- DL manuals

- Jackson

- Dishwasher

- CREW 44

- Installation, Operation And Service Manual

Jackson CREW 44 Installation, Operation And Service Manual

Summary of CREW 44

Page 1

Crew ® crew ® manual • rev n • 07610-003-78-18 • issued: 07-27-10 • revised: 8-22-16 installation, operation, and service manual crew ® series conveyor dishmachines.

Page 3

Manufacturer's warranty one year limited parts and labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation, for a period of (1) one year from date of purchase, but in no event to exceed (18)...

Page 4: Revision History

Ii 07610-003-78-18-n revision letter revision date made by applicable ecns details a 07-27-10 cw/jc n/a initial release of manual. B 02-25-11 jc 8183 8186 8187 8177 transformer change for 208v units. Drain handle operation & alignment change. Door splash shield addition. Rinse paddle switch operatio...

Page 5: III

Iii 07610-003-78-18-n symbols ! Caution ! Warning notice - risk of injury to personnel. - risk of damage to equipment. - risk of electrical shock. - lockout electrical power. - reference data plate. - important note. I - caustic chemicals. Abbreviations & acronyms ansi - american national standards ...

Page 7: Nomenclature

V nomenclature model: serial no.: installation date: service rep. Name: phone number: jackson wws, inc. Provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please have...

Page 8: Table of Contents

Specifications machine dimensions ..................................................................................................................1 side-loader dimensions ............................................................................................................5 steam booster hea...

Page 9: Table of Contents

Parts rinse paddle assemblies .........................................................................................................49 drain assembly parts ...............................................................................................................50 covers, guards & panels ......

Page 10: Specifications

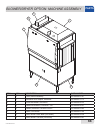

1 07610-003-78-18-n e1 main electrical connection (1.375” dia hole) e2 booster heater elect. Connection (1.375" dia) w main inlet water connection (1/2 npt-f) d drain connection (1-1/2" npt-f) det detergent bulkhead access (.875" dia hole) san** sanitizer inlet to rinse (1/8" npt-f) ra rinse aid con...

Page 11: Specifications

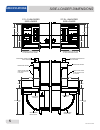

2 07610-003-78-18-n 63 5 8 in 64 1 2 in 61 1 8 in 71 5 8 in 67 1 2 in 15 1 4 in 9 in 83 4 in 11 1 2 in 1112 in 618 in 1412 in 2118 in 235 8 in 1118 in 414 in 73 8 in 23 3 4 in 23 3 4 in 515 8 in (note 2) 43 8 in ra 3 8 in 21 4 in 77 8 in 19 1 8 in 14 7 8 in 21 1 2 in 26 5 8 in 43 8 in table to table...

Page 12: Specifications

3 07610-003-78-18-n e1 main electrical connection (1.375” dia hole) e2 booster heater elect. Connection (1.375" dia) w1 main inlet water connection (1/2 npt-f) w2 pre-wash inlet water conn. (1/2 npt-f) w3*** pre-wash cold water conn. (1/2 npt-f) d1 drain connection, wash (1-1/2" npt-f) d2 drain conn...

Page 13: Specifications

4 07610-003-78-18-n 15 1 4 in 7312 in (note 2) 1018 in (note 3) 71 5 8 in 67 1 2 in 9 in 11 1 2 in 63 5 8 in 64 1 2 in 61 1 8 in 73 8 in 414 in 1118 in 21 in 2312 in 107 8 in 61 in 63 1 2 in 83 4 in 75 8 in 2912 in 93 in m a x (no t e 1) 33 4 in 1718 in 23 3 4 in 3 8 in 21 4 in 73 4 in 19 1 8 in 14 ...

Page 14: Specifications

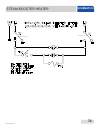

5 07610-003-78-18-n 23.00 29.00 30.32 23.00 29.00 30.32 16.35 16.35 10.00 34.00+1.00 -1.00 10.00 34.00+1.00 -1.00 22.00 22.00 adjustable ventilation duct adapter adjustable ventilation duct adapter side-loader drain hose side-loader drain hose 23" l-r unhooded side-loader 23" r-l unhooded side-loade...

