- DL manuals

- Jackson

- Dishwasher

- Hot Water Sanitizing Undercounter Dishmachines JPX-300NSU

- Technical Manual

Jackson Hot Water Sanitizing Undercounter Dishmachines JPX-300NSU Technical Manual

Summary of Hot Water Sanitizing Undercounter Dishmachines JPX-300NSU

Page 1

Technical manual for jackson model: jpx-300nsu jackson msc inc. P.O. Box 1060 barbourville, ky. 40906 (606) 523-9795 fax: (606) 523-9196 www.Jacksonmsc.Com an company hot water sanitizing undercounter dishmachine august 16, 2005 p/n 7610-002-75-96 (revision e).

Page 2

Manufacturers warranty one year limited parts & labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from the date of purchase, but in no event to exceed (18)...

Page 3

Revision revision date made by applicable ecn details a 03-27-03 maw 6698 release to production b 11-17-03 maw n/a updated part numbers. C 04-29-04 maw n/a added 2nd enodis logo to cover. D 04-18-05 maw n/a removed title “ installation manual for export units” from cover. E 08-16-05 maw 6964, 6988 7...

Page 4: Jpx-300Nsu

Ii model: serial no.: installation date: service rep. Name: phone no.: jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) nomenclature for the model covered in this manual jpx-300nsu jpx-300nsu - hot water sanitizing, electrically-heated dishmachine,.

Page 5

Iii jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) table of contents section description page i. Specification information specifications 2 dimensions 3 ii. Installation & operation instructions installation instructions 5 electrical installation instructions 6 deck mounting of dish...

Page 6

This page is intentionally left blank iv.

Page 7: Section 1:

1 section 1: specification information.

Page 8

Section 1: specification information specifications performance/capabilities operating capacity (racks/hour) racks per hour 30 dishes per hour 600 glasses per hour 600 operating cycle (seconds) wash time 82 drain time 28 rinse time 10 total cycle time (minutes) 2 5 minute timer operating cycle (seco...

Page 9

3 section 1: specification information dimensions dimensions height (minimum): 33 1/4” inside clearance height: 14 1/2” height (maximum): 34 1/4” inside clearance width: 20 1/4” width: 24 1/4” inside clearance depth: 21 1/4” depth: 22 5/8” door open depth: 39 1/2” wall clearance (minimum): 2 1/2” jp...

Page 10: Section 2:

4 section 2: installation/operation instructions.

Page 11

5 section 2: installation & operation instructions installation instructions jackson msc inc. Provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please have this manu...

Page 12

6 section 2: installation & operation instructions electrical installation instructions electrical power connection: electrical and grounding connections must comply with the applicable portions of the national electrical code ansi/nfpa 70 (latest edition) and/or other electrical codes. Disconnect e...

Page 13

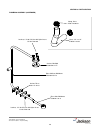

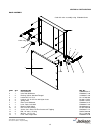

7 section 2: installation & operation instructions installation instructions (continued) deck mounting of the dishmachine: the dishmachine must be secured in place using the deck mounting tracks and caps provided with machine. Install the (4) adjustable feet provided into screw holes where shipping ...

Page 14

8 section 2: installation & operation instructions detergent control detergent usage and water hardness are two factors that contribute greatly to how efficiently your dishmachine will operate. Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified wat...

Page 15

9 section 2: installation & operation instructions operation instructions preparation: before proceeding with the start-up of the unit, verify the following: 1. The strainer is in place and is clean. 2. That the wash and rinse arms are screwed securely into place and that their endcaps are tight. Th...

Page 16: Section 3:

10 section 3: preventative maintenance.

Page 17

Jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) section 3: preventative maintenance preventative maintenance the dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However, this does not mean that some items will not wear out ...

Page 18: Section 4:

12 section 4: troubleshooting.

Page 19

13 section 4: troubleshooting section common problems warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise e...

