- DL manuals

- Jackson

- Dishwasher

- Dynatemp

- Service Manual

Jackson Dynatemp Service Manual

Summary of Dynatemp

Page 1

Dyna temp ® installation, operation, and service manual dynatemp ® manual • rev a • 07610-004-29-29 • issued: 07-27-2016 • revised: n/a dynatemp ® series door-type dishmachines.

Page 3

Manufacturer's warranty one year limited parts and labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation, for a period of (1) one year from date of purchase, but in no event to exceed (18)...

Page 4: Revision History

I revision letter revision date made by applicable ecns details a 07-27-16 jh n/a initial release of the manual. Revision history.

Page 5: Nomenclature

Ii model: serial no.: installation date: service rep. Name: phone number: nomenclature jackson wws, inc. Provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please hav...

Page 6: III

Iii table of contents specifications machine dimensions 1 table dimensions 2 operating capacities 3 electrical requirements 4 installation/operation instructions installation instructions 6 operating instructions 9 detergent control 13 deliming instructions 14 display instructions 15 maintenance pre...

Page 7: Table of Contents

Iv table of contents schematics dynatemp 208/230v, 50/60 hz, 1/3 phase 53 dynatemp 460/480v, 60 hz, 3 phase 54 dynatemp s 208/230v, 50/60 hz, 1/3 phase 55 schematic options drain quench option 56 addendum phase conversion kit 57 display template 58 exhaust fan wiring 59 symbols ! Caution ! Warning n...

Page 8: Specifications

1 07610-004-29-29-a legend a - drain 1-1/2" npt b - water inlet 1/2" npt c - electrical connection d - detergent connection e - rinse aid connection all dimensions from the floor can be increased 2" using the machine's adjustable feet. Specifications dynatemp machine dimensions legend a- drain 1-1/2...

Page 9: Specifications

2 07610-004-29-29-a specifications table dimensions 20 1/2” (52.1 cm) opening 25 1/4” (64.1 cm) 20 1/2” (52.1 cm) opening 25 1/4” (64.1 cm) 2 1/2” (6.4 cm) 4” (10.2 cm) minimum 4” (10.2 cm) minimum 2 1/2” (6.4 cm) 3/4” (1.9 cm) 20 1/2” (52.1 cm) 1 1/2” (3.81 cm) roll table dimensions connection to d...

Page 10: Specifications

3 07610-004-29-29-a performance/capabilities operating capacity: racks per hour 57 dishes per hour 1450 glasses per hour 1450 minimum operating cycle (seconds): cycle 1 wash time 40 cycle 2 wash time 90 cycle 3 wash time 220 rinse time 11 dwell time 7 cycle 1 total time 58 cycle 2 total time 108 cyc...

Page 11: Specifications

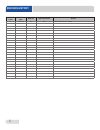

4 07610-004-29-29-a electrical requirements specifications local codes may require more stringent protection than what is displayed here. Always verify with your electrical service contractor that your circuit protection is adequate and meets all applicable national and local codes. Numbers in this ...

Page 12: Installation

5 07610-004-29-29-a electrical requirements installation volts phase hz rinse heater ratings total amps typical electrical circuit 208 1 50 n/a 28 a 35 a 230 1 50 n/a 35 a 45 a dynatemp nb electrical characteristics: 208 3 50 n/a 20 a 25 a 230 3 50 n/a 21 a 30 a 380 3 50 n/a 10 a 15 a 415 3 50 n/a 1...

Page 13: Installation

6 07610-004-29-29-a instructions installation before installing the unit, check the packaging and machine for damage. If the packaging is damaged, the machine might also be damaged. If there is damage to both the packaging and machine, do not throw away the packaging. The dishmachine has been inspec...

Page 14: Installation

7 07610-004-29-29-a instructions installation take care not to confuse static pressure with flow pressure! Plumbing check note: ensure that you have read the section entitled “plumbing the dishmachine” on the previous page before proceeding. Install the water supply line (1/2” id minimum) to the dis...

Page 15: Installation

8 07610-004-29-29-a electrical and grounding connections must comply with the applicable portions of the national electrical code ansi/nfpa 70 (latest edition) and/or other electrical codes. Disconnect electrical power supplies and place a tag at the disconnect switch to indicate that you are workin...