Page 15: Specifications

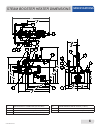

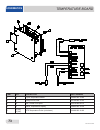

6 07610-003-78-18-n 20 3 4 in 27 8 in 17 1 2 in 24 in 14 5 8 in 33 1 8 in 87 8 in 85 8 in s ps pw c s w1 w2 c 1018 in pw 13 4 in ps w2 11 1 8 in 22 in 33 8 in 193 8 in 2018 in 285 8 in 2014 in w1 s w2 ps pw 33.69 11 3 8 in 22 in 712 in e e e e main electrical connection (7/8" dia hole) w1 main inlet...

Page 16: Specifications

7 07610-003-78-18-n machine dimensions: height 72.5" width 48" depth 30.625" wall clearance: 5' height 19.75" width 21" shipping weight: 750lbs. Shipping size: length 77" depth 41" height 89" 124.06 48.07 25.50 9.00 electrical connection 25.50 9.00 electrical connection 48.07 102.07 124.06 48.07 25....

Page 17: Specifications

8 07610-003-78-18-n machine dimensions: height 72.5" width 48" depth 30.625" wall clearance: 5' height 19.75" width 21" shipping weight: 750lbs. Shipping size: length 77" depth 41" height 89" model designation: 44" 66" 44" steam 66" steam operating capacity: racks per hour 218 218 218 218 dishes per...

Page 18: Specifications

9 07610-003-78-18-n specifications operating parameters model designation: 44" 66" 44" steam 66" steam hot water sanitizing water temperatures (°f): pre-wash temperature (recommended) n/a 110-140 n/a 110-140 minimum wash temperature 160 160 160 160 incoming rinse temperature 180 180 180 180 incoming...

Page 19: Specifications

10 07610-003-78-18-n all electrical ratings provided in this manual are for reference only. Always refer to the machine data plate to get the exact electrical information for this machine. All electrical work performed on machines should be done in accordance with applicable local, state, territoria...

Page 20: Specifications

11 07610-003-78-18-n volts phase freq wash motor amps drive motor amps wash heater amps total load 208 1 60 10.0 1.8 72.1 83.9 230 1 60 10.0 1.8 *59.9 71.7 240 1 60 10.0 1.8 62.5 74.3 208 3 60 8.6 1.1 41.6 51.3 230 3 60 8.4 1.1 *34.6 44.1 240 3 60 8.4 1.1 36.1 45.6 460 3 60 4.2 0.6 **17.3 22.1 480 3...

Page 21: Specifications

12 07610-003-78-18-n volts phase freq pre-wash motor amps wash motor amps drive motor amps wash heater amps total load 208 1 60 10.2 10.0 1.8 86.5 108.5 230 1 60 9.4 10.0 1.8 *71.9 93.1 240 1 60 9.4 10.0 1.8 75.0 96.2 208 3 60 6.8 8.6 1.1 50.0 66.5 230 3 60 6.4 8.4 1.1 *41.5 57.47 240 3 60 6.4 8.4 1...

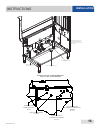

Page 22: Installation

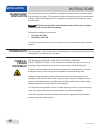

13 07610-003-78-18-n installation instructions before installing the unit, check the packaging and the machine for damage. Damaged packaging might be an indication there is possible damage to the product. If there is any type of damage to both the packaging and the unit, do not throw away the packag...

Page 23: Installation

14 07610-003-78-18-n instructions installation the drain for the unit is a gravity discharge drain. All piping to the machine drain must be a minimum 1-1/2” npt and must not be reduced. There must also be an air gap between the machine drain line and the floor sink or drain. If a grease trap is requ...

Page 24: Installation

15 07610-003-78-18-n installation instructions the dishmachine should be located with an adequate exhaust hood or ventilation system with provisions for venting. This is essential to permit efficient removal of the condensation exhaust. Ensure the exhaust system is acceptable in accordance with appl...

Page 25: Installation

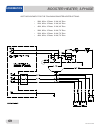

16 07610-003-78-18-n chemical tube insertion point 875" inlet water fitting 1/2" nptf main electrical connection opening 1.375" booster heater electrical connection opening 1.375" shown from rear of left to right unit. Right to left unit is mirrored detergent injection point. Another bulkhead pl...

