- DL manuals

- Jackson MSC

- Dishwasher

- 10AB-N70

- Installation And Operation Manual

Jackson MSC 10AB-N70 Installation And Operation Manual

S6161-1L-FSE-010

0910-LP-113-0825

INSTALLATION AND OPERATION MANUAL FOR

JACKSON MSC

MODEL 10AB-N70 DISHWASHER

N00024-11-C-2111

JACKSON MSC, LLC.

P.O. BOX 1060

HWY. 25E

BARBOURVILLE, KY 40906

PUBLISHED BY DIRECTION OF COMMANDER, NAVAL SEA SYSTEMS COMMAND

APRIL 29, 2013

STATEMENT A

APPROVED FOR PUBLIC RELEASE

DISTRIBUTION UNLIMITED.

Summary of 10AB-N70

Page 1

S6161-1l-fse-010 0910-lp-113-0825 installation and operation manual for jackson msc model 10ab-n70 dishwasher n00024-11-c-2111 jackson msc, llc. P.O. Box 1060 hwy. 25e barbourville, ky 40906 published by direction of commander, naval sea systems command april 29, 2013 statement a approved for public...

Page 2

Approval and procurement record approval data for: s6161-1l-fse-010 title of manual: installation and operation manual for jackson msc model 10ab- n70 dishwasher approval authority: groton, ct design agent, electric boat corporation, dtd april 29, 2013. Contract number ship applicability quantity of...

Page 3

Record of alterations this manual reflects alterations occurring after april 29, 2013 as a result of the following: change no. Deficiency description.

Page 4

Safety-1 safety summary general the following general environmental, safety, and occupational health (esoh) notices supplement the specific warnings and cautions appearing elsewhere in this manual. They are recommended precautions that must be understood and applied during operation and maintenance ...

Page 5

Safety-2 industrial hygiene personnel must observe industrial hygiene requirements. Review requirements for appropriate engineering controls and personal protective equipment (ppe) with the ship's safety officer, or the maintaining activity's industrial hygiene department, to determine appropriate p...

Page 6: Technical Manual

Model 10ab –n70 technical manual installation manual for export units service manual for domestic units electrically heated models: model 10ab-n70 sept. 10, 2012 p/n 07610-003-97-40 jackson msc, llc p.O. Box 1060, hwy 25e barbourville, ky usa 1.606.523.9795 www.Jacksonmsc.Com ®.

Page 7

Manufacturers warranty one year limited parts & labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from date of purchase, but in no event to exceed (18) eig...

Page 8

Revision letter revision date made by applicable ecns details.

Page 9

Table of contents specifications ͷ instructions ͺ ʹͲ ʹʹ maintenance ʹ͵ ʹͷ ʹ ʹ ʹͺ Ƭ ʹͻ parts section ͵ͳ ͵͵ ͵ͷ ͵ ͵ ͵ͻ Ͷͳ Ͷʹ Ͷ͵ ͶͶ Ͷͷ Ͷ Ƭ Ͷ appendix a, dema nitro warewash dispe...

Page 10

5 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) machine dimensions 19 in. 30 3 8 19 1 2 17 in. 2 1 8 25 1 4 drain 1 1 2 " 40 7 16 rinse aid inlet 1/4" npt water pressure regulator, 1/2" npt 16 1 4 5 in. 8 3 8 14 5 16 22 1 2 inlet water connection 1/2” npt view: bottom of d...

Page 11

6 page created: 09-10-2012 technical manual (07610-003-97-40) operating parameters model designation: 10ab-n70 operating capacity: racks per hour 45 dishes per hour 450 glasses per hour 1215 tank capacity (gallons): wash tank 4.5 rinse tank 3 electrical loads (as applicable): wash motor hp 1/3 rinse...

Page 12

7 page created: 09-10-2012 technical manual (07610-003-97-40) notes regarding electrical requirements all electrical ratings provided in this manual are for reference only. Always refer to the machine data plate to get the exact electrical information for your machine. All electrical work performed ...

Page 13

8 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) installation instructions visual inspection: before installing the unit, check the container and the machine for damage. A damaged container may be an indication there is possible damage to the product. If there is any type o...

Page 14

9 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) installation instructions (continued) connecting the drain line: the drain for the unit is a gravity discharge drain. All piping to the machine drain must be a minimum 1-1/2” npt and shall not be reduced. Electrical power con...

