- DL manuals

- Jackson

- Dishwasher

- DISHSTAR HT-E

- Installation, Operation And Service Manual

Jackson DISHSTAR HT-E Installation, Operation And Service Manual - Parts

07610-004-43-79-D

40

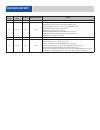

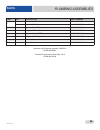

PLUMBING ASSEMBLIES

PARTS

ITEM

QTY

DESCRIPTION

PART NUMBER

1

1

Vacuum Breaker, 1/2" Brass

04820-003-06-13

2

2

Nipple, 1/2" Brass, 2" Long

04730-207-19-00

3

2

Elbow, 90-Degree, 1/2" Street Brass

04730-206-08-00

4

1

Tee, 1/2" x 1/2" x 1/4"

04730-002-22-56

5

2

Union, 1/2" x 1/2" Brass

04730-003-62-44

6

1

Complete Rinse Injector Assembly

05700-004-43-86

1

Rinse Injector

09515-004-22-73

7

1

Gasket, Rinse Manifold

05330-003-75-91

8

1

Pressure Transducer

05945-004-17-01

9

1

Elbow, 90-Degree, 1/4" x 1/4" Brass

04730-003-77-83

10

1

Adapter, Male

04730-401-03-01

11

1

Copper Tube, 1/2" x 15 1/2"

05700-000-97-23

12

1

Union

04730-412-05-01

13

1

Adapter, Male, 1/2" Fitting

04730-011-59-53

14

2

Elbow, 90-Degree, 1/2" Brass

04730-011-42-96

15

3

Nipple, 1/2" Brass

04730-207-15-00

16

1

Tee, 1/2" Brass

04730-211-27-00

17

1

Compression Fitting, 1/2" x 1/4"

04730-004-36-38

18

1

Thermistor Probe, 4" with 18" Cable

06685-004-34-58

19

1

Nipple, Brass 1/2" x 3"

04730-004-20-10

20

1

Harness, Transducer

05700-004-33-62

21

2

Plug, 1/8" Brass

04730-209-07-37

22

1

Adapter

05700-002-29-75

23

1

Thermostat Fitting, Brass

05700-011-73-73

24

1

Nut, Tube, 1/8"

04730-011-59-45

25

1

Fitting, Outlet Elbow

04820-111-51-18

26

1

Check Valve

04820-111-51-14

27

2

Screw, 1/4-20 x 1"

05305-011-81-58

Summary of DISHSTAR HT-E

Page 1

Dishst ar ht -e installation, operation, and service manual dishstar ® ht-e manual • 07610-004-43-79-d dishstar ® series undercounter dishmachines ®.

Page 3

Manufacturer's warranty one year limited parts and labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from date of purchase, but in no event to exceed (18) ...

Page 4: Revision History

Revision letter revision date made by applicable ecns details a 4-11-17 jh n/a initial release of the manual. B 4-27-17 jh n/a corrected pg. 2. Updated pg. 4 due to heaters not running simultaneously. Added description of the three cycles to the operation section. Replaced item #14 on pg. 27 with ne...

Page 5: Dishstar

I dishstar ® ht-e undercounter dishmachine; high-temperature, hot-water sanitizing, with a booster tank and detergent and rinse-aid chemical feeder pumps. The manufacturer provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this man...

Page 6: Table of Contents

Ii table of contents guides symbols ............................................................................................................................................ 1 abbreviations & acronyms ...................................................................................................

Page 7: Table of Contents

Iii table of contents trouble shooting common problems ......................................................................................................................... 20 parts terminal block box, 208/230 v .......................................................................................

Page 8: Guides

1 07610-004-43-79-d guides symbols ! Caution ! Warning notice - risk of injury to personnel. - risk of damage to equipment. - risk of electrical shock. - lockout electrical power. - reference data plate. - important note. I - caustic chemicals. Abbreviations & acronyms ansi - american national stand...