Page 26: Installation

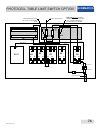

17 07610-003-78-18-n electrical connection points for table limit switch, ventilation fan signal, and chemical dispensing systems. Signal board is located in the main control box behind the lower dress panel. Chemical dispenser tube connection points to rinse injector: p: pressure switch (1/4" npt) ...

Page 27: Installation

18 07610-003-78-18-n curtain installation instructions installation the unit has decals marking the curtain locations inside the machine, starting at the load end and ending at the unload end. The illustrations below indicate the size of the curtain to be placed on the curtain hooks provided. If any...

Page 28: Installation

19 07610-003-78-18-n instructions 1. Connect drain quench assembly to the machine drain via 1.5” npt street elbow (04730-206-32-00). 2. Orient assembly as shown below: installation drain quench kit instructions • this kit should only be installed by qualified service personnel to reduce the risk of ...

Page 29: Installation

20 07610-003-78-18-n drain quench kit instructions installation 3. Connect user-supplied 115v cord (from facility power) into solenoid box as shown below: 4. Connect cold water to inlet side of solenoid valve. Drain quench system if there are any issues after installation, please contact technical s...

Page 30: Operation

21 07610-003-78-18-n before operating the unit, verify the following: • the drain stopper is installed. • the strainers are installed. • the pawl bar is installed and secure. • the actuator switches move with relative freedom and do not bind. • the curtains are installed correctly. To place the unit...

Page 31: Operation

22 07610-003-78-18-n operators should periodically review the following items while the machine is operating. These items are important for operating the machine in an efficient manner. • review wash and rinse temperatures and compare to the minimums on the data plate. • verify the pan strainers are...

Page 32: Operation

23 07610-003-78-18-n to proceed with the delime operation, fill the dishmachine with the amount of delime solution recommended by the chemical supplier. The tank capacities of the machine can be found in the specifications section of this manual. After the chemicals are added, perform the following ...

Page 33: Plc Replacement

24 07610-003-78-18-n plc troubleshooting: green led lights are illuminated on the plc when in operation. The power, ok, and run lights indicate that 24vdc power is available to the plc and that it is functioning properly. If the run light is out, first check that the run toggle switch located behind...

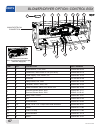

Page 34: Plc1

25 07610-003-78-18-n 1 2 3 4 5 6 7 8 inputs 1 2 3 4 5 6 7 8 outputs pwr run ok plc1 light configuration inputs: 1. On/off button 2. Door switch safety interlocks 3. Rack inlet switch 4. Final rinse switch 5. Lower wash float switch 6. Upper wash float switch 7. Manual / delime switch 8. Spare output...

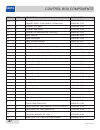

Page 35: Parts

26 07610-003-78-18-n item qty description part number plc1 1 plc, 24vdc (programmed for 44" units) (programmed for 44" units with blower/dryer) 05945-003-92-50 05945-004-10-84 t1 1 transformer 208 to 120vac (208v units) transformer 230/460 to 120vac 05950-011-75-59 05950-011-68-35 t2 1 power supply ...

Page 36: Parts

27 07610-003-78-18-n item qty description part number hc1 1 contactor, 24vdc, 3 pole (used on 3-phase units) contactor, 24vdc, 4 pole (used on 1-phase units) 05945-003-75-02 05945-003-73-22 c1 1 contactor, drive motor 05945-003-75-22 c2 1 contactor, wash pump 05945-003-75-22 c3 1 contactor, pre-wash...

Page 37: Parts

28 07610-003-78-18-n wash motor voltage part number ge part number 208 05945-003-76-29 mt03n 230 05945-003-76-29 mt03n 460 05945-003-76-27 mt03l drive motor voltage part number ge part number 208 05945-003-76-23 mt03f 230 05945-003-76-23 mt03f 460 05945-003-76-21 mt03d pre-wash motor voltage part nu...