Page 15

10 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) installation instructions (continued) view representation pertaining to bottom of dishmachine 874 x 3 plcs. Machine mounted junction box electrical knockouts located on bottom of junction box 19.00 8.00 3.00 bottom of mach...

Page 16

11 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) installation instructions (continued) a detail a b detail b rinse temperture probe inlet (see below) rinse aid inlet 1/4” npt 1-1/2” npt drain connection water inlet 1/2” npt electrical openings 7/8” dia. Note: rinse tempera...

Page 17

Technical manual (07610-003-97-40) installation instructions (continued) page created: 09-10-2012 revised: n/a 12 note: wash temperature probe connection to be made during installation. Front dress panel must be removed to make connection. See below on removal of dress panel. A detail a wash tempera...

Page 18

Technical manual (07610-003-97-40) installation instructions (continued) page created: 09-10-2012 revised: n/a 13 front of remote controller heater start master on wash rinse & fill manual automatic back of remote controller rinse and wash pressure holes to be connected to remote controller during i...

Page 19

Technical manual (07610-003-97-40) installation instructions (continued) 14 page created: 09-10-2012 revised: n/a 10.875 manual rinse & fill wash automatic master start heater on 11.855 16.100 12.500 9.000 10.00 8.375 16.100 6.3125 front of remote controller side of remote controller hole for imcomi...

Page 20

Technical manual (07610-003-97-40) installation instructions (continued) 15 page created: 09-10-2012 revised: n/a a detail a b detail b 1.15” dia. Hole for incoming power ground lug 2 ground lug 1 terminal board 1 1.15” dia. Hole for wiring between remote controller and dishmachine.

Page 21

Technical manual (07610-003-97-40) installation instructions (continued) page created: 09-10-2012 revised: n/a 16 note: electrical connections to be made during install. Use 14 awg wire for connections between the terminal box (tb2) and remote controller (tb1). 14 awg wire is not included. Electrica...

Page 22

Technical manual (07610-003-97-40) installation instructions (continued) 17 page created: 09-10-2012 revised: n/a electrical connection points for terminal box (tb2) terminal box (tb2) note: electrical connections to be made during install. Use 14 awg wire for connections between the terminal box (t...

Page 23

Technical manual (07610-003-97-40) 18 page created: 09-10-2012 revised: n/a installation instructions (continued) electrical connection points for chemical dispensing systems tb1 is located in the remote controller. Illustration below depicts tb1 with chemical connection points only l1 l2 l3 it1 it2...

Page 24

Technical manual (07610-003-97-40) installation instructions (continued) 19 page created: 09-10-2012 revised: n/a 19-1/4” dia. 1-7/8” dia. 10-15/16” 1/2” turndown required all around edge the illustration below depicts dimensions required for mounting 10ab-n70 to a dish table. The dimensions would a...

Page 25

20 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) operation instructions preparation: before proceeding with the start-up of the unit, verify the following: the overflow strainer is installed wash arms and rinse arms are tightly secured to manifolds that the rinse arm...

Page 26

21 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) operation instructions (continued) verify the overflow strainer has not became clogged. Keeping it free of soil and debris allows for much better flow of water through the machine and prevents any sort of redeposit issues....

Page 27

22 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) delime instructions to proceed with the delime operation, fill the dish-machine and the correct amount of delime solution as recommended by the manufacturer of the chemicals. The tank capacities of the machine can be found o...

Page 28

Technical manual (07610-003-97-40) troubleshooting 23 page created: 09-10-2012 revised: n/a warning: inspection, testing and repair of electrical equipment should only be performed by a qualified service technician. Many of the tests require that the unit have power to it and live electrical compone...

Page 29

24 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) troubleshooting (continued) problem possible cause remedy hood binding does not open and close freely. 1. Hood misaligned due to loose hood support pipe nut. 2. Teflon washer on hood between inner and outer hood damaged. 1. ...

Page 30

1. Shut off power to the dish-machine. Turn master switch to off position. 2. Open door and drain machine by lifting overflow strainer. 3. When empty, replace overflow strainer. 4. Remove the pin holding the rinse feed pipe and remove the feed pipe and rinse head assembly. 5. Locate the allen head s...

Page 31

General description: the timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted on the control panel of the control box, to control the automatic functions of the machine. It consists of a clock motor which operates on 60 cycle ac, 120 vac. In addition to the cloc...

