- DL manuals

- Jackson MSC

- Dishwasher

- JP-24BPNSU

- Technical manual

Jackson MSC JP-24BPNSU Technical manual

Summary of JP-24BPNSU

Page 1

Dishwashing machine jp-24bpnsu technical manual description, operation, installation and maintenance instructions june 22, 2000 p/n 7610-002-38-50 visit jackson on the internet at: www.Jacksonmsc.Com high temperature sanitizing undercounter unit 460 volt - 60 hertz - 3 phase.

Page 2

Manufacturers warranty one year limited parts & labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from the date of purchase, but in no event to exceed (18)...

Page 3

Approval data for: title of manual: description, operation, installation, and maintenance instructions for dish- washing machine, model jp-24bpnsu approval authority: (letter of approval from procuring activity contract no. Nsn no. Of units cid/apl dla-400-90-m-1376 7320-01-144-2638 1 432100007 rema...

Page 4

1. Purpose: this technical publication is issued for the purpose of identifying and authorizing the following commercial manual for navy use. Manufacturer: jackson msc inc., barbourville, kentucky 40906 purchase order or contract no.: dla-400-90-m-1376 equipment: dishmachine, model jp-24bpnsu additi...

Page 5

General page specifications ............................................................................................... 1 detail of data plate....................................................................................... 2 general notes......................................................

Page 6

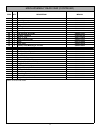

1 performance/capabilities operating capacity (racks/hour) racks per hour 21 dishes per hour 525 glasses per hour 525 operating cycle (seconds) wash time 120 rinse time 15 total cycle time 150 tank capacity (gallons) wash tank 5.65 rinse tank 3 wash pump capacity gallons per minute 60 temperatures w...

Page 7

Details of the jp-24bpnsu data plate 2 model: serial no.: 60hz 3 ph 3 wire wash motor: 3/4 hp 1.6 amps 460 volt 180°f 150°f 120 sec 20 psi minimum wash temperature minimum rinse temperature wash cycle time optimum flow pressure total load: 11.0 amps connect to minimum 15 ampere supply-circuit protec...

Page 8

Before connecting, operating, or adjusting any of the dishmachines covered in this manual, please carefully read through the entire manual to familiarize yourself with the machine and its proper operation. This manual contains important operating, safety, and main- tenance information concerning you...

Page 9

Visual inspection: before installing the unit, check the con- tainer and machine for damage. A damaged container is an indi- cator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away the container. The dishmachine has been inspected a...

Page 10

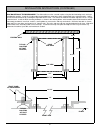

Deck mounting of the dishmachine: the dishmachine must be secured in place using the deck mounting tracks and caps provided with machine. Install the (4) adjustable feet provided into screw holes where shipping bolts were removed earlier. Adjust the level of the dishmachine by screwing the adjustabl...

Page 11

Detergent usage and water hardness are two factors that contribute greatly to how efficient your dishmachine will operate. Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified water treatment specialist can tell you what is needed for maximum efficie...

Page 12

Check off the following items as they are completed before proceeding to operation of dishma- chine. Has the dishmachine been checked for concealed/hidden damage? Has the dishmachine and the surrounding area been properly vented in accordance with all applicable codes? Has the dishmachine been prope...

Page 13

Preparation: before proceeding with the start-up of the unit, verify the following: 1. The strainer is in place and is clean. 2. That the wash and rinse arms are screwed securely into place and that their endcaps are tight. The wash and rinse arms should rotate freely. Power up: to energize the unit...

Page 14

Troubleshooting section 9 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times....

Page 15

Troubleshooting section 10 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times...

Page 16

Troubleshooting section 11 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times...

Page 17

Troubleshooting section 12 warning: inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise extreme caution at all times...

Page 18

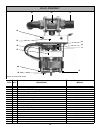

Replacing the pump motor the following list of tools will be needed to complete this procedure. 5/6” nutdriver, phillips screwdriver, 7/16” socket and ratchet, and 7/16” wrench. 1. Disconnect the electrical power to the dishwasher at the main circuit breaker box when servicing. Place a tag on the ci...

Page 19

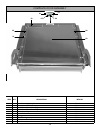

Jp-24b dimensions 14 legend: a .- drain connection flexible hose. 6’-0” free length, 1” id x 1 3/8” od b . - electrical connection. C .- water inlet 1/2” female pipe thread, 2 1/2” aff d .-detergent feeder connection letter dimensions e 2-1/2” f 12” g 19” h 22-5/8” i 16-3/4” j 24” k 8-1/2” l 2-3/4” ...

Page 20

Main assembly front view 15 02 03 06 05 04 01 item qty description mfg no. 01 1 door decal 9905-021-41-49 02 1 complete door 5700-011-39-15 03 1 kick plate 5700-041-86-40 04 1 shroud 5700-031-38-15 05 1 handle 5340-011-60-25 06 1 control, jp24 nsu complete 5700-002-18-39.

Page 21

Main assembly rear view 16 01 08 06 05 04 03 02 01 29 28 09 27 26 25 24 23 22 21 01 20 18 17 16 15 01 13 12 11 09 10 07 22 19 14.

