- DL manuals

- Jackson MSC

- Dishwasher

- TEMPSTAR

- Service Manual

Jackson MSC TEMPSTAR Service Manual

Summary of TEMPSTAR

Page 1

Tempstar tempstar sds tempstar nb service m manual march 4, 2002 p/n 7610-011-86-35 (rev. B) visit jackson on the internet at: www.Jacksonmsc.Com hot water sanitizing upright door dishmachines.

Page 2

Section description page i. General specifications of the tempstar 1 specifications of the tempstar sds 1 specifications of the tempstar nb 1 ii. Instructions installation instructions 2 operation instructions 3 iii. Troubleshooting section 4 iv. Drawing/parts section dimensions tempstar/tempstar nb...

Page 3

Performance/capabilities operating capacity (racks/hour) racks per hour 57 dishes per hour 1425 glasses per hour 1425 operating cycle (seconds) wash time 45 rinse time 11 dwell time 2 total cycle time 60 tank capacity (liters) gallons wash tank (minimum) 8.0 booster tank 3.0 wash pump capacity (lite...

Page 4

Jackson msc inc. Provides technical support for all of the dish- machines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical sup- port staff. Please have this manual with you when you call so that our staff can refer you, if necessary, ...

Page 5

Preparation: before proceeding with the start-up of the unit, verify the following: 1. The pan strainer and pump suction strainer are in place and are clean. 2. The overflow tube and o-ring are installed. 3. That the wash and rinse arms are screwed securely into place and that their endcaps are tigh...

Page 6

Warning: inspection, testing and repair of electrical equipment should only be performed by a qualified service technician. Many of the tests require that the unit have power to it and live electrical components be exposed. Use extreme caution when testing the machine. Problem: dishmachine will not ...

Page 7

Warning: inspection, testing and repair of electrical equipment should only be performed by a qualified service technician. Many of the tests require that the unit have power to it and live electrical components be exposed. Use extreme caution when testing the machine. Problem: doors will not close ...

Page 8

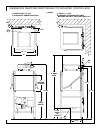

Dimensions tempstar/tempstar nb (side mounted control box) 6 61 3/4” water inlet to floor 10 5/8” adjustable height of 4” to 8”. Ships at 4” space. 14 3/8” note: minimum space required is for both the back and sides. 2 7/8” 15 1/2” a - water inlet (3/4” ips) b- electrical connection point c - drain ...

Page 9

Dimensions tempstar/tempstar nb (top mounted control box) 7 25 1/4” 32” 17” machine opening 64 3/8” 34” table height 76” w/ door open 14 3/8” drain to floor 61 3/4” 60 5/8” a - water inlet (3/4” ips) b- electrical connection point c - drain (1 1/2”ips) d -standard clearance between machine and wall ...

Page 10

Dimensions tempstar sds 8 a - drain 1 1/2” i.P.S. B - water inlet 3/4” i.P.S. C - electrical connection d - standard wall clearance with dishtable 4” 2 7/8” 2 1/2” 2 1/2” 15 1/2” 25 1/4” 25 1/4” 32” 17 1/2” open 76” 7 1/4” 14” 60 3/4” 74” 34” table height a c b a b d d legend.

Page 11

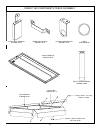

Table dimensions 9 table dimensions corner installation table dimensions connection to dishmachine table dimensions straight through installation 20 1/2” opening 25 1/4” 2 1/4” 4” min. 2 1/2” 4” min. 20 1/2” opening 25 1/4” 20 1/2” 3/4” 1 1/2” roll 4” min 2 1/2” 25 1/4” 20 1/2” opening 25 1/4”.

Page 12

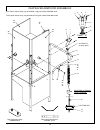

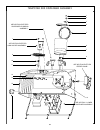

Side mounted control box assembly 10 1 2, 21 3 control box front cover 4 5 6 7, 8 inner control box layout 9,22 11, 22 10, 22 12, 22 13, 14 12, 22 15, 16 17 18, 23, 24 19 control box bottom layout 21, 22 20 the mounting screws for the control box front cover (10-32 x 1/2” slotted trusshead screws) m...

