- DL manuals

- ICP

- Air Conditioner

- HMC009KD1

- Service Manual

ICP HMC009KD1 Service Manual

Summary of HMC009KD1

Page 1

Deluxe high wall mini split service manual model : hmh009kd1 / hmc009kd1 hmh012kd1 / hmc012kd1 hmh018kd1 / hmc018kd1 hmh024kd1 / hmc024kd1 caution - before servicing the unit, read the "safety precautions" in this manual. - only for authorized service personnel. International comfort products.

Page 2: Contents

Functions ...................................................................................................................................... 3 product specifications ................................................................................................................ 5 dimensions........

Page 3: Functions

- 3 - functions indoor unit operation on/off by remote controller sensing the room temperature room temperature control starting current control time delay safety control indoor fan speed control operation indication lamps (led) healthy dehumidification mode sleep mode auto control auto air control ...

Page 4

- 4 - healthy dehumidification operation mode.( ) remote controller operation on/off reset operation mode selection temperature setting timer selection timer setting jet cool timer cancel sleep operation chaos swing (cooling model only) (heating model only) temperature low high cooling operation mod...

Page 5

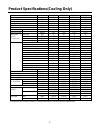

- 5 - product specifications(cooling only) items unit hmc009kd1 hmc012kd1 hmc018kd1 hmc024kd1 power supply ø, v, hz cooling capacity btu/h input w running current a comp. Locked rotor amp. A e.E.R btu/hw air circulation m 3 /min(cfm) moisture removal l/h(pts/hr) noise level indoor, high db(a) (sound...

Page 6

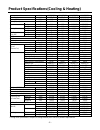

- 6 - product specifications(cooling & heating) items unit hmh009kd1 hmh012kd1 hmh018kd1 hmh024kd1 power supply ø, v, hz 1, 115, 60 1, 115, 60 1, 230/208, 60 1, 230/208, 60 cooling capacity btu/h 9,000 12,000 18,000/17,800 23,000/22,600 heating capacity btu/h 9,000 12,000 19,000/18,700 23,000/22,600...

Page 7: (1) Indoor Unit

(1) indoor unit - 7 - dimensions d w h tubing hole cover tubing hole cover installation plate model 9k 12k 18k, 24k dim w mm(inch) 802(31.6") 888(35.0") 1,080(42.5") h mm(inch) 262(10.3") 287(11.3") 314(12.4") d mm(inch) 165(6.5") 170(6.7") 181(7.1").

Page 8: (2) Outdoor Unit

- 8 - (2) outdoor unit 1. 9k, 12k w l2 l3 l1 d h l4 l5 gas side (3-way valve) liquid side (2-way valve) model 9k, 12k dim unit w mm(inch) 770(30.3) h mm(inch) 540(21.3) d mm(inch) 245(9.6) l1 mm(inch) 287(11.3) l2 mm(inch) 64(2.5) l3 mm(inch) 518(20.4) l4 mm(inch) 10(0.4) l5 mm(inch) 100(3.9).

Page 9

- 9 - w l6 l5 l7 l8 d l1 l2 l9 l10 l3 l4 h gas side 3-way valve liquid side 3-way valve 2. 18k, 24k model 18k, 24k dim w mm(inch) 870(34.3) h mm(inch) 655(25.8) d mm(inch) 320(12.6) l1 mm(inch) 370(14.6) l2 mm(inch) 25(1.0) l3 mm(inch) 630(24.8) l4 mm(inch) 25(1.0) l5 mm(inch) 546(21.5) l6 mm(inch) ...

Page 10: • Cooling Only Models

- 10 - for installation over rated, *a proper quantity of refrigerant should be added for each meter. Ex) 18k: when installed at a distance of 15m, 295g of refrigerant should be added. (15-7.62) x 40g = 295g indoor unit heat exchanger (evaporator) heat exchanger (condenser) compressor gas side capil...