Page 16: Operation

9 07610-004-29-29-a operating instructions operation before operating the unit, verify the following: 1. The pan strainers and suction strainer are in place and are clean. 2. The standpipe and o-ring are installed. 3. The wash and rinse arms are screwed securely into place and the end-caps are tight...

Page 17: Operation

10 07610-004-29-29-a proper preparation of ware will help ensure good results and fewer re-washes. If not done properly, ware might not come out clean and the efficiency of the dishmachine will be reduced. Putting unscraped dishes into the machine affects its performance, so scraps should always be ...

Page 18: Operation

11 07610-004-29-29-a operation operating instructions at the end of the workday/shift: 1. Close the door. 2. When the unit completes the cycle, turn the unit off by pressing the power button. 3. Open the door. 4. Remove and clean the pan strainers and set aside. 5. Pull the drain handle to the open ...

Page 19: Operation

12 07610-004-29-29-a operation operating instructions 7. Unscrew the wash and rinse arms from their manifolds. 8. Verify the nozzles and arms are free from obstruction. If clogged, remove end- caps, clean nozzles with a brush, and flush with fresh water. 9. Wipe the inside of the unit out, removing ...

Page 20: Operation

13 07610-004-29-29-a operation detergent control detergent control detergent usage and water hardness are two factors that contribute greatly to how efficiently this dishmachine will operate. Using detergent in the proper amount can become a source of substantial savings. A qualified water treatment...

Page 21: Deliming

14 07610-004-29-29-a in order to maintain the dishmachine at its optimum performance level, lime and corrosion deposits must be removed. The frequency for deliming will be based on water conditions. A deliming solution is available from your chemical supplier. Read and follow all instructions on the...

Page 22: Operation

15 07610-004-29-29-a operation display instructions 1. When the unit is first powered on, it will go through a sequence to show all leds are working. 2. The unit will then go into standby mode. 3. Press the power button. 4. The display will show “heating” until the wash tank reaches the set temperat...

Page 23: Maintenance

16 07610-004-29-29-a preventative maintenance maintenance jackson highly recommends that any maintenance and repairs not specifically discussed in this manual be performed only by qualified service personnel. Performing maintenance on your dishmachine may void your warranty, lead to larger problems,...

Page 24: Troubleshooting

17 07610-004-29-29-a troubleshooting display programming programming to access programming, the unit should be on and not in cycle. The programming buttons (up-arrow, down-arrow, and select) are hidden on the display and are shown below outlined with red dots. There is a full-size display template a...

Page 25: Troubleshooting

18 07610-004-29-29-a display programming troubleshooting to access programming, the unit should be on and not in cycle. The programming buttons (up-arrow, down-arrow, and select) are hidden on the display and are shown below outlined with red dots. There is a full-size display template at the end of...

Page 26: Troubleshooting

19 07610-004-29-29-a fault codes troubleshooting display shows possible causes remedy “f1 service needed,” “no water in booster” 1. Low or no water pressure. 2. Faulty inlet valve or fill relay. 3. Contactor to booster heater not turning off. 4. Faulty temperature input (p12) on io module. 5. Faulty...

Page 27: Troubleshooting

20 07610-004-29-29-a “f6 service needed,” “no water in wash tank” 1. Low or no water pressure. 2. Faulty inlet valve or fill relay. 3. Contactor to wash heater not turning off. 4. Faulty temperature input (t1) on io module. 5. Faulty temperature probe (t1). 6. Faulty float switch allows heaters to o...

Page 28: Troubleshooting

21 07610-004-29-29-a f12 service needed – check booster thermo- stat faulty temperature probe (t3). Replace probe that connects to p13. F13 communication er- ror. Check 6-pin cable 1. Loose connection in 6-pin cable between display board and io module. 2. Faulty 6-pin cable between display board and...

Page 29: Troubleshooting

22 07610-004-29-29-a common problems troubleshooting problem possible causes remedy digital display does not illuminate after power button is pressed. 1. Service breaker tripped. 2. Machine not connected to power source. 3. Faulty power source. 1. Reset breaker. If it trips, again, contact an electr...

Page 30: Troubleshooting

23 07610-004-29-29-a common problems troubleshooting problem possible causes remedy rinse water is heated, but not reaching required temperature. 1. Faulty rinse heater. 2. Faulty temperature probe (t2- rinse injector, t3-rinse tank). 3. Io module is faulty. 1. Verify that element has very low resis...