Page 38: Parts

29 07610-003-78-18-n description part number fitting, 1", 90 degree hub (2 per 44" units; 1 per 66" units) 05975-003-77-44 fitting, 1" straight hub (1 per 66" units) 05975-003-88-01 fitting, 3/4" str qt 05975-003-77-46 fitting, 3/4" 90 degree qt 05975-003-77-45 fitting, 1/2" npt 90 degree 05975-003-...

Page 39: Parts

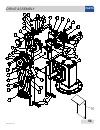

30 07610-003-78-18-n 6 12 5 7 10 11 3 4 1 8 9 2 9 item qty description part number 1 1 heater shroud weldment lower 05700-003-74-21 2 1 heater shroud weldment upper 05700-003-74-24 3 1 gasket, suction casting 05330-003-75-89 4 1 gasket, pump suction 05330-003-75-87 5 1 gasket, heater 05330-200-02-70...

Page 40: Parts

31 07610-003-78-18-n item qty description part number 1 1 gasket, suction casting 05330-003-75-89 2 1 gasket, pump suction 05330-003-75-87 3 1 pre-wash pump suction weldment 05700-003-82-27 4 1 strainer, pre-wash pump 05700-003-81-28 used on all pre-wash tanks and all steam-heated tanks part number ...

Page 41: Parts

32 07610-003-78-18-n voltage phase kw part number contactor 208 1 15 04540-121-68-45 05945-003-73-22 230 1 15 04540-121-68-46 05945-003-73-22 208 3 15 04540-121-68-45 05945-003-75-02 230 3 15 04540-121-68-46 05945-003-75-02 460 3 15 04540-121-68-47 05940-003-75-02 208 1 18 04540-121-79-30 05945-003-...

Page 42: Parts

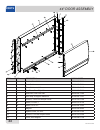

33 07610-003-78-18-n part number description qty item 05700-003-72-32 f-bracket, door guide 2 1 09330-003-73-94 door guide 2 2 05700-003-76-87 w-door weldment 44 1 3 09330-003-73-83 end piece, door right side 1 4 09330-003-73-84 end piece, door left side 1 5 05700-003-72-51 w-door stop & support wel...

Page 43: Parts

34 07610-003-78-18-n part number description qty item 05700-003-72-32 f-bracket, door guide 2 1 09330-003-73-94 door guide 2 2 05700-003-80-32 w-door weldment, 22 pre-wash 1 3 09330-003-73-83 end piece, door right side 1 4 09330-003-73-84 end piece, door left side 1 5 05700-003-82-50 w-door stop & s...

Page 44: Parts

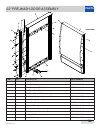

35 07610-003-78-18-n 7 8 1 4 2 3 7 5 3 6 door spring assembly 05700-003-77-49 44" wash doors use 2 assemblies 22" pre-wash doors use 1 assembly item qty description part number 1 1 casting, door spring mount 09515-003-73-78 2 1 spring, door 05315-002-67-29 3 2 spindle, door spring 05700-002-67-28 4 ...

Page 45: Parts

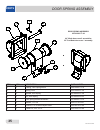

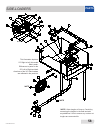

36 07610-003-78-18-n 1 3 2 4 2 5 6 7 8 2 6 item qty description part number 1 1 strainer, inlet, 1/2" 04730-217-01-10 2 3 nipple, 1/2" close, brass 04730-207-15-00 3 1 tee, brass, 1/2" x 1/2" x 1/2" 04730-211-27-00 4 1 regulator, 1/2" 04820-100-04-07 5 1 valve, 1/2" npt brass, 24vdc coil 04810-003-7...

Page 46: Parts

37 07610-003-78-18-n 5 3 1 2 1 7 4 8 6 item qty description part number 1 2 elbow, 90 degree, 1/2" brass 04730-206-08-00 2 1 vacuum breaker, 1/2" vacuum breaker repair kit 04820-003-06-13 06401-003-06-23 3 1 nipple, 1/2" close, brass 04730-207-15-00 4 1 gasket, rinse manifold 05330-003-75-91 5 1 val...

