- DL manuals

- Jackson

- Dishwasher

- Hot Water Sanitizing Undercounter Dishmachines JP-24

- Technical Manual

Jackson Hot Water Sanitizing Undercounter Dishmachines JP-24 Technical Manual - Section 3:

Summary of Hot Water Sanitizing Undercounter Dishmachines JP-24

Page 1

Technical manual installation manual for export units service manual for domestic units for jackson models: jp-24 jp-24f jp-24b jp-24bf an company hot water sanitizing undercounter dishmachines march 6, 2006 p/n 7610-002-49-79 (revision d) jackson msc, inc. P.O. Box 1060 hwy. 25e barbourville, ky. 4...

Page 3

I revision revision date made by applicable ecn details a 07-15-2002 maw 6527 release manual for service use. B 06-04-2003 maw 6673, 6681 6637 updated per ecns. C 02-11-2004 maw 6836 updated per ecns. D 03-06-2006 maw 7421, 7231 6964, 7095 change thermostat from 05930-121-71-29 to 05930-510-03-79. C...

Page 4: Jp-24B

Ii nomenclature for the models covered in this manual jp-24b jp-24 = undercounter, high temperature, hot water sanitizing, no booster tank. Jp-24f = undercounter, high temperature, hot water sanitizing, no booster tank, with top and side panels. Jp-24b = undercounter, high temperature, hot water san...

Page 5

Section description page i. Specification information specifications jp-24/jp-24f 2 specifications jp-24b/jp-24bf 3 dimensions 4 ii. Installation/operation instructions installation instructions 6 electrical installation instructions 7 operation instructions 8 detergent control 9 cycle counter retro...

Page 6: Section 1:

1 section 1: specification information.

Page 7

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 1: specification information specifications of the jp-24/jp-24f 2 performance/capabilities operating capacity (racks/hour) racks per hour 30 dishes per hour 600 glasses per hour 600 operating cycle (seconds) wash ti...

Page 8

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 1: specification information specifications of the jp-24b/jp-24bf 3 performance/capabilities operating capacity (racks/hour) racks per hour 30 dishes per hour 600 glasses per hour 600 operating cycle (seconds) wash ...

Page 9

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 1: specification information jp-24 dimensions 4 legend a - water inlet 1/2” id female pipe thread, 2 1/2” aff b - detergent feeder connection c - electrical connection d - drain connection flexible hose 6’ free leng...

Page 10: Section 2:

Section 2: installation/operation instructions 5.

Page 11

Visual inspection: before installing the unit, check the container and machine for damage. A damaged container is an indi- cator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away the container. The dishmachine has been inspected and...

Page 12

Electrical power connection: electrical and grounding connections must comply with the applicable portions of the national electrical code ansi/nfpa 70 (latest edition) and/or other electrical codes. Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are...

Page 13

Preparation: before proceeding with the start-up of the unit, verify the following: 1. The strainer is in place and is clean. 2. That the wash and rinse arms are screwed securely into place and that their endcaps are tight. The wash and rinse arms should rotate freely. Power up: to energize the unit...

Page 14

Detergent usage and water hardness are two factors that contribute greatly to how efficiently your dishmachine will operate. Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified water treatment spe- cialist can tell you what is needed for maximum eff...

Page 15

1. Locate the template on the front of the plastic control panel in the approximate location as shown in the diagram below. 2. Use a 3/32" diameter drill bit to drill the four mounting holes through the plastic control panel. 3. Mount the template to the front of the control panel using the screws a...

Page 16: Section 3:

Section 3: preventative maintenance 11.

Page 17

The dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However, this does not mean that some items will not wear out in time. Jackson highly recommends that any maintenance and repairs not specifically discussed in this manual should be perfo...

Page 18: Section 4:

Section 4: troubleshooting 13.

Page 19

Warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times. If test points are not ea...

Page 20

Warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times. If test points are not ea...

Page 21: Section 5:

16 section 5: service procedures.

Page 22

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse solenoid valve repair parts kit 17 these dishmachines are equipped with electrical solenoid valves to allow for automatic fill and rinse. These valves are designed to specific tolerances ...

Page 23

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse solenoid valve repair parts kit (continued) 18 4. When replacing the coil, ensure that when removing the coil wire cover that care is taken not to damage the wires inside. Using the mediu...

Page 24

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse solenoid valve repair parts kit (continued) 19 13. Slowly remove the valve bonnet. Note: the spring for the plunger is located directly under the bonnet and may come free if you are not c...

Page 25

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse solenoid valve repair parts kit (continued) 20 19. Using the small flathead screwdriver, lift out the screen retainer. Verify that the holes in it are free of clogs and debris. 20. Again ...

