- DL manuals

- ICP

- Furnace

- ìA1

- Service Manual

ICP ìA1 Service Manual

Summary of ìA1

Page 1

Multi position 2-- stage gas furnaces part number 440 08 2002 02 *9mpt & *9mpv “a1 & a2” manufactured by: this manual supports condensing gas furnaces manufactured in 2001 ã 2001 international comfort products corporation (usa) 4/2002.

Page 2: *9Mpt

*9mpt -- dual certified venting (1 or 2 pipes) *9mpv -- dual certified venting (1 or 2 pipes) variable speed ã 2001 international comfort products corporation (usa) 1136 heil--quaker boulevard, lavergne, tn 37086 all rights reserved throughout the world..

Page 3: Table Of Contents

Service manual two- stage multi position furnace table of contents 1. Introduction 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2. Unit identification 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: 1. Introduction

Two- stage multi position furnace service manual 2 440 08 2002 02 1. Introduction this service manual is designed to be used in conjunction with the installation manual and/or technical support manual provided with each furnace. These furnaces represent the very latest in high efficiency gas furnace...

Page 5

Two- stage multi position furnace service manual 3 440 08 2002 02 component locations for four position furnaces figure 1 circulating air blower rating plate gas valve/ignition module d oor interlock switch pressure switches fan/delay control furnace vent pipe (vent pipe connection through side pane...

Page 6: 4. Electrical Supply

Two- stage multi position furnace service manual 4 440 08 2002 02 6. The combustion blower assembly is mounted on the outlet side of the secondary heat exchanger, this blower creates a partial vacuum (negative pressure) within the heat exchangers drawing the flue products out of the furnace. 7. The ...

Page 7: 5. Interlock Switch

Two- stage multi position furnace service manual 5 440 08 2002 02 5. Interlock switch the blower compartment door of all models is equipped with an interlock switch. This switch is “normally open” (closes when the door is on the furnace) and interrupts furnace op- eration when the door is open. This...

Page 8

Two- stage multi position furnace service manual 6 440 08 2002 02 fire or explosion hazard. Turn off gas at shut off before connecting manometer. Failure to turn off gas at shut off before connecting manometer can result in death, personal injury and/or property damage. ! Gas pressure testing device...

Page 9: 7. L.P. Pressure Switch

Two- stage multi position furnace service manual 7 440 08 2002 02 7. L.P. Pressure switch models converted to operate on l.P. Gas will be installed with an l.P. Pressure switch. The switch will be located in the gas supply line (in a “tee” fitting), just ahead of the gas valve. The purpose of this s...

Page 10: 11. Room Thermostats

Two- stage multi position furnace service manual 8 440 08 2002 02 10. Checking temperature rise checking temperature rise figure 8 thermometer: return air temp. Thermometer; supply air temp. Supply air flow air flow return the furnace is designed to operate within a certain specified range of temper...

Page 11

Two- stage multi position furnace service manual 9 440 08 2002 02 thermostat location figure 9 5 ft. Drafts sun thermostat light shield location the thermostat should not be mounted where it may be af- fected by drafts, discharge air from registers (hot or cold), or heat radiated from the sun of app...

Page 12: 12. Control Wiring

Two- stage multi position furnace service manual 10 440 08 2002 02 12. Control wiring control wiring is an important part of the total equipment installation, since it provides the vital communications link between the thermostat, and the equipment. It is often overlooked as the source of equipment ...

Page 13

Two- stage multi position furnace service manual 11 440 08 2002 02 main limit switch a “normally closed” switch located on the front partition of the furnace. It monitors supply air temperature, and inter- rupts furnace (burner) operation when a supply air tempera- ture is sensed which would result ...

Page 14: 14. Pressure Switches

Two- stage multi position furnace service manual 12 440 08 2002 02 14. Pressure switches transition pressure switch under normal operating conditions, sufficient pressure is de- veloped by the exhaust (combustion) blower to close the switch, and permit the burner to operate. As the condensate drain ...

