- DL manuals

- Jackson MSC

- Dishwasher

- TEMPSTAR HH

- Service Manual

Jackson MSC TEMPSTAR HH Service Manual

Summary of TEMPSTAR HH

Page 1

Tempstar hh tempstar hh nb service m manual march 26, 2002 p/n 7610-002-23-32 (rev. C) visit jackson on the internet at: www.Jacksonmsc.Com hot water sanitizing upright door dishmachines.

Page 2

Section description page i. General specifications 1 ii. Instructions section installation instructions 2 operation instructions 3 water consumption issues 3 iii. Troubleshooting 4 iv. Dimensions 6 v. Table dimensions 7 vi. Parts section main assembly 8 control box assembly 11 hood assembly 12 tub f...

Page 3

Performance/capabilities operating capacity (racks/hour) selection (a) racks per hour 53 dishes per hour 1325 glasses per hour 1325 selection (b) racks per hour 29 dishes per hour 725 glasses per hour 725 selection (c) racks per hour 20 dishes per hour 500 glasses per hour 500 selection (d) racks pe...

Page 4

Jackson msc inc. Provides technical support for all of the dish- machines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical sup- port staff. Please have this manual with you when you call so that our staff can refer you, if necessary, ...

Page 5

Preparation: before proceeding with the start-up of the unit, verify the following: 1. The pan strainer and pump suction strainer are in place and are clean. 2. The overflow tube and o-ring are installed. 3. That the wash and rinse arms are screwed securely into place and that their endcaps are tigh...

Page 6

Warning: inspection, testing and repair of electrical equipment should only be performed by a qualified service technician. Many of the tests require that the unit have power to it and live electrical components be exposed. Use extreme caution when testing the machine. Problem: dishmachine will not ...

Page 7

Problem: wash water is not reaching required temperature. 1. Faulty wash heater. Check element for continuity; if open, relace the heater. 2. Misadjusted/faulty thermostat(s). Verify operation and setting of thermostats, replace if necessary. 3. Wash thermometer is defective. Replace thermometer. Pr...

Page 8

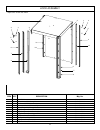

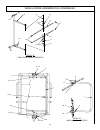

Dimensions 6 p.S. C-electrical connection t 3/4"i.P.S. D-standard wall clearance with dishtable 4" all dimensions in inches 68 1/2” 73 3/4” 86 1/4” 15 3/8” 25 1/4” 3” 25” legend: a - drain 1 1/2” i.P.S. B - water inlet 3/4” i.P.S. C - electrical connection d - standard wall clearance with dishtable ...

Page 9

Table dimensions 7 table dimensions corner installation table dimensions connection to dishmachine table dimensions straight through installation 20 1/2” opening 25 1/4” 2 1/4” 4” min. 2 1/2” 4” min. 20 1/2” opening 25 1/4” 20 1/2” 3/4” 1 1/2” roll 4” min 2 1/2” 25 1/4” 20 1/2” opening 25 1/4”.

Page 10

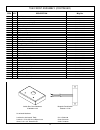

Main assembly 8 1 3 *4 *2 5 6 2 7 8 11 10 12 9 * represents an item not shown..

Page 11

Main assembly (continued) 9 item qty description mfg. No. 1 1 door, upper front assembly 5700-002-24-92 1 door, upper, front weldment 5700-002-29-57 2 glide, upper door 5700-002-00-83 2 2 door, upper, left and right assemblies 5700-002-01-30 2 door, upper, left and right weldment 5700-002-29-59 4 gl...

Page 12

Control box assembl y 10 4 7, 8 9 13 29 30 31 32 *27, *28 25, 26 14, 11 15, 16 17 10, 11 12 1, 2, 3 5, 6 24, 11 22, 23, 21 18, 19 20, 21 * represents an item not shown..

Page 13

Control box assembly 11 item qty description mfg. No. 1 1 bracket, electrical box mounting 5700-002-18-48 2 9 locknut, 1/4"-20 s/s hex w/nylon insert 5310-374-01-00 3 9 washer, 1/4"-20 i.D. S/s 5311-174-01-00 4 1 control box weldment, right hand 5700-002-06-48 4 1 control box weldment, left hand 570...

Page 14

Hood assembly 12 item qty description mfg. No. 1 1 hood weldment 5700-002-01-23 2 6 bolt, 1/4"- 20 x 5/8" long hex 5305-274-24-00 3 26 washer, 1/4" id s/s 5311-174-01-00 4 26 locknut, 1/4"- 20 s/s hex w/nylon inserts 5310-374-01-00 5 20 bolt, 1/4"- 20 x 1/2" long hex 5305-274-02-00 6 2 right/left fr...

Page 15

Tub front assembly 13 3, 4, 5 2 1 28 see page entitled “wash/rinse heaters”. 12 18 *19 15 see page entitled “wash motors”. 15 *7, 27 20 24 21, 9 10, 23 21, 22 14, 23 17 25, 26 see page entitled “wash/rinse heaters”. 16 pump support bracket complete assembly 5700-002-00-46. Nut, 1/4”-20 serrated nut ...

Page 16

Tub front assembly (continued) 14 item qty description mfg. No. 1 1 tub weldment 5700-002-01-25 2 1 frame weldment 5700-031-48-01 3 8 screw, 1/4"-20 x 1/2" long 5305-274-02-00 4 8 locknut, 1/4"-20 with nylon insert 5310-374-02-00 5 8 washer, 1/4"-20 id, s/s, flat 5311-174-01-00 6 1 gasket, rinse hea...