Page 32

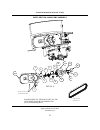

Technical manual (07610-003-97-40) service instructions for wash pump 27 page created: 09-10-2012 revised: n/a seal, crane bearings (2 req.) ring, retainer shaft washer, phenolic housing, pump pump housing gasket rotation impeller installing new seal in wash pump 1. Remove the four bolts holding pum...

Page 33

Technical manual (07610-003-97-40) service instructions for incoming water solenoid valve 28 page created: 09-10-2012 revised: n/a diaphragm cartridge possible problems: pilot port extension #1 clogged, hole #2 clogged. Remedy pass heated straight pin through hole #2 or clean hole #1. Disassembly: t...

Page 34

Technical manual (07610-003-97-40) master switch: the switch interrupts all power going to the control circuit, this means that all switches on remote controller are inoperable until master switch is turned “on”. Start switch: this switch controls the timer motor through two circuits (see electrical...

Page 35

If a switch is found to be defective, replacement can be achieved by placing the new switch next to the old one. To make sure the new switch is not upside down, line it up with the keyways. Transfer wires one at a time to the new switch. If this is not practical, pull wires off, one at and tag them ...

Page 36

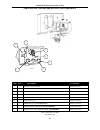

31 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) parts section: control box components 11 11 12 12 2 3 1 8 18 15 7 14 10 16 19 9 10 13 17 the illustration to the left depicts components of the remote controller with control cover. Please refer to the parts list on the next...

Page 37

32 page created: 09-10-2012 revised: n/a parts section: control box components (continued) item qty description part number 1 1 w-control box 05700-003-93-10 2 1 w-gauge box 05700-003-97-92 3 1 w-control box bracket 05700-003-95-04 4 1 w-control box cover 05700-003-97-93 5 1 decal 07610-003-97-40 6 ...

Page 38

33 page created: 09-10-2012 revised: n/a parts section: hood assemblies technical manual (07610-003-97-40) please refer to the parts list on the next page for part numbers and quantities required 5 4 3 7 6 11 2 1 10 8 9 9 o-ring part number (05330-400-03-08) located inside of union 13 12 2 1 14 loca...

Page 39

34 page created: 09-10-2012 revised: n/a parts section: hood assemblies (continued) item qty description part number 1 2 washer, phenolic 2.5 dia. X 3/16 thick 05311-369-02-00 2 2 washer, hood 05311-179-01-00 3 1 f-washer 05700-000-29-69 4 1 gasket, 2” o.D. X 1 1/2” x 1/16” 05330-200-23-00 5 2 o-rin...

Page 40

35 page created: 09-10-2012 revised: n/a parts section: rinse arm assembly item qty description part number 1 2 assembly, rinse head (complete, with all items pictured above) 05700-000-28-68 2 2 plug, rinse arm 04730-609-04-00 3 2 washer, nylatron 5311-369-08-00 4 1 bushing, rinse head 05700-000-28-...

Page 41

36 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) parts section: tub assembly intake strainer part# 04730-017-15-10 overflow strainer part# 04730-017-15-05 rack support part# 05700-000-13-43 o-ring (used below overflow strainer) part# 5330-400-05-00 rinse feed casting part#...

Page 42

37 page created: 09-10-2012 revised: n/a parts section: wash pump assembly technical manual (07610-003-97-40) a please refer to the parts list on the next page for part numbers and quantities required pulley connects to wash pump motor 16 v-belt, part # 03030-200-05-21 detail a 1 2 3 5 6 7 8 10 9 4 ...

Page 43

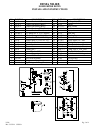

38 page created: 09-10-2012 revised: n/a parts section: wash pump assembly (continued) item qty description part number 1 1 pulley, 5/8” bore x 2-1/2” od 03020-300-01-69 2 1 impeller 05700-000-18-25 3 1 seal, ceramic 05330-300-02-27 4 1 pump housing gasket 05330-200-03-06 5 1 seal, crane 05330-300-0...

Page 44

39 page created: 09-10-2012 revised: n/a parts section: inlet plumbing assembly technical manual (07610-003-97-40) 2 10 1 13 1 10 3 10 9 10 8 5 7 1 6 4 1 12 1 14 1 11 5 please refer to the parts list on the next page for part numbers and quantities required water hammer arrestor kit kit part number:...