Page 11: • Cooling & Heating Models

- 11 - indoor unit heat exchanger (evaporator) heat exchanger (condenser) reversing valve compressor cooling heating gas side capillary tube check valve liquid side outdoor unit • cooling & heating models model 9k, 12k (cooling & heating) 18k (cooling & heating) 24k (cooling & heating) pipe size(dia...

Page 12: Wiring Diagram

- 12 - wiring diagram (1) indoor unit 1. 9k, 12k, 18k, 24k(cooling only models, cooling & heating models) 4 3 2 1 bldc motor step motor main p.C.B indoor wiring diagram to outdoor unit display p.C.B (room) (pipe) thermistor cn-up/down 3854ar7074a cn-motor pillar terminal c n -d c /d c c n -d isp c n...

Page 13: (2) Outdoor Unit

- 13 - (2) outdoor unit • cooling only models 1. 9k, 12k 3. 24k 2. 18k bl bl bk bk fuse 3.15a fuse 2.5a znr cn-dc/dc ry-comp 3 4 main p.C.B yl motor rd bl br bl rd br bl terminal block to indoor unit power input 3854a30077z outdoor wiring diagram rd br bk bl g h f c capacitor cn-trans transformer t/...

Page 14

- 14 - • cooling & heating models 1. 9k, 12k 2. 18k, 24k 4way- valve bk rd ry-4way bl bl bk bk fuse 3.15a ry-fan ry-heater znr cn-dc/dc ry-comp 3 4 main p.C.B bk yl motor rd bl rd br bl rd br o.L.P bl terminal block to indoor unit power input 3854a30077w outdoor wiring diagram rd br bk bl wh wh g wh...

Page 15: Operation Details

(1) the function of main control 1. Time delay safety control • 3min.; the compressor operation is delayed for 3 minutes to balance the pressure of cycle. (protection of compressor) • 5sec.; the indoor fan is delayed for 5 seconds, when operating initially, to prevent noises occurred by the vertical...

Page 16

4. Auto operation (electronic control mode) • the operation procedure is shown below. (cooling & heating model) ❋ if initial mode is decided, that mode is continued without the room temperature changing. ■ auto operation for cooling - 16 - press start/stop button select auto operation mode check the...

Page 17

■ auto operation for dehumidification(only heating model) • the setting temperature will be same that of the auto operation for cooling. - compressor on temperature; setting temperature +2°f - compressor off temperature; setting temperture -1°f ■ auto operation for heating(only heating model) - comp...

Page 18

5. Healthy dehumidification • when the dehumidification operation input by the remote control is received, the intake air temperature is detected and the setting temp is automatically set according to the intake air temperature. 26°c ≤ intake air temp ➲ 25°c 24°c ≤ intake intake air temp ➲ intake ai...

Page 19

- 19 - 6. Heating operation mode(only heating model) the unit will operate according to the setting conditions by the remote controller. The operation diagram is shown below. Intake air temp. Setting temp. +6°f (compressor off) setting temp. (compressor on) selecting fan speed selecting fan speed a ...

Page 20

7. Cooling or heating mode with sleep mode auto control • when selecting the cooling( ) or the heating( ) combined with the sleep mode auto control( ), the operation diagram is as following. ■ cooling mode with the sleep mode • the setting temperature will be automatically raised by 2°f 30 minutes l...

Page 21

- 21 - 8. Forced operation operation procedures when the remote control can't be used. Open the front panel upward and move the slide switch to the forced operation position. If you want to stop operation, move the slide switch to the auto restart or the remote control position. In case the power co...

Page 22: Display Function

• cooling, soft dry, fan, heating • sleep mode • timer mode • hot-start, defrost • compressor on • buzzer sound • power input or reset : one short beep. • when operation stop button is pressed : one long beep. • when remote controller buttons except for operation stop are pressed : two short beep. -...

Page 23: Installation

- 23 - installation important! Please read this instruction sheet completely before installing the product. This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operate...

Page 24

(1) installation parts provided (2) installation of indoor, outdoor unit read completely, then follow step by step. 1) select the best location 1. Indoor unit ■ do not have any heat or steam near the unit. ■ select a place where there are no obstacles in front of the unit. ■ make sure that condensat...

