- DL manuals

- JAC

- Trucks

- HFC1061

- Owner's Manual

JAC HFC1061 Owner's Manual

Thank you for choosing JAC. We are pleased to welcome you to the growing number of discriminating people who drive

JAC truck. The advanced engineering and high-quality construction of each JAC we build is something of which we are

proud.

This Owner's Manual will introduce you to the features and operation of your new vehicle. If is suggested that you read it

carefully since the information it contains can contribute greatly to the satisfaction you receive from your new vehicle.

The manufacturer also recommends that all service and maintenance on your vehicle be performed by an authorized

JAC dealer. JAC dealers are prepared to provide high-quality service, maintenance and any other assistance that may

be required.

ANHUI JIANGHUAI AUTOMOBILE CO., LTD.

May. 2008

FOREWORD

Summary of HFC1061

Page 1

Thank you for choosing jac. We are pleased to welcome you to the growing number of discriminating people who drive jac truck. The advanced engineering and high-quality construction of each jac we build is something of which we are proud. This owner's manual will introduce you to the features and ope...

Page 2

All information in this owner's manual is current at the time of publication. However jac reserves the right to make changes at any time so that our police of continual product improvement may be carried out. This manual applies to all current jac models and includes description and explanation of o...

Page 3

1 vehicle using.

Page 4

Use of instruments and ap鄄 paratus in the cab integrated switch and instru鄄 ment cluster integrated switch (figure below), which is composed of steering shaft lock seat尧ignition start lock and combination switch lies underneath the steering wheel. Ignition switch ignition switch is on the right side...

Page 5

Ment panel can be spouted to the windshield glass through the spout under the window. 荫 is the indication of wiper. Turning the control handle clockwise in horizontal direction can control the wiper. Turn the control handle clock鄄 wise by 12o to the 'lo' position, the wiper works at a low speed. Kee...

Page 6

Instrument cluster new pattern of instrument cluster (air brake) indicator lamp water temper鄄 ature gauge fuel gauge air pressure gauge mileometer speedometer tripmeter old pattern of instrument cluster (air brake) mileometer speedometer fuel gauge indicator lamp button for returning to zero water t...

Page 7

Indicators : 1. Turning indication light ( ) when the turning control handle is on the left (right) turning position, left (right) turning indicator light will flash. If the warning switch is pressed, the left and right turning indication light will flash at the same time. 2. High beam indication li...

Page 8

Choosing different air speed and direction of air sending. Operation 1. Start the engine. 2. Press switch 4 of the air condi - tioner to start air sender. The switch has four grades from left to right to make the air speed more and more quick as well as making air stronger and stronger. 3. Operate a...

Page 9

Rotate it to lock the door. 2. The door can be locked outside without the key. First press the lock button on the inner side of the doors to the fixed position, then pull the outside door handle outwards and close the door at the same time. 3. Pull out the inside door handle to open the door. 4. Pre...

Page 10

The locking function of lock arm on the rear bracket, then lower the cab down slowly. After the safety lock be locked, fasten the locking mech - anism. Inspection and maintenance 1. Check periodically the rubber pad assemblies which are used to strengthen the front尧rear support, if found damaged, it...

Page 11

Violently is forbidden. 2. Start in winter when it is very cold, referring to the following measures to start engine. 荫 use hot water to take the place of cooling water, turn on the drainage switch when heating the water. When the hot water flow out and the engine body become warm, close the drainag...

Page 12

18 engine. When running, do not increase or decrease the vehicle speed abruptly and do not shake the steering wheel without reason, listen whether there is abnormal noise or not, check the reading and indicator lamp of all the instruments for normalization. If finding abnormal noise or abnormal even...

Page 13

20 back -up light lights. The vehicle speed must be less than 5 km/h when backing. If the driver cannot discern the situation behind the vehicle because the vehicle is loading or because of other reasons, the backing operation must be commanded by one person who is not in the vehicle. Do not back th...

Page 14

Air inlet and air exhaust systems inlet system includes air inlet pipe assembly尧 air filter 尧branch pipe of air inlet. Air exhaust system includes exhaust pipe尧 muffler and exhaust tailpipe etc. Using and maintenance 1. Service life of engine has the clos鄄 est relationship with the working condition...

