- DL manuals

- Jackson MSC

- Dishwasher

- 24

- Service Manual

Jackson MSC 24 Service Manual

Summary of 24

Page 1

World headquarters & manufacturing operations highway 25e, p.O. Box 1060 barbourville, ky 40906 888/800-jmsc fax: 606/523-9196 7610-100-04-00

Page 2

Index warranty inside front cover specifications 3 general instructions (installation) 4-5 installation instructions for wall mount dispenser unit only 6 installation of tie down assembly for canadian standards 7 general instructions (operation) 8 operator's instructions for wall mount dispensing un...

Page 3: Specifications

Specifications operating capacity 100% racks per hour dishes per hour glasses per hour 17 425 425 operating cycle wash time, seconds rinse time, seconds total cycle, seconds 60 27 180 wash tank capacity (gallons) 2.7 wash/rinse pump capacity (gpm) 60 requirements 100% inlet temperature, °f gallons p...

Page 4: General Instructions

General instructions (installation) note: read the following instructions carefully. Proper installation of your jackson dishwasher will assure proper machine operation. Uncrating 24l: 1. Remove straps around carton. 2. Open top flaps of dishwasher carton. 3. Remove any packing from top and sides of...

Page 5

Installation of model 24lm top and table gasket: these instructions are to be used for applying the adhesive backed sponge rubber strip to the top of the machine prior to setting the table in place. Included with the model 24lm table is a 6' length of 1/4" thick x 1" wide sponge rubber adhesive back...

Page 6

Installation instructions for wall mount dispenser unit only 1. Supplied with the unit is a wall mounted dispenser unit consisting of three peristaltic pumps mounted inside of a stainless box with conduit and wires coming from the bottom. With the lower kick plate removed connect the conduit to the ...

Page 7

Installation of tie down assembly for canadian standards 1. Locate the desired floor area in which the unit is going to be installed. 2. Place the base cradle in the exact location the machine will set with the end having the holes drilled in it to the rear. 3. Mark the holes and then drill two hole...

Page 8: General Instructions

General instructions (operation) note: read the following instructions carefully. Proper operation of your jackson dishwasher will assure clean and sanitized glasses and dishes at optimum efficiency. Dish preparation: 1. Scrape dishes thoroughly. 2. Pre-wash dishes by soaking or spraying with hose. ...

Page 9: General Instructions

Operator's instructions for wall mount dispensing units 1. Check that the pan strainer is clean. Strainer must be clean for proper machine operation (wash/rinse head must be removed first, then strainer may be removed for cleaning). 2. Insert a rack of dishes and then close the door and turn handle....

Page 10: 24L Cycle Sequence Chart

24l cycle sequence chart operator 1. Push power switch 2. Close door 3. Latch door handle 4. Push fill switch 5. Push start switch 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Operation energizes to handle switch closes door side switch energizes the machine manually fills machine energizes timer motor d...

Page 11

Item p/n description item p/n description 1. 1865 wash head cap with race 6. 1875 wash head center shaft 2. 1870 wash head cap set screw 7. 1936 wash head fixed race 3. 1940 wash head bearing 1/4 " s/s 8. 1886 wash head shaft holding pin 4. 1890 wash head small manifold 9. 1096 upper pump housing w/...

Page 12: Timer For Model 24L

Timer for model 24l general description: the timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted on the lower control panel of the jackson dishwashing machine to control the automatic functions of this machine. It consists of a clock motor which operates on 60 ...

Page 13: Timer For Model 24L

Timer for model 24l wall mount dispensing systems general description: the timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted on the lower control panel of the jackson dishwashing machine to control the automatic functions of this machine. It consists of a clo...

Page 14: Timer Motor and

Timer motor and adjustment to cams (for wall mount dispensing systems) caution: always remove the power to the machine before working on the control panel or while servicing the components in the door panel. All electrical checks should be made by qualified personnel. A defective motor is indicated ...

Page 15: Defective Motor

Defective motor caution: always remove the power to the machine before working on the control panel or while servicing the components in the door panel. All electrical checks should be made by qualified personnel. A defective motor is indicated by the fact that the cams do not rotate or the machine ...

Page 16: Replacement of Switches

Replacement of switches in front door there are three switches installed in the door's upper right hand corner. These are the start, drain, and fill. Before working on the machine, it is important that the power be turned off at the customer's circuit breaker to prevent the possibility of electrical...

Page 17: Checkout

Checkout (interlock system) note: all electrical checks should be made by qualified service personnel. If it is determined that the proper power is being applied to the machine's incoming terminal blocks, then further check of the interlock system should be made. Note: this checkout would only be pe...

Page 18: Operator Controls

Operator controls the operator of this machine has only three control switches which he can operate. These switches are located in the top righthand corner of the machine's front door. 1. The start switch initiates automatic operation of the machine. 2. The drain switch allows the user to manually d...

Page 19: Dispensing Systems

Operator controls for wall mount dispensing systems the operator of this machine has six control switches which he can operate. Three of these switches are located in the top righthand corner of the machine's front door and the remainder, in the dispenser box. 1. The start switch initiates automatic...

Page 20: Peristaltic Pump Sanitizing

Peristaltic pump sanitizing dispensing system (for wall mount dispensing systems) the three peristaltic pumps are mounted in the dispenser box which is attached to the wall or unit. The pump receive their electrical signals from two sources. The first source is the rinse/fill switch which is used to...

Page 21: Peristaltic Pump Sanitizing

Peristaltic pump sanitizing dispensing system (operation) the three peristaltic pumps are mounted in the dispenser box which is attached to the wall or unit. The pump receive their electrical signals from two sources. The first source is the rinse/fill swi tch which is used to prime the pump when it...

