th...

29 441 01 2611 06 figure 32 top mounted internal filter 9² center clip side--to--side figure 33 filter clip construction 3² 1 1 / 4 ² 1 1 / 2 ² 11 / 16 ² 26 ga. Galvanized steel note: if filters are only suitable for heating application, ad- vise homeowner that filter size may need to be increased i...

30 441 01 2611 06 2. Turn gas on. Operate the furnace by using a jumper wire on the r to w thermostat connections on the fan board. 3. Remove manifold pressure adjustment screw cover on fur- nace gas control valve. Turn adjusting screw counterclock- wise to decrease manifold pressure and clockwise t...

31 441 01 2611 06 manifold pressure and orifice size for high altitude applications table 7 natural gas manifold pressure (²²²² w.C.) table 7 mean elevation feet above sea level heating value 0 to 2000 2001 to 3000 3001 to 4000 4001 to 5000 5001 to 6000 6001 to 7000 7001 to 8000 at altitude btu/cu. ...

32 441 01 2611 06 figure 37 manifold 25--23--51z some models may vary figure 38 clearances measure from face of orifice to the back side of the manifold. 1.21² 1.11² 29.3 mm +1.5 --1.1 8. Reassemble all parts in reverse order as removed. Be sure to engage the main burner orifices in the proper openi...

33 441 01 2611 06 changing blower speed electrical shock hazard. Failure to disconnect power could result in death, personal injury and/or property damage. Turn off power to furnace before changing speed taps. ! Warning note: the speed taps that the manufacturer sets at the factory for this furnace ...

34 441 01 2611 06 14. Sequence of operation & diagnostics the following is the normal operating sequence. Cooling (y) request: 24 vac signals applied to y & g terminals of eft (electronic fan timer) control. · cool motor speed is energized after 5 second cool fan on delay time. Y & g signals removed...

35 441 01 2611 06 gas control valve diagnostic codes (see figure 40) off = control not powered heartbeat = normal operation (standby or call for heat) 1 flash = not used 2 flashes = low pressure switch closed when should be open 3 flashes = low pressure switch circuit was still sensed as open 30 sec...

36 441 01 2611 06.

37 441 01 2611 06 international comfort products, llc lewisburg, tn 37091 fast parts division (866) 380--3278 models n8mpn050b12a1 n8mpl050b12a1 n8mpn075b12a1 n8mpl075b12a1 n8mpn075f16a1 n8mpl075f16a1 n8mpn100f14a1 n8mpl100f20a1 n8mpn100f20a1 n8mpl100j22a1 n8mpn100j22a1 n8mpl125j20a1 n8mpn125j20a1 n...

38 441 01 2611 06 this data is subject to change without notice model specifications manufacturers number (mfr no -- see rating plate) all models (n8mpn) specifications n8mpn 050b12 n8mpn 075b12 n8mpn 075f16 n8mpn 100f14 n8mpn 100f20 n8mpn 100j22 n8mpn 125j20 n8mpn 125j22 general input (btuh) output...

39 441 01 2611 06 this data is subject to change without notice manufacturers number (mfr no -- see rating plate) all models (n8mpl) specifications n8mpl 050b12 n8mpl 075b12 n8mpl 075f16 n8mpl 100f20 n8mpl 100j22 n8mpl 125j20 n8mpl 125j22 general input (btuh) output (btuh) temp. Rise ( ° f) 50,000 4...

40 441 01 2611 06 this data is subject to change without notice manufacturers number (mfr no -- see rating plate) all models (*8mpn) specifications *8mpn 050b12 *8mpn 075b12 *8mpn 075f16 *8mpn 100f14 *8mpn 100f20 *8mpn 100j20 *8mpn 125j20 *8mpn 150j20 general input (btuh) output (btuh) temp. Rise ( ...

41 441 01 2611 06 this data is subject to change without notice manufacturers number (mfr no -- see rating plate) all models (*8mpl) specifications *8mpl 050b12 *8mpl 075b12 *8mpl 075f16 *8mpl 100f20 *8mpl 100j20 *8mpl 125j20 general input (btuh) output (btuh) temp. Rise ( ° f) 50,000 40,000 35--65 ...

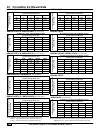

E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati c p ressure in ches of w .C. E xterrnal s tati ...