Page 15

Two- stage multi position furnace service manual 13 440 08 2002 02 table 3 approximate operating pressures (inches of w.C.) @blower/@transition model vent length (high fire) (low fire) 50 mbtu & short -- (5 ft. No elbows) --1.80/--2.60 --1.20/--1.90 50 mbtu & 75 mbtu long -- (40 ft. + 5 90° elbows) ...

Page 16

Two- stage multi position furnace service manual 14 440 08 2002 02 dual certified models require a combustion air inlet pipe to bring in all air for combustion from outside the struc- ture only when installed as a direct vent furnace (i.E. Two pipe installation) consult the appropriate venting table...

Page 17

Two- stage multi position furnace service manual 15 440 08 2002 02 “a” “a” inlet figure 19 sidewall inlet vent and exhaust-- air termination dimension “a” is touching or 2² maximum separation. 12²²²² min. Grade or snow level 18²²²² min. For cold climates (sustained below 0°°°° f) 8²²²² min. 20¢¢¢¢ m...

Page 18

Two- stage multi position furnace service manual 16 440 08 2002 02 17. Concentric vent termination vent/combustion air piping charts table 6 concentric termination kit naha001cv & naha002vc venting table dual piping only 50,000 & 75,000 btuh furnaces naha002cv -- 35¢ & (4) 90° elbows with 2² pvc pip...

Page 19: 18. Exhaust Blower

Two- stage multi position furnace service manual 17 440 08 2002 02 18. Exhaust blower figure 25 exhaust blower vent pipe (top panel exit) rubber coupling & clamps 90° elbow blower vent fitting & clamps vent pipe (side panel exit) vent fitting & clamps 25--23--35 drain side view cl rotate downward 20...

Page 20

Two- stage multi position furnace service manual 18 440 08 2002 02 20. Honeywell st9162a series fan timer/furnace control honeywell st9162a figure 27 the honeywell st9162a electronic fan timer/fur- nace control is an integrated electronic control, which con- tains no user serviceable components. In ...

Page 21

Two- stage multi position furnace service manual 19 440 08 2002 02 21. St9162a/sv9541q testing sequence if furnace successfully passes this testing sequence, it can be assumed that there are no problems with the st9162a/sv9541q control sys- tem. If it does not, however, it doesnot necessarilymean th...

Page 22

Two- stage multi position furnace service manual 20 440 08 2002 02 23. Honeywell sv9541q system operation & diagnostics the following is the normal operating sequence for the 2--stage control system. Cooling (y) request: 24 vac signals applied to y & g terminals of eft (electronic fan timer) control...

Page 23

Two- stage multi position furnace service manual 21 440 08 2002 02 24 vac signals applied to w1 and w2 terminals of eft control. · same light--off routine as described for the signal stage thermostat operation except that at the end of the selected heat fan on delay, the inducer remains on high fire...

Page 24: 25. Capacitors

Two- stage multi position furnace service manual 22 440 08 2002 02 24. Checking flame current the honeywell sv9541q ignition system used in this furnace series proves (verifies) flame via the flame rectification method. Flame rectification is a process of converting alternating current (a.C.) into d...

Page 25

Two- stage multi position furnace service manual 23 440 08 2002 02 figure 32 variable speed models d.C. Motor speed wires wire color motor speed blue common white low heat green circulating black high heat yellow cooling brown dehum. (80%)* * function enabled only when energized with cooling speed. ...

Page 26

Two- stage multi position furnace service manual 24 440 08 2002 02 table 7 blower performance data 75,000 btuh (psc motor) air delivery in cubic feet per minute (cfm) (furnace rated @ 0.5² w.C. Esp) tap low med l med h high .10 706 917 1163 1368 e .20 677 875 1120 1319 ssu re . .30 636 840 1076 1263...

