Series 24 models 24a-af, 24b-bf-bp hot water sanitizing undercounter dishmachine from serial no. 23000 instruction manual includes: -warranty policy -specifications -installation requirements -care and cleaning -operating instructions -troubleshooting -illustrated parts -optional drain pump -service...

Index warranty inside front cover specifications 2 concealed damage 4 general instructions (installation) 5 installation checklist 9 general instructions(operation) 10 general instructions (preventive maintenance) 11 removal of rinse and/or wash head assemblies (general instructions) 12 timer for se...

Note: all dimensions from floor can be increased 1" with adjustable feet supplied. Power/connections overall product, in place performance/capacities model model 24(f) 24b(f) wash pump motor model model horsepower electric heat wash 1/2 1/2 operating capacity 24(f) 24b(f) kw 1.0 1.0 racks per hour 2...

Model 24 table package options general information 24.1 package • the system combines the 24 or 24b dishwasher with a standard dishtable. • 42" wall mounted overshelf in 1-x package. • the dishtable and overshelf are constructed of 18-8 304 series 16 gauge stainless steel. • heavy duty pre-rinse spr...

Concealed damage important: for your protection, please read and observe the following: this merchandise has been thoroughly inspected and carefully packed before leaving our warehouse. If it is found that the shipment has concealed damage, please do not return it to us, but notify and file a claim ...

General instructions (installation) refer to specification section for further details. Note: read the following instructions carefully. Proper installation of your jackson dishwasher will assure proper machine operation. Uncrating 24: 1. Remove wooden blocks from carton. 2. Slide carton sleeve upwa...

Installation of top and sides on 'f' and 'p' models: 1. Insert rear barrier with angle facing out. Install prior to placing top on uit. 2. Place top on unit, making sure front lip is under flange, but does not interfere with latch or switch mechanism. Place studs in holes on back of unit. Use 1/4-20...

Installation of model 24 top and table gasket: these instructions are to be used for applying the adhesive backed sponge rubber strip to the top of the machine prior to setting the table in place. Included with the model 24 table is a 6 foot length of 1/4" thick x 1" wide sponge rubber adhesive back...

5. Using the two holes in bracket #4 as a guide, drill two holes 9/64" diameter in the side panel of machine. Note: drill through first thickness of metal only. 6. Using the self-tapping screws supplied, screw them through bracket #4 and into the side panel of machine until screws are tight. Removal...

Installation checklist please check off the following items as they are completed. All items must be completed and checked off before proceeding to machine operation. In the event that installation information is needed, please call one of jackson products authorized service agencies, dealership whe...

General instructions (operation) note: read the following instructions carefully. Proper operation of your jackson dishwasher will assure clean and sanitized glasses and dishes, at optimum efficiency. Dish preparation: 1. Scrape dishes thoroughly. 2. Pre-wash dishes by soaking or with hose. 3. Place...

General instructions (preventive maintenance) user serviceable areas (the following is to be performed daily or as needed.) note: read the following instructions carefully. Proper maintenance of your jackson dishwasher must be conducted for warranty consideration. 1. Remove all lime and corrosion de...

Removal of rinse and/or wash head assemblies (general instructions) user serviceable parts (the following is to be performed daily or as needed.) 1. Drain unit by placing switch in the off/drain position. 2. Open the door and allow the unit a few minutes to cool off. 3. Remove the pin holding the ri...

Item p/n description item p/n description 1. 0186500 wash head cap with race 6. 0187500 wash head center shaft 2. 0187000 wash head cap set screw 7. 0193601 wash head fixed race 3. 0194000 wash head bearing 1/4" sis 8. 0109600 upper pump housing 4. 0189000 wash head small manifold 9. 0188601 w/tubes...

Timer for model 24 dishwashers general description: the timer is a solid state, 4 channel cmos device with a 120v, 50 or 60 cycle, 1 amp rating. All components are environmentally encapsulated and quick connect terminals are marked for corresponding wires. Principle of operation: wash cycle function...

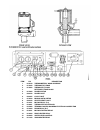

Function of switches, circuit breaker and indicating lights on/fill off/drain switch: p/n 0155600 this switch serves as the main control for the unit. When pressed into the 'on' position, it activates the heater controls, the automatic fill and readies the unit for the wash cycle. When turned off, a...

Thermostat adjustment the thermostat can be adjusted by turning screw #1 (see picture) on the thermostat control box cover. (remember the present setting, in case the problems are elsewhere in the control circuit.) a cw rotation is used to obtain a lower temperature setting and a ccw rotation is use...