Page 9: Specifications

07610-004-43-79-d 2 specifications machine dimensions 2 6 [6 6 0 m m ] 1 6 3 /4 [4 2 6 m m ] (w it h d o o r o p e n ) 1/4 [7 mm] 24 1/4 [615 mm] 1 4 [3 6 2 m m ] d is h c le a ra n c e 3 3 5 /16 [8 4 6 m m ] 6 5/8 [169 mm] 7 1/2 [190 mm] 3 7/8 [99 mm] 8 [202 mm] 9 3/4 [246 mm] 3 3/8 [87 mm] 3 [76 m...

Page 10: Specifications

3 07610-004-43-79-d dishstar ® ht-e operating capacity: racks per hour 27 dishes per hour 675 glasses per hour 972 tank capacity (gallons): wash tank 3 rinse tank 1 always refer to the machine data plate for specific electrical and water requirements. The material provided on this page is for refere...

Page 11: Specifications

07610-004-43-79-d 4 all electrical ratings provided in this manual are for reference only. Always refer to the machine data plate to get exact electrical information for this machine. All electrical work performed on machines should be done in accordance with applicable local, state, territorial, an...

Page 12: Installation

5 07610-004-43-79-d instructions installation water supply connections: water hardness higher than 5 gpg before installing the machine, check packaging and machine for damage. Damaged packaging might be an indication of damage to the machine. If there is any type of damage to both packaging and unit...

Page 13: Installation

07610-004-43-79-d 6 if water hardness tests at 5 gpg or lower, install the water supply line (1/2” id pipe size minimum) to the machine’s incoming water connection point using copper pipe (or order the 1/2” id flexible hose kit offered by the manufacturer). It is recommended that a water shut-off va...

Page 14: Installation

7 07610-004-43-79-d electrical and grounding conductors must comply with the applicable portions of the national electric code ansi/nfpa 70 (latest edition) and/or other electrical codes. The data plate is located on the left-front of the dishmachine. Refer to the data plate for machine operating re...

Page 15: Chemical Feeder

07610-004-43-79-d 8 chemical feeder equipment priming chemical feeder pumps warning! Some of the chemicals used in dishwashing may cause chemical burns if they come in contact with skin. Wear protective gear when handling these chemicals. If any skin comes in contact with these chemicals, immediatel...

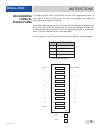

Page 16: Programming

9 07610-004-43-79-d programming chemical feeder pumps instructions installation 3. To prime the rinse-aid pump, press the ii button and hold for one minute. The amount of rinse-aid might need to be adjusted depending on water hardness and results. 4. Please refer to to the section below for instruct...

Page 17: Programming

07610-004-43-79-d 10 programming chemical feeder pumps instructions installation to change any other values, you will have to return to the programming mode. To revert back to a previous setting, you must return to that option and change the parameter back to the previous setting. Once in the progra...

Page 18: Operation

11 07610-004-43-79-d operating instructions operation before operating the machine , verify the following: 1. Strainers are in place and clean. 2. Wash and rinse arms are screwed securely into place and end-caps are tight. 3. Wash and rinse arms rotate freely. 4. Chemical levels are correct. To ener...

Page 19: Washing A Rack

07610-004-43-79-d 12 proper ware preparation helps ensure good results and fewer re-washes. If not done properly, ware might not come out clean and the efficiency of the dishmachine will be reduced. Scraps should always be removed from ware before being loaded into a rack. Pre-rinsing and pre-soakin...

Page 20: Operation

13 07610-004-43-79-d 6. Press the “start” button and the machine will begin the wash cycle. 7. After the wash cycle is complete, the machine will automatically enter the rinse cycle. 8. Once the rinse cycle is complete, the machine will automatically enter the sanitize cycle. 9. After the sanitize c...

