- DL manuals

- Jack

- Wood stove

- BIG BJ90

- Owner's manual

Jack BIG BJ90 Owner's manual

OWNER’S

MANUAL

ASSEMBLY

INSTALLATION

OPERATION

REPAIR PARTS

MODEL NUMBERS

BJ90 AND SJ125

CANADIAN MODELS

BJ90-C AND SJ125-C

CAUTION:

Read Rules and Instructions

Carefully for Safe Operation

IMPORTANT:

Installation must be made in

accordance with State and

Local Ordinances which may

differ from this Installation

Manual.

SUPER JACK

MODEL SJ125

BIG JACK

MODEL BJ90

SUPER JACK & BIG JACK

WOOD and COAL FIRED

WARM AIR CENTRAL

SUPPLEMENTARY FURNACES

ALPHA AMERICAN CO., 10 INDUSTRIAL BLVD., PALISADE, MN 56469

www.yukon-eagle.com

All furnaces in this owner’s manual

are UL Listed under UL FILE #11473

Summary of BIG BJ90

Page 1

Owner’s manual assembly installation operation repair parts model numbers bj90 and sj125 canadian models bj90-c and sj125-c caution: read rules and instructions carefully for safe operation important: installation must be made in accordance with state and local ordinances which may differ from this ...

Page 2: D A N G E R

D a n g e r risk of fire or explosion do not burn garbage, gasoline, drain oil, kerosene, thinners, etc. Warning risk of fire tightly close the firing door and ash door during operation. Do not operate with flue draft exceeding .03" w.C. Do not store flammable materials within marked installation cl...

Page 3: Contents

Contents introduction safety statements..............................................................................................................2, 4-5 epa regulations…………............................................…......................................................6-7 safety statement/insta...

Page 4: Safety Statements

Stop for safety! Safe assembly, operating and maintenance practices should always be followed whenever using any equipment. Wherever you see the caution sign, extra safety precautions should be taken. You must stop, read, and carefully follow the safety instructions before proceeding. Read through t...

Page 5: Caution

Caution inspect flue pipes, flue pipe joints, and flue pipe seals regularly to ensure that smoke and flue gases are not drawn into, and circulated by, the air circulation system. Add-on to gas furnace installations installation shall comply with can/csa-b365 and if changes are made to the central fu...

Page 6

This manual describes the installation and operation of the models sj125 super jack and bj90 big jack wood or coal burning furnaces. These furnace models meet the 2015 u.S. Environmental protection agency’s (epa) requirements for central forced air furnaces sold after may 15, 2015. Under specific te...

Page 7

This furnace is designed to burn natural wood and coal only. Higher efficiencies and lower emissions generally result when burning air dried seasoned hardwoods, as compared to softwoods or to green or freshly cut hard- woods. Do not burn: (1) garbage; (2) lawn clippings or yard waste (3) material co...

Page 8: Safety Statements

To the installer it is necessary to ensure that there is sufficient air flow through each furnace after the add- on installation has been completed. It is suggested that the temperature rise method be used since most installers are likely to have the necessary equipment. The temperature measurements...

Page 9

Inspect shipment note any damage to the shipping cartons. Remove all items from your shipping cartons. Check all items against the packing list below. Note any items lost or damaged in shipment. Refer to the exploded view and parts list in the back of the manual for the part names and numbers of mis...

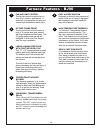

Page 10: Furnace Features - Sj125

1 fan and limit control the fan limit control turns the fan on and off. It works off of temperature and also provides a high temperature safety limit. 2 3 4 5 6 7 8 9 secondary heat exchanger more heat exchanger surface means less heat up the chimney. Made of 10 gauge steel rectangular tubes, which ...

Page 11: Furnace Features - Sj125

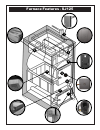

3 1 2 4 5 6 7 8 9 furnace features - sj125.