Page 27

Two- stage multi position furnace service manual 25 440 08 2002 02 figure 35 checking temperature rise thermometer: return air temp. Thermometer; supply air temp. 3¢ min from ra- diant scene return supply air flow air flow checking approximate air flow if an inclined manometer or magnehelic gauge is...

Page 28

Two- stage multi position furnace service manual 26 440 08 2002 02 blower motor control figure 36 *example cooling airflows switches 6, 7 & 8: 000 3.5 ton 001 3.0 ton 010 2.5 ton 011 2.0 ton *see “technical support manual” for correct airflow rates. 0 1 0 input signal or thermostat connections note:...

Page 29: 27. Blower Rotation

Two- stage multi position furnace service manual 27 440 08 2002 02 2 speed models - p.S.C. Motor heating speeds should it be necessary to change blower speeds to obtain proper temperature rise on either (or both) high fire, and/or low fire, simply take the appropriate speed tap wire, and plug it on ...

Page 30

Two- stage multi position furnace service manual 28 440 08 2002 02 figure 39 upflow installations (dual certified *9mpt & *9mpv(a1) models) supply air ex ha us t inle t return air vent pipe vent pipe grommet vent fitting & clamps rubber plug drain line 90°°°° elbow plastic caps rubber cou- pling & c...

Page 31

Two- stage multi position furnace service manual 29 440 08 2002 02 combustion blower mounting screws (4) figure 40 horizontal left installations (dual certified *9mpt & *9mpv(a1) models) supply air ex ha us t inle t vent pipe vent pipe grommet vent fitting & clamps rubber plug drain line 90°°°° elbo...

Page 32

Two- stage multi position furnace service manual 30 440 08 2002 02 figure 41 horizontal right installations (dual certified *9mpt & *9mpv) supply air ex ha us t inle t vent pipe vent pipe grommet vent fitting & clamps rubber plug drain line 90°°°° elbow plastic caps rubber coupling & clamps 5 / 8 ²²...

Page 33

Two- stage multi position furnace service manual 31 440 08 2002 02 pressure switch hose, transition pressure switch, blower (hi fire) pressure switch hose, blower rotate downward 20° to 30° plastic caps figure 42 downflow installations (dual certified *9mpt & *9mpv models(a1) models) vent pipe vent ...

Page 34

Two- stage multi position furnace service manual 32 440 08 2002 02 ai r f lo w ai r f lo w supply air ex ha us t inle t return air vent pipe vent pipe grommet vent fitting & clamps yellow plastic cap drain line 90°°°° street elbow plastic cap rubber coupling & clamps 5 / 8 ²²²² hose & clamps combust...

Page 35

Two- stage multi position furnace service manual 33 440 08 2002 02 this configuration allows left side venting from the furnace. If right side venting is required, the combustion blower must be relocated on the plastic transition box. Remove the four(4) screws that secure the blower to the transitio...

Page 36

Two- stage multi position furnace service manual 34 440 08 2002 02 ai r f lo w combustion blower mounting screws (4) figure 45 supply air ex ha us t inle t vent pipe vent pipe grommet vent fitting & clamps yellow plastic cap drain line plastic cap rubber coupling & clamps 5 / 8 ²²²² hose & clamps co...

Page 37

Two- stage multi position furnace service manual 35 440 08 2002 02 ai r f lo w figure 46 supply air ex ha us t inle t vent pipe vent pipe grommet vent fitting & clamps yellow plastic cap drain line 90°°°° street elbow plastic caps rubber coupling & clamps 5 / 8 ²²²² hose & clamps combustion air pipe...

Page 38

Two- stage multi position furnace service manual 36 440 08 2002 02 route the hose to the smaller drain stub on the condensate trap. Cut off excess hose and discard. Connect the hose to the drain stub on the trap and secure with a 5 / 8 ² clamp. Note: ensure hoses maintain a downward slope to the con...

