- DL manuals

- Jackson

- Dishwasher

- AVENGER HT-E

- Installation, Operation & Service Manual

Jackson AVENGER HT-E Installation, Operation & Service Manual

Summary of AVENGER HT-E

Page 1

Avenger series undercounter dishmachines installation, operation & service manual for jackson model(s): avenger ht-e avenger lt-e avenger ht-e technical manual • revision p • p/n 07610-004-04-18 • issued 01-01-2014 • revised 09-22-2015.

Page 3

Manufacturers warranty one year limited parts & labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from date of purchase, but in no event to exceed (18) eig...

Page 4: Revision History

I revision letter revision date made by applicable ecns details a 04/17/13 rlc ecr 8259 release to production b 02/20/14 mhh qof ndb 229 update control, wash and strainer assemblies. Update schematic. C 06/27/14 mhh 8301 update schematic d 07/02/14 rc qof-ndb-266 removed ventilation requirements e 0...

Page 5: Avenger Ht-E

Ii avenger ht-e high temperature, hot water sanitizing, with a booster tank detergent & rinse aid chemical feeder pumps avenger lt-e low temperature, chemical sanitizing, with detergent, rinse aid & sanitizer chemical feeder pumps. Model: serial no.: installation date: service rep. Name: phone numbe...

Page 6: III

Iii table of contents specifications ................................................................................................ 1 machine dimensions ................................................................................................................. 1 operating parameters ...........

Page 7: Specifications

1 machine dimensions specifications 16 5 8 [422 mm] 25 5 8 [650 mm] 1 [25 mm] wall clearance 33 5 16 [846 mm] 14 [356 mm] dish clearance 6 7 8 [175 mm] 14 5 8 [373 mm] 24 3 16 [615 mm] legend: a- water inlet - 3/4" male garden hose thread (m-ght) (connect to a true 1/2" id water line) *note: water i...

Page 8: Specifications

2 model designation: avenger ht-e avenger lt-e operating capacity: racks per hour 26 30 dishes per hour 468 480 glasses per hour 936 960 tank capacity (gallons): wash tank 3 3 rinse tank 2.12 n/a electrical loads (as applicable): wash motor hp 0.75 0.75 wash heater kw 4 1.5 rinse heater kw 4 n/a not...

Page 9: Specifications

3 note 1: mca (minimum circuit ampacity) = 125% x largest motor +fla of all other motors + all other loads. Note 2: mop (maximum overcurrent protective device) = 225% x largest motor + fla of all other motors + all other loads. All electrical ratings provided in this manual are for reference only. A...

Page 10: Installation

4 before installing unit, check container and machine for damage. A damaged container may be an indication of damage to the machine. If there is any type of damage to both container and unit, do not throw away the container. The dishmachine has been inspected at the factory prior to shipping and is ...

Page 11: Installation

5 instructions installation water supply connections: water hardness greater than 5 gpg water supply connection: water hardness of 5 gpg or less pressure regulator shock absorber connecting the drain line plumbing check if water hardness tests at greater than 5 gpg, install the hts-11 into the water...

Page 12: Installation

6 instructions installation electrical power connections electrical and grounding conductors must comply with the applicable portions of the national electric code ansi/nfpa 70 (latest edition) and/or other electrical codes. The data plate is located at the left front side of the dishmachine. Refer ...

Page 13: Installation

7 instructions installation chemical feeder equipment priming chemical feeder pumps warning: some of the chemicals used in dishwashing may cause chemical burns if they come in contact with skin. Wear protective gear when handling these chemicals. If any skin comes in contact with these chemicals, im...

Page 14: Programming

8 programming instructions for chemical feeder pumps (installation technician only) the chemical feeder pump timers are located on screens 3, 4 & 5. To access the programming mode follow the process detailed below. Instructions installation 1. Press “a” to cycle through screens until reaching the "f...

Page 15: Installation

9 instructions installation detergent usage and water hardness are two factors that contribute greatly to how efficiently this dishmachine will operate. Using detergent in the proper amount can become a source of substantial savings. A qualified water treatment specialist can relate what is needed f...

