- DL manuals

- Jackson

- Laboratory Equipment

- CONSERVER XL

- Service Manual

Jackson CONSERVER XL Service Manual

Summary of CONSERVER XL

Page 1

Service m manual october 24, 2001 p/n 7610-002-10-23 (revision b) visit jackson on the internet at: www.Jacksonmsc.Com conserver xl.

Page 2

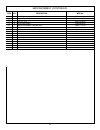

General page specifications .............................................................................................. 1 installation instructions .............................................................................. 2 chemical dispensing equipment .........................................

Page 3

1 performance/capabilities operating capacity (racks/hour) racks per hour 37 dishes per hour 925 glasses per hour 925 operating cycle (seconds) wash time 42 rinse time 25 total cycle time 87 tank capacity (gallons) wash tank (minimum) 1.49 wash pump capacity gallons per minute 61 temperatures wash--...

Page 4

Visual inspection: before installing the unit, check the con- tainer and machine for damage. A damaged container is an indi- cator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away the container. The dishmachine has been inspected a...

Page 5

To prepare pumps for operation the conserver xl dishmachine is supplied with detergent, rinse additive and sanitizer dispensing peristaltic-pumps. Locate the open ends of the chemical tubes with the tube stiffeners and place each one in the appropriate container. A. Red tubing = detergent b. Blue tu...

Page 6

Preparation: before proceeding with the start-up of the unit, verify the following: 1. The sump strainer is in place and is clean. 2. The drain stopper is installed. 3. That the wash and rinse arms are screwed securely into place and that their endcaps are tight. The wash and rinse arms should rotat...

Page 7

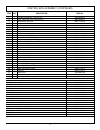

The conserver xl cam timer is a 1 minute, 30 second, 8-cam timer (cam 8 is a spare) that controls the operation of the dishma- chine. The following is a description of the set points for each cam and the function of each switch. Cam 1: cam 1 is a cut cam with a single notch and serves as the cycle/r...

Page 8

2 seconds into cycle *wash pump starts, runs for 40 seconds, then shuts down. Controlled by c2 cam. 4 seconds into cycle *detergent feed pump is energized. The length of time will be field determined. Time will depend on the detergent used and water conditions. Controlled by c6 cam. 10 seconds into ...

Page 9

Troubleshooting section 7 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times....

Page 10

Troubleshooting section 8 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times....

Page 11

Troubleshooting section 9 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times....

Page 12

Troubleshooting section 10 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times...

Page 13

Troubleshooting section 11 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times...

Page 14

Dimensions 12 jackson 65 1/2" 73 7/8" w/ door open 13" 61 7/8" floor to c of water inlet back of machine to c of drain 11 1/4" 56 1/8" 34" table height 3/4" 5" top of machine to c of elec. Con. 3 3/4" 15 1/4" edge of water inlet to side of machine 4" back of control box to back of machine 2 3/8" c o...

Page 15

Table dimensions 13 table dimensions corner installation table dimensions connection to dishmachine table dimensions straight through installation 20 1/2” opening 25 1/4” 2 1/4” 4” min. 2 1/2” 4” min. 20 1/2” opening 25 1/4” 20 1/2” 3/4” 1 1/2” roll 4” min 2 1/2” 25 1/4” 20 1/2” opening 25 1/4”.

Page 16

Main assembly 14 1 2, 3 4 - not shown 5, 6, 7, 8 11 12, 13 - not shown 9 10 - not shown 14.

Page 17

Main assembly (continued) 15 item qty description mfg no. 1 1 door, right, with studs, conserver xl 5700-001-99-95 2 1 magnet, reed switch 5930-111-51-68 3 2 nut, hex, 8-32 5310-272-02-00 4 6 plastic door guides 5330-600-02-00 5 1 magnet, reed switch, hood mounted 5930-111-41-70 6 2 screw, 8-32 x 3/...

Page 18

Control box assembly 16.

Page 19

Control box assembly (continued) 17 item qty description mfg no. 1 1 control box weldment, conserver xl 5700-002-04-57 2 1 decal, control box front, conserver xl 9905-002-04-61 3 1 thermometer, 96" lead 6685-111-68-49 4 1 switch, on/off, dpst 5930-111-38-79 5 1 cycle light, conserver xl 5945-504-08-...

Page 20

8 cam timer 18 cycle/ reset wash drain fill sanitizer detergent rinse aid spare cam item qty description mfg no. 1 1 timer motor 5945-306-14-00 2 8 microswitch 5930-011-65-81 02 01.

Page 21

Peristaltic pump assembly 19 item qty description mfg. No. 1 2 screw, 8-32 x 3/8" phillips flat head 5305-011-37-07 2 1 housing, front 4320-111-37-08 3 1 anko roller 4320-111-36-70 4 1 peri pump squeeze tube 5700-111-35-29 5 4 screw, 6-32 x 3/4" phillips pan head 5305-011-37-05 6 1 screw, 8-32 x 1/2...

Page 22

Hood assembly 20 item qty description mfg no. 1 1 hood weldment 5700-002-04-44 2 1 support, left, hood 5700-002-00-18 3 1 support, right, hood 5700-002-00-17 4 1 right door guide 5700-002-05-74 5 1 left door guide 5700-002-05-75 6 4 door guide 5700-002-05-73 7 26 locknut, 1/4"-20, with nylon insert,...