Page 15

24 the liquid level in the radiator, if the liquid is found insufficient, it should be added to specified level. 3. Drainage of cooling system. In cold region and in winter, for long - time parking or finishing using the vehicle everyday without using anti- freezing preservative liquid, the cool鄄 in...

Page 16

26 3 manual throttle drawing wire: using with the foot throttle can quick鄄 en the preheating of the engine or in鄄 crease the idling speed. Using and adjustment 1. Check the chucking position of the linkage rod and the accelerator mechanism for rightness and reliabil鄄 ity, check the direction of the ...

Page 17

Chassis 29.

Page 18

Clutch brief description of the structure: the clutch equipped for this series truck is single -plate dry type di鄄 aphragm spring clutch. Clutch facing is composed of two friction discs and clutch facing riveted with rivet. Clutch pressure plate presses friction discs on pillar by using pressure pro...

Page 19

Transmission transmissions equipped for the chassis of this series of truck are lc5t97, lc5t30, lc6t46. Among these, lc5t97 and lc5t30 are man鄄 ual fixed axle with stages. There are five forward gears and one back gear. The second, third, fourth and fifth gear has synchronizer that is synchromesh. T...

Page 20

When the engine works at an over fast speed to avoid accelerating the wear of the synchronizer. 5. When shifting, the force should be gentle. The hand force must be act鄄 ed on the control rod until the gear reaches the correct position. Shifting with flap of push and loosening is in鄄 appropriate and...

Page 21

Knock and stack when doing disas鄄 sembly and assembly work or carry鄄 ing. Replace for a new one if the shaft is distorted or the balancer is desquamated, otherwise, there will be vibration, noise, and extra impact in running, which can damage other assemblies and even endangered running. 2. Check oi...

Page 22

0.30mm,0.40mm, 0.45 and 0.5mm. Normally, the clearance between these two gears is 0.15 -0.25mm, while the side play ranges under 0.07mm. To adjust side play, mea鄄 sure four points with equal angle around the driven gear, and the gauge outfit of micrometer should be in a vertical position. To adjust ...

Page 23

1. Front bumper bracket assembly 2. The first cross beam 3. The first cross beam reinforced plate 4. The second cross beam as鄄 sembly 5. Front spring fixed support as鄄 sembly 6. Side member 7. Engine front support assembly 8. Front steel spring limit stop 9. Engine front support outer sup鄄 port 10. ...

Page 24

1. Frame 2. Rear leaf spring 3. Rear center bolt 4. Rear absorber 5. Secondary spring bracket 6. Rear shackle clamp using and maintenance of leaf spring 1. When vehicle runs for 200km and 500km during the beginning of break -in period, check and tighten u-type bolt on leaf spring with spec鄄 ified to...

Page 25

Front axle brief description of structure: front axle assembly is composed of front axle, steering knuckle, left &right steering knuckle arms, king pin, front brake and tie rod etc. Adjustment of front axle: 1. Adjusting of the front wheel hub bearing: to adjust front hub bearing in axial retighteni...

Page 26

1. Steering gear fuel inlet nipple 2. Steering gear fuel outlet nipple 3. Power-steering fuel return flexible pipe 4. Power-steering flexible pipe assembly 5. Power-steering oil container assembly 6. Power-steering oil container supporter 7. Oil pump outlet bolt 8. Oil pump inlet nipple 9. Oil pump ...

Page 27

Check and maintenance: 1. Replace steering gear oil in time and clean &replace filtering screen in oil tank when a new truck runs for 3000 -4000km and runs every 5000 km afterwards. 2. Check oil volume and oil quality in oil cylinder often, adding or replacing if oil goes bad. 3. Pay attention to th...

Page 28

Rod, clean and check each component to make sure there is no crack on the body of cross and straight pull rod as well as making sure screw thread on two ends not worn and limit wearing scope to 2mm for cotter pin hole of cross and straight pull rod , 0.5mm for spheri cal surface. Also make sure spri...

Page 29

Brake pipeline is arranged as fol鄄 lows: compressed air produced by air compressor 1 comes into the main air reservoir 3 (namely wet air reservoir); and then the air is separat鄄 ed into two and come into the front chamber 9 of the auxiliary air reser鄄 voir and the rear chamber 4 of the main air rese...