Page 39

Two- stage multi position furnace service manual 37 440 08 2002 02 mount the condensate drain trap in a vertical position to either the right or left side of the furnace using the two screws and gasket that are provided. If needed, remove the hole plugs from the furnace side panel and relocated to t...

Page 40

Two- stage multi position furnace service manual 38 440 08 2002 02 28. Heat exchanger removal/replacement “exploded” parts view -- typical four position furnaces figure 48 25--23--43a secondary heat exchanger 1. Turn ”off” electrical power and gas supply to furnace. 2. Disconnect vent pipe to furnac...

Page 41

Two- stage multi position furnace service manual 39 440 08 2002 02 honeywell sv9541q “smart valve” sequence of operation power applied to appliance thermostat calls for heat combustion blower de--energized three second flame failure recycle delay five minute wait period pilot lights and flame is sen...

Page 42

Two- stage multi position furnace service manual 40 440 08 2002 02 honeywell sv9541q “smart valve” trouble shooting the 6 + x designation indicates a combination of flash codes: 6 flashes shows the control is in soft lockout, followed by x flashes to indicate the reason the control went into soft lo...

Page 43

Two- stage multi position furnace service manual 41 440 08 2002 02 honeywell sv9541q “smart valve” trouble shooting continued led status indicates check/repair 6 flashes + 3 flashes soft lockout. Last failure was pressure switch maximum recycle count exceeded combustion air blower is de--energized, ...

Page 44

Two- stage multi position furnace service manual 42 440 08 2002 02 sv9541q electrical variation 2--stage connector (pin #) description voltage signal when signal is present neutrals (5-- 1 / 4 ² qc’s) neutral 0 vac (neutral and earth ground should be at the same potential) always present 120 vac lin...

Page 45

Two- stage multi position furnace service manual 43 440 08 2002 02 sv9541q electrical variation 2--stage con’t connector (pin #) description voltage signal when signal is present c1 (pin 4) data line non--periodic 1 /2 wave rectified ac present when the door interlock switch is closed. Same signal a...

Page 46

Two- stage multi position furnace service manual 44 440 08 2002 02 always check current techenical support manual this data is subject to change without notice technical service data *9mpv (a1 & a2) specifications *9mpv050f12a *9mpv075f12a *9mpv100j20a *9mpv125l20a general gas type nat l.P. Nat l.P....

Page 47

Two- stage multi position furnace service manual 45 440 08 2002 02 always check current techenical support manual circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings continuous blower (cfm) @ 0.10²²²² static switch settings furnace model #1 #2 50k 75k 100k 125...

Page 48

Two- stage multi position furnace service manual 46 440 08 2002 02 always check current techenical support manual this data is subject to change without notice circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 1 esp²²²² w.C. *9mpv050 cooling (cfm vs. ...

Page 49

Two- stage multi position furnace service manual 47 440 08 2002 02 always check current techenical support manual circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 3 esp²²²² w.C. *9mpv050 lo heat (cfm vs. External static pressure ) sc f m 0 100 200 30...

Page 50

Two- stage multi position furnace service manual 48 440 08 2002 02 always check current techenical support manual this data is subject to change without notice circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 5 *9mpv075 hi heat (cfm vs. External stat...

Page 51

Two- stage multi position furnace service manual 49 440 08 2002 02 always check current techenical support manual circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 7 esp²²²² w.C. *9mpv100 cooling (cfm vs. External static pressure ) sc f m 0 500 1000 1...

Page 52

Two- stage multi position furnace service manual 50 440 08 2002 02 always check current techenical support manual this data is subject to change without notice circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 9 esp²²²² w.C. *9mpv100 lo heat (cfm vs. ...

Page 53

Two- stage multi position furnace service manual 51 440 08 2002 02 always check current techenical support manual circulation air blower data - *9mpv(a1 & a2) heating, cooling & continuous airflow settings figure 11 esp²²²² w.C. *9mpv125 lo heat (cfm vs. External static pressure ) sc f m 0 500 1000 ...