Page 12

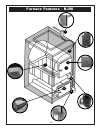

1 fan and limit control the fan limit control turns the fan on and off in furnace applications. It works off of temperature and also pro- vides a high temperature safety limit. 2 3 4 5 6 7 picture frame front the front and back of the furnace is built of 10 gauge steel and painted with high temperat...

Page 13

1 2 3 4 5 6 7 furnace features - bj90 13.

Page 14: Specifications

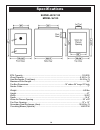

Btu capacity..............................................................................................................125,000 wood capacity........................................................................................................5.25 cu. Ft. Heat exchanger (total area)................

Page 15: Specifications

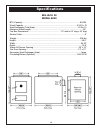

Big jack 90 model bj90 btu capacity................................................................................................ ...........90,000 wood capacity...................................................................................................5.25 cu. Ft heat exchanger (total area...

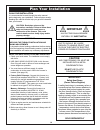

Page 16: Plan Your Installation

Plan your installation it is recommended to read through the entire manual before beginning your installation. Follow all steps exactly. Reading this manual will also help you get all the benefits from your furnace. Caution: read these rules and the instructions carefully. Failure to follow these ru...

Page 17: Plan Your Installation

Locating the furnace locate the furnace as close to the chimney or flue as possible. The furnace should be located no more than 10 feet away from the chimney. You will need 1” rise per linear foot of pipe as a minimum. The furnace should be located with respect to building construction and the place...

Page 18: Plan Your Installation

Typical installations • series add-on ‚ parallel add-on ƒ independent installation • ‚ ƒ ducts and plenums shall be constructed entirely of sheet metal. Important ! ! Plan your installation 18.

Page 19: Plan Your Installation

Proper chimneys the national fire protection association (nfpa) requires that all factory built chimneys be listed and installed in accordance with conditions of the listing in the manufacturers instructions. Nfpa also requires that your chimney extend at least three (3) feet above the highest point...

Page 20: Plan Your Installation

Furnace located in confined space when the furnace is in utility room, install two open grilles. Place them in a wall or door opening to the rest of the house. One grille will supply combustion air. Locate it near the floor. The other grille is for ventilation. Locate it close to the ceiling. Each g...

Page 21: Plan Your Installation

Combustion air make-up outside air must be provided to furnace for proper fuel combustion. This is provided by openings to outside of building. These openings shall have unobstructed areas not less than the areas of the flue pipe. Important: outside air is needed to replace air used by the burner an...

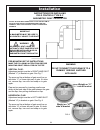

Page 22: Installation

Place furnace review all instructions in the planning your installation section. Place the furnace in the pre-selected location. Refer to page 17 in the plan your installation section. Make sure the furnace is level. Furnace casing the furnace casing is shipped unassembled in a carton attached to th...

Page 23: Installation

Canadian furnaces only all jack furnaces that are shipped to canada will include an insulated front panel casing and an insulated back panel casing. Big jack (bj90-c) front panel installation: slide front panel down to straddle over the firing door. Press top of panel in securely. Attach to furnace ...

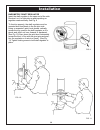

Page 24: Installation

Big jack super jack junction box mounting bracket junction box mounting bracket draft inducer motor draft inducer motor remove the three (3) self tapping screws off the front of the furnace. (set aside) line up the gasket to the mounting flange of the draft inducer and using the 3 screws, tighten on...

Page 25: Installation

Installing the honeywell fan and limit control included in the accessory carton is a white sheet metal bracket that is 8-1/4 inches high and 3-1/4 inches wide. It has a 7/8” hole in it 6 inches from the bottom. Right below the 7/8” hole are 2 screw holes. This bracket also has 2 screw mounting holes...

Page 26: Installation

Honeywell digital thermostat mounting the thermostat the thermostat must be mounted on an interior centrally located wall. Place it away from direct sunlight, drafts, and approximately 5 feet above the floor. It is not required that they be level. Place them right next to each other. See fig. 6. A h...