Page 45

40 page created: 09-10-2012 revised: n/a parts section: inlet plumbing assembly (continued) technical manual (07610-003-97-40) item qty description part number 1 6 elbow, 1/2” 90 degree 04730-406-01-01 2 1 vacuum breaker 1/2” vacuum breaker repair kit 04820-300-07-00 6401-003-06-23 3 1 regulator, wa...

Page 46

41 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) parts section: wash manifold assembly 4 1 5 2 6 3 3 item qty description part number 1 1 w– wash manifold 10ab-n70 05700-003-97-96 2 1 wash head, bottom 05700-000-10-36 3 34 bearing, ball (1/4 s/s) (11 ball bearings between ...

Page 47

42 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) parts section: heaters and booster tank components item qty description part number 1 3 heaters, 4.47kw @ 254v 04540-003-93-91 2 1 rinse thermostat 05930-003-13-65 3 2 nut, lock 6-32 05310-373-03-00 4 1 fitting, 1/4” brass (...

Page 48

43 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) parts section: miscellaneous components drain plumbing part# 05700-003-96-55 hood support bracket part # 05700-000-27-55 hardware for mounting hood support: flat head bolt 1/4-20 x 1/2” part# 05305-174-14-00 (2 each) bolt, 1...

Page 49

Technical manual (07610-003-97-40) parts section: dish racks 44 page created: 09-10-2012 revised: n/a rack glassware, no pegs part# 07320-100-13-01 rack dishware, with pegs part# 07320-100-09-01.

Page 50

Technical manual (07610-003-97-40) parts section: spare parts kit (06401-003-98-41) page created: 09-10-2012 revised: n/a 45 item qty description part number 1 1 assembly, impeller (includes ceramic seal 05330-300-02-27) 05700-000-61-96 2 2 bearing 03110-100-01-24 3 2 thermometer, 160” capillary 066...

Page 51

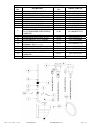

46 page created: 09-10-2012 revised: n/a technical manual (07610-003-97-40) electrical schematic legend mtr- wash pump motor 1/3 hp mc– motor contactor hc– heater contactor heaters– 4.47 kw t1– transformer 1sw– heater toggle switch 2sw– master toggle switch 3sw– start toggle switch 4sw– wash toggle ...

Page 52

L1 l2 l3 it1 it2 it3 1 2 3 4 5 6 7 8 9 10 11 14 15 21 22 1 l1 3 l2 5 l3 2 1 4 2 6 3 hcr 23 blu it2 it3 it1 red blk blk (l1) blk (l2) blk (l3) red red red red blk blk blk h1 x2 h3 f1 h2 f2 h4 x1 1mol n.O. Com l1 1 l2 3 l3 5 no 13 1 a t1 2 t2 4 t3 6 no 14 2 a 1m l1 1 l2 3 l3 5 no 13 1 a t1 2 t2 4 t3 6...

Page 53

47 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers alabama california p & d appliance gcs service inc. 4220-c roseville road philadelphia, pa jones-mcleod appliance barkers food machinery north highlands, ca (215)925-6217 svc services 95660 800-4...

Page 54

48 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers jones-mcleod appliance svc hawaii indiana certified service center 854 lakeside drive 1051 goodwin drive mobile, al 36693 food eqmt. Parts & gcs service inc. Lexington, ky 40505 (251) 666-7278 se...

Page 55

49 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers emr service division michigan gcs service inc. New hampshire 106 williamsport circle st. Louis, mo salisbury, md 21804 gcs service inc. (314) 638-7444 gcs service inc. (410) 543-8197 livonia, mi ...

Page 56

50 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers b.E.S.T. Inc. Authorized appliance ohio oregon 3003 genesee street servicecenter buffalo, ny 14225 904 s. Marshall st. Certified service center ron's service (716) 893-6464 winston-salem, nc 2740...

Page 57

51 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers rhode island whaley foodservice repairs gcs service inc. Gcs service inc. 4740-a franchise street houston, tx virginia beach, va gcs service inc. N. Charleston, sc 29418 (713)785-9187 (757) 464-3...

Page 58

52 page created: 07-06-2011 revised: n/a technical manual (07610-003-78-18) maintenance & repair centers general parts, inc. W223 n735 saratoga drive waukesha, wi 53186 (262) 650-6666 (800) 279-9946 (262) 650-6660 fax wyoming hawkins commercial appliance service 3000 s. Wyandot st. Englewood, co 801...