Page 30

54 adjusting arm 1冤lubrication: mount oil month on adjusting arm, use lithium base grease periodically to lubricate ad鄄 justing arm (maximum lubrication in鄄 terval is limited to 10000km), or else, life of adjusting arm will decrease. 2冤check adjusting arm's counter鄄 clockwise force moment periodical...

Page 31

Periodical inspection 1. Class -one inspection (1500 - 2000km) 荫 exclude oil water in air-reservoir 荫 fill lubrication into position that needs lubrication. 荫 check and adjust loosening and tightening degree of air compressor. 2. Class -two inspection (10000 - 12000km) 荫 disassemble and adjust brake...

Page 32

Fluid away. 因 fill system with brake fluid. 因 brake pedal's free play should be 5 - 8mm after adjusted, or it will cause main booster work abnormally and make brake drum over hot. 3. Running brake system 荫 brief description of this system: the running brake is hydraulic drum, both front and tear are...

Page 33

Adjustment clearance between parking brake drum and friction disc is 0.65mm, and the upper clearance is as same as the lower clearance. Because of friction disc wearing, this clearance must be adjusted in time. The steps of adjusting are shown as follows: 1. Jack up the rear axle to make one wheel o...

Page 34

Maintenance of spare wheel regulator check whether the spare tire is loose and whether chain and wheel brack鄄 et spring rupture before everyday us鄄 ing; if there is anything wrong, re鄄 place it immediately. Lubrication should be applied to the driving parts of the riser in case of rust and for conve...

Page 35

64 1. Chassis cable harness assembly 2. Start/choke controller 3. Electric horn device 4. Generator 5. Water temperature sensor 6. Oil pressure sensor 7. Engine earth cable 8. Backgear earth cable 9. Starter 10. Fuel gauge sensor 11. Low air pressure alarm device 12. Battery general: schematic diagr...

Page 36

66 re-assembly headlight is necessary. Methods for it: park vehicle on flat road, put vision screen that paral鄄 leled flat surface of headlight on place straight ahead ( also using flat wall) to keep distance of 10m be鄄 tween vision screen and flat surface of headlight.( figure below) adjust and tes...

Page 37

Tional charging should be done once every month. Local temperature specific gravity of fully charged battery under 15益 where temp -40益 above in winter 1.290 1援260 where temp -30益 above in winter 1援280 1援250 where temp -20益 above in winter 1援270 1援240 where temp 0益 below in winter 1援270 1援240 winter ...

Page 38

Vehicle maintenance 71.

Page 39

Notice during breaking -in period to improve vehicle's reliability and economical efficiency and also to use it longer, follow these during breaking -in period which is speci鄄 fied as 2000-2500km. Before breaking-in 1. Clean vehicle with water, and check all bolts and nuts for tighten. 2. Check the ...

Page 40

Second-class maintenance after break -in period and finish maintenance during break-in period by force. Do daily maintenance and periodic maintenance according to running condition and technical con鄄 dition. Traveled distance of second- class maintenance is 1500km when running on road of good condit...

Page 41

Being used, the vehicle will often be broken along with it travels longer and longer. In order to recover vehi鄄 cle to normal situation and to prolong its service life, the trouble must been found out and been disposed in an effective way. To shoot troubles of engine, refer to engine operating instr...

Page 42

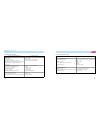

78 2. Clutch trouble shooting trouble symptom and probable cause checking and remedy 3. Clutch can't release completely a援 too long free play of pedal b援 crack or distort of wave sheetc援broken damper spring a援 adjust 3-5mm b援 replace c援replace 1. Shaking clutch a援overloading b援not start in low gear ...

Page 43

Trouble symptom and probable cause checking and remedy 1. Gears break off a. Gears break off b. Worn or damaged coupling c. Improperly adjusted linkage d. Distorted, worn, or crack spring or locking ball e. Worn shift fork and groove face f. Worn synchronizer hub and sleeve g. Worn or damaged synchr...

Page 44

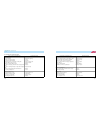

Trouble symptom and probable cause checking and remedy 1. Hard to steering , steering wheel doesn't return well a. Insufficient lubrication of steering linkage mechanism b. Improper alignment of front wheel c. Improper toe in front of the wheel d. Improper camber and caster of king pin e. Worn thrus...