Page 27: Installation

Electric wiring all electrical wiring must be done in accordance with the national electrical code. The code needs to be legally authorized in the area where the installation is being made. The circuit protector device must be located in a convenient place near the furnace. No lighter than 14 awg wi...

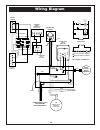

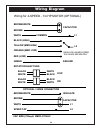

Page 28: Wiring Diagram

Rc r y c w g r c w g y f l jumper r r w g c y indicates trans-relay terminals indicates thermostat terminals air circulating blower (optional) transformer relay front view transformer relay back view honeywell digital thermostat (jack furnace) fan and limit control combustion blower add-on furnace b...

Page 29: Wiring Diagram

Brown/white brown white black (high) yellow (med high) orange (med low) red (low) green rotation-shaft end cap common l1 l2 ground insulate unused speed tap leads separately black white black white white black black white ccw cw optional 3 wire connection brown/white brown white speed tap l1 l2 cap ...

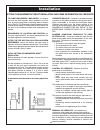

Page 30: Installation

Warning check your chimney. The chimney is a very important part of your heating system. It must be the right size, properly constructed and in good condition. No furnace can function properly with a bad chimney. The chimney must supply a draft of .03 water column. If possible, use a 15 foot or high...

Page 31: Installation

Instructions for installing field controls type r-c barometric draft regulator do not attach draft regulator to top or bottom of the flue pipe, nor in a room separated from the furnace. Best location is as close to furnace as possible. Pre-mounting set up instructions make the following alterations ...

Page 32: Installation

Barometric draft regulator insert the draft regulator in the open end of the stub. Revolve it so it is right-side-up and imprinting on regulator reads normally. See fig. 9 to function properly, the draft regulator must be mounted level and plumb in the tee joint stub. Using a carpenter’s spirit leve...

Page 33: Installation

To function properly and safely, it is impera- tive that the draft regulator when installed in the tee stub, is pointing away from surrounding walls or obstruc- tions. (see fig. 12) placement of draft regulator pointing toward nearby wall(s) or obstruction(s) could result in a hot spot on the expose...

Page 34: Installation

Importance of draft draft is the force which moves air from the appliance up through the chimney. The amount of draft in in your chimney depends on the length of the chimney, local geography, nearby obstructions and other factors. Too much draft may cause excessive temperatures in the appliance and ...

Page 35: Operating Instructions

Species pound weight per cord btu’s per cord air dried wood equivalent value #2 fuel oil gallons hickory 4,327 27,700,000 198 apple 4,100 26,500,000 189 white oak 4,012 25,700,000 184 beech 3,757 24,000,000 171 red oak 3,757 24,000,000 171 sugar maple 3,757 24,000,000 171 yellow birch 3,689 23,600,0...

Page 36: Operating Instructions

Helpful hints set the draft to proper setting. The chimney, hook-ups, and kinds of wood will be a factor. Open the disc on the side of the draft inducer motor (sup- plied with your jack furnace) to allow air into the furnace for combustion. (for coal) while lighting the coal fire, open disc all the ...

Page 37: Operating Instructions

Best burn practices a properly installed, correctly used wood-burning appli- ance should be smoke free. If you see or smell smoke that means you may have a problem. Practice the fol- lowing guidelines to burn wise in your appliance and reduce smoke inside and outside your home. Practical tips for bu...

Page 38: Operating Instructions

Starting a wood fire 1. Place several pieces of crumpled paper in the center of your firebox. In a criss-cross pattern, place a couple hand- fuls of dry kindling wood 3/4” thickness, then several small dry pieces of firewood. Never use chemicals or fluids such as gasoline, charcoal lighter fluid, dr...

Page 39: Operating Instructions

Questions? Visit www.Yukon-eagle.Com or call 1-800-358-0060 operating instructions for burning coal on 1/2-inch opening grates (optional) the following instructions are for burning various types of coal, storage of coal, and the cleaning of the furnace. Some coal is oil-treated at the mine. Some use...