Page 13

Other components not shown: connector, 1/2”, 90 deg plastic 5975-011-45-14 connector, 3/4”, 45 deg plastic 5975-011-47-74 connector, 1/2”, 45 deg plastic 5975-011-45-23 connector, 1/2”, 90 deg metal 5975-111-01-00 grommet, 1/2” od x 3/8” id 5325-011-46-73 grommet, 7/8” split 5975-200-40-00 plug 5975...

Page 14

Top mounted control box assembly 12 21 20 1 2 3 4 5 6 7 9 8 10 11 12 13 14 19 18 17 16 15.

Page 15

Other components not shown: cover, top mount control box 5700-002-23-03 decal, warning-disconnect power 9905-100-75-93 screw, 10-32 x 3/8” phillips truss head 5305-173-12-00 leg, control box 5700-002-33-05 screw, 1/4”-20 x 2 3/4” hex head cap 5305-274-13-00 washer, 1/4”-20 id s/s 5311-174-01-00 lock...

Page 16

Sds side mounted control box assembly 14 cover, dielectric control panel 5700-021-50-89 bracket, side mount electrical box 5700-041-65-68 6 14 15 19 20 23 22 11 12 13 10 16 17 18 9 8 7 1 2 3 4 5 25 21 24 26 27.

Page 17

Other components not shown: connector, 1/2”, 90 deg plastic 5975-011-45-14 connector, 3/4”, 45 deg plastic 5975-011-47-74 connector, 1/2”, 45 deg plastic 5975-011-45-23 connector, 1/2”, 90 deg metal 5975-111-01-00 grommet, 1/2” od x 3/8” id 5325-011-46-73 grommet, 7/8” split 5975-200-40-00 plug, 1/2...

Page 18

Hood assembly 16 1 2 3, 5 4 6 7 8 9 10 item qty description mfg. No. 1 1 hood weldment (tempstar/tempstar nb) 5700-041-94-39 1 1 hood weldment (tempstar sds only) 5700-041-47-87 2 1 left front hood support 5700-021-33-18 3 1 right front hood support 5700-021-33-17 4 1 double door guide, front left 5...

Page 19

Hood assembly (single piece weldment) 17 item qty description mfg. No. 1 1 hood weldment (tempstar /tempstar nb) 5700-002-29-79 1 1 hood weldment (tempstar sds) 5700-002-36-91 2 1 plug, bulkhead 4730-609-05-00 3 1 frame weldment 5700-031-48-01 1 2 3 switch box weldment 5700-002-14-34 sds switch box ...

Page 20

Cantilever arm/door assemblies 18 1 3 *2 15 16 17 12 13 14 11 28 27 26 27 29 27 30 31 18 19 20 21 24 25 22 23 21 22 8 4 5 6 5 7 9 10 see detail “a” for parts detail. Detail “a” bottom rail mounting of spring to bottom rail back corner steam plugs may be ordered using part number 5700-002-25-01. Fron...

Page 21

Cantilever arm/door assemblies (continued) 19 item qty description mfg. No. 1 2 bracket, cantilever support 5700-031-88-00 2 6 wear button .50 dia 5700-011-88-01 3 2 yoke assembly 5700-000-75-77 4 2 clevis pin 5315-700-01-00 5 4 washer, nylon 5311-369-03-00 6 2 bushing 3120-100-03-00 7 2 cotter pin ...

Page 22

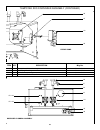

Tub front assembly 20 1, 2, 3 4 5 7 24 25 *26 6 see page entitled “wash motors”. 12 8 9 11 10 *27 20 13, 14 16, 18 14, 15 17, 18 19 21, 22 see page entitled “wash/rinse heaters”. 23 * represents an item not shown. Pump support bracket complete assembly 5700-002-00-46. Nut, 1/4”-20 serrated nut 5310-...

Page 23

Wash tank heating system explanation the wash tank heater system is electrically connected in the circuit so that it is dependent upon the dishwasher being properly filled with and maintaining a safe water level. The system is made up of two thermostats (mounted in the junction box behind the front ...