Page 47: Parts

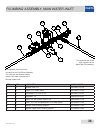

38 07610-003-78-18-n 1 2 4 5 6 12 3 11 10 7 8 7 5 9 7 10 7 11 12 3 3 3 standard pre-wash fill plumbing pre-wash fill plumbing with optional cold water fill item qty description part number 1 1 tube weldment, tank fill 05700-003-76-81 2 1 gasket, rinse manifold 05330-003-75-91 3 4 (6)* locknut, 1/4"-...

Page 48: Parts

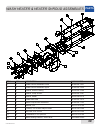

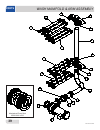

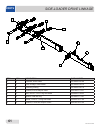

39 07610-003-78-18-n 1 2 4 5 4 6 7 13 8 9 14 14 10 11 11 10 12 14 13 3 mechanical pump seal 05330-002-34-22 parts wash manifold & arm assembly.

Page 49: Parts

40 07610-003-78-18-n item qty description part number 1 1 pump & motor assembly see table below 2 1 gasket, pump suction 05330-003-75-87 3 1 gasket, pump discharge 05330-003-75-88 4 2 hose clamp, range 2-9/16" to 3-1/2" 04730-003-15-40 5 1 hose, wash pump discharge 05700-003-77-62 6 1 (l-r machines)...

Page 50: Parts

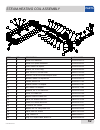

41 07610-003-78-18-n 1 1 2 2 3 4 5 4 6 16 15 9 8 11 16 13 9 12 8 9 12 8 11 14 16 8 10 10 7 9 8 15 16 5 4 4 3 8 illustrates parts for a left to right pre-wash illustrates parts for a right to left pre-wash mechanical pump seal 05330-002-34-22 parts pre-wash manifold & arm assemblies.

Page 51: Parts

42 07610-003-78-18-n item qty description part number 1 1 pump & motor assembly see table below 2 1 gasket, pump suction 05330-003-75-87 3 1 gasket, pump discharge 05330-003-75-88 4 2 hose clamp, range 2-9/16" to 3-1/2" 04730-003-15-40 5 1 hose, wash pump discharge 05700-003-77-62 6 1 lower manifold...

Page 52: Parts

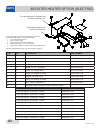

43 07610-003-78-18-n rinse injector connections p: pressure switch s: sanitizer r: rinse aid note 1 note 2 5 14 16 3 4 17 22 22 21 20 23 18 8 1 9 8 15 7 1 2 1 19 16 6 12 10 10 11 5 parts rinse assembly.

Page 53: Parts

44 07610-003-78-18-n item qty description part number 1 3 elbow, 90 deg., 1/2" brass 04730-206-08-00 2 1 vacuum breaker, 1/2" 04820-003-06-13 3 1 upper rinse arm 05700-003-76-02 4 1 lower rinse arm 05700-003-76-04 5 1 rinse manifold 05700-003-76-79 6 1 rinse injector (l-r units) (r-l units) 05700-00...

Page 54: Parts

45 07610-003-78-18-n pawl bar weldment and pawl dogs arranged for all 44" units pawl bar weldment and pawl dogs arranged for all 66" units pawl bar weldment for all 44" units pawl bar weldment for all 66" units 2 1 6 3 4 3 5 typical pawl dog with hardware item qty description part number 1 1 pawl ba...

Page 55: Parts

46 07610-003-78-18-n pawl bar weldment and pawl dogs arranged for all 44" units pawl bar weldment and pawl dogs arranged for all 66" units pawl bar weldment for all 44" units pawl bar weldment for all 66" units 2 1 item qty description part number 1 1 pawl bar bracket weldment 05700-003-74-39 2 2 sc...

Page 56: Parts

47 07610-003-78-18-n drive rod hole cover 05700-003-75-68 pawl bar drive linkage 09515-021-87-73 item qty description part number 1 1 top guide block 05700-011-69-49 2 1 bottom guide block 05700-011-69-50 3 1 pawl bar gutter weldment 05700-021-66-86 4 1 drive gutter gasket (not shown) 05330-011-68-5...