Page 22

* refers to an item not shown. Main assembly rear view (continued) 17 item qty description mfg no. 01 4 tricnut, 10-32 5340-118-05-00 02 1 rinse injector 5700-031-41-83 03 1 thermometer, rinse 6685-111-40-39 04 3 plug, 1/4" brass 4730-209-01-00 05 1 gasket, vellumoid 5330-111-42-81 06 1 rinse tube s...

Page 23

Control panel assembly 18 04 06 07 08 09 10 11 12 13 16 15 18 18 20 18 22 23 24 26 28 19 05 03 02 01 29 25 21 15 17 14 30 27 item qty description mfg no. 01 1 fitting, 1/4 barb 1/4fnpt swivel 4730-011-95-42 02 1 tie wrap 5975-602-01-16 03 1 hose, 5/16 x 12" 5700-011-86-45 04 1 acme transformer, 480 ...

Page 24

* refers to an item not shown incoming plumbing assembly 19 02 03 04 03 05 06 03 09 08 07 item qty description mfg no. 01 2 elbow, 1/2" c to ftg 4730-406-31-01 02 1 union, 1/2" c to c 4730-412-05-01 03 3 adapter, 1/2" ftg x male 4730-011-59-53 04 1 valve, solenoid 1/2" 115 volt 4810-100-12-18 05 1 b...

Page 25

Motor assembly 20 01 02 03 04 05 06 07 08 04 09 04 10 11 01 item qty description mfg no. 01 2 hose clamp, 13/16-1 1/2, #16 4730-719-06-09 02 1 motor, wash 6105-121-60-06 03 1 formed drain hose 4720-121-40-36 04 4 hose clamp, 1 5/16" - 2 1/4" # 28 4730-719-01-37 05 4 hose,1 1/4 x 2 1/4 reinforced 570...

Page 26

Wash & rinse arm assembly 21 01 05 07 09 10 12 11 14 15 16 02 03 04 06 13 08 02 17 18 item qty description mfg no. 01 1 rinse hub weldment 5700-021-38-31 02 2 rinse arm assembly 5700-031-39-21 03 1 left frame assembly 5700-031-35-58 04 1 left hinge cover 5700-002-18-41 05 1 left hinge stop 5700-021-...

Page 27

Booster tank assembly 22 06 05 04 02 01 07 08 09 10 11 12 13 03 item qty description mfg no. 01 4 leg, zinc 1-1/4 leveler 3/8" swivel 5340-108-02-00 02 1 screw, 10-32 x 3/8" truss head 5305-173-12-00 03 1 shroud 5700-031-38-15 04 4 nut, hex 5/16-18 s/s 5310-275-01-00 05 1 heater, 480v 4540-111-51-46...

Page 28

* refers to an item not shown. Valve assembly 23 item qty description mfg no. 1 valve, assembly 115v, jp 5700-002-23-22 01 1 hosebarb, 1 x 3/4 npt polypropylene 4730-011-65-86 02 1 valve, w/ brackets 5700-002-23-23 03 1 hosebarb, 90 deg 3/4 npt x 1 4730-011-65-87 04 4 fastener, 10-32 5340-111-58-10 ...

Page 29

Complete door assembly 24 item qty description mfg no. Door assembly, complete 5700-011-39-15 01 12 screw,10-32 x 1/2" 5305-011-44-51 02 1 seal channel, inner door right 5700-031-32-91 03 1 seal channel, inner door top 5700-031-32-90 04 1 latch assembly 5700-011-44-41 05 2 latch roller 5700-011-44-3...

Page 30

Complete door assembly (continued) 25 01 02 03 04 05 07 09 10 11 12 13 06 item qty description mfg no. 01 1 switch striker 5700-011-44-24 02 2 screw, 10-32 x 1/2" pan ph. Head 5305-011-44-52 03 2 locknut, 10-32 5310-373-02-00 04 1 door handle 5340-011-60-25 05 1 outer door 5700-031-35-72 06 12 faste...

Page 31

Kick plate assembly 26 01 02 03 04 02 05 06 07 08 09 02 item qty description mfg no. 01 2 locknut, 1/4-20 s/s 5310-374-01-00 02 3 decal, warning-disconnect power 9905-100-75-93 03 1 dielectrical cover, booster tank 5700-011-40-50 04 1 dielectric cover, electrical panel 5700-011-40-49 05 1 kickplate ...

Page 32

Control panel 27 01 02 03 04 05 06 07 08 09 08 10 11 item qty description mfg no. 01 1 control panel 4730-011-95-42 02 1 decal, vontrol panel 5975-602-01-16 03 1 guage, 0-100 psi w/ green zone 5700-011-86-45 04 1 switch, on/fill & off/drain 5950-011-50-70 05 1 delime switch 4730-011-95-41 06 4 circu...

Page 33

* refers to an item not shown. Inside view 28 01 02 03 04 08 09 10 06 05 03 03 11 13 03 03 07 12 item qty description mfg no. 01 2 rinse hub weldment 5700-021-38-31 02 2 gasket, vellumoid 5330-111-42-81 03 4 locknut, 1/4-20, low profile 5310-374-02-00 04 2 rinse arm 5700-031-38-30 05 1 left rack gui...