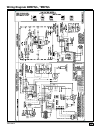

43 441 01 2611 06 wiring diagram n8mpn/l, *8mpn/l.

44 441 01 2611 06 parts for n8mpn/l 25--24--32a--1 n 18 z x s 14 l 9 p 1 b c 2 a d e j 7 6 f 8 5 4 3 g h bb 17 16 16 w 10 v 15 u k 13 12 11 t s r dd cc m aa.

A 45 441 01 2611 06 replacement parts - n8mpn (natural gas) models -- n8mpn050b12a1, n8mpn075b12a1, n8mpn075f16a1, n8mpn100f14a1, n8mpn100f20a1, n8mpn100j22a1, n8mpn125j20a1, n8mpn125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key des...

46 441 01 2611 06 replacement parts - n8mpn (natural gas) models -- n8mpn050b12a1, n8mpn075b12a1, n8mpn075f16a1, n8mpn100f14a1, n8mpn100f20a1, n8mpn100j22a1, n8mpn125j20a1, n8mpn125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

47 441 01 2611 06 replacement parts - n8mpn (natural gas) models -- n8mpn050b12a1, n8mpn075b12a1, n8mpn075f16a1, n8mpn100f14a1, n8mpn100f20a1, n8mpn100j22a1, n8mpn125j20a1, n8mpn125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

A 48 441 01 2611 06 replacement parts - n8mpl (natural gas) models -- n8mpl050b12a1, n8mpl075b12a1, n8mpl075f16a1, n8mpl100f20a1, n8mpl100j22a1, n8mpl125j20a1, n8mpl125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key description part n...

49 441 01 2611 06 replacement parts - n8mpl (natural gas) models -- n8mpl050b12a1, n8mpl075b12a1, n8mpl075f16a1, n8mpl100f20a1, n8mpl100j20a1, n8mpl100j22a1, n8mpl125j20a1, n8mpl125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

50 441 01 2611 06 replacement parts - n8mpl (natural gas) models -- n8mpl050b12a1, n8mpl075b12a1, n8mpl075f16a1, n8mpl100f20a1, n8mpl100j20a1, n8mpl100j22a1, n8mpl125j20a1, n8mpl125j22a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

51 441 01 2611 06 parts for *8mpn/l 13 12 11 s 14 15 w 10 u v 16 l r 16 17 8 7 n 6 5 4 3 k j h 9 b c a 2 1 bb aa 18 x cc m d t s p z f e g f u dd 25--23--49a.

A 52 441 01 2611 06 replacement parts - *8mpn (natural gas) models -- *8mpn050b12a1, *8mpn075b12a1, *8mpn075f16a1, *8mpn100f14a1, *8mpn100f20a1, *8mpn100j20a1, *8mpn125j20a1, *8mpn150j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key des...

53 441 01 2611 06 replacement parts - *8mpn (natural gas) models -- *8mpn050b12a1, *8mpn075b12a1, *8mpn075f16a1, *8mpn100f14a1, *8mpn100f20a1, *8mpn100j20a1, *8mpn125j20a1, *8mpn150j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

54 441 01 2611 06 replacement parts - *8mpn (natural gas) models -- *8mpn050b12a1, *8mpn075b12a1, *8mpn075f16a1, *8mpn100f14a1, *8mpn100f20a1, *8mpn100j20a1, *8mpn125j20a1, *8mpn150j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key descr...

A 55 441 01 2611 06 replacement parts - *8mpl (natural gas) models -- *8mpl050b12a1, *8mpl075b12a1, *8mpl075f16a1, *8mpl100f20a1, *8mpl100j20a1, *8mpl125j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key description part *8mpl key no. De...

56 441 01 2611 06 replacement parts - *8mpl (natural gas) models -- *8mpl050b12a1, *8mpl075b12a1, *8mpl075f16a1, *8mpl100f20a1, *8mpl100j20a1, *8mpl125j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key description part *8mpl key no. Desc...

57 441 01 2611 06 replacement parts - *8mpl (natural gas) models -- *8mpl050b12a1, *8mpl075b12a1, *8mpl075f16a1, *8mpl100f20a1, *8mpl100j20a1, *8mpl125j20a1 replacement part supplied will be current active part. For parts not listed, consult place of purchase. Key description part *8mpl key no. Desc...