Page 21: Operational

07610-004-43-79-d 14 1. Close the door and turn the machine off by pushing the “power” button. 2. The drain pump will activate and empty the machine of water. 3. When draining stops, remove and clean the strainers and set aside. 4. Unscrew the wash and rinse arms from their manifolds. 5. Verify the ...

Page 22: Shutdown &

15 07610-004-43-79-d 6. Replace end-caps and use a screwdriver to ensure they are tight. 7. Ensure the float is free of debris. 8. Spray or wipe out interior of machine. 9. Replace wash and rinse arms. 10. Replace the strainers and ensure they are laying flat. 11. Use stainless steel polish to clean...

Page 23: Operation

07610-004-43-79-d 16 deliming operation in order to maintain the machine at its optimum performance level, lime and corro- sion deposits must be removed. The frequency for deliming will be based on water conditions. A deliming solution is available from your chemical supplier. Read and follow all in...

Page 24: Detergent

17 07610-004-43-79-d detergent usage and water hardness are two factors that contribute greatly to how efficiently this machine operates. Using detergent in the proper amount can become a source of substantial savings. A qualified water treatment specialist can determine what is needed for maximum e...

Page 25: Maintenance

07610-004-43-79-d 18 preventative maintenance maintenance the manufacturer of this machine highly recommends that any maintenance and repairs not specifically discussed in this manual only be performed by qualified service personnel. Performing maintenance on the machine may void a warranty. By foll...

Page 26: Maintenance

19 07610-004-43-79-d preventative maintenance maintenance 5. Do not overfill racks. 6. Ensure that glasses are placed upside-down in the rack. 7. Ensure that all chemicals being injected into machine have been verified at the correct concentrations. 8. Clean the machine at the end of every workday (...

Page 27: Troubleshooting

07610-004-43-79-d 20 problem possible cause remedy water overflow from bottom of door. 1. Clogged drain. 2. Machine not level. 3. Excessive inlet pressure. 4. Detergent foaming. 5. Wash or rinse arm end-cap missing. 1. Remove obstruction. 2. Level machine or increase height to the front. 3. Install ...

Page 28: Troubleshooting

21 07610-004-43-79-d rinse water runs continuously with breaker turned off. 1. Defective plunger in solenoid valve. 2. Defective diaphragm in solenoid valve. 1. Replace plunger. 2. Replace diaphragm. Wash temperature not within range. 1. Water level low. 2. Rtd setpoint too low. 3. Defective rtd. 4....

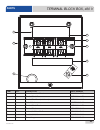

Page 29: Parts

07610-004-43-79-d 22 item qty description part number 1 1 power connection decal 09905-011-47-35 2 1 terminal block box 05700-003-27-69 1 terminal box cover (not shown) 05700-003-27-70 3 1 strain relief 05975-003-37-56 4 1 terminal block track 05700-000-43-60 5 2 terminal block 05940-500-02-19 6 2 l...

Page 30: Parts

23 07610-004-43-79-d item qty description part number 1 1 power connection decal 09905-011-47-35 2 1 terminal block box 05700-004-44-79 1 terminal box cover (not shown) 05700-004-44-80 3 1 strain relief 05975-210-03-00 4 1 terminal block track 05700-004-44-72 5 3 terminal block 05940-500-02-19 6 2 l...

Page 31: Parts

07610-004-43-79-d 24 control kick panel parts item qty description part number complete control kick panel assembly 05700-004-41-87 1 1 control kick panel 05700-004-41-86 2 1 display assembly 05700-004-19-47 3 1 communication cable 05700-004-33-64 1 2 3.

Page 32: Parts

25 07610-004-43-79-d electrical panel, 208/230 v parts item qty description part number complete electrical panel assembly, 208/230 v 05700-004-42-07 1 1 electrical panel 05700-004-40-63 2 3 contactor, 208/230 v 05945-002-74-20 3 13 screw, 10-32 x 5/8" 05305-003-02-12 4 3 screw, 10-32 x 1” 05305-002...