Page 34

Right side assembly 29 01 02 03 04 05 06 05 09 10 11 12 08 13 07.

Page 35

Right side assembly (continued) 30 item qty description mfg no. 01 1 complete door assembly 5700-011-39-15 02 1 bushing, snap 1/2" 5975-210-05-00 03 1 shroud 5700-031-38-15 04 12 fastener, 10-32 monel, s/s 5340-111-58-10 05 2 spring, door 5340-011-44-58 06 1 electrical, control panel weldment 5700-0...

Page 36

Left and right side panels 31 item qty description mfg no. 01 1 panel, left side 5700-041-38-08 02 1 panel, right side 5700-041-38-37 03 12 screw, 10-32 x 1/2" phillips, truss head 5305-011-39-36 01 02 03.

Page 37

32 jp-24bpnsu electrical diagram 460 volt - 60 hertz - 3 phase.

Page 38

33 ref: navseainst 4160.3a (insert classification of tmder here) classifica t i o n : n a v s e a s 0 0 0 5-a a -g y d -0 3 0 / t m m p navsea/spawar technical manual deficiency/evaluation report (tmder) instruction: continue on 8 1/2" x 11" paper if additional space is needed. 1 . U s e t h i s r e...

Page 39

34 -----------------------------------------------------------------------------------fold here department of the navy place postage here ------------------- official business commander nsdsa code 5e30 navsurfwarcendiv 4363 missile way port hueneme ca 93043-4307 -------------------------------------...

Page 40

35 ref: navseainst 4160.3a (insert classification of tmder here) classifica t i o n : n a v s e a s 0 0 0 5-a a -g y d -0 3 0 / t m m p navsea/spawar technical manual deficiency/evaluation report (tmder) instruction: continue on 8 1/2" x 11" paper if additional space is needed. 1. Use this report to...

Page 41

36 -----------------------------------------------------------------------------------fold here department of the navy place postage here ------------------- official business commander nsdsa code 5e30 navsurfwarcendiv 4363 missile way port hueneme ca 93043-4307 -------------------------------------...

Page 42

Alabama jones-mcleod appliance 1616 7th avenue north birmingham, al 35203 (205) 251-0159 (800) 821-1150 (205) 322-1440 fax jones-mcleod appliance 854 lakeside drive mobile, al 36693 (334) 666-7278 (800) 237-9859 (334) 661-0223 fax alaska restaurant appliance service 7219 roosevelt way ne seattle, wa...

Page 43

Florida (cont) gcs service, inc. # 13 4305 vineland road suite g-12 orlando, fl 32811 (407) 841-2551 (800) 338-7322 (407) 423-8425 fax jones-mcleod appliance 854 lakeside drive mobile, al 36693 (334) 666-7278 (800) 237-9859 (334) 661-0223 fax georgia gcs service, inc. #16 3127presidential dr. Atlant...

Page 44

Maryland gcs service, inc. #07 2660 pittman drive silver spring, md 20910 (301) 585-7550 (dc) (410) 792-0388 (balt) (800) 638-7278 (301) 495-4410 fax emr service division 700 east 25th street baltimore, md 21218 (410) 467-8080 (800) 879-4994 (410) 467-4191 fax emr service division 106 willamsport ci...

Page 45

New jersey (cont) gcs service, inc. #44 817 n. Third street philadelphia, pa 19123 (215) 925-6217 (800) 441-9115 (215) 925-6208 fax food service equipment 2101 parkway south broomall, pa 19123 (610) 356-6900 (610) 356-2038 fax new mexico stove parts supply co. 2120 solana street ft. Worth, tx 76117 ...

Page 46

Pennsylvania (cont) gcs service, inc. #44 4400 lewis road, suite e harrisburg, pa 17111 (717) 564-3282 (800) 367-3225 (717) 564-9286 fax k & d parts & service 1833-41 n. Cameron street harrisburg, pa 17103 (717) 236-9039 (800) 932-0503 (717) 238-4367 fax afs-authorized factory service, co. 940 first...

Page 47

Virginia (cont) gcs service, inc. #18 5760 northampton blvd. Suite 106 virginia beach, va 23455 (757) 464-3500 (800) 476-4278 (757) 464-4106 fax gcs service, inc. #07 2660 pittman drive silver spring, md 20910 (301) 585-7550 (dc) (410) 792-0388 (balt) (800) 638-7278 (301) 495-4410 fax washington res...

Page 48

Kontac industries 6504 south broadway edmonton, ab t6b0e7 (780) 469-4869 (800) 661-2500 (780) 465-6937 fax key food equipment services #105-3728 north fraser way burnaby, bc v5j5g1 (604) 433-4484 (800) 665-2655 (604) 433-4684 fax choquette - cks 2710 lancaster road unit 119 ottawa, ot k1b4t7 (613) 7...

Page 49

Important information data sheet 44 model: serial no.: installation date: service rep. Name: phone no.: notes:.