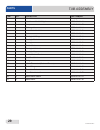

Page 31: Parts

24 07610-004-29-29-a control box assembly parts control box shown with cover (05700-004-27-52) removed. Item qty description part number 1 1 timer, universal 05945-003-75-23 2 2 nut, conduit black nylon 3/4" 05975-003-81-29 3 1 bracket, fuse strip 05700-002-42-03 4 1 fitting 05975-011-65-51 5 2 fitt...

Page 32: Parts

25 07610-004-29-29-a hood assembly parts 2 1 3 4 item qty description part number 1 1 hood 05700-004-20-68 2 4 pin, clevis 5/16 x 1-1/4 05315-004-07-24 3 2 roller, bottom hood lateral 09330-004-07-30 4 2 roller, bottom rear 09330-004-07-29 1 hood top (not shown) 05700-004-20-62 2.

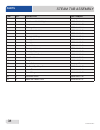

Page 33: Parts

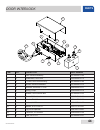

26 07610-004-29-29-a cantilever arm assembly parts 14 9 10 1 2 3 4 5 6 7 8 16 15 18 17 11 12 3d 3c 3b 3a 3e 13 19 9 yoke assembly (item #3) expanded view.

Page 34: Parts

27 07610-004-29-29-a cantilever arm assembly parts item qty description part number 1 1 pivot, cantilever arm right 09515-004-25-38 1 pivot, cantilever arm left 09515-004-25-91 2 2 bushing, door pivot outer 09330-004-26-71 3 2 yoke assembly 05700-000-75-77 3a 1 cotter pin 05315-207-01-00 3b 1 yoke 0...

Page 35: Parts

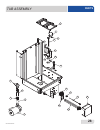

28 07610-004-29-29-a tub assembly parts 12 11 10 13 14 20 21 4 19 18 17 15 16 1 2 3 5 6 7 8 9.

Page 36: Parts

29 07610-004-29-29-a tub assembly parts item qty description part number 1 1 wash motor see page 39 2 1 wash lower manifold nipple 05700-021-34-84 3 2 clamp 04730-719-01-37 4 1 discharge hose 05700-011-88-24 5 1 lower wash manifold 05700-031-46-00 6 2 strainer 05700-004-26-21 7 1 standpipe lift supp...

Page 37: Parts

30 07610-004-29-29-a steam tub assembly parts 12 11 14 20 21 4 19 18 17 16 1 2 3 5 7 8 9 6 13 15 10

Page 38: Parts

31 07610-004-29-29-a parts steam tub assembly item qty description part number 1 1 wash motor see page 39 2 1 wash lower manifold nipple 05700-021-34-84 3 2 clamp 04730-719-01-37 4 1 discharge hose 05700-011-88-24 5 1 lower wash manifold 05700-031-46-00 6 2 strainer 05700-004-26-21 7 1 standpipe lif...

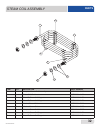

Page 39: Parts

32 07610-004-29-29-a steam coil assembly parts item qty description part number complete steam coil assembly 05700-002-08-62 1 1 steam coil weldment 05700-021-41-38 2 1 stand c, steam coil support 05700-002-08-52 3 1 stand d, steam coil support 05700-002-08-53 4 4 gasket, steam coil 05700-001-17-86 ...

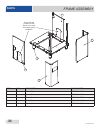

Page 40: Parts

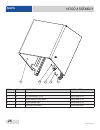

33 07610-004-29-29-a frame assembly parts item qty description part number 1 1 panel, right 05700-004-20-80 2 1 panel, front 05700-004-10-02 3 1 panel, control 05700-004-27-88 4 4 bullet foot 05340-004-14-99 5 1 panel, left 05700-004-20-83 1 2 3 4 5 punch-outs are provided on both panels; to be used...

Page 41: Parts

34 07610-004-29-29-a rinse tank assembly parts item qty description part number 1 1 booster tank weldment 05700-001-22-02 2 2 locknut, 10-24 with nylon insert 05310-373-01-00 3 2 washer, #10 s/s flat 05311-173-01-00 4 1 decal, warning - disconnect power 09905-100-75-93 5 1 booster tank cover weldmen...