Page 57: Parts

48 07610-003-78-18-n 2 3 6 5 1 8 4 7 item qty description part number 1 1 rack paddle weldment 05700-003-76-71 2 1 bumper, rack paddle 09330-003-74-82 3 2 screw, 1/4-20 x 7/8" s/s 05305-274-05-00 4 2 locknut, 1/4-20 low profile w/nylon insert 05310-374-02-00 5 1 locknut, 1/4-20 hex w/nylon insert 05...

Page 58: Parts

49 07610-003-78-18-n 4 1 2 3 7 8 5 6 rinse paddle assembly for left-to-right units rinse paddle weldment for right-to-left units (all other parts are the same regardless of direction) 1 item qty description part number 1 1 rinse paddle weldment (left-to-right) (right-to-left) 05700-003-81-91 05700-0...

Page 59: Parts

50 07610-003-78-18-n 1 3 6 6 4 5 5 2 1 3 6 6 4 1 2 3 7 8 5 6 item qty description part number 1 1 drain handle 05700-003-83-66 2 1 drain standpipe (overflow) 05700-003-75-55 3 2 drain handle bracket 05700-003-83-67 4 2 drain standpipe 05700-003-82-76 5 1 o-ring 05330-400-05-00 6 2 locknut, 1/4-20 he...

Page 60: Parts

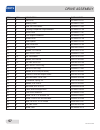

51 07610-003-78-18-n num revision control# orig drwn by date parts list rev: part no: scale: title: drawn by: date: date: date: checked by: approved by: part to be free from all burrs and sharp edges do not scale drawing this print is the property of jackson wws,inc. And is subject to recall and ret...

Page 61: Parts

52 07610-003-78-18-n drive motor guard 05700-003-79-45 start switch bracket 05700-003-74-65 fill tube bracket 05700-003-79-55 conduit bracket 05700-003-77-87 limit switch bracket 05700-021-71-18 upper drive support bracket 05700-003-77-18 panel bracket, left 05700-003-78-13 lower drive support brack...

Page 62: Parts

53 07610-003-78-18-n front rack rail 05700-003-79-09 (44" l-r) 05700-003-79-09 (44" r-l) 05700-003-81-93 (66" l-r) 05700-003-81-89 (66" r-l) rear rack rail 05700-003-77-54 (44" units) 05700-003-80-57 (66" units) curtain bracket, end 05700-003-77-60 curtain bracket, middle 05700-003-77-61 strainer, w...

Page 63: Parts

54 07610-003-78-18-n item qty description part number 1 2 1 1 ventilation cowl ventilation cowl, left side (for door accent panel option) ventilation cowl, right side (for door accent panel option) 05700-003-77-50 05700-003-75-77 05700-003-75-78 2 2 ventilation scoop 05700-003-75-74 3 2 ventilation ...

Page 64: Parts

55 07610-003-78-18-n 1a 7 5 10 9 8 step 1 step 2 step 3 item qty description part number 1a 1b 1 1 ventilation cowl w/cutout for left side loader ventilation cowl w/cutout for right side loader 05700-003-84-67 05700-003-84-66 2 1 ventilation scoop (not shown) 05700-003-75-74 3 1 ventilation duct ada...

Page 65: Parts

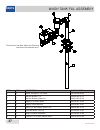

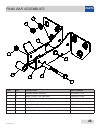

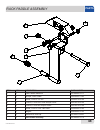

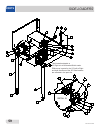

56 07610-003-78-18-n 24 6 3 17 23 15 13 9 26 14 22 20 21 12 10 19 29 29 28 16 13 14 16 13 8 25 11 4 5 20 11 27 21 13 16 2 11 1 14 15 13 17 13 7 30 drive assembly parts.

Page 66: Parts

57 07610-003-78-18-n item qty description part number 1 1 hub, drive 05700-011-67-97 2 1 bearing, roller 03120-011-71-81 3 1 gear, 50/1 drive motor 06105-011-71-88 4 2 coupling & expansion legs weldment 05700-021-67-50 5 1 block, pillow 03120-021-71-87 6 1 drive support weldment 05700-003-75-61 7 1 ...

