- DL manuals

- Intergas

- Boiler

- HSE-125-N

- Installation And Service Manual

Intergas HSE-125-N Installation And Service Manual

PN7331833

Model: HSE – 125 – N/P

Gas-fired Condensing Boiler and

Instantaneous Water Heater

INSTALLATION AND SERVICE MANUAL

Allied Engineering Company

Division of E-Z-Rect Manufacturing Ltd.

Manufacturers of Gas and Electric Boilers, Stainless Steel Tanks, Heat Exchangers and Electric Boosters.

94 Riverside Drive, North Vancouver, BC V7H 2M6

•

Tel: (604) 929-1214

•

www.alliedboilers.com

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

•

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

•

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas supplier, call the fire department.

•

Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

•

Improper, installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury or loss of life. Read all instructions before installation or service.

•

Save this manual for future reference.

EEV

246473

Summary of HSE-125-N

Page 1

Pn7331833 model: hse – 125 – n/p gas-fired condensing boiler and instantaneous water heater installation and service manual allied engineering company division of e-z-rect manufacturing ltd. Manufacturers of gas and electric boilers, stainless steel tanks, heat exchangers and electric boosters. 94 r...

Page 2

Hse installation and service manual 2 table of contents section page about our manuals ...................................................................................................................................... 5 abbreviations and names used ..................................................

Page 3

Hse installation and service manual 3 1.7.9.1 horizontal twin tube side venting with a combined terminal cap............................................. 28 1.7.9.2 horizontal twin tube side venting with twin terminal caps ...................................................... 29 1.7.9.3 vertical (r...

Page 4

Hse installation and service manual 4 4.2.8.2 check the gas-air ratio ............................................................................................................... 53 4.2.8.3 check burner flame ...........................................................................................

Page 5

Hse installation and service manual 5 about our manuals your super hot intergas appliance has been provided with two manuals: • user's information manual - this manual is intended for the owner or user of the appliance and provides information on routine operation and maintenance, and emergency shut...

Page 6

Hse installation and service manual 6 technical specifications hse-125-n hse-125-p technical data natural gas propane ch (central heating – boiler) nominal input rate* 1000 btu/h (kw) 28.7 – 124 (8.4 – 36.3) nominal output rate 1000 btu/h (kw) 27.3 – 118 (8.0 – 34.5) afue % 95 maximum ch operating p...

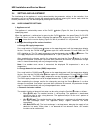

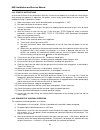

Page 7: Major Components

Hse installation and service manual 7 a ch pump m flue discharge b gas valve n wiring connecting block / terminal c burner controller with operating panel o condensate discharge d supply sensor s1 p dhw sensor s3 e return sensor s2 q condensate trap f blower r heat exchanger g dhw flow switch s oper...

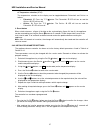

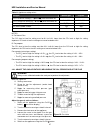

Page 8: Dimensions

Hse installation and service manual 8 dimensions 17.7” 450mm 4.7” 120mm 10.6” 270mm 5.9” 150mm 31.9” 810mm 7.5” 190mm 2.6” 65mm 4.7” 120mm 3.5” 90mm 4.5” 115mm 7.9” 200mm f y z y, z y a e c d d,e a,b,c f b 2.0” 50mm 1.2/1.4”[30/35mm] 10.6” [270mm] 2.6” [65mm] 2.0” [50mm] 5.3” 135mm 2.6” 65mm 2.6” 65...

Page 9

Hse installation and service manual 9 description of the appliance the super hot intergas hse is a combined high efficiency condensing boiler and instantaneous water heater that is designed for providing central heating (ch) and/or domestic hot water (dhw). The actual required input rate for ch and ...

Page 10

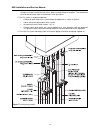

Hse installation and service manual 10 figure 1 appliance with parts installation instructions section 1 1.1 receiving, moving and unpacking inspect shipment for possible damage. All goods are carefully manufactured, inspected, checked and packed by experienced workers. The manufacturer's responsibi...

Page 11

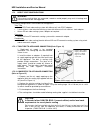

Hse installation and service manual 11 figure 2 install in kitchen cupboard or closed closet 1.3 location and installation 1.3.1 location this appliance is intended for an indoor, wall hung installation using the wall mounting strip or optional mounting frame. The appliance should be mounted on a wa...

Page 12

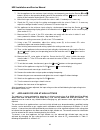

Hse installation and service manual 12 figure 4 wall mounting strip figure 3 remove front cover figure 5 mounting frame 1.3.5 remove front cover remove the front cover on the appliance as follows, refer to figure 3: 1. Unscrew both screws (b) at the bottom of the appliance. 2. Lift the front panel (...

