- DL manuals

- Jackson

- Dishwasher

- 100 B/PRB

- Service manual

Jackson 100 B/PRB Service manual

MODEL 100 B/PRB

HIGH TEMPERATURE DOOR

TYPE DISHWASHER

SERVICE MANUAL

INCLUDES:

-Warranty Policy -Basic Functions of Dishwasher

-Installation Requirements -Maintenance and Care

-Operating Instructions -Illustrated Parts List

-Description of Components -Electrical Diagrams

WORLD HEADQUARTERS & MANUFACTURING OPERATIONS

Highway 25E, P.O. Box 1060

Barbourville, KY 40906

888/800-JMSC

FAX 606/523-9196

March 12,1999 (Reprinted without change) 7610-100-02-00 Rev A

Summary of 100 B/PRB

Page 1

Model 100 b/prb high temperature door type dishwasher service manual includes: -warranty policy -basic functions of dishwasher -installation requirements -maintenance and care -operating instructions -illustrated parts list -description of components -electrical diagrams world headquarters & manufac...

Page 2: Index

Index specificiations 2 general instructions (installation/dimensions) 4 general instructions (operation) 6 general instructions (preventive maintenance) 7 removal of rinse and/or wash head assemblies 8 timer for model 100 dishwashers 10 defective timer motor 11 function of switches. Circuit breaker...

Page 3: Specifications

Specifications specifications 100 series item #_________ model 100 100b 100prb operating capacity racks per hour (nsf rated) 55 55 55 dishes per hour 1375 1375 1375 glasses per hour 1375 1375 1375 operating cycle wash time-sec 48 48 48 rinse time-sec 10 10 10 total cycle-sec 60 60 60 wash tank capac...

Page 4

Specifications 100 series, cont'd dimensions length 24" 24" 24" width 24" 24" 24" height 57" 57" 57" standard table height 34" 34" 34" maximum clearance for dishes 15" 15" 15" standard eq. Racks dish 19-3/4 x 19-3/4 2 2 2 combination 2 2 2 shipping weight approximate basic model 400 400 400 electric...

Page 5: General Instructions

General instructions (installation / dimensions) for 100b, prb series note: read the following instructions carefully. Proper installation of your jackson dishwasher will assure proper machine operation. 1. Open side doors, the front door (hook open) and remove dish, cup, and glass racks, and set to...

Page 7: General Instructions

General instructions (operation) 100b, prb read instructions carefully: proper operation of your jackson dishwasher will assure clean and sanitized glasses and dishes at optimum efficiency. Dish preparation 1. Scrape the dishes thoroughly. 2. Pre-rinse the dishes by soaking or by spraying off with a...

Page 8: General Instructions

General instructions (preventive maintenance) (the following is to be performed as needed.) read carefully: proper maintenance of your jackson dishwasher will insure optimum service with a minimum of down time. 1. To remove all lime and corrosion deposits. (as needed or at least weekly) a. Fill the ...

Page 9: Removal of Rinse And/or

Removal of rinse and/or wash head assemblies general instructions 1. Turn master switch to off position. 2. Open door and drain machine by lifting overflow strainer. 3. When empty, replace overflow strainer. 4. With wrench, remove pipe fitting holding lower rinse feed pipe to machine and remove feed...

Page 10

21. Replace rinse assembly and feed pipe. 22. Close all doors and refill dishwasher. 23. Run through several cycles and recheck wash arms for easy movement. Adjust if necessary. 24. If removal of upper wash or rinse assembly is necessary, then extra care must be taken to support assembly. It will dr...

Page 11

Timer for model 100 dishwashers general description the timer is a self-contained (frame-mounted) timer of the repeating cycle type. It is mounted on the control panel of jackson automatic dishwashing machines, to control the automatic functions of these machines. It consists of a clock motor which ...

Page 12: Defective Timer Motor

Defective timer motor a defective motor is indicated by the fact that the cams do not rotate or the machine does not perform the automatic operations or performs a specific part of the cycle continuously, but works okay on manual. Remember, the timer motor is controlled by the start switch and the h...

Page 13

Function of switches, circuit breaker and indicating lights circuit breaker p/n 0012000 rated 15 amps, controls power to control circuit only, i.E. Timer, relays. Solenoid valve, water-level control and motors. Circuit breaker does not cutoff power in control box at incoming terminal board and rinse...