Page 45

Trouble symptom and probable cause checking and remedy 3. Hot rear axle a. Oil leak because of damaged seal gasket, loosening oil drain plug, and jammed vent hole, result in insufficient lubrication b. Bad lubrication c. Over-tighten between pinion and driven gear, over- tighten on bearing a. Fill u...

Page 46

Trouble symptom and probable cause checking and remedy 3. Wander front wheel a. One of the front brake or damper is disabled b. One of the front tire low pressure c. Disalign or break of front leaf spring d. Damaged grinding wheel e. Improper toe in front of the wheel 4. Power steering bump leaking ...

Page 47

88 trouble symptom and probable cause checking and remedy a援 big clearance between parking brake and brake drum b援 oily dirt on brake drum and shoe c援 over wearing of friction disc a援 adjust it to 0.65mm b. Clean c. Replace 9. Parking brake trouble shooting owner爷s manual for hfc1061,hfc1063,hfc1083...

Page 48

90 trouble symptom and probable cause checking and remedy 1. Badly worn wheel a. High or low tire pressure b. Overloading or dissymmetrical loading c. Loosening hub bearing d. Improper toe-in of front wheel e. Emergency brake, start or stop and frequent sudden acceleration f. No wheel transposition ...

Page 49

Location of product emblem and vin code 1. Location of product emblem: in a position that is exterior side of the rear side of the right longitudinal member on the frame. As shown in the following diagram; please find the location on vehicle. Product emblem independent small emblem 2. Location of vi...

Page 50

No. Number of steel plate spring (front/rear) 1 9/12 vehicle model hfc1061ks engine model yz4105qf engine displacment and power (ml/kw) 4087/75 outside dimension (length伊width伊height) 渊mm冤 6810伊2010伊2300 axle distance (mm) 3815 2 9/12 hfc1061kr1s yz4105qf 4087/75 6810伊2010伊2300 3815 3 hfc1061k1s cy4...

Page 51

96 no. Number of steel plate spring (front/rear) 7 9/12 vehicle model hfc1061k1 engine model cy4105q cy4102bzq engine displacment and power (ml/kw) 4087/74 3856/81 outside dimension (length伊width伊height) 渊mm冤 6810伊2010伊2300 axle distance (mm) 3815 8 9/12 hfc1061k1r1 cy4105q cy4102bzq 4087/74 3856/81...

Page 52

98 no. Number of steel plate spring (front/rear) vehicle model engine model engine displacment and power (ml/kw) outside dimension (length伊width伊height) 渊mm冤 axle distance (mm) 15 9/12 hfc1061k9 cyqd32tic 3153/101.5 6810伊1995伊2250 3815 13 9/12 hfc1061k8 cy4102bzlq 3856/88 6810伊1995伊2250 3815 14 hfc1...

Page 53

No. Number of steel plate spring (front/rear) 18 9/12 vehicle model hfc1063kr1 engine model yz4105qf cy4105q engine displacment and power (ml/kw) 4087/75 4087/74 outside dimension (length伊width伊height) 渊mm冤 6990伊2130伊2315 axle distance (mm) 4150 19 9/12 hfc1063k1 yz4108q 4324/81 6990伊2130伊2315 4150 ...

Page 54

102 no. Number of steel plate spring (front/rear) 24 9/12 vehicle model hfc1063k4r1 engine model cy4102bzlq engine displacment and power (ml/kw) 3856/88 outside dimension (length伊width伊height) 渊mm冤 6990伊2110伊2260 axle distance (mm) 4150 25 9/12 hfc1063k5 cy4102bzq 3856/88 6990伊2130伊2315 4150 26 hfc1...

Page 55

No. Position to lubricate lubricant code lubricating points/dosage 1 transmission shaft universal joint g 3 2 transmission shaft spline g 1 add replace 3 battery terminal g 2 add replace replace 4 transmission z 6l(for reference) add replace replace 5 clutch master cylinder oil cup y 0.5l replace on...

Page 56

Appendix 3: oil type in lubrication symbol in the table illustration b l-bcd4 diesel engine oil gb11123渊summer冤袁lecd30 diesel engine oil gb11123渊winter冤 j 15w/20 or 15w/40 thickened oil g gb49 2# calcium base grease zl gb5671 lithium base grease q half of hu-20# gasoline engine oil渊gb2537冤and half o...