Page 20

14 section 4: troubleshooting section common problems problem: rinse water not at required temperature range. 1. Thermometer is defective. Replace. 2. Thermostat is defective. Adjust the thermostat. Replace if necessary. Problem: machine doesn’t drain when “power off” switch is pressed. 1. Drain sol...

Page 21: Section 5:

15 section 5: service procedures.

Page 22

16 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) section 5: service procedures rinse solenoid valve repair parts kit these dishmachines are equipped with electrical solenoid valves to allow for automatic fill and rinse. These valves are designed to specific tolerances and design asp...

Page 23

17 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) section 5: service procedures rinse solenoid valve repair parts kit (continued) 4. When replacing the coil, ensure that when removing the coil wire cover that care is taken not to damage the wires inside. Using the medium flathead sc...

Page 24

18 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) section 5: service procedures rinse solenoid valve repair parts kit (continued) 13. Slowly remove the valve bonnet. Note: the spring for the plunger is located directly under the bonnet and may come free if you are not careful. Remove...

Page 25

19 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) section 5: service procedures rinse solenoid valve repair parts kit (continued) 19. Using the small flathead screwdriver, lift out the screen retainer. Verify that the holes in it are free of clogs and debris. 20. Again using the sma...

Page 26

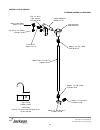

20 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) section 5: service procedures vacuum breaker repair parts kit these dishmachines are equipped with vacuum breakers to serve as back-flow prevention devices. Asse requirements specify what type of back-flow prevention is nec- essary on...

Page 27

21 jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) section 5: service procedures vacuum breaker repair parts kit (continued) 6. Your repair kit comes with a new plunger. Examine the old one and ensure that the mating surface is not damaged or cut. Also inspect the rubber seal on the ...

Page 28: Section 6:

22 section 6: parts section.

Page 29

23 section 6: parts section electrical panel assembly item qty description mfg. No. 1 1 bushing, snap 5975-210-03-00 2 1 track, terminal 6 7/8" 5700-021-62-91 3 2 end clamp 5940-111-60-30 4 2 contactor,mini 5945-111-60-07 5 9 screw, 10-32 x 3/8 phillips truss round head 5305-173-12-00 6 1 track, ter...

Page 30

24 section 6: parts section switch panel assembly item qty description mfg. No. 1 1 switch panel weldment 5700-002-71-11 2 1 decal, control panel 5700-002-75-75 3 1 switch, yellow reed 5930-011-47-50 4 1 decal, high limit 9905-002-75-98 5 1 switch, prime 5930-002-68-27 6 1 light, amber 5945-504-06-1...

Page 31

25 section 6: parts section switch panel assembly (with stainless steel switches) item qty description mfg. No. 1 1 switch panel weldment 5700-003-02-65 2 1 decal, control panel 5700-002-75-75 3 1 switch, yellow reed 5930-011-47-50 4 1 decal, high limit 9905-002-75-98 5 1 switch, prime 5930-003-05-3...

Page 32

26 section 6: parts section kick panel assembly jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) thermometer, wash 48” 6685-111-68-48 decal, wash 9905-002-68-95 fitting, 1/4” 4730-011-95-42 pressure hose assembly 5700-002-72-17 nylon loop 4320-002-71-22 locknut, 6-32 hex s/s with nylon...

Page 33

27 section 6: parts section plumbing assembly jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) union, 1/2" c to c 4730-412-05-01 nipple, 1/2" close 4730-207-15-00 valve, solenoid 1/2" 220 volt 4810-100-09-18 tee, 1/2 x 1/2 x 1/4 4730-411-25-01 adapter, 1/2" ftg. X male 4730-401-03-01 ...

Page 34

28 section 6: parts section plumbing assembly (continued) jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) vacuum breaker 4820-300-07-00 adapter, 1/2" ftg. X male 4730-401-03-01 plug, 1/4” brass 2 per machine 4730-209-01-00 injector weldment 5700-031-41-83 fitting, outlet elbow 4820-11...