Page 14: Panel

Replacement of switches in control panel there are five switches installed in the control box cover panel. These are the start, master, manual wash, rinse/fill and heater switches. Before working on machine, it is important that power be turned off at customer's circuit breaker to prevent the possib...

Page 15: Thermostat Adjustment

Thermostat adjustment the thermostat can be adjusted by turning screw # 1 (see picture) on the thermostat control box cover. (remember the present setting, in case the problems are elsewhere in the control circuit.) a cw rotation is used to obtain a lower temperature setting and a ccw rotation is us...

Page 16: Service Instructions

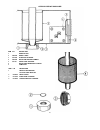

Service instructions (incoming water solenoid valve) solenoid valve to take the valve apart disassembly - these valves may be taken apart by unscrewing the bonnet and the enclosing tube assembly from the valve body assembly. See fig. 3. After unscrewing, carefully lift off the bonnet and enclosing t...

Page 17: Rinse Tank Heater System

Rinse tank heater system function the rinse tank heater system is electrically connected in the circuit so that it is dependent upon the dishwasher being properly filled with and maintaining a safe water level. The automatic fill system, therefore, should operate properly before the heat system can ...

Page 18

B. If heat relay closes: 1. Check power supply at incoming terminal board l1 and l2. It should be 220v, approximately. 2. Check power at positions 4 and 5, figure 1. Voltage should read approximately 220v; if not, check wires for breaks or bad connections. 3. Check power at positions 6 and 7. Voltag...

Page 19: Wash Tank Heater System

Wash tank heater system function the wash tank heater system is electrically connected in the circuit so that it is dependent upon the dishwasher being properly filled with and maintaining a safe water level. The automatic fill system, therefore, should operate properly before the heat system can be...

Page 20

Bb - - if heat relay does close: 1. Check power supply at terminal board #2 between terminals #5 and #7; it should be approximately 220v. 2. Check power at position 4; there should be no voltage. 3. Check position 5; voltage should be approximately 120v to ground. 4. Check power at position 6; volta...

Page 21: Replacing Seal and

Replacing seal and ceramic on wash pumps function the pump is part of the total motor-pump system and utilizes one shaft seal and ceramic to prevent the pump from leaking around the impeller and shaft. One gasket is used to prevent leakage between the pump mounting plate and the machine pump plate. ...

Page 22

Item p/n description 1 0102600 pump motor, 50 cycle 1 0102700 pump motor, 60 cycle 2 0106500 woodruff key 3 3691300 washer, rubber 4 0108000 snap ring 5 0105000 ceramic face w/ "o" ring 6 0104500 pump mounting plate 7 0105000 seal face 8 plate to motor mounting bolts & lockwashers 9 0105000 seal ass...

Page 23: Replacing Seal and

Replacing seal and ceramic on rinse pumps function the pump is part of the total motor-pump system and utilizes one seal and ceramic to prevent the pump from leaking around the impeller and shaft. One gasket is used to prevent leakage in between the pump mounting plate and the machine pump plate. Re...

Page 24

Item p/n description 1 0086100 pump motor, 50 cycle 1 0086000 pump motor, 60 cycle 2 0088000 pump mounting plate 3 0089000 pump ceramic face w/retainer cup 4 0087500 pump impeller seal 5 0089500 pump impeller 6 0090000 pump mounting gasket 7 0090500 pump plate to motor mounting bolts 8 0091000 mount...

Page 25: Of Cantilever

Instructions for adjusting tension of cantilever problem: doors raise hard, but lower easily. Solution: 1. Back off (loosen) upper adjusting nuts (f) on both eyebolts (e) about two or three complete turns. 2. Tighten lower adjusting nuts (g) on both eyebolts (e) a complete turn. 3. Check door for ea...

Page 27: Applying Nylatron Strip to

Applying nylatron strip to 100 series door p/n 0051800 instructions for installing new door guides its important when removing the old door guides that the surface be cleaned thoroughly. This can be done with a solvent that will dissolve the remaining glue and/or the use of a fine sandpaper to scrat...

Page 28: Water Level Control

Water level control (els) (for rinse tank) p/n 0205000 function the water level control device utilized on power rinse (prb) models only, automatically maintains the water level in the rinse tank. The rinse tank water level control is energized by the master switch. The control is designed to sense ...