Page 22

P/n 465 complete pump assembly item p/n description item p/n description 1. 465apump motor 8. 465hface plate 2. 465bpump housing 9. 465i plate mounting 3. 465chousing mounting bolts screws (4) 8/32 (3) 10/32 fillster head 10. 465jintake or suction 4. 465 dcam roller assembly tubing 5. 465ecam roller...

Page 23: Service Instructions

Service instructions (incoming water solenoid valve) solenoid valve p/n 1420 to take the valve apart: disassembly — these valves may be taken apart by unscrewing the bonnet and the enclosing tube assembly from the valve body assembly. See fig. 3. After unscrewing, carefully lift off the bonnet and e...

Page 24: Seal and Ceramic For

Seal and ceramic for pump system (general information) the wash and drain pump are part of the total motor pump system. One seal and ceramic are utilized to prevent the pump from leaking. Replacement of seal and/or ceramic: 1. Drain machine either by depressing drain switch or by baiting out. 2. Tur...

Page 25: Trouble Shooting Guide

Trouble shooting guide problem cause solution water overflow out bottom of 1. Machine not level. 1. Level machine, slight tilt front door when wash pump to rear. Is operating. 2. Overflow drain clogged. 2. Remove obstruction, checking inside of machine first. 3. Water level in machine's 3. Solenoid ...

Page 26: Trouble Shooting Guide

Trouble shooting guide problem cause solution fill water runs continuously 1. Defective plunger in 1. Replace plunger. With circuit breaker controlling solenoid valve. Machine turned off. 2. Defective diaphragm in 2. Check holes in diaphragm solenoid valve. Cartridge to insure that they are open. Th...

Page 27: Trouble Shooting Guide

Trouble shooting guide problem cause solution machine doesn't drain when 1. Drain solenoid clogged. 1. Remove obstruction. Drain switch is depressed. 2. Defective drain switch. 2. Replace. 3. Defective motor or 3. Replace. Motor start relay. 4. Defective drain solenoid. 4. Replace. 5. Defective moto...

Page 28

Front view of machine item p/n description 1. 512 door handle assembly 2. Switches — drain, fill. Start 3. 492 front door 4. 1889 wash/rinse assembly 5. 1420 solenoid (fill) 6. 553 flow control 7. 1536 "y" strainer 8. 303 electrical control panel mounting plate 9. 1251 upper rinse head assembly 10. ...

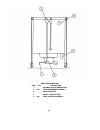

Page 29

Back view of machine item p/n description 1. Incoming water connection 2. 1841 vacuum breaker assembly 3. Equalizing vent 4. Drain — gravity feed 5. 1081 pump & motor assembly 29.

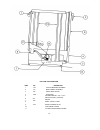

Page 30

Left side view of machine item 1. 2. 3. 4. P/n 1841 512 492 549a description vacuum breaker assembly door handle assembly front door, outer kick panel 5. 6. 7. 834 1081 incoming water • 120º • 140º f adjusting feet (4 places) motor 8. 9. 10. 11. 1424 drain - gravity feed drain solenoid valve side fr...

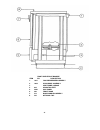

Page 31

Right side view of machine item p/n description 1. 1841 vacuum breaker assembly 2. 1889 wash/rinse assembly 3. Side frame & brace 4. 834 adjusting feet 5. 549a kick panel 6. 492 front door 7. 512 door handle assembly 8. 547 optional top 31.

Page 32

Bottom view of machine item p/n description 1. 1081 pump motor (wash — rinse) 2. 536 drain hoses 3. Overflow drain — gravity feed 4. 1424 drain valve 5. 1691 thermometer 6. 1536 "y" strainer 7. 553 flow control 8. 1420 solenoid — fresh water 32.

Page 33

33 item p/n description 1. 1536 "y" strainer 2. Removeable filter 3. 553 flow control 4. 1420 solenoid valve 1/2" 5. Pipe union.

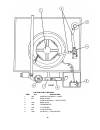

Page 34

Pump and m0tor assembly item 1. 2. P/n 1085 description motor mounting plate 3. 1085 stationary seal assembly 4. 1085 shim washers 5. 1085 rotating ceramic 6. 1085 propeller for drain pump 7. 1085 "o" ring seal 8. 1085 drain inlet plate 9. 1095 suction adapter plate 10. 1090 impeller for wash pump 1...

Page 35

Item p/n description 1. 1691 thermometer 2. 1665 terminal board 3. Grounding lug 4. 1207 motor starting relay 5. 1246 drain relay (motor reversing) 6. 1713 timer 7. 460 sanitizing pump (l/lf models only) (located behind bracket) 8. 1213 motor relay 35.

Page 36

36 1. Gauge 2. Bracket 3. Nuts wash/rinse head assembly located item p/n description 1. 1889 wash assembly 2. Wash reservoir.

Page 37

Note: all neutral wires “white” all ground wires “green” all other wires “red”.

Page 38: Complete Parts List For 24L

Complete parts list for 24l 303 control panel, wired (lower front) for 24l 1 447 door handle cam nut 2 465 dispenser peristaltic pump, complete 1 465a dispenser peristaltic pump motor 1 465b dispenser peristaltic pump housing 1 465c dispenser peristaltic pump housing mounting bolts 3 465d dispenser ...

Page 39

Complete parts list for 24l 1647 switch bracket, for latch interlock 1 1656 terminal board, 3-pole 1 1691 thermometer, standard 1 1713 timer, 110v, 7 cams adjustable. Wall mount units 1 1719 timer, 115v for 24l(5cam) 6173500 1 1775 timer micro switches, plastic module-type 5 1841 vacuum breaker, slo...