Page 16: Installation

10 operating instructions installation before proceeding with the start-up of the unit, verify the following: 1. Strainers are in place and clean. 2. Wash and rinse arms are screwed securely into place and end caps are tight. 3. Wash and rinse arms rotate freely. 4. Chemical levels for machine chemi...

Page 17: Installation

11 operating instructions installation to wash a rack, open the door completely and slide the rack into the unit. Close the door, press the start button and the unit will start. After the machine has drained and the cycle light turns off, the cycle is complete. As the workday progresses, operators s...

Page 18: Maintenance

12 preventative maintenance maintenance the manufacturer of this dishmachine highly recommends that any maintenance and repairs not specifically discussed in this manual should be performed by qualified service personnel only. Performing maintenance on the dishmachine may void a warranty. By followi...

Page 19: Maintenance

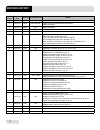

13 troubleshooting maintenance problem possible cause remedy water overflow from bottom of door. 1. Clogged drain. 2. Machine not level. 3. Excessive inlet pressure. 4. Detergent foaming. 5. Wash or rinse arm end plug missing. 6. Top float failure. 1. Remove obstruction. 2. Level machine or increase...

Page 20: Maintenance

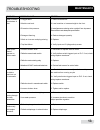

14 problem possible cause remedy wash temperature not at required reading on home screen. 1. Water level low. 2. Rtd set point too slow. 3. Defective rtd. 4. Wash heater defective. 5. Defective heater contactor r1. 1. Check water level. If low, run new fill cycle. 2. Check fault screen. 3. Adjust wa...

Page 21: Maintenance

15 wash temperature temeratura del lavado rinse temperature temperatura de aclarado rinse pressure enjuague presiÓn f/c r i n s e a i d p r i m e de l i me de t e r g e n t p r i m e p o w e r f l u s h troubleshooting maintenance the "flush" light will activate after the unit has completed a predet...

Page 22: Maintenance

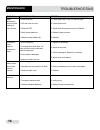

16 the avenger ht-e comes equipped with a plc programmed to make troubleshooting and diagnostics more user-friendly. The following pages detail each screen associated with the avenger ht-e plc display. Plc troubleshooting maintenance screen 1: home the home screen will be displayed when the machine ...

Page 23: Millenium 3

17 millenium 3 crouzet faults: 6 the “faults” screen will be displayed when the operator has pressed “a” or “b” to cycle through screens and is intended to show the technician any faults that have occurred. A b c d plc troubleshooting maintenance screen 2: faults line c will show any fault observed ...

Page 24: Millenium 3

18 fill cycle timers: fill timer: s det timer: r/a timer: 0012.0s s millenium 3 crouzet 0010.0 the “fill cycle timers” screen allows the user to edit the fill, detergent and rinse aid timers for the initial fill cycle. A b c d plc troubleshooting maintenance screen 3: fill cycle timers 1. Line b dis...

Page 25: Millenium 3

19 wash cycle timers: wash time: 00075s rinse time: drain time: 00008s s millenium 3 crouzet screen 4 is the first “wash cycle timers” screen and allows the user to edit the wash, rinse and drain timers for the initial wash cycle. A b c d plc troubleshooting maintenance screen 4: wash cycle timers 1...

Page 26: Millenium 3

20 wash cycle timers: det timer: r/a timer: 00008s san time: s millenium 3 crouzet 0005.0 s 00008 screen 5 is the second "wash cycle timers" screen and allows the user to edit the detergent and rinse aid timers for the initial wash cycle. A b c d plc troubleshooting maintenance screen 5: wash cycle ...

Page 27: Maintenance

21 plc troubleshooting maintenance screen 6 is the "temperature setpoints" screen and allows the user to edit the wash tank, top rinse tank and bottom rinse tank temperatures. Screen 6: temperature setpoints 1. Line c shows the wash tank temperature. • press + or - to highlight line b. • press ok to...