Rinse tank heater system function: the rinse tank heater system is electrically connected in the circuit with the control system functioning on 110/130v and the power system functioning on 208/230v for both systems. The heat circuit is controlled by the 'on/fill' switch (mounted on front panel) and ...

A - on/fill switch f - reset light b - water level control g -relay c -thermostat h - rinse heater d - (wash) ring heater x - terminal board e - thermostatic overload.

Wash tank heater system function: the wash tank heater system is electrically connected in the circuit, with the control system functioning on 110v and the power system functioning on 208/230v. (on models without built-in booster, power circuit is 110v.) the heat circuit is controlled by the water l...

Water level control as used on 24 p/n 0204400 (110v, 60 cycle) function: the water level control device is utilized on this machine to automatically control the filling of the wash tank and the activation of the wash tank heater. Note: all electrical checks should be made by qualified service person...

Service instructions (incoming water solenoid valve) solenoid valve p/n 0142100 (110v, used on 60 cycle machine) to take the valve apart: disassembly — these valves may be taken apart by unscrewing the bonnet and the enclosing tube assembly from the valve body assembly. See fig. 3. After unscrewing,...

Beware of counterfeiting! No, not money, but counterfeiting of parts that could cost you hundreds of dollars. The only difference between this form of counterfeiting and monetary counterfeiting is that is may be legal. In our economy it's called competitive business. However, as an end user, are you...

Trouble shooting guide problem cause solution water overflow out bottom of machine not level. Level machine. Front door when wash pump slight tilt to rear is operating. Overflow drain clogged. Remove obstruction, checking inside of machine first. Water level in machine's solenoid valve not closing a...

Trouble shooting guide problem cause solution rinse doesn't operate on timer defective. Replace. Automatic during timed cycle (but does operate on auto/fill operation). Rinse water runs continuously defective plunger in replace plunger. With circuit breaker controlling solenoid valve. Machine turned...

Trouble shooting guide problem cause solution thermostat defective. Adjust using instructions on thermostat page and heater system's checkout page. Replace if necessary. Water level protection control defective. Replace. (auto/fill would run continuously.) heater element defective. Replace. R-2 defe...

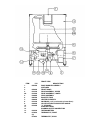

Front view item p/n description 1. 0052700 door handle assembly 2. Switches 3. 0052600 front door 4. 0125100 rinse assembly, upper 4a. 0125200 rinse assembly, lower 5. 0188900 wash assembly 6. 0005700 booster tank 7. 0060000 heater elements 8. 0142100 solenoid, (110v, used on 60 cycle machines) 9. 0...

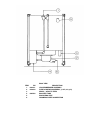

Back view item p/n description 1. 0184101 vacuum breaker assembly 2. 0108100 pump & motor asssembly, (110v, 60 cycle) 3. Drain — gravity feed 4. 0005700 booster tank 5. Equalizing vent 6. Incoming water connection.

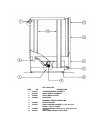

Left side view item p/n description 1. 0184101 vacuum breaker assembly 2. 0052700 door handle assembly 3. 0052600 front door, outer 4. 0054902 kick panel 5. Incoming water connection 6. 0083400 adjusting feet 7. 0108100 pump & motor assembly, (110v, 60 cycle) 8. Drain — gravity feed 9. 0142400 drain...

Right side view item p/n description 1. 0184101 vacuum breaker assembly 2. 0125100 rinse assembly, upper 2a. 0125200 rinse assembly, lower 3. 0004000 side frame & brace, right hand 4. 0188900 wash assembly 5. 0005700 booster tank 6. 0083400 adjusting feet 7. 0054902 kick panel 8. 0052600 front door ...

Item p/n description 1. 0153600 "y" strainer 2. Removable filter 3. 0185000 valve for health inspector 4. 0142100 solenoid valve 1/2" (110v, used on 60 cycle machine) 5. Pipe union.

Rinse tank item p/n description 1. 0005700 booster tank 2. 0060001 bus bar 3. 0060000 booster heater element 4. Thermostat coupling 5. 0060002 heater element gasket 6. Water inlet 7. Thermometer coupling 8. Water outlet item p/n description 1. 0056900 wash tank ring element 2. 0125200 rinse assembly...

1. Booster tank heater element p/n 0060000 2. Element gasket p/n 0060002.

Pump and motor assembly item kit# description 1. Motor (11) 2. 0108501 mounting plate 3. 0108501 stationary seal assembly 4. 0108501 shim washers 5. 0108501 rotating ceramic 6. 0108501 propeller for drain pump 7. 0109501 "o" ring seal 8. 0109501 drain inlet plate 9. 0109501 suction adapter plate 10....