Page 17

Motors - thermostats - wash heaters - rinse heaters 15 40°f rise 70°f rise model volts hz phase wash heater rinse heater (12 kw) rinse heater (14 kw) tempstar hh 208 60 1 4540-121-47-39 4540-121-47-40 4540-121-63-38 tempstar hh 230 60 1 4540-121-47-39 4540-121-47-40 4540-121-63-38 tempstar hh 208 60...

Page 18

Inner tub components/track assembly 16 overflow support bracket 5700-001-27-55 wash overflow weldment 5700-001-25-69 o-ring 5330-400-05-00 strainer weldment 5700-021-50-07 suction strain weldment 5700-002-16-13 suction strain bracket 5700-002-18-28 rack guide 5700-001-28-19 rack weldment 5700-002-01...

Page 19

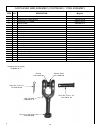

Cantilever arm assembly 17 1 2 3 4 5 6 9 10 7 8 18 19 18 21 20 17 14 16 12 15 13 11 12 14 22.

Page 20

Cantilever arm assembly (continued) / yoke assembly 18 item qty description mfg. No. 1 4 locknut, 1/4"- 20 s/s hex w/nylon insert 5310-374-01-00 2 2 cantilever arm support bracket 5700-031-88-00 3 6 wear button, 1/2" uhmw 5700-011-88-01 4 2 yoke assembly 5700-000-75-77 5 2 spring pin, 1/4" dia. X 1 ...

Page 21

*represents an item not shown. Door brackets 19 inside rear view of the left door inside view of the front left or right side corners inside rear view of the right door 1 2 4 3 5 7 6 *8 9 10 11 item qty description mfg. No. 1 6 door stop weldment 5700-002-29-60 2 32 locknut, 1/4"-20 w/ nylon insert ...

Page 22

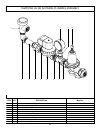

Tempstar hh incoming plumbing/outlet plumbing assembly 20 when servicing plumbing components, take care not to damage the threads of each individual item. Damaged threads can cause leaks and loss of pressure, which could adversely effect the performance of the dishmachine. It is strongly recommended...

Page 23

Incoming plumbing/outlet plumbing assembly 21 item qty description mfg. No. 1 1 water pressure regulator, 3/4" npt 6685-011-58-22 2 1 valve, ball, 1/4" npt 4810-011-72-67 3 1 gauge, pressure, 0-100 psi 6685-111-88-34 4 2 nipple, close, 3/4" npt 4730-207-34-00 5 1 tee, brass, 3/4" npt x 3/4" npt x 1/...

Page 24

Tempstar hh nb incoming plumbing assembly 22 2 3 4 5 6 7 5 5 8 1 9 10 item qty description mfg. No. 1 1 vacuum breaker, 3/4" npt 4820-300-08-00 2 1 elbow, brass, street, 3/4" npt 4730-206-04-34 3 1 nipple, brass, 3/4" npt x 3" 4730-011-38-29 4 1 union, brass, 3/4" npt 4730-212-05-00 5 3 nipple, clos...

Page 25

3/4” solenoid valve & 3/4” npt vacuum breaker repair parts kits 23 screw data plate coil & housing valve bonnet spring 4810-200-04-18 plunger 4810-200-04-18 spring position is moved for clarity. Goes below the plunger. O-ring 4810-100-10-18 diaphragm retainer diaphragm 4810-100-10-18 screen retainer...

Page 26

Wash & rinse arm/manifold assemblies 24 13 18 14 11 12 15 15 14 13 11 2, 3, 4 5 7 16, 8 6, 10 5 9 7 1 detail “b” wash arms & manifold detail “a” final rinse arms & manifold 12 10 10 10 10 5 17 20 16 2, 3, 19 5 20 9, 17 1.

Page 27

25 wash & rinse arm/manifold assemblies (continued) item qty description mfg. No. 1 1 upper manifold 5700-031-34-82 2 4 nut, 3/8"-16 s/s hex 5310-276-01-00 3 4 lockwasher 3/8 5311-276-01-00 4 2 bolt, hex 3/8-16 x 7/8" lg 5306-011-36-95 5 2 o ring 5330-111-35-15 6 1 positioning bracket, manifold tube...

Page 28

460 volt machine transformer mounting box 26 460v transformer 5950-111-65-93 2 amp circuit breaker 5925-111-64-18 transformer mounting bracket 5700-031-62-82 transformer mounting box 5700-002-10-01 transformer mounting box top (not shown) 5700-000-78-53.

Page 29

Safety door interlock (sdi) option 27 safety door interlock box bottom 5700-001-21-26 safety door interlock box cover 5700-001-21-27 other safety door interlock (sdi) components (not shown): pipe clamp (found on the side of the machine) 5700-000-35-05 solenoid, electrical interlock option 4810-100-6...

Page 30

Exhaust fan control option 28 delay timer 5945-011-65-44 2” din rail 5700-002-36-09 terminal board 5940-011-84-41.

Page 31

False panel installation 1. Remove the rack assembly from the dishmachine. 2. The false panel will mount inside of the dishmachine. 3. Position the panel in the dishmachine on the side to be closed. 4. Hold the panel against the side of the dishmachine and push upward. 5. The panel will clip in at t...

Page 32

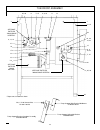

30 tempstar hh electrical diagram 208-230 volt - 60 hertz - single &three phase.

Page 33

Tempstar hh electrical diagram 460 volt - 60 hertz - three phase 31.

Page 34

Tempstar hh nb electrical diagram 208-230 volt - 60 hertz - single &three phase 32 h1 wash heater m1 wash motor r1 wash heater contactor r2 wash motor contactor r3 control relay f1 dispenser fuse block s1 power switch s2 door switch s3 auto/manual (delime) switch s4 selector switch cycle 4 s5 select...

Page 35

Tempstar hh nb electrical diagram 460 volt - 60 hertz - three phase 33.