Page 59: Appendix A

Appendix a dema nitro warewash dispenser a-1.

Page 60

Table of contents part 1 nitro warewash dispenser user’s manual part 2 solid rinse bowl installation instructions part 3 viking bowl installation instructions part 4 nitro warewash dispenser training manual.

Page 61: Part 1

Part 1 nitro warewash dispenser user’s manual.

Page 62

I-980 page 1 of 8 rev. E-35763 6/10/10 dema nitro ware wash chemical dispensing overview the dema® nitro is a digital ware wash dispenser designed to dispense cleaning chemicals into ware wash and dish machines. The unit is triggered by a ware wash machine. The nitro is programmed via the front pane...

Page 63

I-980 page 2 of 8 rev. E-35763 6/10/10 packing list x = included in kit part number description n.Dl .Ta n.Ll .Ta n.D ll .Ta n .Ll l. Ta 904.8t rinse check valve ¼” od teflon ball x x x x 80.55 liquid detergent feed injection elbow x x 81.312.1 split pick up tube stiffener 1 2 2 3 25.68.20 20 ft ¼” ...

Page 64

I-980 page 3 of 8 rev. E-35763 6/10/10 replacement parts list model shown is of an n.Ll.Ta no. Kit no. Description 1 81.316.1 nitro/nitro express power supply replacement kit 2 81.316.12 nitro control board replacement 81.316.4 nitro/express detergent pump head & motor conv or replacement kit 81.316...

Page 65

I-980 page 4 of 8 rev. E-35763 6/10/10 installation warning: installation of dema products must meet all applicable electrical codes and regulations established by national, city, county, parish, provincial or other agencies. It is possible that electrical codes and regulations require that a certif...

Page 66

I-980 page 5 of 8 rev. E-35763 6/10/10 the following steps will help to insure the proper wiring of the unit. The unit should be triggered to power on from the dish machine that it is being used in conjunction with. Dema engineering does not recommend powering the unit separately from the dish machi...

Page 67

I-980 page 6 of 8 rev. E-35763 6/10/10 initial programming the programming of this unit is done through the control board, display, and buttons on the front of the unit. Programming of the unit is as follows: company name press and hold “enter” button for 3 seconds until backlight comes on press lan...

Page 68

I-980 page 7 of 8 rev. E-35763 6/10/10 modify programming when modifying the programming of the unit. Use the flow chart below for modifications. The menus change slightly when modifying the programming. Company name press and hold “enter” button for 3 seconds until backlight comes on press language...

Page 69

I-980 page 8 of 8 rev. E-35763 6/10/10 troubleshooting (some models may not include all items listed below) symptom probable cause remedy no power is being supplied to the unit 1. Trigger cables connected to the wrong place on the machine. 2. Switch on bottom of unit is turned off. 3. Power is not c...

Page 70: Part 2

Part 2 solid rinse bowl installation instructions.

Page 71: Dema 581-Rb

Dema 581-rb solid rinse bowl installation instructions i-568 pg. 1 of 4 rev. J-35524 3/25/10 all hardware required for installation is included with unit per individual order. No brackets or other hardware necessary. Note: all work should be done in a neat workmanship manner and adhere to all applic...

Page 72: Dema 581-Rb

Dema 581-rb solid rinse bowl installation instructions i-568 pg. 2 of 4 rev. J-35524 3/25/10 the detergent dispenser may call for the detergent numerous times after the reservoir is full, but no more product will be dissolved until the lcs senses that more is needed. No. Part no. Description 1 81-14...

Page 73: Dema 581-Rb

Dema 581-rb solid rinse bowl installation instructions i-568 pg. 3 of 4 rev. J-35524 3/25/10 no. Part no. Description no. Part no. Description 1 61-93 vacuum breaker ¼” (brass) 20 58-9 o-ring only (ep) 2 58-54-4 compression elbow (brass) 21 58-28 spring 3 58-53-8 compression fitting (brass) 22 58-11...

Page 74: Dema 581-Rb

Dema 581-rb solid rinse bowl installation instructions i-568 pg. 4 of 4 rev. J-35524 3/25/10 returns: no merchandise may be returned for credit without dema’s written permission. Return merchandise authorization number required in advance of return. Warranty: dema products are warranted against defe...

Page 75: Part 3

Part 3 viking bowl installation instructions.