Page 25

3) how to fix installation plate the wall you select should be strong and solid enough to prevent vibration 1. Mount the installation plate on the wall with four type a screws. If mounting the unit on a concrete wall, use anchor bolts. ■ mount the installation plate horizontally by aligning the cent...

Page 26: Of Piping

(3) flaring work and connection of piping 1) flaring work main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the following pro- cedure. 1. Cut the pipes and the cable. ■ use the piping kit accessory or the pipes purchased locally. ■ measure the distance be...

Page 27

2) connection of piping --indoor ■ preparing the indoor unit's piping and drain hose for installation through the wall. ■ remove the plastic tubing retainer(see illustration below) and pull the tubing and drain hose away from chassis. ■ replace the plastic tubing holder in the original posi- tion. 1...

Page 28

■ tighten the flare nut with a wrench. ■ when extending the drain hose at the indoor unit, install the drain pipe. 6. Wrap the insulation material around the connecting portion. ■ overlap the connection pipe insulation material and the indoor unit pipe insulation material. Bind them together with vi...

Page 29

3. Insert the connecting cable into the indoor unit. ■ don't connect the cable to the indoor unit. ■ make a small loop with the cable for easy connection later. 4. Tape the drain hose and the connecting cable. 5. Indoor unit installation ■ hang the indoor unit from the hooks at the top of the instal...

Page 30

■ bundle the piping and drain hose together by wrapping them with cloth tape over the range within which they fit into the rear piping housing section. 8. Reroute the pipings and the drain hose across the back of the chassis. 9. Set the pipings and the drain hose to the back of the chassis with the ...

Page 31: Indoor Unit and Outdoor Unit

(4) connecting the cable between indoor unit and outdoor unit 1. Remove the cover control from the unit by loosen- ing the 3 screws. 2. Dismount caps on the conduit panel. 3. Temporarily mount the conduit tubes on the con- duit panel. 4. Properly connect both the power supply and low voltage lines t...

Page 32

Connection method of the connecting cable(example) (1) dismount two-caps on the conduit panel. (2) make a hole appropriate for the passage of connection cable through on cap by tool. (for low voltage line) (3) pass the connecting cable through the hole. (4) properly connect the cable on the terminal...

Page 33

Connect the cable to the indoor unit 1. Connect the wires to the terminals on the control board individually according to the outdoor unit connection. • ensure that the color of the wires of outdoor unit and the terminal no. Are the same as those of indoor unit respec- tively. (refer to wiring diagr...

Page 34: Forming The Pipings

(5) checking the drainage and forming the pipings 1) checking the drainage 1. To remove the front panel from the indoor unit, remove the front panel from the indoor unit cabinet. ■ set the air direction louvers up-and-down to the posi- tion(horizontally) by hand. ■ remove the securing screws that re...

Page 35: (6) Air Purging

(6) air purging air and moisture remaining in the refrigerant system have undesirable effects as indicated below. • pressure in the system rises. • operating current rises. • cooling(or heating) efficiency drops. • moisture in the refrigerant circuit may freeze and block capillary tubing. • water ma...

Page 36

■ evacuation 1. Connect the charge hose end described in the pre- ceding steps to the vacuum pump to evacuate the tubing and indoor unit. Confirm the "lo" knob of the manifold valve is open. Then, run the vacuum pump. The operation time for evacuation varied with the tubing length and capacity of th...

Page 37: (7) Test Running

(7) test running 1. Check that all tubing and wiring have been properly connected. 2. Check that the gas and liquid side service valves are fully open. 1. Prepare remote control remove the battery cover by pulling it according to the arrow direction. Insert new batteries making sure that the (+) and...

Page 38: Operation

- 38 - operation (1) name and function-remote control (cooling models) signal transmitter. Transmits the signals to the room air conditioner. Remote controller on off ° c / ° f set cancel signal transmitter 4 5 6 7 9 1 2 3 8 on/off timer buttons used to set the time of starting and stopping operatio...