Page 28: Millenium 3

22 sanisure select: 0=oof 1=on millenium 3 crouzet 1. Line b shows the off option. • press + or - to highlight line b. • press ok to turn sanisure off and reset fault 5. 2. Line c shows the on option. • press + or - to highlight line c. • press ok to turn sanisure on. 3. Line d will display the sani...

Page 29: Maintenance

23 plc troubleshooting maintenance 1. Line c displays the number of cycles since the last "flush" or complete tub drain. 2. Line d shows the number of cycles that perform before the "flush" light activates. • press + or - to highlight line d. • press ok to enter highlight mode. • press + or - to mak...

Page 30: Millenium 3

24 123456789abcdefg 123456789a 23:59 millenium 3 crouzet fahrenheit/celuis selectl 0=celsius 1=fahrenheit millenium 3 crouzet 1. Line a (inputs) will highlight when the connected component sends a signal to the plc. Multiple inputs may be highlighted at the same time. 2. Line c (outputs) will highli...

Page 31: Maintenance

25 plc troubleshooting maintenance 25 1. Line a shows a reading of the wash rtd. 2. Line b shows a reading of the rinse injector rtd. 3. Line c shows a reading from the pressure transducer. 4. Line d shows if temperature is displaying in celsius (1) or fahrenheit (0). 1. Press ok for 10 seconds on s...

Page 32: Parts

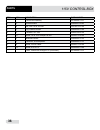

26 num revision control# orig drwn by date parts list rev: part no: scale: title: drawn by: date: date: date: checked by: approved by: part to be free from all burrs and sharp edges do not scale drawing this print is the property of jackson wws,inc. And is subject to recall and return on demand. Any...

Page 33: Parts

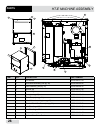

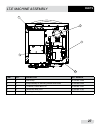

27 lt-e machine assembly parts item qty description part number 1 1 drain pump 04730-004-18-89 2 1 pump assembly w/ mounting bracket and hoses 05700-004-04-04 3 1 f-channel, control box lt-e 05700-004-12-01 4 1 control box slide 115v 05700-004-11-52 5 1 plumbing assembly 05700-004-18-93 4 1 2 5 3.

Page 34: Parts

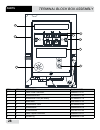

28 item qty description part number 1 1 decal, power connection 09905-011-47-35 2 1 terminal block box 05700-003-27-69 1 terminal box cover (not shown) 05700-003-27-70 3 1 strain relief 05975-003-37-56 4 1 terminal block track 05700-000-43-60 5 2 terminal block 05940-500-02-19 6 2 10-24 lock nut 053...

Page 35: Parts

29 control panel parts num revision control# orig drwn by date parts list rev: part no: scale: title: drawn by: date: date: date: checked by: approved by: part to be free from all burrs and sharp edges do not scale drawing this print is the property of jackson wws,inc. And is subject to recall and r...

Page 36: Parts

30 control panel parts item qty description part number 1 1 wash heater 4kw 04540-003-99-44 1 **480v heater 04540-004-12-29 1 wash heater 1.5kw 115v (avenger lt-e only) 04540-004-11-48 2 3 heater gasket 05330-100-01-10 1 **480v heater gasket 05330-004-13-19 3 1 rinse booster (see page 40, rinse tank...

Page 37: Parts

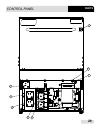

31 control kick panel parts 1 2 3 note: dielectric cover hidden for clarity 4 6 5 7 8 9 1 2 3 note: dielectric cover hidden for clarity 4 6 5 7 8 9 item qty description part number 1 1 a-control panel, avenger ht-es 05700-004-00-10 2 2 terminal board, 4 pos jm96054 05940-021-94-85 3 16 nut, lock 10-...

