- DL manuals

- Jackson MSC

- Dishwasher

- 10A

- Service manual

Jackson MSC 10A Service manual

Summary of 10A

Page 1

Models covered in this manual: 10a 10ab 10aprb 10ab/aprb 4sh 10a/ab/aprb 5hh s e r v i c e m a n u a l www.Jacksonmsc.Com 10 series round dishmachines (electrically heated) june 3, 2002 p/n 7610-002-41-09 (revision b).

Page 2

Sectiondescription page i. General specifications 1 ii. Instructions section installation instructions 2 operation instructions 4 preventative maintenance 5 iii. Service procedures rinse head/wash head assemblies 6 timer for 10 dishmachines 7 function of switches, circuit breaker & indicating lights...

Page 3

Performance/capabilities operating capacity (racks/hour) racks per hour 45 dishes per hour 950 glasses per hour 950 operating cycle (seconds) wash time 60 rinse time 10 total cycle time 72 tank capacity (gallons) wash tank 4.5 booster tank (10ab and 10aprb only) 3.0 pump capacity (gallons) wash pump...

Page 4

Jackson msc inc. Provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please have this manual with you when you call so that our staff can refer you, if necessary, to t...

Page 5

Water supply connection: ensure that you have read the section entitled “plumbing the dishmachine” above before pro- ceeding. Install the water supply line (3/4” pipe size minimum) to the end of the y-strainer. It is recommended that a water shut-off valve be installed in the water line between the ...

Page 6

Preparation: 1. Ensure that the pump intake strainer (1) and basket overflow strainer (2) are inserted and tight. 2. Ensure that the wash and rinse arms are installed and secure. 3. Remove all solid wastes in order to avoid obstructing filters, drain and wash and rinse arms. 4. Ware that is encruste...

Page 7

Proper maintenance of you jackson dishmachine will insure optimum service with a minimum of down time. 1. To delime the booster tank. A. Remove the support pipe nut and lift the whole hood assembly away from the unit. B. Loosen the fitting going into bottom side of booster tank. C. Drain approximate...

Page 8

1. Turn master switch to off position. 2. Open hood and drain machine by lifting overflow strainer. 3. When empty, replace overflow strainer. 4. Remove the pin holding the rinse feed pipe and remove the feed pipe and rinse head assembly. 5. Locate the allen head set screw in wash head cap, insert al...

Page 9

General description: the timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted on the control panel of the control box, to control the automatic functions of the machine. It consists of a clock motor which operates on 60 cycle ac, 220 vac. In addition to the cloc...

Page 10

Function of switches, circuit breaker & indicating lights circuit breaker: rated 15 amps, controls power to the control circuit only, i.E. Timer, relays, solenoid valve, water level control and motors. The circuit breaker does not cut off power in the control box at incoming terminal board and rinse...

Page 11

The thermostat can be adjusted by turning screw #1 (see diagram) on the thermostat housing cover. (remember the preset setting i n case the problems are elsewhere in the control circuit.) a clockwise rotation is used to obtain a lower temperature setting and a coun- terclockwise rotation is used to ...

Page 12

The rinse tank heater system is electrically connected in the circuit and is controlled by a heat switch (mounted on the front panel) and a thermostat (mounted near the right front leg underneath) which activates the coil on the heat relay, mounted in the control box. When higher temperature is requ...

Page 13

The wash tank heater control system is electrically connected in the circuit to operate on 208-230 volts. The heat circuit is controlled by a heat switch (mounted right front panel), water level control (mounted top inside control box), and thermostat (mounted right front leg underneath). When highe...

Page 14

This water level control is used on this machine in conjunction with a sensor, master switch, thermostat all of which help control the action of the wash tank heater. The wash heater water level control is energized when the master switch is turned on. When the water level decreases in the wash tank...

Page 15

The water control is used on this machine in conjunction with a sensing probe, to detect the water level in the rinse tank, and to con- trol the automatic refilling of it. When the water level decreases as the rinse pump starts to push water through the rinse tubes, the probe then sends a signal to ...

Page 16

Replacing seal and ceramic on wash and rinse pumps the pump is part of the total motor-pump system and utilizes one seal and ceramic to prevent the pump from leaking around the impeller and shaft. One gasket is used to prevent leakage in between the pump and mounting plate and the machine pump plate...