Page 39

- 39 - (2) name and function-remote control (heat pump models) signal transmitter. Transmits the signals to the room air conditioner. Remote controller on off set cancel ° c / ° f signal transmitter 4 5 6 7 9 8 1 2 3 on/off timer buttons used to set the time of starting and stopping operation. Time ...

Page 40

- 40 - disassembly of the parts (indoor unit) warning : disconnect the unit from power supply before making any checks. Be sure the power switch is set to “off”. To remove the grille from the chassis. • set the up-and-down air discharge louver to open position (horizontally) by finger pressure. • re...

Page 41

- 41 - 2. To remove the control box. • remove 2 securing screws. • pull the control box out from the chassis careful- ly. 3. To remove the discharge grille. • unhook the discharge grille and pull the dis- charge grille out from the chassis carefully. 4. To remove the evaporator. • remove 3 screws se...

Page 42

- 42 - • unhook the tab on the right inside of the chassis at the same time, slightly pull the evaporator toward you until the tab is clear of the slot. 5. To remove the cross-flow fan • loosen the screw securing the cross-flow fan to the fan motor (do not remove). • lift up the right side of the cr...

Page 43

- 43 - warning : disconnect the unit from power supply before making any checks. Be sure the power switch is set to “off”. To remove the grille from the chassis. • set the up-and-down air discharge louver to open position (horizontally) by finger pressure. • remove the securing screws • to remove th...

Page 44

2. To remove the control box. • remove 2 securing screws. • pull the control box out from the chassis carefully. 3. To remove the discharge grille. • remove the securing screw. • pressing the right side of the discharge grille downward slightly, unhook the discharge grille. • pull the discharge gril...

Page 45

- 45 - • unhook the tab on the right inside of the chassis at the same time, slightly pull the evaporator toward you until the tab is clear of the slot. 5. To remove the cross-flow fan • loosen the screw securing the cross-flow fan to the fan motor (do not remove). • lift up the right side of the cr...

Page 46: Cycle Troubleshooting Guide

1. Trouble analysis 1. Check temperature difference between intake and discharge air and operating current. Temp. Difference operating current temp. Difference :approx. 0°f current :less than 80% of rated current temp. Difference :approx. 8°c(14°f) current :less than 80% of rated current temp. Diffe...

Page 47

- 47 - - 47 - 2. Product does not operate at all. (* refer to electronic control device drawing and schematic diagram.) turn off main power turn on main power does "beeping" sound is made from the indoor unit? Primarily, the operating condition of micom is ok. Check the voltage of power(about ac 208...

Page 48

- 48 - 3. The product is not operate with the remote controller. Turn on main power while the compressor has been stopped, the compressor does not operate owing to the delaying function for 3 minutes after stopped. Caused by other parts except the remote controller cause by the remote controller whe...

Page 49

- 49 - 4. Compressor/outdoor fan are unable to drive. Turn on main power operate "cooling mode( )" by setting the desired temperature of the remote controller is less than one of the indoor temperature by 2°f at least. When in fan mode, compressor/outdoor fan is stopped. Check the sensor for indoor ...

Page 50

- 50 - 5. When indoor fan does not operate. Check connecting condition of the cn-motor con- nector does the voltage of terminal of cn-dc/dc connector in indoor unit corresponds to the values in the table of page 51? Do the voltage of terminal of cn-dc/dc connector in outdoor unit corresponds to the ...

Page 51

- 51 - • confirm that the vertical louver is normally geared with the shaft of stepping motor. • if the regular torque is detected when rotating the vertical louver with hands ⇒ normal • check the connecting condition of cn-up/down connector • check the soldering condition(on pwb) of cn-up/down conn...

Page 52

- 52 - • the operation indicator of indoor unit blinks five times. • the red indicator of outdoor unit blinks five times. Check the connecting wires between indoor and outdoor unit for the connecting error and the contacting condition. Check the installation condition of outdoor unit. Check for the ...