Page 33: Parts

07610-004-43-79-d 26 electrical panel, 460 v parts item qty description part number complete electrical panel assembly, 460 v 05700-004-44-50 1 1 electrical panel 05700-004-40-63 2 3 contactor, 460 v 05945-111-60-07 3 2 end-cap, contactor 05940-111-60-30 4 1 dinrail, 7 3/4" 05700-002-79-13 5 6 screw...

Page 34: Parts

27 07610-004-43-79-d parts chemical feeder pump assembly 1 9 6 5 4 3 7 10 11 12 14 16 17 18 19 8 2 13 15 1 2 complete peri-pump panel assembly, 208/230 v 05700-004-42-08 complete peri-pump panel assembly, 460 v 05700-004-44-45.

Page 35: Parts

07610-004-43-79-d 28 item qty description part number 1 2 stiffener, chemical tube 05700-002-66-49 2 1 chemical port assembly 05700-004-30-86 3 1 tubing, red, 1/4" x 120" 05700-011-37-15 4 1 tubing, red, 1/4" x 80" 05700-011-37-14 5 1 tubing, clear, 1/8" x 120" 05700-002-76-14 6 1 tubing, clear, 1/8...

Page 36: Parts

29 07610-004-43-79-d door assembly parts (12 plc's) (6 plc's) (2 plc's) (2 plc's) (2 plc's) (12 plc's) (3 plc's) (2 plc's) (2 plc's) (2 plc's) (3 plc's) 1 15 8 9 19 4 17 14 7 6 13 2 10 11 18 16 12 20 21 18 7 22 23 24 21 5 3 15 18 11 10 2 21.

Page 37: Parts

07610-004-43-79-d 30 door assembly parts item qty description part number 1 1 outer door weldment 05700-004-36-55 2 2 screw, 10-32 x 1/4" 05305-173-01-00 3 2 bolt, 1/4-20 x 3/8" hex 05305-274-20-00 4 2 locknut, 6-32 hex with nylon insert 05310-373-03-00 5 2 washer, 1/4-20 id 05311-174-01-00 6 1 gask...

Page 38: Parts

31 07610-004-43-79-d miscellaneous door components parts 1 2 3 10 6 7 8 9 5 4.

Page 39: Parts

07610-004-43-79-d 32 miscellaneous door components parts item qty description part number 1 1 switch mounting plate assembly 05700-003-33-54 2 1 door spring 05700-003-32-85 3 1 cover, left hinge weldment 05700-004-36-80 4 1 cover, right hinge weldment 05700-004-36-81 hinge components secured with lo...

Page 40: Parts

33 07610-004-43-79-d wash & motor assembly parts 3 4 5 5 6 5 1 2 7 5 5 10 11 12 13 13 15 15 16 16 15 17 18 19 8 9 13 13 14.

Page 41: Parts

07610-004-43-79-d 34 item qty description part number 1 1 wash arm assembly 05700-021-39-23 2 1 motor support 05700-004-40-61 3 1 wash halo 05700-004-42-21 4 2 pipe clamp 05700-000-35-06 5 5 wash arm end-cap 05700-003-31-59 6 2 screw, 1/4-20 x 1/2" 05307-011-36-96 7 4 locknut, 1/4-20 hex with nylon ...

Page 42: Parts

35 07610-004-43-79-d item qty description part number 1 1 complete rinse manifold assembly 05700-004-40-58 2 1 pipe clamp 05700-000-35-06 3 4 rinse arm end-cap 04730-111-60-41 4 2 complete rinse arm assembly 05700-004-39-39 2 rinse arm 05700-004-38-75 5 3 washer, rinse arm 05330-011-42-10 6 2 bearin...