Page 76: Dema 5800V & 5800V.B

Dema 5800v & 5800v.B viking bowl installation instructions choose a location on the wall that will allow gravity feed of the chemical to the dish machine. You don't want to be more than 5' from the bottom of the viking bowl to the bulkhead fitting in the dish machine tank wall. The 5/8" i.D. Clear p...

Page 77

Viking bowl parts list item no. Description dema part no. Viking part no. 1 spray arm with brass plug 58.300 voa intplug v80 2 stainless steel ball 58.301 cha vkbssbl 000 3 mpt fitting with o-ring 58.302 voa ny11mpt v81 4 ¼” jaco nut w/ ring & ferrule 58.303 cha 1/4jacp 000 5 plated brass collar 58....

Page 78: Part 4

Part 4 nitro warewash dispenser training manual.

Page 79

Nitro bridges the gap between compact basic dispensers and large feature full dispensers too bulky for smaller kitchen environments – probe or probeless operation from the same unit – pre-wired power supply – password protected digital programming – multi-lingual display – quick change pump – option...

Page 80

Nitro features • 100-260vac 50/60hz main power (constant power) • 24-480vac trigger signals • detergent pump output 6 oz./min (180ml / min) • rinse pump output 1.3 oz./min (40ml / min).

Page 81: Sanitizer

Nitro button functions sanitizer prime button primes sanitizer and moves cursor left in programming det. Prime / down arrow primes detergent and decreases value or moves cursor down exit button exits the programming and moves cursor right in programming rinse prime / up arrow primes rinse and increa...

Page 82

Idle screen & priming • idle / default screen shown when unit is not being programmed • unit will return to this screen during long periods of no button activity • press and hold any prime button to prime each pump.

Page 83

Language screen- english • press enter to modify language • use up & down arrows to select between 4 languages – english, spanish, portuguese and french • press enter to select desired language • press down arrow for rack count screen.

Page 84

Rack count • displays number of rack counts registered • rack counts are generated by rinse length in conveyor mode or machine operations in door mode • press down arrow for information screen.

Page 85

Information screen • displays the following information • det – p = probeless mode – c = concentration mode • sp – not applicable for probeless mode – detergent set point in concentration mode • input – actual probe reading • press down arrow for new program.

Page 86

New program • create new program • can be for either door or conveyor machine types and probeless or concentration mode • press enter to create new program.

Page 87

Concentration mode – detergent control mode • press enter to modify setting • use up or down arrows to change between probeless or concentration • press enter when concentration is displayed • press down arrow to advance to machine type.

Page 88

Concentration mode - machine type • press enter to modify setting • use up or down arrows to change between conveyor and door • press enter when desired machine type is displayed • press down arrow to advance to trigger mode.

Page 89

Concentration mode – trigger mode • press enter to modify setting • use up or down arrows to change between detergent/rinse, detergent only or rinse only • press enter when desired mode is displayed • press down arrow to advance to concentration set point.

Page 90

Concentration mode – concentration set point • press enter to modify setting • use up & down arrows to adjust concentration set point • press enter when desired setting is displayed • press down arrow to advance to feed rate.

Page 91

Concentration mode – feed rate • controls how quickly set point is reached, high feed rate can lead to over shooting – 5 is a good starting point • press enter to modify setting • use up & down arrows to adjust feed rate • press enter when desired setting is displayed • press down arrow to advance t...

Page 92

Concentration mode – feed limit • limits the amount of time that the detergent pump will run without reaching set point • press enter to modify setting • use up & down arrows to adjust feed limit in minutes and seconds • press down arrow to advance to alarm delay.

Page 93

Concentration mode - alarm delay • amount of time before detergent alarm sounds • press enter to modify setting • use up & down arrows to adjust time setting (minutes / seconds) • press enter when desired setting is displayed • press down arrow to advance to alarm volume.

Page 94

Concentration mode - alarm volume • sets volume of audible detergent alarm • press enter to modify setting • use up or down arrows to adjust volume • press enter when desired volume is reached • press down arrow to advance to rinse speed.

Page 95

Concentration mode - rinse speed • adjust rinse pump speed • press enter to modify setting • use up & down arrows to adjust rinse speed • press enter when desired speed is displayed • press down arrow to advance to rinse length.

Page 96

Concentration mode – rinse delay • for door machine only • delays rinse pump activation up to 15 seconds • press enter to modify setting • use up & down arrows to adjust rinse delay • press enter when desired rinse delay is displayed • press up or down arrow to advance to other screens.