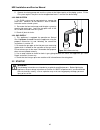

Page 13

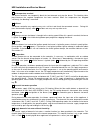

Hse installation and service manual 13 figure 6 install condensate trap 1.3.7 install the condensate trap (refer to figure 6) warning risk of exhaust gases escaping to the appliance room! The condensate trap must always be filled with water or condensate so that it forms a liquid-filled trap. Check ...

Page 14

Hse installation and service manual 14 figure 7 install piping systems all pipes must be installed tension-free in order to avoid ticking of the pipes. The connections must not be twisted in order to avoid leaks at the joint points. 2. The ch system is recommended with: • a make up water loop in the...

Page 15

Hse installation and service manual 15 figure 8 example of make up water loop 1.4.1.2 pressure relief valve warning the pressure relief valve discharges pressurized hot water which can turn into steam. Steam exiting the discharge outlet can explosively expand in all directions. Always maintain a saf...

Page 16

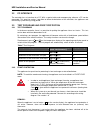

Hse installation and service manual 16 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 (bar) 2.9 5.8 8.7 11.6 14.5 17.4 20.3 23.2 26.1 29.0 (psi) x y 15 13 11 9 7 5 3 1 4.0 (l/min) (gpm) 3.4 2.9 2.4 1.9 1.3 0.8 0.3 figure 9 dhw flow rate vs. Water pressure 1.4.1.6 corrosion prevention (internal) the use o...

Page 17

Hse installation and service manual 17 1.4.2.3 pressure relief valve or temperature and pressure relief valve a pressure relief valve must be installed near the domestic hot water outlet. If the unit is connected to a separate storage vessel, the separate vessel must have its own temperature and pre...

Page 18

Hse installation and service manual 18 figure 11 open control panel figure 10 sediment trap for gas line outside the appliance jacket and as required in section 1.2 . The valve should be readily accessible for turning on and off. When a vertical section of gas piping is supplied on the upstream side...

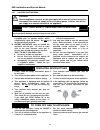

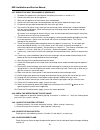

Page 19

Hse installation and service manual 19 a ground terminal heat exchanger f fuse (3.15a t) p1 ch pump s3 dhw sensor b cable of ignition/flame sensor g gas valve r resistor s5 flow switch dhw c burner controller i ionisation/ignition probe s1 ch flow sensor s7 high limit e ground terminals burner contr...

Page 20

Hse installation and service manual 20 1.7 venting and combustion air definitions a direct vent (a balanced flue) appliance – an appliance that operates with all air for combustion obtained from the outdoor atmosphere and all flue gases discharged to the outdoor atmosphere. A non-direct vent applian...

Page 21

Hse installation and service manual 21 installation code, can/csa b149.1 . When re-sizing any portion of the common venting system, the common venting system should be resized to approach the minimum size as determined using the appropriate tables in part 11 of the national fuel gas code, ansi z223....

Page 22

Hse installation and service manual 22 pp venting tube and components: • in canada, m&g: pp system, certified type of ulc s636 • in usa, ansi/astm, pp system, certified type stainless steel venting tube and components (certified types for category iv): • flexmaster canada ltd.: z-vent • z-flex u.S.,...

Page 23

Hse installation and service manual 23 b) on any wall that has an opening between the terminal and the open side of the structure. It is highly recommended that the vent terminal be located where it will not be exposed to normal prevailing winds. The vertical termination shall extend to the required...

Page 24

Hse installation and service manual 24 table 2 direct vent terminal clearances (refer to figure 13) canadian installations 1 us installations 2 a= clearance above grade, veranda, porch, deck, or balcony 12 inches (30 cm) 12 inches (30 cm) b= clearance to window or door that may be opened 6 inches (1...

Page 25

Hse installation and service manual 25 figure 14 air supply and flue openings 1.7.5 direct vent configurations warning failure to ensure that tubes are connected, seated or sealed properly may result in leakage and eventual failure of the sealing gasket. Five venting configurations are available for...

Page 26

Hse installation and service manual 26 1.7.6 equivalent vent/air intake tube length and diameters the resistance of the combustion air supply and the flue gas tubes depends on the length, the diameter, components used and venting configuration of the venting system. For the appliance to operate norm...

Page 27

Hse installation and service manual 27 l5=2 ft [0 .5m] l2=2 ft [0 .5m] l 4 =2 0 f t [6 m] l 3 =2 2 f t [7 .5 m] l 1 = 3 f t [1 m] l 6 =5 f t [1 .5 m] figure 15: sample of venting length estimate figure 16 sample of side termination installation 1.7.9 vent installations the following installation pro...

Page 28

Hse installation and service manual 28 supply piping. Therefore, venting lengths must be within the specified minimum and maximum equivalent venting system length in table 3. 8. Slide the adapters (if required) or air supply and flue tubes into the combustion air intake and flue outlet of the applia...

