- DL manuals

- Intergas

- Boiler

- Compact HRE 18 OV

- Installation, Service And User Instructions Manual

Intergas Compact HRE 18 OV Installation, Service And User Instructions Manual

Intergas Heating Ltd

1

Compact HRE

18 OV

(G.C. 41-291-04)

24 OV

(G.C. 41-291-05)

30 OV

(G.C. 41-291-06)

Installation, service

and user instructions

Please read these installation instructions carefully before installing and using

the appliance. Keep these installation instructions with the appliance.

Always act in accordance with the instructions indicated.

Summary of Compact HRE 18 OV

Page 1

Intergas heating ltd 1 compact hre 18 ov (g.C. 41-291-04) 24 ov (g.C. 41-291-05) 30 ov (g.C. 41-291-06) installation, service and user instructions please read these installation instructions carefully before installing and using the appliance. Keep these installation instructions with the appliance...

Page 2

Intergas heating ltd 2 benchmark scheme benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s instr...

Page 3

Intergas heating ltd 3 9 commissioning the appliance 24 9.1 filling and venting the appliance and the installation....................................................................................................................24 9.2 commissioning the appliance ......................................

Page 4

Intergas heating ltd 4 1 preface 1.1 regulation the intergas boiler meets the requirements of statutory instrument 'the boiler (efficiency) regulations' and is deemed to meet the requirements of: • gas appliance directive 90/396/eec • boiler efficiency directive 92/42/eec • low voltage directive 200...

Page 5

Intergas heating ltd 5 1.6 abbreviations and descriptions used description referred to as high efficiency he intergas compact hre ov wall mounted gas fired boiler appliance appliance plus pipe work for central heating ch installation appliance plus pipe work for domestic hot water dhw installation 1...

Page 6

Intergas heating ltd 6 2 safety regulations the manufacturer intergas heating ltd accepts no liability whatsoever for damage or injury caused by failure to adhere (strictly) to the safety regulations and instructions, or carelessness during installation of the intergas compact hre ov high efficiency...

Page 7

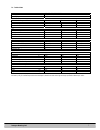

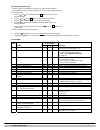

Intergas heating ltd 7 2.4 technical data appliance category c13; c33; c43; c53; c63; c83 gas supply pressure 20 mbar -g20 ; 37 mbar – g31 gas category ii2h3p technical data compact hre ov 18 24 30 sedbuk rating a a a gas council number g.C. 41-291-04 g.C. 41-291-05 g.C. 41-291-06 ch nom. Input rati...

Page 8

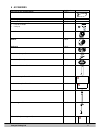

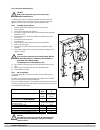

Intergas heating ltd 8 2.5 components a. Flue pipe adapter j. Mains lead 230 v ac without plug (stripped) b. Flow ch k. Condensate trap c. Return ch l. Ionisation / ignition electrode d. Sight glass m. Fan e. Sensor s1 n. Gas valve f. Heat exchanger o. Position of data plate g. Sensor s1 p. Boiler c...

Page 9

Intergas heating ltd 9 3 general boiler information 3.1 general the intergas compact hre ov wall mounted, gas fired boiler is suitable for use in open vent systems with a heating system feed tank. The appliance is designed to deliver heat to the water in a ch system and when an indirectly heated dom...

Page 10

Intergas heating ltd 10 4 operation 4.1 general the intergas compact hre ov wall mounted, gas fired open vent boiler is a modulating high efficiency boiler. This means that the power is adjusted in line with the desired heat requirement. It is designed to be used in an open vented system with heatin...

Page 11

Intergas heating ltd 11 4 ignition when the fan has reached the starting speed, the burner is ignited by means of electrical sparks. During ignition the code 4 is visible. If the burner does not ignite, a new ignition attempt occurs after approximately 15 seconds. If after 4 ignition attempts the bu...

Page 12

Intergas heating ltd 12 4.6 test programs the boiler controller has a facility for placing the appliance in test mode. Activation of a test program will result in the appliance starting operation at a fixed fan speed, without the control functions being actuated. The safety functions do remain activ...

Page 13

Intergas heating ltd 13 5 installer handy hints • the installer shall instruct the user on the operation of the boiler and safety devices contained within the boiler. The installer should then hand over the instructions indicating the included benchmark commissioning checklist that has been complete...