Page 42: Parts

35 07610-004-29-29-a parts incoming/outlet plumbing assembly 16 15 11 12 13 10 9 8 7 5 4 3 2 1 17 18 1 6 14 5 4 2 5 9 7 16 19 20 21 23 12 5 24 1 goes to bottom connection on booster. 7 22 25.

Page 43: Parts

36 07610-004-29-29-a parts incoming/outlet plumbing assembly item qty description part number 1 3 elbow, 90 degree 1/2 street brass 04730-206-08-00 2 2 nipple, 1/2" x 6" long brass 04730-003-62-38 3 1 y-strainer 04730-217-01-10 4 2 nipple, 1/2" x 2" long 04730-207-19-00 5 3 bushing, hex 3/4"m to 1/2...

Page 44: Parts

37 07610-004-29-29-a parts dynatemp nb inlet plumbing 16 15 11 12 13 10 9 8 7 4 3 2 1 17 9 1 6 14 5 19 20 21 22 3 2 6 8 2 5 18.

Page 45: Parts

38 07610-004-29-29-a parts dynatemp nb inlet plumbing item qty description part number 1 2 bushing, hex 3/4"m to 1/2"f brass 04730-002-56-27 2 3 elbow, 90 degree 1/2 street brass 04730-206-08-00 3 2 nipple, 1/2 close brass 04730-207-15-00 4 1 union, 1/2" x 1/2" brass 04730-003-62-44 5 2 nipple, 1/2"...

Page 46: Parts

39 07610-004-29-29-a incoming steam plumbing assemblies parts item qty description part number complete assembly 05700-002-01-55 1 1 union, 3/4’’ npt, black iron 04730-912-01-00 2 1 bushing, reducing, 3/4’’ to 1/2’’ 04730-911-02-34 3 2 elbow, 3/4” 90° street 04730-011-87-37 4 1 nipple, close, 3/4’’ ...

Page 47: Parts

40 07610-004-29-29-a incoming steam plumbing assemblies parts item qty description part number complete assembly 05700-002-01-60 1 1 bushing, reducing, 3/4’’ to 1/2’’ 04730-911-02-34 2 2 union, 3/4’’ npt, black iron 04730-912-01-01 3 1 elbow, 90b 3/4” npt black iron 04730-906-10-34 4 4 nipple, close...

Page 48: Parts

41 07610-004-29-29-a wash motors parts model volts hz phase wash motor assembly dynatemp/dynatemp nb 208 50 1 06105-002-19-87 dynatemp/dynatemp nb 208 50 3 06105-002-19-87 dynatemp/dynatemp nb 208 60 1 06105-002-69-78 dynatemp/dynatemp nb 208 60 3 06105-002-69-78 dynatemp/dynatemp nb 230 50 1 06105-...

Page 49: Parts

42 07610-004-29-29-a item qty description part number 1 1 motor, 1hp/115-230v/60hz 06105-004-24-80 1 1 motor, 2hp/480v/60hz 3ph 06105-121-64-21 motor & pump assembly parts 1.

Page 50: Parts

43 07610-004-29-29-a parts wash heaters/rinse heaters model volts hz phase wash heater rinse heater (12 kw) rinse heater (14 kw) dynatemp 208 50/60 1 04540-121-47-39 04540-121-47-40 04540-121-63-38 dynatemp 208 50/60 3 04540-121-47-39 04540-121-47-40 04540-121-63-38 dynatemp 230 50/60 1 04540-121-47...

Page 51: Parts

44 07610-004-29-29-a parts door interlock item qty description part number door interlock assembly 05700-004-23-06 1 1 guide block, door lock 09330-004-22-72 2 1 f-cover, door lock mounting 05700-004-22-80 3 1 w-rod, interlock weldment 05700-004-23-15 4 1 soleniod, horizontal 1" push 04820-004-24-11...

Page 52: Parts

45 07610-004-29-29-a parts dynatemp plumbing options pressure regulator option water arrestor, 1/2” 06685-100-05-00 tee, 3/4” x 3/4” x 1/2” 04730-211-06-00 nipple, 3/4” npt, close, brass 04730-207-34-00 shock absorber (water arrestor) option water pressure regulator, 3/4" 06685-011-58-22.

Page 53: Parts

46 07610-004-29-29-a parts solenoid valve & vacuum breaker screw data plate coil & housing valve bonnet spring 06401-003-07-40 plunger 06401-003-07-40 o-ring 06401-003-07-42 diaphragm retainer diaphragm 06401-003-07-42 screen retainer mesh screen valve body complete 240 volt solenoid valve assembly ...