Page 97: • For Conveyor Machine

Concentration mode - rinse length • for conveyor machine type only • rinse length should match the amount of rinse time per rack • allows nitro to count racks on a conveyor machine • use up & down arrows to adjust rinse length • press enter when desired length is displayed • press down arrow to adva...

Page 98

Concentration mode - sanitizer speed • adjust sanitizer pump speed • press enter to modify setting • use up & down arrows to adjust sanitizer speed • press enter when desired speed is displayed • press down arrow to advance to company name • note: advance to slide 34 for company name or proceed to n...

Page 99

Probeless mode - detergent control mode • press enter to modify setting • use up or down arrows to change between probeless or concentration • press enter when desired mode is displayed • press down arrow to advance to machine type.

Page 100

Probeless mode - machine type • press enter to modify setting • use up or down arrows to change between conveyor and door • press enter when desired machine type is displayed • press down arrow to advance to trigger mode.

Page 101

Probeless mode – trigger mode • press enter to modify setting • use up or down arrows to change between detergent/rinse, detergent only or rinse only • press enter when desired mode is displayed • press down arrow to advance to recharge time.

Page 102

Probeless mode - recharge time • the “top off” or subsequent detergent feeds after initial new tank detergent feed • press enter to modify setting • use up & down arrows to adjust time setting (minutes & seconds) • press enter when desired setting is displayed • press down arrow to advance to dwell ...

Page 103: • For Conveyor Machine

Probeless mode - dwell time • for conveyor machine type only • amount of time between initial and subsequent recharges • press enter to modify setting • use up & down arrows to adjust time setting (minutes / seconds) • press enter when desired setting is displayed • press down arrow to advance to in...

Page 104: Only

Probeless mode -dead cycles • for door machine type only • the number of machine operations that will not get a subsequent recharge • press enter to modify setting • use up & down arrows to adjust number of cycles between recharges • press enter when desired setting is displayed • press down arrow t...

Page 105

Probeless mode -initial charge • the time the detergent will dispenser for a new tank of water • press enter to modify setting • use up & down arrows to adjust time setting (minutes / seconds) • press enter when desired setting is displayed • press down arrow to advance to charge clock (conveyor mod...

Page 106: • For Conveyor Machine

Probeless mode - charge clock • for conveyor machine type only • allows dispenser to provide initial charge after a defined period of time without trigger signals • press enter to modify setting • use up & down arrows to adjust time setting (hours / minutes) • press enter when desired setting is dis...

Page 107

Probeless mode –charge activate • for door machine type only • allows the dispenser to recognize machine fill versus rinse cycle • trigger mode must be set to “rinse only” • press enter to modify setting • use up & down arrows to adjust time setting • press enter when desired seconds are displayed •...

Page 108

Probeless mode - rinse speed • press enter to modify setting • use up & down arrows to adjust rinse speed • press enter when desired speed is displayed • press down arrow to advance to rinse length (conveyor mode) or sanitizer speed (door mode).

Page 109: • For Conveyor Machine

Probeless mode - rinse length • for conveyor machine type only • rinse length should match the amount of rinse time per rack • allows nitro to count racks on a conveyor machine • use up & down arrows to adjust rinse length • press enter when desired length is displayed • press down arrow to advance ...

Page 110

Probeless mode - sanitizer speed • press enter to modify setting • use up & down arrows to adjust sanitizer speed • press enter when desired speed is displayed • press down arrow to advance to company name.

Page 111

Company name • up to 16 characters • press enter to modify setting • use left & right arrows to move between characters • use up & down arrows to at adjust each character • press enter when desired name is displayed • press down arrow to advance to rack count.

Page 112

Rack count • displays number of rack counts registered • rack counts are generated by rinse length in conveyor mode or machine operations in door mode • press enter to reset and follow on-screen instructions • press down arrow to advance to enter code.

Page 113

Enter new code • access code gains access to system programming setup • press enter to modify access code.

Page 114

Enter program code • use sanitizer button to move cursor left and exit button to move cursor right • use up & down arrows to change digit in each position • press enter when access code is displayed • note: default value out of box is 0000

Page 115

Accept program code • press exit to accept new access code • press any other button to reject new access code.

Page 116

• press exit to leave programming mode or use up & down arrows to navigate to other screens to make changes.