Page 54

Two- stage multi position furnace service manual 52 440 08 2002 02 always check current techenical support manual this data is subject to change without notice technical service data *9mpt (a1 & a2) specifications *9mpt050f12a *9mpt075f14a *9mpt100j16a *9mpt125l20a general gas type nat l.P. Nat l.P....

Page 55

Two- stage multi position furnace service manual 53 440 08 2002 02 always check current techenical support manual circulation air blower data *9mpt (a1 & a2) for 050(a1 & a2) models 3 ton units speed cfm speed tap low med l med h hi 0.1 826 1083 1301 1408 0.2 804 1050 1242 1347 0.3 770 1028 1195 129...

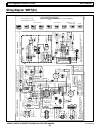

Page 56: Wiring Diagram (

Two- stage multi position furnace service manual 54 440 08 2002 02 always check current techenical support manual this data is subject to change without notice wiring diagram ( 1 / 2 hp dc blower motor) *9mpv050(a1) 12 30 sec. 12 12 12 12 2 stage 4 3 12 single stage 4 3 l imit m ai n 12 1 * thermo s...

Page 57

Two- stage multi position furnace service manual 55 440 08 2002 02 always check current techenical support manual wiring diagram (1 hp dc blower motor) *9mpv075, 100 & 125(a1) 12 30 sec. 12 12 12 12 2 stage 4 3 12 single stage 4 3 l imit m ai n 12 1 * thermo stat 4 2 st age p 2 interna l circui t bo...

Page 58: Wiring Diagram (

Two- stage multi position furnace service manual 56 440 08 2002 02 always check current techenical support manual this data is subject to change without notice wiring diagram ( 1 / 2 hp dc blower motor) *9mpv050(a2) 12 30 sec. 12 12 12 12 2 stage 4 3 12 single stage 4 3 l imit m ai n 12 1 * thermo s...

Page 59

Two- stage multi position furnace service manual 57 440 08 2002 02 always check current techenical support manual wiring diagram (1 hp dc blower motor) *9mpv075, 100 & 125(a2) 12 30 sec. 12 12 12 12 2 stage 4 3 12 single stage 4 3 l imit m ai n 12 1 * 2-stage 4 2 st age p 2 intern al circuit boar d ...

Page 60: Wiring Diagram *9Mpt(A1)

Two- stage multi position furnace service manual 58 440 08 2002 02 always check current techenical support manual this data is subject to change without notice wiring diagram *9mpt(a1) n 2 st age 8 5 1 6 2 4 1 3 7 n sen so r (som e mo de ls ) cap aci to r igni te r hum ea c n m o to r in d u c e r i...

Page 61: Wiring Diagram *9Mpt(A2)

Two- stage multi position furnace service manual 59 440 08 2002 02 always check current techenical support manual wiring diagram *9mpt(a2) n 2 s tag e 8 5 1 6 2 4 1 3 7 n sens o r (s om e m o de ls) ca pa cit o r ig ni te r hu m eac n m o to r in d u c e r indh l o n hi g h 2 1 h o t n e u tr a l o ...

Page 62: Index

Index a adjusting heat anticipator, 9 adjusting manifold pressure, 6 air proving switch, see pressure switch b blower assembly, conditioned air, 22 blower rotation, 27 blower speeds, changing, 25 blower speeds, selecting, 23 blower, exhaust, 17 burners, 7 c capacitors, 22 checking approximate air fl...

Page 63: Index

Index p piping, vent/combustion air, 13--16 polarity, line voltage, 4 pressure switches, 12--14 pressures, approximate operating, 13 r roll out limit switch, 11 room thermostat, 8 s sequence of operation chart, sv9541q, 39 st9162a testing sequence, 19 supply, electrical, 4 supply, gas, 5 sv9541q sys...