Page 23

Cantilever arm assembly 21 item qty description mfg no. 1 1 arm, cantilever, conserver xl 5700-002-00-20 2 2 sleeve, cantilever arm 5700-000-85-69 3 2 arm, block, cantilver arm 5700-000-31-87 4 2 bolt, eye, 3/8"-16 5306-956-05-00 5 4 nut, hex, s/s, 3/8"-16 5310-276-01-00 6 2 washer, impeller 5311-17...

Page 24

Wash tub assembly 22 item qty description mfg no. 1 1 tub weldment 5700-002-04-38 2 1 fitting, chemical drip 5700-002-05-62 3 1 spillway weldment 5700-002-04-41 4 2 drain seat gasket 5700-002-04-42 5 1 sump strainer 5700-002-06-25 6 1 drain seat insert 5700-021-34-38 7 1 bulkhead to 1/2" hosebarb fi...

Page 25

Accumulator assembly 23 item qty description mfg no. 1 1 accumulator weldment, conserver xl 5700-002-04-63 2 1 accumulator strainer 5700-002-00-38 3 6 bolt, 1/4"-20 x 1/2" long 5305-274-02-00 4 6 washer, s/s, 1/4"-20 5311-174-01-00 *5 6 locknut, 1/4"-20, with nylon insert, s/s 5310-374-01-00 * - ite...

Page 26

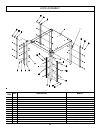

Frame assembly 24 item qty description mfg no. 1 1 lower frame, conserver xl 5700-001-99-80 2 1 leg, front left frame assembly 5700-002-04-36 3 1 leg, short, conserver xl 5700-002-03-72 4 2 bracket, spring mounting 5700-002-04-37 5 1 tub support 5700-001-99-83 6 4 bullet feet 5340-108-02-06 7 9 bolt...

Page 27

Incoming plumbing assembly 25 item qty description mfg no. 1 1 tube, copper, 3/4" x 4" long 5700-001-07-38 2 2 elbow, brass, 90 deg., 3/4" npt 4730-406-42-01 3 1 vacuum breaker, brass, 3/4" 4820-300-08-00 4 1 solenoid valve. 3/4" npt, 100 volt 4810-100-53-00 5 1 adapter, 3/4" mnpt 4730-401-11-01 6 1...

Page 28

3/4” 110/120v solenoid valve repair parts 26 screw data plate 1 valve bonnet 2 spring position is moved for clarity. Goes below item 3. 3 4 diaphragm retainer 5 screen retainer mesh screen valve body item qty description mfg no. 1 1 coil & housing, 115v 4810-200-01-18 2 1 spring 4810-200-04-18 3 1 p...

Page 29

Vacuum breaker repair kit (3/4” npt) 27 cap screw data plate cap cap retainer o-ring plunger components of repair kit 4820-001-60-57 body order the entire assembly using part number 4820-300-08-00..

Page 30

Wash motor assembly 28 item qty description mfg no. 1 1 pump & motor assembly 6105-121-35-18 2 1 pump support assembly 5700-002-05-88 3 1 nipple, pump outlet 5700-021-33-50 4 2 clamp, 1 5/16" to 2 1/4" 4730-719-01-37 5 1 fitting, 3/8" barb x 1/8" mnpt 4730-111-35-02 6 2 clamp, 7/16" to 25/32" 4730-0...

Page 31

Wash arm assembly 29 item qty description mfg no. 1 1 complete wash arm assembly 5700-021-63-81 2 1 wash arm weldment 5700-021-63-42 3 2 wash arm endcaps 5700-011-35-92 4 1 bearing assembly 5700-021-63-80

Page 32

Wash manifold assembly 30 item qty description mfg no. 1 1 tube, wash manifold 5700-002-00-19 2 2 o-ring, wash manifold 5330-111-35-15 3 1 lower wash manifold weldment 5700-002-05-87 4 1 upper wash manifold casting 5700-031-34-82 5 2 manifold gasket 5700-111-35-03 6 2 bolt, 3/8"-16 x 7/8" long 5306-...

Page 33

Drain solenoid assembly 31 item qty description mfg no. 1 1 solenoid bracket weldment 5700-002-05-91 2 1 elbow, 3/8" tube x 3/8"-18 npt 4730-206-23-00 3 2 locknut, brass, 3/8"-18 npt 5700-000-66-01 4 4 locknut, 10-24 s/s hex with nylon insert 5310-373-01-00 5 2 tricnut, 10-32 5340-118-05-00 6 1 drai...

Page 34

Door wrap assembly 32 1 7 6 5 4 3 2 item qty description mfg no. 1 1 door wrap 5700-001-99-96 2 6 nylon door bushing 5700-000-86-66 3 6 nylon washer 5311-369-03-00 4 6 washer, flat, 1/4", s/s 5311-174-01-00 5 6 screw, phillips flathead, 1/4"-20 x 1-1/2" 5305011-44-50 6 6 washer, lock, split, 1/4", s...

Page 35

33 conserver xl electrical diagram 115 volt - 60 hertz - single phase.