Page 29

Hse installation and service manual 29 figure 19 side venting 1.7.9.2 horizontal twin tube side venting with twin terminal caps figure 19 is a typical installation for a side venting installation using two 45˚ elbows as twin terminal caps and adapters (if required) for air inlet and flue outlet on t...

Page 30

Hse installation and service manual 30 1.7.9.5 concentric connections with a combined terminal cap caution: in canada, follow can/csa b149.1 (current edition) and/or local code requirements for use of plastic venting plastic vents shall be installed such that the first 3 feet (92 cm), or total vent ...

Page 31

Hse installation and service manual 31 figure 25 horizontal twin pipe to concentric figure 27 vertical concentric venting figure 26 vertical twin pipe to concentric venting concentric pipe adapter figure 24 horizontal concentric venting Ø4.7” [120mm] (see note) Ø4.3” [110mm] 2.0” [50mm] max. 27.6” [...

Page 32

Hse installation and service manual 32 controller section 2 2.1 controller operation the appliance uses a microprocessor based controller to manage all functions including ignition and flame supervision, continuously modulating/monitoring each heat demand from the heating system or from the domestic...

Page 33

Hse installation and service manual 33 figure 28 operating and display panel table 5 operating and display panel display operating controls 1. Power on/off led 2. Ch led 3. Dhw led 4. Temperature display 5. Fahrenheit led 6. Celsius led 7. Dhw eco mode led 8. Dhw comfort function led 9. Service disp...

Page 34

Hse installation and service manual 34 1 set temperature reached the burner controller can temporarily block the heat demand and stop the burner. This blocking takes place because the required temperature has been reached. When the temperature has dropped sufficiently, the blocking is cancelled. 2 s...

Page 35

Hse installation and service manual 35 2.2 pc interface the controller has an interface for a pc. With a special cable and accompanying software, a pc can be connected. This provision makes it possible to follow the behaviour of the controller, the appliance and the heating system during a long peri...

Page 36

Hse installation and service manual 36 2.4 setting and adjustment the functioning of the appliance is mainly determined by the parameter settings in the controller. User parameters can be set directly through the operating panel without entering the service code, while the installer parameters only ...

Page 37

Hse installation and service manual 37 d. Temperature selection (°f/°c) the temperature selection on the display can be toggled between fahrenheit and celsius as follows: • fahrenheit, °f: press the ˚f/˚c button. The fahrenheit °f led will turn on and the celsius °c led will turn off. • celsius, °c:...

Page 38

Hse installation and service manual 38 2.4.3 setting and description of parameters the factory default settings and setting ranges for all parameters are shown in table 8. The ch operating input rating can be changed by adjusting the ch input rating % and/or blower speed following the sections 2.4.2...

Page 39

Hse installation and service manual 39 figure 29 pump stage adjustment 2.4.4 setting ch & dhw operating input rating ch or dhw operating input rating is determined based on the ch or dhw input rating % (parameter 3 & 4), blower speed (parameter h) and maximum input rating. Table 9 ch or dhw operatin...

Page 40

Hse installation and service manual 40 t supply t outside t max. T min. A b 10 20 30 40 50 60 70 80 90 0 y x -30 -20 -10 0 10 20 30 °c 50 68 86 104 122 140 158 176 194 32 °f °c -22 -4 14 32 50 68 86 °f a curve: factory default setting b curve: an example of user setting x axis – outdoor temperature ...

Page 41

Hse installation and service manual 41 figure 32 manual air vent startup instructions section 3 warning if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Warning connect the appliance to the mains voltage only af...

Page 42

Hse installation and service manual 42 figure 33 condensate trap 5. Operate circulating pump and vent the system at the highest points of the piping system. Fill the ch system again if the pressure has dropped too low as a result of the de-aerating. 3.2.2 dhw system 1. The dhw system can be connecte...

Page 43

Hse installation and service manual 43 3.3.1 lighting instructions warning should appliance overheat, or the gas supply fail to shut off, do not turn off or disconnect the electrical supply to the circulating pump. Instead, shut off the gas supply at a location external to the appliance. For your sa...

Page 44

Hse installation and service manual 44 3.3.2 startup instructions in the event of failure of any component, either the system will not operate or it will go into safety lockout. After placing the appliance in operation, the ignition system safety shutoff device must be tested. The method of testing ...

Page 45

Hse installation and service manual 45 5) after flame is established, the controller will modulate the firing rate depending upon the sensed difference between the supply and return water temperatures and the set point of supply temperature. If an outdoor temperature sensor is connected to the appli...

Page 46

Hse installation and service manual 46 3.5 conversion to propane warning this conversion should only be carried out by a qualified heating installer or service technician. When the appliance is connected to a type of gas other than the type specified on the rating plate, the gas orifice ring must be...