Page 14

Intergas heating ltd 14 6 accessories description article number pipe cover set (incl. Mounting material) 093217 outside sensor 203207 dhw storage cylinder sensor 065117 diverter valve 230 v 092647 concentric connection Ø80x125 • concentric flue adapter • sealing cap 090557 bend 45° 084661 bend 90° ...

Page 15

Intergas heating ltd 15 elbow 60° (for plume management kit) 081285 extension l = 100 incl. Wall bracket (for plume management kit) 081286.

Page 16

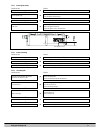

Intergas heating ltd 16 7 installation 7.1 overall dimensions a = supply ch Ø22 b = return ch Ø22 c = gas ½” f = condensate drain Ø25 (flexible) g = drain prv Ø15 h = 840 compact hre ov 30 h = 780 compact hre ov 24 h = 720 compact hre ov 18 z1= standard flue pipe Ø60/100 (concentric) z2= standard of...

Page 17

Intergas heating ltd 17 7.2 installation location • if the boiler is to be installed in any room or compartment, it does not require any purpose made ventilation for combustion air. If sited in a room containing a bath or shower then particular reference is drawn to the current i.E.E. Wiring regulat...

Page 18

Intergas heating ltd 18 7.3 installing the appliance 1. Unpack the appliance. 2. Check the contents of the packaging. It consists of: • appliance (a) • wall mounting strip (b) • condensate trap (c) • pressure fitting 22 mm (2 pcs) • installation instructions • operating instructions • warranty card ...

Page 19

Intergas heating ltd 19 8 connection 8.1 connecting ch installation 1. Flush the ch system thoroughly to clean. 2. Connect the flue and return pipe to the installation using the enclosed press fittings 22 mm. 3. All pipes must be fitted unstressed in order to prevent the pipes from ticking. Make sur...

Page 20

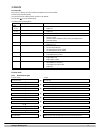

Intergas heating ltd 20 8.2.1 electrical connections temperature control connector x4 notes room thermostat 6 – 7 voltage free outside temperature sensor 8 – 9 - frost protection thermostat 6 – 7 parallel to room thermostat power supply 24 v dc 6 – 7 – 9 6 = 24 v dc 7 = room thermostat 9 = 0 v dc op...

Page 21

Intergas heating ltd 21 8.3.2 230 volt room thermostat to be connected to contacts 1 and 3 of connector x2 and remove link 6-7. See electrical diagram. Warning high voltage isolate the appliance from the electrical supply before connecting the thermostat. 8.4 flue system 8.4.1 flue pipe and air supp...

Page 22

Intergas heating ltd 22 8.4.2 flue pipe position terminal position min. Distance a directly below an open able window or other opening e.G. Air brick 300 mm b below gutters, soil pipes or drain pipes 75 mm c below eaves 200 mm d below balconies or car front roofs 200 mm e from vertical drain pipes a...

Page 23

Intergas heating ltd 23 8.4.3 horizontal flue system the 60/100 mm horizontal flue system may be extended up to a maximum of 15 metres. For every bend used the following flue length reductions apply: - 45° bend = 1 metre and for a 90° bend this is 1,5 metres. Caution only an intergas approved flue i...

Page 24

Intergas heating ltd 24 9 commissioning the appliance at the time of commissioning, complete all relevant sections of the benchmark checklist located on page 41 of this document. 9.1 filling and venting the appliance and the installation 9.1.1 ch system caution if an additive is added to the ch wate...

Page 25

Intergas heating ltd 25 9.2 commissioning the appliance read-out operation 1 on / off a on / off button 2 ch operation or setting maximum ch temperature b dhw / ch button, for setting desired temperature 3 dhw operation or setting dhw temperature (not applicable for compact hre ov) c - button 4 desi...

Page 26

Intergas heating ltd 26 9.3 setting and adjusting the clock functions 9.3.1 setting the clock • press the button for less than 1 second and repeat this untill ‘’clock’’ appears. For adjusting the clock to the correct time press the [+] or [-] button. Note: holding the button for more than 1 second w...

Page 27

Intergas heating ltd 27 9.5 shutting down caution drain the appliance and the installation if mains power has been interrupted and there is a possibility of freezing. 1. Drain the appliance at the drain tap. 2. Drain the installation at the lowest point. 9.5.1 frost protection • to avoid freezing of...