Page 26

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures vacuum breaker repair parts kit 21 these dishmachines are equipped with vacuum breakers to serve as back-flow prevention devices. Asse requirements specify what type of back-flow prevention is ...

Page 27

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures vacuum breaker repair parts kit (continued) 22 6. Your repair kit comes with a new plunger. Examine the old one and ensure that the mating surface is not damaged or cut. Also inspect the rubber...

Page 28

Replacing the pump motor the following list of tools will be needed to complete this procedure. 5/6” nutdriver, phillips screwdriver, 7/16” socket and ratchet, and 7/16” wrench. 1. Disconnect the electrical power to the dishwasher at the main circuit breaker box when servicing. Place a tag on the ci...

Page 29

Replacing the drain valve the following list of tools will be needed to complete this procedure. 5/16” nutdriver, flat screwdriver, phillips screwdriver, and 7/16” socket and ratchet. 1. Disconnect the electrical power to the dishwasher at the main circuit breaker box when servicing. Place a tag on ...

Page 30

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse regulating thermostat replacement 25 many dishmachines comes with integral booster tanks to ensure proper temperature of the final rinse. Jackson has predominantly used two manufacturers ...

Page 31

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse regulating thermostat replacement 26 remove the thermostat bracket mounting nuts with the 3/8” nutdriver. 5. Attach the jumper wires to the wires that you removed from the old thermostat....

Page 32

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse regulating thermostat replacement 27 6. Slide the new imperial brass fitting from your kit onto the new thermostat. 7. Insert the new thermostat/brass fitting combination into the well an...

Page 33

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 5: service procedures rinse regulating thermostat replacement 28 11. Attach the ring ends of the jumpers to the cups/screws removed from the thermostat and attach them. The white jumper is to be connected to common....

Page 34: Section 6:

Section 6: parts section 29.

Page 35

Item qty description mfg. No. 1 1 gauge, 0-100 psi w/green zone 06680-011-86-42 2 1 fitting, 1/4” barb x 1/4” fnpt swivel 04730-011-95-42 3 1 hose, 5/16” x 12" 05700-011-86-45 4 1 fitting, 1/4” barb x 1/4” mnpt swivel 04730-011-95-41 5 1 control panel (208-240 volt) 09330-041-41-94 5 1 control panel...

Page 36

Item qty description mfg. No. 1 1 electrical control panel weldment 05700-011-41-79 2 1 bushing, snap 05975-210-03-00 3 1 contactor, motor 05945-002-74-20 4 8 screw, 10-32 x 3/8” phillips truss round head 05305-173-12-00 5 1 locknut, 10-24 s/s hex with nylon insert 05310-373-01-00 6 1 wire lug 05940...

Page 37

Item qty description mfg. No. 1 1 electrical control panel weldment 05700-011-41-79 2 1 bushing, snap 05975-210-03-00 3 1 contactor, motor 05945-002-74-20 4 9 screw, 10-32 x 3/8” phillips truss round head 05305-173-12-00 5 1 locknut, 10-24 s/s hex with nylon insert 05310-373-01-00 6 1 wire lug 05940...

Page 38

Item qty description mfg. No. 1 1 bushing, snap 05975-210-03-00 2 1 track, terminal 6 7/8" 05700-021-62-91 3 2 end clamp 05940-111-60-30 4 2 contactor, mini 05945-111-60-07 5 9 screw, 10-32 x 3/8” phillips truss round head 05305-173-12-00 6 1 track, terminal 3 3/4" 05700-011-62-89 7 1 decal, l1, l2,...

Page 39

Item qty description mfg. No. 1 1 gauge, 0-100 psi with green zone 06680-011-86-42 2 1 thermometer, 96” wash 06685-111-68-49 3 1 thermometer, 48” rinse 06685-111-68-48 4 1 control panel, remote jp-24 09330-041-73-91 5 1 decal, jp-24 external control panel 09905-031-73-94 6 1 fitting, 1/4” barb x 1/4...

Page 40

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section electrical panel assembly (external option & amtrak option) 35 13 12, 7 front view external option inside view of amtrak & external options electrical component mounting bracket 05700-031-84-85 cont...

Page 41

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section electrical panel assembly (external option & amtrak option) (continued) 36 item qty description mfg. No. 1 1 control box, jp-24 external machined 05700-031-73-01 1 1 control box, amtrak 24 remote 05...

Page 42

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section kick plate assembly 37 kickplate weldment 05700-041-86-40 control panel assembly 05700-011-40-93 control panel only 09330-041-41-94 460 control panel assembly 05700-002-18-38 460 control panel only ...