Page 67: Parts

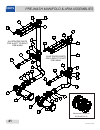

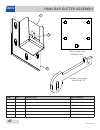

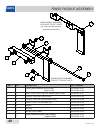

58 07610-003-78-18-n detail a 13 14 16 18 19 17 17 16 4 5 2 1 3 4 16 14 16 15 14 16 a 25 31 30 29 28 26 27 26 32 33 32 33 32 this illustration depicts a 23" right to left unhooded side-loader. Differences in parts for the 23" left to right and both directions of the 30" side-loaders are reflected in...

Page 68: Parts

59 07610-003-78-18-n 6 16 8 4 15 1 16 9 11 12 10 6 7 8 23 16 b 7 16 detail b 21 24 24 20 14 16 14 16 23 16 22 this illustration depicts a 23" right to left unhooded side-loader. Differences in parts for the 23" left to right and both directions of the 30" side-loaders are reflected in the parts list...

Page 69: Parts

60 07610-003-78-18-n item qty description part number 1 1 tub weldment, 23" side-loader l-r tub weldment, 23" side-loader r-l tub weldment, 30" side-loader l-r tub weldment, 30" side-loader r-l 05700-003-84-59 05700-003-84-58 05700-003-88-46 05700-003-88-39 2 1 rack support l-r 05700-003-90-00 3 1 s...

Page 70: Parts

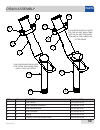

61 07610-003-78-18-n 5 4 6 7 8 3 1 2 item qty description part number 1 1 pawl bar, side-loader 05700-021-86-88 2 1 drive linkage, side-loader 05700-001-99-16 3 3 pawl dog w/wing 05700-021-86-79 4 3 locknut, 3/8-16 w/nylon insert 05310-011-72-55 5 3 bolt, 3/8-16 x 1-3/4" long hex head 05306-011-36-9...

Page 71: Parts

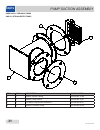

62 07610-003-78-18-n 1 5 4 6 3 2 7 8 8 9 10 11 12 13 14 13 15 16 17 18 20 19 13 12 11 10 9 8 8 item qty description part number 1 1 steam coil weldment 05700-003-83-70 2 3 steam coil spacer weldment 05700-003-83-33 3 3 plate, steam coil spacer 05700-003-83-32 4 6 sleeve, 1/4" x 5/8" long 05700-003-8...

Page 72: Parts

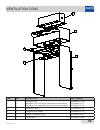

63 07610-003-78-18-n 1 2 3 4 5 6 7 8 9 10 11 this hose connects to the main inlet plumbing solenoid valve. This hose connects to the final rinse plumbing. Booster heater part number 12 kw (40 degree f rise) 208v, 3-phase 04540-003-76-58 12 kw (40 degree f rise) 240v, 3-phase 04540-003-76-60 12 kw (4...

Page 73: Parts

64 07610-003-78-18-n 27 30 26 22 29 21 31 26 32 24 28 26 33 26 34 26 30 26 25 23 22 21 20 10 19 15 14 11 12 13 14 18 17 15 16 16 15 11 14 13 12 11 10 9 4 5 4 4 7 8 2 24 17 1 2 3 6 item qty description part number 1 1 steam booster heater, st-t120 04420-002-43-94 2 2 u-bolt, 1/2-13 thread, zinc coate...

Page 74: Parts

65 07610-003-78-18-n item qty description part number 6 1 elbow, 90 deg. 3/4" black iron 04730-906-10-34 7 1 reducer, 1-1/2" x 3/4" black iron 04730-002-36-81 8 1 platform, j120 steam booster 05700-002-36-72 9 1 regulating valve, 3/4" 04820-100-01-06 10 2 nipple, 3/4" x 6" long brass 05700-001-26-74...

Page 75: Parts

66 07610-003-78-18-n item qty description part number 1 1 cover, blower assembly 05700-004-01-97 2 1 ventilation duct adapter, weldment 05700-003-75-73 3 1 door assembly, blower 05700-004-00-32 4 1 panel weldment, exhaust top 05700-004-00-61 5 1 panel, blower tub side right 05700-004-03-93 6 1 panel...