Page 53

- 53 - 8. The phenomena in case of connecting error indoor unit connector type condition open and connecting error open open open open short between terminals ( ③ and ④ ) of room-th. Short between terminals ( ① and ② ) of pipe-th. Short between terminals • the same as the phenomenon of outdoor unit....

Page 54

- 54 - outdoor unit connector type condition open • pwb pattern is damaged when applying the power. Connecting reversely connecting reversely open open open open connecting error ( ① ↔ ② ) connecting error ( ① ↔ ③ ) connecting error ( ① ↔ ④ ) connecting error ( ② ↔ ③ ) connecting error ( ② ↔ ④ ) con...

Page 55

9. Voltage of connectors according to indoor fan speed - 55 - 1 2 3 4 4 3 2 1 1 1 4 3 1 2 3 4 5 2 3 4 5 6 2 indoor fan motor indoor pwb assy connecting wires between indoor and outdoor indoor connecting terminal outdoor connecting terminal input power power trans cn-power cn-motor cn-trans cn-dc/dc ...

Page 56: Electronic Control Device

(1) main pwb assy(indoor unit) • pwb assy svc part list - 56 - electronic control device 1 24k heating model 6871a10035a open 56k 3k open open open 2 24k cooling model 6871a10035b 12k 56k 3k open open open 3 18k heating model 6871a10035c open 56k 6.8k oepn open open 4 18k cooling model 6871a10035d 1...

Page 57

1 12k heaing model 6871a10036e 6.8k 5.1k 1k open 39k o o o o o o 2 12k cooling model 6871a10036f 6.8k 5.1k 1k open 39k x x x x x x 3 9k heaing model 6871a10036g 6.8k 10k 6.8k 3k open o o o o o o 4 18k heaing model 6871a10036c 6.8k 10k 5.1k 6.8k 12k o o o o o o 5 18k cooling model 6871a10036d 6.8k 10...

Page 58: (3) Display Pwb Assy

(3) display pwb assy - 58 - (p/no: 6871a30009c).

Page 59: 1. Indoor Unit

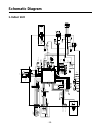

1. Indoor unit - 59 - schematic diagram 64 17 12 16 14 15 13 operation cmp timer sleep 7 9 8 11 10 4 6 5 3 2 1 37 31. 24 19 22 23 20 21 18 25 26 29 27 28 30 32 33 35 34 36 50 57 62 61 63 59 58 60 56 54 55 52 53 51 41 40 42 38 39 45 44 43 47 46 49 48 poly sw rxe250 option c04d dc12v vss0 vdd0 sw01f c...

Page 60: 2. Outdoor Unit

2. Outdoor unit - 60 - 3 2 1 ic9 ic10 5 tlp521-1bl tlp521-1bl cn-dc/dc 4 2 3 1 470uf 20v c05 4 2 3 1 8 2 3 220 vr71 r75 23.2k 1% 2k 100uf 25v c73 + 4 r74 5.1k 8 7 29.4k 20k 34k 1.06k 102 1 - + - d92 c92 50v 1n4148 8 104 ic7 5.23k 13k 3k 3 + 14 9 hcp6068 56 r95 d91 1n4148 3 4 2 1 2 1 3 4 2.7k r92 dc ...

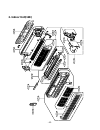

Page 61: 1. Indoor Unit (9K)

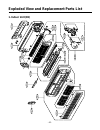

1. Indoor unit (9k) - 61 - exploded view and replacement parts list 267110 249951 354212 135312 135311 359011 131410 733010 342800 268712 152302 159901 263230 268714 352150 346810 35211b 135314 146811.

Page 62: Parts List(9K)

- 62 - parts list(9k) 131410 chassis assy 3141a20001b 1 1 r 135311 grille assy,discharge(indoor) 3531a10005m 1 1 r 135312 grille assy,front(indoor) 3531a10073 1k 1b r 135314 grille assy,inlet sub 3531a20031 1z 1y r 146811 motor assy,step 4681ar2727h 1 1 r 152302 filter(mech),a/c 5230ar2630a 2 2 r 15...