Page 43

Item qty description mfg. No. 1 1 y-strainer, 1/2" 04730-217-01-10 2 3 adapter, 1/2" ftg. X male 04730-011-59-53 3 1 tee, 1/2” c x 1/2” c x 1/4” female 04730-411-25-01 4 1 ball valve, test cock 1/4" 04810-011-72-67 5 1 valve, solenoid 1/2", 115 volt 04810-100-12-18 6 1 union, 1/2" c to c 04730-412-0...

Page 44

Item qty description mfg. No. 1 1 y-strainer, 1/2" 04730-217-01-10 2 3 adapter, 1/2" ftg. X male 04730-011-59-53 3 1 tee, 1/2 x 1/2 x 1/4 04730-411-25-01 4 1 ball valve, test cock 1/4" 04810-011-72-67 5 1 valve, solenoid 1/2" 220 volt 04810-100-09-18 6 1 union, 1/2" c to c 04730-412-05-01 7 2 elbow,...

Page 45

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section rinse stiffener/rinse hub weldment 40 rinse hub weldment 05700-021-38-31 rinse tube stiffener 05700-011-44-32 vellumoid rinse gasket 05330-111-42-81 clamp, hose 04730-719-06-09 hose, 3/4” x 8 1/2” 0...

Page 46

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a 41 section 6: parts section rinse solenoid valve & vacuum breaker repair parts kits/water pressure regulator kit option complete 110 volt solenoid valve assembly, 1/2” 04810-100-12-18 coil & housing only, 1/2” 06401-003-07-...

Page 47

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section drain valve assembly 42 3 1 3 4 5 6 12 7 8 9 10 11 18 13 14 15 16 17 item qty description mfg. No. 1 diverter valve assembly, 115 volt 06401-012-23-21 1 diverter valve assembly, 220 volt 06401-022-2...

Page 48

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section drain plumbing assembly 43 item qty description mfg. No. 1 3 clamp, 3/16” to 1 1/2” 04730-719-06-09 2 1 hose, formed drain 04720-121-40-36 3 2 bolt, 10-32 x 1/2” slotted truss head 05305-173-04-00 4...

Page 49

Item qty description mfg. No. 1 1 motor, wash, 115/230 v, 60 hz, complete 06105-131-50-93 motor, only 06105-021-44-03 1 1 motor, wash, 115/230 v, 50 hz, complete 06105-002-14-93 motor, only 06105-003-19-78 1 1 motor, wash, 460 v, 60 hz, complete 06105-121-60-06 motor, only 06105-002-64-03 2 1 pump m...

Page 50

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a 45 section 6: parts section rinse tank & components/strip heater kit 40°f rise 70°f rise model volts hz phase rinse heater (8.2 kw) rinse heater (10 kw) jpx-300h 208 50 1 04540-111-43-21 04540-021-62-57 jpx-300h 230 50 1 04...

Page 51

Item qty description mfg. No. 1 1 door handle, s/s 05340-011-60-25 2 1 seal channel, inner door, left 05700-031-32-89 3 1 kit, outer door with tricnuts 06401-003-19-59 4 1 right hinge assembly weldment 05700-021-38-75 5 1 spray baffle 05700-031-37-56 6 1 left hinge assembly weldment 05700-021-38-76 ...

Page 52

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section miscellaneous door sub-assemblies 47 door spring 05340-011-44-58 hinge retaining plate 05700-011-44-37 door latch casting 05700-011-44-40 latch roller 05700-011-44-38 latch spring 05700-011-44-39 do...

Page 53

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section rinse arm & wash arm assemblies 48 washer, rinse arm 05330-011-42-10 o-ring (not shown) 05330-002-60-69 rinse arm 05700-031-38-30 plug, rinse arm 04730-609-04-00 bushing, rinse head 05700-021-33-84 ...

Page 54

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section frame & panel components/miscellaneous parts 49 back panel 05700-031-44-33 guide, left rack 05700-031-37-89 guide, right rack 05700-031-37-88 strainer spacer 05700-021-35-83 attaches with: nut, nylo...

Page 55

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 6: parts section cycle counter retrofit kit 50 instructions for adding cycle counter to jp -24 undercounter dish machine 1. Locate the template on the front of the plastic control panel in the approximate location a...

Page 56: Section 7:

51 section 7: electrical schematics.

Page 57

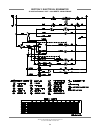

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 7: electrical schematics jp-24/jp-24f 208-230 volt - 50/60 hertz - single phase 52.

Page 58

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 7: electrical schematics jp-24b/jp-24bf 208-230 volt - 50/60 hertz - single phase 53.

Page 59

Jp-24 technical manual 7610-002-49-79 rev. D issued: 03-06-2006 revised: n/a section 7: electrical schematics jp-24b/jp-24bf 460 volt - 60 hertz - three phase 54.