Page 28

Intergas heating ltd 28 10 setting and adjustment the functioning of the appliance is determined primarily by the (parameter) settings in the boiler controller. Part of this can be set directly via the operating panel; another part can only be adjusted using the installer code. 10.1 directly via the...

Page 29

Intergas heating ltd 29 10.2 setting via the service code the boiler controller in the appliance is factory set in accordance with the parameters. These parameters can only be changed using the service code. Proceed as follows to activate the program memory: 1. Press the and keys simultaneously unti...

Page 30

Intergas heating ltd 30 10.4 setting maximum ch power the maximum ch power is set at 70% in the factory. If more or less power is necessary for the ch installation, the maximum ch power can be changed by changing the fan rpm. See table setting ch power. This table shows the relationship between the ...

Page 31

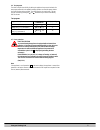

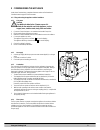

Intergas heating ltd 31 10.7 conversion to different gas type caution work on gas carrying parts may only be carried out by a qualified competent person. If a different type of gas is connected to the appliance than that for which the appliance has been set by the manufacturer, the gas metering ring...

Page 32

Intergas heating ltd 32 a. Co 2 demands at low setting for natural gas the co 2 level at low setting must be equal to or max. 0.3 % lower than the level at high setting. Important: the co 2 level at low setting must never be under 8.6%. For example (natural gas): 1: co 2 level at high setting is 9.2...

Page 33

Intergas heating ltd 33 11 faults 11.1 fault codes if the fault led is flashing, the boiler controller has detected a fault. A fault code will be indicated on the temperature display. Once the fault has been rectified the boiler controller can be restarted . Press the reset key on the operating pane...

Page 34

Intergas heating ltd 34 11.2.2 burner ignites noisily possible causes: solution: gas supply pressure too high. ¨ the house pressure switch may be faulty. Contact the gas company . No ª incorrect ignition gap. ¨ replace the ignition pin . Check the ignition electrode gap. No ª gas/air adjustment not ...

Page 35

Intergas heating ltd 35 11.2.5 the power is reduced possible causes: solution: at high rpm the power has fallen by more than 5%. ¨ check appliance and flue system for fouling. Clean the appliance and flue system. 11.2.6 ch does not reach temperature possible causes: solution: room thermostat setting...

Page 36

Intergas heating ltd 36 12 maintenance the appliance and the installation should be checked and if necessary cleaned every year by a registered expert. For assembly and disassembly the following tools can be used: 1. Cross head screwdriver 2. Allen key 8 mm 3. Adjustable spanner after servicing, com...

Page 37

Intergas heating ltd 37 12.3 assembly caution when fitting the various seals check for damage, hardening, tears or hairline tears and/or discoloration. Where necessary fit a new seal. Also check whether seals are still correctly positioned. Failure to fit the sensors s1 and/or s2, or to fit them cor...

Page 38

Intergas heating ltd 38 13 electrical diagram a earth connections heat-exchanger f fuse (2a t) p1 external ch pump s7 ch water pressure sensor b spark plug cover g gas valve + ignition unit r resistance v fan c boiler controller i ionisation-/ ignition probe s1 flow sensor e earth connections boiler...

Page 39

Intergas heating ltd 39 14 short spares list description article number boiler controller 074277 fan 074397 wall mounting strip 145308 temperature sensor (heat exchanger) 200117 ignition / ionisation electrode 209367 ignition cable 221357 gas valve siemens 801467 ignition module 801477 condensate tr...

Page 40

Intergas heating ltd 40 15 warranty conditions with due regard for the conditions indicated below, intergas heating ltd warrants to the authorised installer the soundness of the materials used in and the correct operation of its central heating products, when used for the purpose for which they are ...

Page 41

Intergas heating ltd 41 17 gas boiler system commissioning checklist.

Page 42

Intergas heating ltd 42 18 service record.

Page 43

Intergas heating ltd 43 __________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________ ______________________________________________...

Page 44

Intergas heating ltd 44 intergas boilers are manufactured in a kiwa iso 9001 certified production faccility. Intergas heating ltd 88324701 intergas heating limited unit 6, west court buntsford park road bromsgrove worcestershire b60 3dx telephone : 01527 888000 fax : 01527 888001 info@intergasheatin...