Page 43: Parts

07610-004-43-79-d 36 plumbing options parts pressure regulator option water arrestor, 1/2” 06685-100-05-00 tee, 1/2” x 1/2” x 1/2” 04730-211-27-00 nipple, 1/2” npt, brass 04730-207-15-00 shock absorber (water arrestor) option water pressure regulator, 1/2” 05700-100-04-07 water arrestor repair kit (...

Page 44: Parts

37 07610-004-43-79-d plumbing assemblies parts 6 5 4 3 2 7 1.

Page 45: Parts

07610-004-43-79-d 38 complete inlet plumbing assembly, 208/230 v 05700-004-09-03 complete inlet plumbing assembly, 460 v 05700-004-44-40 item qty description part number 1 1 valve, 1/2", 208/230 v 04810-003-71-56 1 valve, 1/2", 460 v 04810-003-71-55 2 1 union, 1/2" x 1/2" brass 04730-003-62-44 3 1 n...

Page 46: Parts

39 07610-004-43-79-d plumbing assemblies parts 1 2 3 4 2 5 6 7 8 9 10 11 12 13 14 18 16 15 15 5 3 20 6 27 26 25 24 23 22 21 complete plumbing assembly 05700-004-43-02 19 17 14 15.

Page 47: Parts

07610-004-43-79-d 40 plumbing assemblies parts item qty description part number 1 1 vacuum breaker, 1/2" brass 04820-003-06-13 2 2 nipple, 1/2" brass, 2" long 04730-207-19-00 3 2 elbow, 90-degree, 1/2" street brass 04730-206-08-00 4 1 tee, 1/2" x 1/2" x 1/4" 04730-002-22-56 5 2 union, 1/2" x 1/2" br...

Page 48: Parts

41 07610-004-43-79-d rinse tank assembly parts 1 2 3 4 5 front of rinse tank 6 7 8 back of rinse tank 9.

Page 49: Parts

07610-004-43-79-d 42 item qty description part number 1 1 rinse tank, 208/230 v 05700-004-41-88 1 rinse tank, 460 v 05700-004-44-46 2 1 heater gasket 05330-011-47-79 3 1 rinse heater, 5.45 kw, 208-230 v 04540-004-45-12 1 rinse heater, 5.45 kw, 460 v 04540-121-65-99 4 4 lockwasher, split 5/16" 05311-...

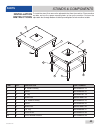

Page 50: Parts

43 07610-004-43-79-d stands & components parts to install the stand, first remove the adjustable feet from the machine. Place machine on table and use the square mounting holes to line-up the machine. Re-insert the adjustable feet through bottom of table top and tighten to lock machine to table. Ins...

Page 51: Parts

07610-004-43-79-d 44 miscellaneous parts parts 1 2 3 4 item qty description part number 1 1 rail, left rack 05700-031-37-88 2 1 rail, right rack 05700-031-37-88 3 1 splash shield 05700-003-33-51 4 1 strainer 05700-004-09-43 5 1 drain quench kit 06401-002-59-99 6 1 dual float switch 06680-121-70-16 7...

Page 52: Schematics

45 07610-004-43-79-d schematics programming header temperature sensor inputs t4 t2 t1 ac signals i1 i2 i3 i4 i5 analog input 24 vdc out / rs‐232 relay assignments k1 power k2 booster heater k3 wash heater k4 varies by model k5 varies by model k6 varies by model k7 varies by model k8 varies by model ...

Page 53: Schematics

07610-004-43-79-d 46 schematics gnd red r3 m1 blk blk l1 14 ga 14 ga l1 14 ga 14 ga 14 ga 14 ga l3 h2 hlrs wht/blk blu 4 1 6 r4 a b r2 8 r4 7 a r1 b 480 volts, 50/60 hz, 3-phase r3 t2 l2 l1 r2 t1 r2 t3 l3 t2 r2 l2 gry/wht wht red vio hlts i1 i2 i3 i4 delime drain close cycle 2/3 & extended cycle sta...

Page 54

Jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com dishstar ® ht-e manual • 07610-004-43-79-d.