Page 17

Problem: nothing on the machine operates. 1. No voltage to the dishmachine. Check to see if the customer’s fuse has blown or the circuit breaker has tripped. Replace or reset. 2. Machine circuit breaker tripped or turned off. Turn on or reset. 3. Voltage to machine low or circuit to machine broken. ...

Page 18

Problem: vacuum breaker leaks. 1. Limed up. To disassemble: use flat jaw wrench or channel locks. Remove the poppet. Clean poppet, top, and body. Reassemble parts removed. 2. Faulty. Replace needed parts or whole vacuum breaker. Problem: wash arms spray water but do not rotate. 1. Wash cap adjusted ...

Page 19

Problem: none of the automatic functions work (wash, rinse). 1. Start switch faulty. Check switch. Replace if necessary, see instructions page concerning replacement of switches in control panel. 2. Wire connections poor. Correct the connection. 3. Timer rinse or wash microswitch faulty. See instruc...

Page 20

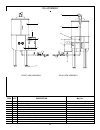

Dimensions 10a (no booster) 18 notes: a - water inlet 1/2” i.P.S. Plumbing can be directed either left or right. B - drain connection 1 1/2” i.P.S. C - electrical connection d - clearance for dishes 14” e - power rinse pump motor (10aprb only) f - booster tank (10ab and 10aprb only) all dimensions i...

Page 21

Dimensions 10ab/aprb (standard unit) 19 notes: a - water inlet 1/2” i.P.S. Plumbing can be directed either left or right. B - drain connection 1 1/2” i.P.S. C - electrical connection d - clearance for dishes 14” e - power rinse pump motor (10aprb only) f - booster tank (10ab and 10aprb only) all dim...

Page 22

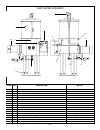

Dimensions 10ab/aprb 4sh (4” shorter hood/9” shorter legs) 20 notes: a - water inlet 1/2” i.P.S. Plumbing can be directed either left or right. B - drain connection 1 1/2” i.P.S. C - electrical connection d - clearance for dishes 10” e - power rinse pump motor (10aprb only) f - booster tank (10ab an...

Page 23

Dimensions 10ab/aprb 5hh (5” higher hood) 21 notes: a - water inlet 1/2” i.P.S. Plumbing can be directed either left or right. B - drain connection 1 1/2” i.P.S. C - electrical connection d - clearance for dishes 19” e - power rinse pump motor (10aprb only) f - booster tank (10ab and 10aprb only) al...

Page 24

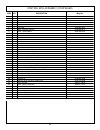

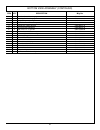

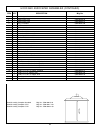

Table dimensions 22 10 1x package 10 2x package 10 3x package legend a - 10” high backsplash, 2” turnback at 45 degree b - 3” high, 1 1/2” diameter rolled edge c - scrap block d - scrap basket with slide bars e - 20” x 20” x 5” deep pre-rinse sink f - heavy duty pre-rinse g - 20” slanted wall mounte...

Page 25

10a assembly 23 item qty description mfg. No. 1 1 hood assembly refer to hood assembly page 2 1 control box support bracket 5700-000-24-76 3 1 shroud 5700-000-24-77 4 4 bullet feet 5340-108-01-03 5 1 complete control box assembly refer to control box assembly page 6 1 vacuum breaker assembly refer t...

Page 26

10ab/10aprb assembly 24 item qty description mfg. No. 1 1 hood assembly refer to hood assembly page 2 1 motor and pump assembly 5700-002-60-91 2a 1 motor and pump assembly (aprb only) 5700-002-60-91 3 1 shroud, without holes for gauges 5700-000-24-77 3 1 shroud, with holes for gauges 5700-002-60-36 ...

Page 27

Control box assembly 25 2, 3, 4, 5 1 6 6 14 18, 19, 20, 10 30 31 4 7, 8, 9, 10, 11 5 16 17 29 24, 25, 9, 10, 11 26, 27, 28 32, 4 1 12 13 6 15 21, 22, 23 21, 22, 23 14 aprb only the complete control box attaches to the control box support bracket with 2 of each item: locknut, 1/4"-20 s/s hex w/ nylon...