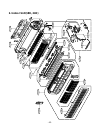

Page 63: 2. Indoor Unit(12K)

2. Indoor unit(12k) - 63 - 267110 249951 354212 135312 135311 359011 131410 733010 342800 268712 152302 159901-2 159901-1 263230 268714 352150 346810 35211b 135314 146811.

Page 64: Parts List(12K)

Parts list(12k) - 64 - 131410 chassis assy 3141a20003d 1 1 r 135311 grille assy, discharge(indoor) 3531a10023t 1 1 r 135312 grille assy, front 3531a10030 1y 1z r 135314 grille assy, inlet 3531a10032 1w 1x r 146811 motor assy, step 4681ar2727h 1 1 r 152302 filter(mech), a/c 5230a20004a 2 2 r 159901-1...

Page 65: 2. Indoor Unit(18K, 24K)

- 65 - 2. Indoor unit(18k, 24k) 131410 267110 249951 135312 135311 354212 359011 733010 342800 268712 152302 159901-2 159901-1 263230 268714 352150 346810 146811 146811 135314.

Page 66: Parts List(18K, 24K)

- 66 - parts list(18k, 24k) 131410 chassis assy 3141a20002d 1 1 1 1 r 135311 grille assy, discharge(indoor) 3531a10008r 1 1 1 1 r 135312 grille assy, front(indoor) 3531a10026 1x 1y 1x 1y r 135314 grille assy, inlet sub 3531a20032 1r 1s 1r 1s r 146811 motor assy, step 4681ar2727h 1 1 1 1 r 152302 fil...

Page 67: 4. Outdoor Unit(9K, 12K)

- 67 - 550140 554160 567502 552116 561410 553000 552111 437210 559010 546810 554031 261704 w0czz 430410 552203-3 552203-1 437212 435511 552202 649950 668711 4. Outdoor unit(9k, 12k).

Page 68: Parts List(9K, 12K)

Parts list(9k, 12k) - 68 - 552116 tube assy,reversing 5211a20140 1f 1g r 552202 valve,reversing 5220ar3084b 1 1 r 552203-1 valve,service 2h02479h 1 1 r 5220a20005a 1 1 r 552203-3 valve,service 2h01890l 1 1 r 5220a20003a 1 1 r 553000 heater,sump 5300ar2915d 1 1 r 554031 condenser assy,bent 5403a20019...

Page 69: 5. Outdoor Unit(18K)

5. Outdoor unit(18k) - 69 - 552116 649950 561410 554160 567502 447910 550140 552203-2 552203-3 435512 437210 559010 546810 668711 552111 w0czz 554031 261704 437212 435511 553000 430411.

Page 70: Parts List(18K)

Parts list(18k) - 70 - 261704 transformer, power 6171aq3178a 1 1 430411 base assy, weld(outdoor) 3041a30003f 1 1 r 435511 cover assy, control(outdoor) 3551ar7184t 1 1 r 435512 cover assy, top(outdoor) 3h03266j 1 1 r 437210 panel assy, front(outdoor) 3721a20005b 1 1 r 437212 panel assy, rear 3720ap00...

Page 71: 5. Outdoor Unit(24K)

5. Outdoor unit(24k) - 71 - 649950 552111 668711 w0czz 550140 553000 552116 552202 561440 552203-3 552203-1 435511 430411 435512 554031 437212 437210 559010 546811 554031 261704.

Page 72: Parts List(24K)

Parts list(24k) - 72 - 261704 transformer, power 6171aq3198a 1 1 r 430411 base assy, weld(outdoor) 3041a30003u 1 1 r 435511 cover assy, control(outdoor) 3551ar7184t 1 1 r 435512 cover assy, top(outdoor) 3h03266j 1 1 r 437210 panel assy, front(outdoor) 3721a20005b 1 1 r 437212 panel assy, rear 3720ap...

Page 73

P/no.: 3828a20048m printed in korea.