Item p/n description 1. 0169100 thermometers, wash and rinse 2. 0170018 thermostat, rinse 2. 0170023 thermostat, wash 3. Detergent fuse block 4. 0155600 power switch 5. 0083518 power light 6. 0083507 cycle light 7. 0159700 manual/auto switch 8. 0083518 heater reset light 9. 0122701 motor relay (r-3)...

Note: all wires mtw 2/64 insulation temp rated 90 c/194 f degrees rl rinse heater relay wm wash motor pl power light hrl heater reset light r2 mash heater relay run main run winding rths rinse thermostat m/a sw manual/automatic switch r3 wash motor relay c.N. Wash start winding llc1 liquid leuel con...

Legend rh rinse heater wh wash heater sr start relay run run motor winding cw wash start winding ccw drain start winding o.L. Motor overload r1 rinse heat contactor r2 wash heat relay r3 wash motor relay r4 drain cycle relay llc1 liquid level control llp low level probe psw power switch dsw door saf...

Wiring diagram model 24b solid state timer 115-208/230 volt 60 cy 1 ph.

Optional pump drain appendix index four main areas of the pump drain system (drawinga-4) air gap drain mounting (drawing a-5) drain pump motor (drawinga-6) pump intake hose assembly to sump (drawinga-t) water level float installation (drawing a-8) functional breakdown of the four main parts of the 2...

Air gap drain mounting 1.) 0052110 ----- air gap 2.) 0052124 ----- drain hose clamp 3.) 0052101 ----- drain hose 4.) 0052120 ----- drain barb reducer 5.) 0052102 ----- drain hose 6.) 0052122 ----- drain hose clamp.

1.) 2.) 3.) 4.) 5.) 0052100 ----- drain pump motor 0052122 ----- drain hose clamp 0052102 ----- drain hose 0052108 ----- drain hose 0052123 ----- drain hose clamp 6.) 7.) 8.) 9.) 10.) 0052112 ----- drain pump motor vent clamp 0052111 ----- drain pump motor vent cap 0052113 ----- drain relay time del...

1.) 2.) 3.) 0052106 ----- drain elbow from sump to pump intake 0052120 ----- drain barb reducer 0052123 ----- drain hose clamp 4.) 5.) 6.) 0052124 ----- drain hose clamp 0052107 ----- drain hose 0052108 ----- drain hose drawing a-7.

1.) 0052103 drain float switch 2.) 0052105 drain float cover 3.) 0052104 drain cord clips drawing a-8.

Functional breakdown of the four main parts of the 24bp and 24ap pump drain system note: refer to drawing a-4. A.) with machine properly leveled, by adjusting the feet on all comers, the front of the unit should be 1/4" to 1/2" higher than the back of the unit. B.) with machine filled and power swit...

General installation instructions of machine drain line step 1: location of drain line connection note: refer to drawing a-1. The drain line connection on this machine is located at rear of machine in the upper-right-hand comer. Connection size is 3/4“. Use 3/4" reinforced hose. Step 2: drain line i...

Pumped drain component layout (solid state timer) 1.) 0052100 drain, pump motor 6.) 02044 00 water level control 2.) 0052113 drain, time delay relay 7.) 0120500 relay rinse heater 3.) 0046523 dispenser connection fuse plate 8.) 0124400 relay drain cycle 4.) 0121300 relay 110v, for pump motor & wash ...

Parts list for the pump drain system this parts list includes parts (only) for the pump drain system of the model 24bp. Part number description 0052100 drain pump assembly 0052101 drain hose, 1/2 " id (air vent) 0052102 drain hose, 3/4" x 27" 0052103 drain float switch 0052104 drain cord clips 00521...

Complete parts list for series 24 0005700 booster tank (stripped) 1 0051700 door latch and switch bracket 1 0052300 door gasket 1 0052400 door gasket, clamp assembly 1 0052600 door, front, outer only (stripped) 1 0052700 door handle 1 0053400 drain hose-pump to solenoid valve, short 1 0053500 drain ...

Complete parts list for series 24 0165600 terminal board, 3-pole 1 0169100 thermometer, 36" cap, rinse 1 0169601 thermostatic overload, heater 1 0170018 thermostat, rinse, 180°, fixed 1 0170023 thermostat, wash, 150°, fixed 1 0174400 timer, solid state 1 0177500 timer micro switches, plastic module-...