Page 38: Parts

32 208/230v control box parts c 1 h c 1 h c 2 h c 3 11 5 10 4 2 8 11 7 1 12 vio/wht org/wht wht/red blue/wht 9 2 2 5 3 3 5 5 5 c 1 h c 1 h c 2 h c 3 11 5 10 4 2 8 11 7 1 12 vio/wht org/wht wht/red blue/wht 9 2 2 5 3 3 5 5 5.

Page 39: Parts

33 208/230v control box parts c 1 h c 1 h c 2 h c 3 11 5 10 4 2 8 11 7 1 12 vio/wht org/wht wht/red blue/wht 9 2 2 5 3 3 5 5 5 item qty description part number 1 1 control box, avenger ht-e 05700-004-11-32 2 2 power supply, 100-240 vac 12vdc 1.2a 15 watt 05950-004-11-16 3 2 peripump, 36 rpm, 24vdc 0...

Page 40: Parts

34 480v control box parts part number description qty item 04320-004-09-56 peripump, 36 rpm 24vdc 2 1 05945-003-75-22 contactor, 24vdc, 460v max, 5hp 4 2 05945-003-75-17 overload, 10-14a, 600vac max, (mto3p) 1 3 05940-200-76-00 lug,lama214q/panduit ground 1 4 05920-011-72-89 holder, bm6031sq sinpo f...

Page 41: Parts

35 115v control box parts part number description qty item 5 05310-373-01-00 nut, lock10-24 s/s hex w/nylon in 4 2 05940-200-76-00 lug,lama214q/panduit ground 1 3 05945-109-05-69 contactor,cr453ca2aaa ge 2 po 110v 2 4 05305-173-26-00 screw, 10-32 x 3/8 phillips pan hd 17 5 05940-002-31-31 multimate ...

Page 42: Parts

36 parts 115v control box item qty description part number control box assembly 05700-004-11-52 1 2 terminal board 05940-021-94-85 2 4 nut, lock 10-24 s/s hex 05310-373-01-00 3 1 lug, panduit ground 05940-200-76-00 4 2 contactor, ge 110v 05945-109-05-69 5 17 screw, 10-32 x 3/8 phillips pan hd 05305-...

Page 43: Parts

37 chemical feeder pump assembly parts item qty description part number 1 2 chemical pump w/squeeze tube 04320-004-10-39 2 2 chemical pump complete assembly w/motor 04320-004-09-56 1 2.

Page 44: Parts

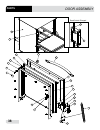

8 12 16 15 14 13 11 4 10 9 7 17 18 6 5 4 3 2 1 door assembly parts 38 19 part num ber desc riptio n qty item 05340 -003-3 2-37 sprin g, do or 1 1 05700 -003-3 2-84 tube , doo r spr ing 2 2 part s list 20 22 reed switch enlarged 24 23.

Page 45: Parts

39 door assembly parts item qty description part number 1 1 flush mount plug 05975-004-04-36 2 12 10-32 x 1/2” phillips pan head screw n/a 3 1 door channel seal 05700-003-55-49 4 2 left & right door gasket 05330-003-58-36 5 1 top door gasket 05330-003-58-35 6 1 inner door 05700-004-08-31 7 1 start b...

Page 46: Parts

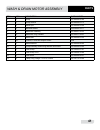

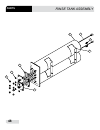

40 wash & drain motor assembly parts 10 11 12 13 1 2 3 4 5 9 8 6 7.

Page 47: Parts

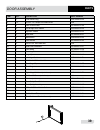

41 wash & drain motor assembly parts item qty description part number 1 1 sump 05700-004-02-94 2 1 sump strainer 05700-004-03-73 3 1 stand pipe 05700-004-04-40 4 1 manifold gasket 05330-002-34-77 5 2 wash arm assembly 05700-021-39-23 6 2 wash arm plug, es2000 05700-011-35-92 7 1 wash halo 05700-004-...