Page 28

Control box assembly (continued) 26 item qty description mfg. No. 1 1 control box panel w/ decal 9905-500-07-10 2 1 timer 5945-303-19-00 3 1 bracket, timer mounting 5700-000-34-28 4 4 screw, 10-32 x 3/8" phillips truss head 5305-173-12-00 5 4 locknut, 10-32 s/s hex w/ nylon insert 5310-273-01-00 6 3...

Page 29

Ordering replacement wire for your dishmachine jackson dishmachines have several color and gauges of wire used in them and it may become necessary to replace these wires. Wire may be ordered from jackson msc inc., but please note that it is only available in feet. Ensure that you order the correct c...

Page 30

Ordering replacement wire (continued)/conduit & fittings 28 miscellaneous wire: brown (18 gauge) 6145-104-20-00 brown (20 gauge) 6145-104-08-97 orange (18 gauge) 6145-104-34-00 orange with black stripes (18 gauge) 6145-011-35-62 orange with blue stripes (18 gauge) 6145-011-46-39 orange with white st...

Page 31

Tub assembly 29 1 30 15 16 17 16 18 21 22 23 24 22 25 22 26 27 28 20 19 29 4 5 8 9 10 11 3 2 12, 13 14 6 7 lundy probe assembly.

Page 32

Tub assembly (continued) 30 item qty description mfg. No. 1 1 wire spring ring 5315-700-03-00 2 1 cable assembly 3020-201-09-01 3 1 support, rack weldment 5700-000-13-43 4 1 intake strainer 5700-000-03-02 5 1 bulk head plug 4730-609-05-00 6 1 casting, rinse feed 5700-000-16-47 7 1 gasket, rinse feed...

Page 33

Bottom view assembly 31 9 7, 8 refer to thermostat housing assembly page refer to pump & motor assembly page 14, 8 15 16, 17 1 2, 3 4 5, 6 10, 11, 12, 13 wash tank section.

Page 34

Bottom view assembly (continued) 32 item qty description mfg. No. 1 1 shroud, without holes for gauges 5700-000-24-77 1 1 shroud, with holes for gauges 5700-002-60-36 2 2 gauge, temperature 6685-111-68-48 3 1 decal, wash and rinse temperature 9905-100-43-21 4 1 control box support bracket 5700-000-2...

Page 35

Wash tank cross view / tub to booster connection 33 thermal overload mfg. No.: 5945-301-49-00 3, 4, 5 2 1 stainless steel tye wrap mfg. No.: 5975-602-02-20 overflow strainer mfg. No.: 4730-017-15-05 o-ring mfg. No.: 5330-400-05-00 intake strainer mfg. No.: 5700-000-03-02 6, 7, 8 9 10 10a 12a 11 12 1...

Page 36

10ab/aprb rinse booster & associated parts 34 heater bus bar (1 phase) mfg. No.: 5700-000-24-36 rinse heater mfg. No.: 4540-100-21-10 rinse tank weldment mfg. No.: 5700-000-24-84 wrapper, rinse heater cover mfg. No.: 5700-000-26-40 decal, warning-disconnect power mfg. No.: 9905-100-75-93 attaches wi...

Page 37

Pump and motor assembly 35 item qty description mfg. No. 1 complete motor and pump assembly 5700-002-60-91 1 1 motor, 115/230 volt, 1/2 hp, 1 ph, 60 hz, 6105-101-65-00 2 1 flange, motor mounting, epoxied and painted 5700-002-60-97 3 1 seal, crane 5330-300-09-27 4 1 seal, ceramic 5330-300-02-27 5 1 i...

Page 38

Thermostat housing assembly 36 item qty description mfg. No. 1 1 thermostat box weldment 5700-000-59-70 2 1 front and bottom, thermostat box 5700-001-21-23 3 1 bushing, snap in 5975-210-09-00 4 1 thermostat, rinse (not used on 10a) 5930-510-02-00 5 1 thermostat, wash 5930-510-01-00 6 1 overload, the...