Page 47

Hse installation and service manual 47 figure 35 gas valve table 11 appliance setting values gas type natural gas propane co 2 % at low fire setting (l) ( and ) with front cover off see notes below see notes below co 2 % at high fire setting (h) ( and ) with front cover off 9.4 ± 0.5 10.3 ±0.5 gas i...

Page 48

Hse installation and service manual 48 7. Set the appliance to the maximum input rating by simultaneously pressing the service and buttons (twice) on the operating display panel of the controller until an h appears on the service display of the controller display panel. (see section 2.3.1) 8. Measur...

Page 49

Hse installation and service manual 49 use at altitudes above 2000 feet (609 m) in u.S.A. In usa, for appliance installations at altitudes above 2000 feet (609 m) above sea level, the input rating of the appliance should be reduced at the rate of 4 percent for each 1,000 feet (305 m) above sea level...

Page 50

Hse installation and service manual 50 3.12 installer's checklist reference section the information printed on the appliance rating plate matches the application (i.E. Altitude, input and fuel type). 3.7, 3.8 all applicable electrical codes have been met. 1.2, 1.6 gas piping has been purged and chec...

Page 51

Hse installation and service manual 51 service & maintenance instructions section 4 4.1 service & maintenance instructions warning electrical shock hazard – before servicing the appliance, disconnect the appliance and heating system from the power supply by switching off the emergency power off butt...

Page 52

Hse installation and service manual 52 4.2.2 inspect the condensation trap and discharge tube 1. Follow the maintenance schedule required by the neutralizer supplier. 2. Shut off the appliance and remove the condensate discharge tube from the outlet of condensation trap. Unscrew the slip ring nut fr...

Page 53

Hse installation and service manual 53 4.2.7 service the heat exchanger if necessary 1. Shutdown the appliance as described in the lighting instructions in section 3.3.1. 2. Remove the front cover of the appliance. 3. Wait until the appliance and the burner have cooled down. 4. Remove the wire conne...

Page 54

Hse installation and service manual 54 4.2.9 completion of inspection and service 1. Replace the front cover. 2. Put the appliance into operation at the maximum input, and check the gasket joint of the appliance case, including the gasket joints connecting air intake and flue tubes to appliance case...

Page 55

Hse installation and service manual 55 4.3 service checklist reference section do not store anything against the appliance or allow dirt or debris to accumulate in the area immediately surrounding the appliance. The flow of air supply and exhaust must not be obstructed. 4.2.1 check air openings are ...

Page 56

Hse installation and service manual 56 4.4 caution: water replenishment avoid unnecessary replenishment of water in the ch system. It can allow oxygen to enter the system and cause serious corrosion problems for system components which are not anti-corrosion type. As well, an excessive amount of min...

Page 57

Hse installation and service manual 57 replacement parts section 5 note: to supply the correct part it is important that you state the appliance model, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with retu...

Page 58

Hse installation and service manual 58 troubleshooting guide section 6 6.1 possible problems and solutions when the service display or the operating panel is flashing, the burner controller has detected a fault. If multiple faults exist, the temperature display shows an additional code (refer to tab...

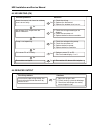

Page 59

Hse installation and service manual 59 6.2 burner fails to ignite 1. Open the manual gas shutoff valve. 1. Contact the gas company. 1. Clean heat exchanger/venting system 1. Check the cabling. 2. Check the spark probe 3. Replace the ignition unit. 1. Make the adjustment, see section 3.6. 1. Replace ...

Page 60

Hse installation and service manual 60 6.3 burner ignites with noise drawing for spark probe gap 6.4 burner resonates 1. The gas regulator may be faulty. Contact the gas company. Gas inlet pressure too high. 1. Make the adjustment. See section 3.6 . 1. Replace the spark probe. 2. Replace the ignitio...

Page 61

Hse installation and service manual 61 6.5 no heating (ch) 6.6 reduced output 1. Check the wiring. 2. Replace the thermostat. 3. Replace the outdoor reset sensor. Room thermostat not closed or outdoor reset sensor faulty. 1. Check the voltage to the pump. 2. Check the connector x4. 3. Replace defect...

Page 62

Hse installation and service manual 62 6.7 ch supply water does not reach correct temperature 6.8 no domestic hot water (dhw) 1. Check the setting and adjust if necessary. Room thermostat settings not correct. 1. Correct the pump setting or replace the pump. 1. Check for water circulation: at least ...

Page 63

Hse installation and service manual 63 6.9 domestic hot water does not reach correct temperature 6.10 ntc temperature sensors data table 13 ntc resistances ntc 12 kohm t, °c (°f) r, ohm t, °c (°f) r, ohm t, °c (°f) r, ohm -15 (5) 76020 25 (77) 12000 65 (149) 2752 -10 (14) 58880 30 (86) 9805 70 (158)...

Page 64

Hse installation and service manual 64 notes.