Page 29: Water Level Control

Water level control (els) (initial fill and wash-heat circuit) p/n 0205000 function this control is activated when the master switch is turned on. The primary function is to automatically control the proper initial filling of the wash tank, then to activate the wash and rinse tank heat circuit it wi...

Page 30

4. Be sure wash tank is empty and master switch and heat switch are off. Carefully reapply power to machine. Begin by turning master switch on. With an insulated jumper wire, touch jumper between terminals c & h; relay in clear plastic cube should activate as wire is touched to terminals. Observe re...

Page 31: Trouble Shooting Guide

Trouble shooting guide problem cause solution 1- no voltage to dishwasher, nothing on machine a. Customer's fuse blown or a. Replace or reset. Operates. Circuit breaker tripped. 2- machine circuit breaker 2- turn on or reset. Tripped or turned off. 3- voltage to machine low or 3- contact your electr...

Page 32: Trouble Shooting Guide

Trouble shooting guide problem cause solution fills slowly and/or rinse is 1- low water pressure. 1- check water pressure by: weak. A. Turn heat and master switch off. B. Empty wash tub. C. Replace overflow strainer, close doors. D. Turn on master switch. E. As you push up fill switch, time the seco...

Page 33: Trouble Shooting Guide

Trouble shooting guide problem cause solution machine won't work on automatic. Wash and rinse work only on manual. 1- timer motor faulty. 1- pull control panel and observe timer operation. See instruction page for changing timer motor. 2- master or start switch faulty. 2- replace switch. 3- start sw...

Page 34: Trouble Shooting Guide

Trouble shooting guide problem cause solution wash motor does not 1-wash micro switch in timer 1- check timer, see instruc- operate on automatic. Faulty tion page on timer but rinses on automatic and washes on manual machine begins to 1- timer motor, micro switch 1- check timer, see instruc- wash wh...

Page 35: Trouble Shooting Guide

Trouble shooting guide problem wash pump leaks cause 1- impeller seal is worn (leaks around shaft) solution 1- remove and inspect pump and motor assembly, see instruction page on pump seals and ceramic replacement 2- pump assembly is not seated to base of machine (leaks around mounting plate). 2- re...

Page 36: Trouble Shooting Guide

Trouble shooting guide problem cause solution low rinse temperature 1- machine using more water 1- if this trouble occurs, it indication than normal by rinse running should be determined that throughout wash cycle, caused the rinse is running during by faulty rinse microswitch in the wash cycle by i...

Page 37: Trouble Shooting Guide

Trouble shooting guide problem cause solution rinse pump leaks. 1- impeller seal is worn. 1- see instruction page on prb models only. Ceramic replacement 2- impeller ceramic is worn or 2- same as 1. Scored. Indicator light(s) do 1- lights faulty or poor connec- 1- replace or correct not glow at any ...

Page 38

Front view item p/n description item p/n description 1 0068000 booster tank 10 0019900 control box & panel 2 0058000 wash tank heater 11 0169400 thermostat box 3 0151000 inside pump strainer 12 0012000 control circuit protection device 4 0152000 large overflow stainer 13 0101800 wash pump & motor, 5...

Page 39

Item p/n description item p/n description 1 0085100 rinse pump & motor (prb only), 50 cycle 11 0008700 cantilever spring rods 1 0085000 rinse pump & motor (prb only), 60 cycle 12 0011501 cantilever door coupler 2 customer's water connection 13 0007500 breather tube (prb only) 3 0019900 control box &...

Page 40

Right side view item p/n description item p/n description 1 customer's water connection 12 detergent dispenser fitting 2 0165500 customer's electrical connection 13 external vacuum breaker piping 3 0019900 control box & panel 14 0009000 cantilever spring 4 0012000 control circuit protection device 1...

Page 41

Item p/n description item p/n description 1 0006800 booster tank 10 6007900 cantilever arm 2 detergent sensor fitting 11 0011500 cantilever door coupler 3 0009000 cantilever spring 12 0136000 lower rinse head assembly 4 external vacuum breaker piping 13 0200000 lower wash head assembly 5 0008700 can...

Page 42

Bottom view item p/n description item p/n description 1 0083300 adjustable foot 7 0012000 control circuit protection device 2 0006800 booster tank 8 0153700 'y' strainer 3 detergent sensor fitting 9 0143000 solenoid valve 4 wash tank 10 0101800 wash pump & motor, 50 cycle 5 drain outlet 10 0102000 w...