Page 35

29 section 6: parts section plumbing assembly (continued) jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) rinse stiffener weldment 5700-002-59-79 locknut, 1/4”-20 s/s hex with nylon insert 5310-374-01-00 gasket, manifold 5330-002-34-77 gasket, rinse 330-111-42-81 rinse hub weldment 5...

Page 36

30 section 6: parts section 1/2” solenoid valve & 1/2” npt vacuum breaker repair parts kits jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) screw data plate coil & housing valve bonnet spring & plunger kit 6401-003-07-40 diaphragm retainer screen retainer mesh screen valve body comple...

Page 37

31 section 6: parts section drain valve assembly item qty description mfg. No. 1 1 valve, with brackets 5700-002-23-28 2 1 hosebarb, 1” x 3/4” npt polypropylene 4730-011-65-86 3 1 hosebarb, 90 b 1” x 3/4” npt 4730-011-65-87 4 1 plate, motor mounting weldment 5700-031-96-02 5 4 tricnut, 10-32 ak fast...

Page 38

32 section 6: parts section drain plumbing assembly item qty description mfg. No. 1 3 clamp, 3/16” to 1 1/2” 4730-719-06-09 2 1 hose, formed drain 4720-121-40-36 3 2 bolt, 10-32 x 1/2” slotted truss head 5305-173-04-00 4 1 diverter valve assembly 5700-002-23-21 5 1 clamp, 11/16” to 1 1/4” 4730-002-1...

Page 39

33 section 6: parts section wash motor to wash tub assembly item qty description mfg. No. 1 1 hub, discharge machined 5700-021-37-90 2 1 gasket, 2” o.D. X 1 1/2” i.D. X 1/16” 5330-200-23-00 3 1 nut, jam 1 1/2”-12 npt 5700-000-86-23 4 4 hose clamp, 1 5/16" - 2 1/4" # 28 4730-719-01-37 5 1 hose,1 1/4”...

Page 40

34 section 6: parts section rinse tank & components jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) 40°f rise 70°f rise volts hz phase rinse heater (8.2 kw) rinse heater (10 kw) 460 60 3 4540-111-51-46 4540-002-29-82 thermostat, high limit 5930-011-49-43 decal, high limit 9905-011-84-...

Page 41

35 section 6: parts section door assembly item qty description mfg. No. 1 1 door weldment 5700-002-59-37 2 1 inner door weldment 5700-002-71-80 3 2 bearing, nyliner standard flanged 3120-002-71-66 4 2 lockwasher, 3/8” s/s 5311-276-01-00 5 2 locknut, 3/8”-16 s/s hex with nylon insert 5310-011-72-55 6...

Page 42

36 section 6: parts section rinse arm & wash arm assemblies jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) washer, rinse arm 5330-011-42-10 rinse arm 5700-031-38-30 plug, rinse arm 4730-609-04-00 bushing, rinse head 5700-021-33-84 bearing, rinse head 3120-002-72-24 ring, retaining 53...

Page 43

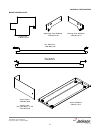

37 section 6: parts section miscellaneous parts jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)) rail, right rack 5700-002-59-94 rail, left rack 5700-002-59-93 back panel 5700-031-44-33 strainer spacer 5700-002-70-60 attaches with: nut, nylon wing, 1/4”-20 5310-994-01-00 strainer weld...

Page 44

38 section 6: parts section frame, & panel components jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005) right frame weldment 5700-002-59-36 left frame weldment 5700-002-59-35 the swivel feet used on the unit may be ordered using 5340-002-71-71 right dress panel 5700-002-71-07 left dress...

Page 45: Section 7:

Section 7: electrical diagrams 39.

Page 46

40 section 7: electrical diagrams jpx-300nsu 460 volt, 60 hertz, three phase jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005)).

Page 47

41 section 7: electrical diagrams jpx-300nsu 460 volt, 60 hertz, three phase (with stainless steel switches) jpx-300nsu technical manual 7610-002-75-96 rev. E (08/16/2005).