Page 54: Parts

47 07610-004-29-29-a parts wash & rinse arm assemblies 7 15 12 11 17 10 4 14 13 9 19 16 1 2 3 4 5 6 4 8 18.

Page 55: Parts

48 07610-004-29-29-a parts wash & rinse arm assemblies item qty description part number 1 1 wash manifold 05700-004-28-58 2 1 rinse manifold 05700-004-26-07 3 2 clip, retaining, rinse head bushing 05340-112-01-11 4 6 washer, rinse arm 05330-011-42-10 5 2 o-ring, rinse arm 05330-004-32-57 6 2 bushing...

Page 56: Parts

49 07610-004-29-29-a parts go*box components a go*box is a kit of the most-needed parts for a particular model or model family to successfully effect a repair in the first call, 90% or more of the time. The following components can be ordered together using part number 06401-004-34-17 item qty descr...

Page 57: Parts

50 07610-004-29-29-a parts drain quench assembly item qty description part number 1 1 nipple, 1/4 npt x 3 brass 04730-004-08-07 2 1 nipple, 1/4 npt x 3 brass 04730-004-08-07 3 1 reducer, 1-1/2 x 1/2 hex brass 04730-002-55-75 4 1 nipple, 1-1/12 brass close 04730-207-40-00 5 1 tee, 1-1/2 brass 04730-0...

Page 58: Parts

51 07610-004-29-29-a parts drain quench assembly item qty description part number 1 1 bracket, drain quench 05700-004-07-92 2 1 liquid tight fitting (large) 05975-011-65-51 3 1 conduit fitting, 45°-1/2" 05975-011-45-23 4 2 lock nut, 6-32 hex 05310-373-03-00 5 1 thermostat 05930-011-49-43 6 1 conduit...

Page 59: Parts

52 07610-004-29-29-a parts drain quench assembly connect 1 1/2” drain plumbing (elbow can be removed if not needed). Connect 1/4” cold-water line..

Page 60: Schematics

53 07610-004-29-29-a schematics dynatemp 208/230v, 50/60 hz, 1/3 phase programming header temperature sensor inputs t4 (spare) t2 (rinse injector) gry/blu t1 (wash) red/wht ac signals i1 i2 i3 i4 i5 analog input piezo switch 24 vdc out / rs-232 relay assignments k1 power k2 booster heater k3 wash he...

Page 61: Schematics

54 07610-004-29-29-a dynatemp 460/480v, 50/60 hz, 3 phase schematics programming header temperature sensor inputs t4 (spare) t2 (rinse injector) gry/blu t1 (wash) red/wht ac signals i1 i2 i3 i4 i5 analog input piezo switch 24 vdc out / rs-232 relay assignments k1 power k2 booster heater k3 wash heat...

Page 62: Schematics

55 07610-004-29-29-a schematics dynatemp s 208/230v, 50/60 hz, 1/3 phase programming header temperature sensor inputs t4 (spare) t2 (rinse injector) gry/blu t1 (wash) red/wht ac signals i1 i2 i3 i4 i5 analog input piezo switch 24 vdc out / rs-232 relay assignments k1 power k2 booster heater k3 wash ...

Page 63: Schematics

56 07610-004-29-29-a drain quench option schematics.

Page 64: Addendum

57 07610-004-29-29-a dynatemp units that are manufactured with the data plate above are able to be field-converted to different phases and voltages. To accomplish this, your unit should have shipped with the dynatemp phase conversion kit, part number 06401-003-71-71. This kit contains the appropriat...

Page 65: Addendum

58 07610-004-29-29-a display template addendum this page can be copied and the display templates cut-out. Lay the cut-out over the display and use the up-arrow, down- arrow, and select buttons to locate the hidden programming buttons..

Page 66: Addendum

59 07610-004-29-29-a addendum exhaust fan wiring wiring diagram terminal board do not connect primary load directly to terminal board! ! Caution warning: disconnect power to machine before servicing exhaust fan connection l1 l2 constant voltage connection rinse aid dispenser connection detergent dis...

Page 68

61 jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com dynatemp ® manual • rev a • 07610-004-29-29 • issued: 07-27-2016 • revised: n/a.