Page 48: Parts

42 3 1 2 4 wash arm assembly parts item qty description part number complete wash arm assembly 05700-021-39-23 1 1 wash arm w/plug 05700-021-46-58 2 1 bearing, assembly 05700-021-35-97 3 1 o-ring 05330-002-60-69 4 1 end plugs 05700-011-35-92.

Page 49: Parts

43 rinse manifold assembly parts item qty description part number 1 complete rinse arm assembly 05700-004-01-56 1 2 rinse arm, plugs 05700-004-05-23 2 1 nozzle 04730-004-01-07 3 1 washer, rinse arm 05330-011-42-10 4 1 bearing, rinse arm 03120-004-12-13 5 1 bushing, rinse head 05700-021-33-84 6 1 o-r...

Page 50: Parts

44 ht- e plumbing assembly parts part number description qty item 04730-401-03-01 adapter, male (cu to msps) 2 1 04730-406-31-01 elbow, 1/2 s. Cu. To ftg. 3 2 04810-003-71-56 valve, 1/2" 8210g094hw 208/60 1 3 04730-411-25-01 tee, 1/2c x 1/2c x 1/4 female 1 4 04730-011-59-53 adapter, 1/2 fitg. X male...

Page 51: Parts

45 ht- e plumbing assembly parts item qty description part number 1 1 vavle, 1/2" 208/60v 04810-003-71-56 1 valve, 1/2" 115v 04810-003-71-55 2 1 a-plumbing, inc to reg, avg ht es 05700-004-04-44 3 1 union, 1/2” (c/c) (733cast) 04730-412-05-01 4 1 adapter, male (cu to msps) 04730-401-03-01 5 1 transd...

Page 52: Parts

46 lt- e plumbing assembly parts 4 16 17 18 20 2 14 13 11 19 15 7 3 10 5 9 6 8 12 1 11 24 25 23 22 21 26 rinse injector assembly.

Page 53: Parts

47 lt- e plumbing assembly parts item qty description part number 1 1 valve, 1/2" 115v 04810-003-71-55 2 1 a-plumbing, inc to reg, avg ht es 05700-004-04-44 3 1 union, 1/2” (c/c) (733cast) 04730-412-05-01 4 1 adapter, male (cu to msps) 04730-401-03-01 5 1 transducer, pressure 0-50 psig 05945-004-17-...

Page 54: Parts

48 rinse tank assembly parts 8 7 6 5 2 3 4 1.

Page 55: Parts

49 rinse tank assembly parts item qty description part number 1 2 booster heater, 2kw 04540-003-98-38 1 ** 480v unit only 04540-004-13-30 2 2 heater gasket 05330-100-01-10 1 ** 480v heater gasket 05330-011-47-79 3 8 lockwasher, split 5/16" s/s n/a 4 8 nut, hex 5/16-18 s/s n/a 5 1 w-booster 05700-004...

Page 56: Parts

50 wash pump assembly parts part number description qty item 05700-004-08-21 f-hose 1 1/4 x 8 1 1 05700-004-02-94 w-sump, avenger ht es 1 2 04730-719-18-00 clamp, reg. Range 1-1/16 - 2 hs24 5 3 04730-003-91-41 pump,drain avenger ht es 1 4 04720-004-20-12 elbow, 1 hose barb drain 2 5 04720-111-39-73 ...

Page 57: Parts

51 wash pump assembly parts ** models with 480v control box 3 item qty description part number 1 1 hose 1-1/4 x 8 05700-004-08-21 2 1 sump 05700-004-02-94 3 2 clamp, reg. Range 1-1/16 to 2 hs24 04730-719-18-00 4 1 pump, drain 04730-003-91-41 5 2 elbow, hose barb drain 04720-004-20-12 6 1 hose, drain...

Page 58: Schematics

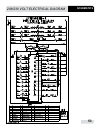

52 schematics 115 volt electrical diagram.

Page 59: Schematics

53 schematics 208/230 volt electrical diagram.

Page 60: Schematics

54 schematics 480 volt electrical diagram.

Page 61

55 avenger ht-e technical manual • p/n 07610-004-04-18 jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com.