Page 43

42 high level probe p/n 0084300 low level probe p/n 0084500 vacuum breaker p/n 0184301 item p/n description 1 bonnet 2 0184700 disk 3 0184700 gasket 4 0184700 poppet 5 body 1 probe boot 2 nuts 3 lockwasher 4 probe 5 tank coupling 1 nut, 6/32 s/s 2 washer rubber 3 porcelain, outer 4 insert, silastic ...

Page 44

Cutaway view of wash sump item p/n description 1 drain fitting 2 0005400 drain '0' ring 3 0152000 overflow strainer 4 0058000 wash tank heater element 5 015100 inside pump strainer 6 wash tank thermostat sheath 7 sump wall item p/n description 1 drain fitting welded to wash sump bottom 2 0054000 dra...

Page 45

Item p/n description 1 thermostat probe fitting 2 thermometer probe fitting 3 incoming water fitting 4 0060500 booster heater elements 5 0058800 heater element bus bars & 0058900 (3 phase connection) 44 item p/n description 1 0006800 booster tank (b model) (new style-not shown) 2 external vacuum bre...

Page 46

45 booster tank heater element p/n 0060500 wash tank heater element p/n 0058000

Page 47

Control box and control panel components item p/n description item p/n description 1 grounding lug 10 0157500 heater switch 2 0165500 customer's electric connection 11 0162500 start switch 3 0123000 heater relay (3 pole/3 phase) 12 0157500 master switch 0124000 (4 pole/1 phase) 13 0083500 automatic ...

Page 48

R1 & r2: contactors m sw: master switch on-off 1-els, control, high level fill, low level cut-off in wash tank & rinse tank, low voltage sensor, 24v. To probe h.Sw: heat & light switch ths: independent thermostat control wash heater: (1)-1500w. S-sw: start switch • starts the automatic cycle when th...

Page 49

Rinse heaters (6) 2200 w hc: contactor cb 1: over current circuit breakers-15a. R1&2: contactor m sw: master switch on off 1 els, control, high level fill, low level cut off in wash tank & rinse tank heat. Low voltage sensor, 24v. To probe h sw: heat & light switch w ths & r-ths: independent thermos...

Page 50

Rinse heaters (6) 2500 w hc: contactor (heater) cb.1: over current circuit breakers. 15 amps rating r1, r2 & r3: contactors (wash & rinse motors, and wash heater) m-sw: master switch on-off 1 els, control, high level fill, low level cut-off in wash tank & rinse tank heat, low voltage sensor, 24v. To...

Page 51

Rh rinse heaters ((6) 2500 w hc: contactor (heate r) cb 1 over current, circuit breaker 15amp rating rl & r2 contactors (wash & rinse motor) m sw master switch on off 1 els. Control. High level fill, low level cut-off in wash tank & rinse tank heat, low voltage sensor, 24 v. To probe h sw: heat & li...

Page 52

Hc: contactor (heater) rh: rinse heaters. (6) 2500 w. Cb-1: over current, current circuit breaker, 15amps rating r1 & r2: contactors (wash & rinse motors) m-sw: master switch on-off 1 els: control, high level fill, low level cut-off in wash tank & rinse tank heat, low voltage sensor, 24 v. To probe ...

Page 53: Parts List For Model 100

Parts list for model 100 b/prb dishwashers part number description serial numbers 100 0006800 booster tank for machine (stripped) b all 1 0006900 booster tank for machine (stripped) pr all 1 0006900 booster tank for machine (stripped) prb all 1 6007900 cantilever assy comp. (includes pans 79; 83; 87...

Page 54

Part number description serial numbers 100 0084300 probe; small lundy 2800 2w 0084500 probe, large warrick hi-level all 1r 0084700 probe; cover rubber (for 845) all 1r 0085000 pump assy. Comp. W/motor, 1/2 hp, 3450 rpm, rinse (prb only) 1200 1r 0085100 pump assembly, complete w/motor, 1/2 hp, 2850 r...

Page 55

Part number description serial numbers 100 3700 strainer, 'y', 3/4" all 1 4000 switch, rinse/fill (all) (spdt) momentary slip disconnect af24, 451; 2618; 1149 1 0155500 switch, manual wash (dpdt) (all) slip disconnect af24, 451; 2618; 1149 1 0157500 switch, master (dpst) (all) slip disconnect (used ...