Page 76: Parts

67 07610-003-78-18-n 16 13 12 10 9 8 7 5 4 3 2 1 main electrical connection 6 15 208-230v blower control box does not include the transformer (#2) and power supply (#3). Item qty description part number 1 1 terminal block, 115a, 600v 05940-004-08-35 2 1 transformer, 208/230/460 to 120 (0.05 kva) 059...

Page 77: Parts

68 07610-003-78-18-n item qty description part number 1 1 blower, 208-230v, 60hz dual cage blower, 265-460v, 60hz dual cage 06105-002-72-15 06105-002-88-36 2 2 heater, 4.5kw, 208v blower air 04540-002-74-29 3 1 blower heater box, weldment 05700-004-00-72 4 8 bolt, hex head 1/4-20 x 3/4" 05305-274-04...

Page 78: Schematics

69 07610-003-78-18-n use this schematic for the following booster heater options: • 208v, 60hz, 3-phase, 12 kw, 40° rise • 230v, 60hz, 3-phase, 12 kw, 40° rise • 460v, 60hz, 3-phase, 12 kw, 40° rise • 208v, 60hz, 3-phase, 18 kw, 70° rise • 230v, 60hz, 3-phase, 18 kw, 70° rise • 460v, 60hz, 3-phase, ...

Page 79: Schematics

70 07610-003-78-18-n use this schematic for the following booster heater options: • 208v, 60hz, 1-phase, 12 kw, 40° rise • 230v, 60hz, 1-phase, 12 kw, 40° rise booster heater, 1-phase, 12kw schematics.

Page 80: Schematics

71 07610-003-78-18-n use this schematic for the following booster heater options: • 208v, 60hz, 1-phase, 18 kw, 70° rise • 230v, 60hz, 1-phase, 18 kw, 70° rise booster heater, 1-phase, 18kw schematics.

Page 81: Schematics

72 07610-003-78-18-n steam booster heater schematics.

Page 82: Schematics

73 07610-003-78-18-n 4 2 1 3 3 item qty description part number 1 1 cyclic temperature board 06685-002-74-86 2 1 gauge cover, red 05700-002-75-62 3 8 nut, thumb 6-32 nylon 05310-002-83-12 4 1 decal, temperature display 09905-003-78-29 5 2 (44") 3 (66") rtd temperature probe (not shown) 06680-002-16-...

Page 83: Schematics

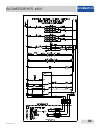

74 07610-003-78-18-n dc+ dc- table limit c/o door signal drive c/o plc 9 a1 a2 14 a2 a1 14 9 a2 a1 9 14 a1 a2 9 14 12 14 a1 a2 9 44 i2 r2 plc1 r1 r3 r6 r4 from door switch ensure red/white to #12 of r3 is connected here red / white red / white red / white red / black red red / black red photo-eye ca...

Page 84: Schematics

75 07610-003-78-18-n 208/230/460 volt, 60 hz, 3-phase 44" electrically-heated schematics.

Page 85: Schematics

76 07610-003-78-18-n 208/230 volt, 60 hz, 1-phase 44" electrically-heated schematics.

Page 86: Schematics

77 07610-003-78-18-n 208/230/460 volt, 60 hz, 3-phase 44" steam-heated schematics.

Page 87: Schematics

78 07610-003-78-18-n 208/230 volt, 60 hz, 1-phase 44" steam-heated schematics.

Page 88: Schematics

79 07610-003-78-18-n 208/230/460 volt, 60 hz, 3-phase 66" electrically-heated schematics.

Page 89: Schematics

80 07610-003-78-18-n 208/230 volt, 60 hz, 1-phase 66" electrically-heated schematics.

Page 90: Schematics

81 07610-003-78-18-n 208/230/460 volt, 60 hz, 3-phase 66" steam-heated schematics.

Page 91: Schematics

82 07610-003-78-18-n 208/230 volt, 60 hz, 1-phase 66" steam-heated schematics.

Page 92: Schematics

83 07610-003-78-18-n blower/dryer, 240v schematics.

Page 93: Schematics

84 07610-003-78-18-n blower/dryer, 480v schematics.

Page 94

85 85 jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com crew ® manual • rev n • 07610-003-78-18 • issued: 07-27-10 • revised: 8-22-16.