Page 40: Operating Instructions

What size coal should i burn? The air space between the furnace grates is 1/2 inch. Therefore, coal smaller than 1/2 inch can fall through the grates into the ash pan. • pea size coal ranges from 9/16 to 11/16 inch. • nut size coal ranges from 1-3/16 to 1-5/8 inches. • stove size coal ranges from 1-...

Page 41: Maintenance

Important: keep ash drawer empty. Primary air to the wood chamber travels under the grate. The grates will warp and eventually burn out if ashes are permitted to build up above them. Ash removal when burning wood, every morning when there is just a bed of hot embers, run your poker over top of grate...

Page 42: Maintenance

Maintain gasket material as part of the annual maintenance of your furnace it is important to inspect the gasket material (1” rope gasket) around the inside of the firing door and ash pan door to ensure proper sealing of the firebox. The gasket material keeps added air from getting into the firebox,...

Page 43: Maintenance

1. At the start of the heating season... Ÿ it is advisable to have your local furnace profes- sional inspect and service your furnace for the coming heating season. Ÿ the furnace, smoke pipe and chimney should be cleaned and checked for repairs. 2. Emergency stops Ÿ shut off all electrical power at ...

Page 44: Maintenance

Faulty chimney and/or draft problems - causes and cures a sound chimney system is imperative, especially when burning wood. Indoor chimney, either masonry or type “ht” metal chimneys are the best. Because warm air rises, a warm chimney allows the smoke and other by-products of combustion a natural e...

Page 45: Maintenance

Top of chimney lower than surrounding objects remedy: extend chimney above all objects within 30 feet chimney cap pushed over flue or flue obstructed by a ventilator remedy: remove obstruction accumulation of soot or debris in offset remedy: remove air leaks through cracks in flue and chimney disclo...

Page 46

Super jack - sj125 exploded views & parts lists 46.

Page 47

Key no. Part no. Description qty 1 309 jacket (top) 1 2 304 damper plate w/rod 1 3 303 damper control rod 1 4 307 jacket side (right) 1 5 302 clean out plate gasket 2 6 301 clean out plate 2 7 10090332 10090102 fire door assembly screws (4) - ash door screws (2) - draft inducer screws (3) 8 113 fire...

Page 48: Big Jack - Bj90

Big jack - bj90 exploded views & parts lists 48.

Page 49: Big Jack - Bj90

Key no. Part no. Description qty 1 205 jacket (top) 1 2 204 jacket side (right) 1 3 113 firebrick (9 x 4-½ x 1-¼) 19-1/2 4 119 smoke flap assembly 1 5 117 grate fillers 2 6 105 heavy duty cast iron grate 1 7 111 draft inducer gasket 1 8 110 draft inducer 1 9 115 fire door gasket 1 10 114 fire door &...

Page 50

Service hints & troubleshooting main blower vibrating when in use... Possible cause loose allen screw on squirrel cage defective motor or blower bearings weight on squirrel cage wheel moved in shipment main blower or blowers continue to run... Possible cause fan and limit control on unit is set too ...

Page 51

Possible cause the use of wet, frozen or unseasoned wood the use of soft wood, particularly those of high resin con- tent such as plywood or blandex with glue poor natural draft or an obstruction in the stove pipe or chimney flue smoldering fire inadequate amount of oxygen supplied to the combustion...

Page 52: Notes

Notes model number: __________________________________ serial number:__________ installation date:_______________________contractor_________________________ service calls:__________________________________________________________________ ______________________________________________________________...

Page 53: Notes

Notes.

Page 54: Notes

Notes notes.

Page 55: Notes

Notes.

Page 56: Owner’S

Owner’s manual assembly installation operation repair parts model numbers bj90 and sj125 canadian models bj90-c and sj125-c caution: read rules and instructions carefully for safe operation important: installation must be made in accordance with state and local ordinances which may differ from this ...