Page 39

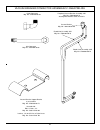

Incoming plumbing assemblies 37 item qty description mfg. No. 1 1 solenoid valve, 1/2" 208-240 volt 4810-100-09-18 2 2 adapter, 1/2" fitting x male 4730-011-59-53 3 1 tee, 1/2" c x 1/2" c x 1/4" female brass 4730-411-25-01 4 1 ball valve, 1/4" test cock 4810-011-72-67 5 1 gauge, 0-100 pressure 6685-...

Page 40

1/2” solenoid valve & 1/2” npt vacuum breaker repair parts kits 38 screw data plate coil & housing valve bonnet spring 4810-200-04-18 plunger 4810-200-04-18 o-ring 4810-100-03-18 diaphragm retainer diaphragm 4810-100-03-18 screen retainer mesh screen valve body complete 220 volt solenoid valve assem...

Page 41

Hood and associated assemblies 39 2 1 3 14 15 16 17 18 19 5 4 11 12 13 9, 10 20 7 8 6 5 4.

Page 42

Hood and associated assemblies (continued) 40 item qty description mfg. No. 1 1 hood support, standard 5700-000-05-57 1 1 hood support, 4sh 5700-002-60-99 1 1 hood support, 5hh 5700-000-62-91 2 1 plug, 1/4" plated 5700-002-61-00 3 1 nut, plated 5700-000-05-52 4 2 washer, s/s hood 5311-179-01-00 5 2 ...

Page 43

Vacuum breaker/connector assemblies 10a 41 outlet connector mfg. No.: 5700-002-61-19 complete vacuum breaker assembly mfg. No.: 5700-002-61-18 plated outlet assembly mfg. No.: 5700-002-61-21 outlet connector mfg. No.: 5700-002-61-19 plated inlet assembly mfg. No.: 5700-002-61-20

Page 44

Vacuum breaker/connector assemblies 10ab/aprb all units 42 plated outlet assembly, standard mfg. No.: 5700-002-61-13 plated outlet assembly, 4sh before machine serial no. 45973 mfg. No.: 5700-002-61-14 plated outlet assembly, 5hh mfg. No.: 5700-002-61-15 plated inlet assembly, standard mfg. No.: 570...

Page 45

Vacuum breaker/connector assemblies 10ab/aprb 4sh 43 plated outlet assembly, 4sh mfg. No.: 5700-002-60-79 plated inlet assembly, 4sh mfg. No.: 5700-002-60-78 vacuum breaker mfg. No.: 4820-300-07-00 inlet connector mfg. No.: 5700-002-60-93 outlet connector mfg. No.: 5700-002-60-92 complete vacuum bre...

Page 46

Part no. Description serial no. Qty. 6401-000-54-00 booster tank for machine (stripped) ab af 28,000 1 6401-000-58-00 booster tank for machine (stripped) aprb af 28,000 1 5925-105-10-01 circuit breaker, 15 amp (specify number from part) specify 1 0016300 control box, complete wired a af 28,000 1 570...

Page 47

Part no. Description serial no. Qty. 7320-100-14-01 rack, eight-compartment basket (silverware) moulded all models (p4c8) 7320-100-05-01 rack, twelve-compartment basket (silverware) moulded all models (p4c12) 6400-000-90-24 rack, square moulded w/stainless “h” bar (for 20” x 20” sinks), dishtables -...

Page 48

10a, 10ab, 10aprb electrical schematics 46 l1 l2 terminal board #1 customer service 15 amp rating circuit breaker ½ hp 5.3 amps wash motor wash heater 09905-002-57-63 a 10a 208/220v 1 phase 630 watts l1 rinse heaters 6900 watts l2 15 amp rating circuit breaker ½ hp 5.3 amps wash motor 630 watts ½ hp...

Page 49

10a 208-230 volt/ 60 hertz / 1phase wiring diagram 47.

Page 50

10ab 208-230 volt/ 60 hertz / 1phase wiring diagram 48 9905-000-54-97.

Page 51

10ab 208-230 volt/ 60 hertz / 3phase wiring diagram 49 9905-002-55-90a.

Page 52

10aprb 208-230 volt/ 60 hertz / 1phase wiring diagram 50 9905-002-55-91a.

Page 53

10aprb 208-230 volt/ 60 hertz / 3phase wiring diagram 51 9905-002-55-92a.