Page 24

Rinse tank assembly 22 1 2 3 12 7, 11 4, 5, 6, 13 8 9, 10 item qty description mfg. No. 1 4 locknut, 1/4"-20 with nylon insert 5310-374-01-00 2 4 washer, 1/4" id, s/s, flat 5311-174-01-00 3 1 booster tank weldment 5700-001-22-02 4 1 fitting, 1/4" imperial brass 5310-924-02-05 5 1 thermostat bracket ...

Page 25

Inner tub components/track assembly 23 overflow support bracket 5700-001-27-55 wash overflow weldment 5700-001-25-69 o-ring 5330-400-05-00 strainer weldment 5700-021-50-07 suction strain weldment 5700-001-22-23 suction strain bracket 5700-001-22-24 rack guide 5700-001-28-19 rack weldment 5700-002-01...

Page 26

Wash pump exploded view 24 replacement motors are available for purchase. Contact jackson msc directly to ensure that you order the correct motor for your model. Casing gasket 5330-002-00-31 impeller 5700-002-01-08 mechanical seal 5330-002-06-21.

Page 27

Details concerning the tempstar models wash motor assemblies: the pumps for the tempstar models covered in this manual are close coupled centrifugal pumps. The pump casings are made from iron and may be prone to oxidation if still water is left in the casing for an extended amount of time. It is rec...

Page 28

This unit has a probe-direct sensing type thermostat with fixed set point and adjustable range for both wash and booster tank heat reg- ulating. The same type thermostat is used as the high limit sensor for the wash tank heater. It operates a precision single double throw switch through a lever for ...

Page 29

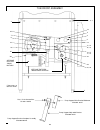

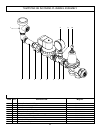

Incoming plumbing/outlet plumbing assembly 27 when servicing plumbing components, take care not to damage the threads of each individual item. Damaged threads can cause leaks and loss of pressure, which could adversely effect the performance of the tempstar dishmachine. It is strongly recommended th...

Page 30

Incoming plumbing/outlet plumbing assembly 28 item qty description mfg. No. 1 1 water pressure regulator, 3/4" npt 6685-011-58-22 2 1 valve, ball, 1/4" npt 4810-011-72-67 3 1 gauge, pressure, 0-100 psi 6685-111-88-34 4 2 nipple, close, 3/4" npt 4730-207-34-00 5 1 tee, brass, 3/4" npt x 3/4" npt x 1/...

Page 31

Tempstar nb incoming plumbing assembly 29 2 3 4 5 6 7 5 5 8 1 9 10 item qty description mfg. No. 1 1 vacuum breaker, 3/4" npt 4820-300-08-00 2 1 elbow, brass, street, 3/4" npt 4730-206-04-34 3 1 nipple, brass, 3/4" npt x 3" 4730-011-38-29 4 1 union, brass, 3/4" npt 4730-212-05-00 5 3 nipple, close, ...

Page 32

Tempstar sds incoming plumbing assembly 30 item qty description mfg. No. 1 1 gauge, pressure, 0-100 psi 6685-111-88-34 2 1 valve, ball, 1/4" npt 4810-011-72-67 3 1 tee, 1/4" x 1/4" x 1/4" brass 4730-011-51-20 4 2 nipple, 1/4" close brass 4730-207-02-00 5 1 regulator, pressure 6685-111-48-54 6 1 gaug...

Page 33

3/4” solenoid valve & 3/4” npt vacuum breaker repair parts kits 31 screw data plate coil & housing valve bonnet spring 4810-200-04-18 plunger 4810-200-04-18 spring position is moved for clarity. Goes below the plunger. O-ring 4810-100-10-18 diaphragm retainer diaphragm 4810-100-10-18 screen retainer...

Page 34

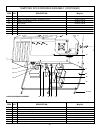

Wash & rinse arm/manifold assemblies 32 13 18 14 11 12 15 15 14 13 11 2, 3, 4 5 7 16, 8 6, 10 5 9 7 1 detail “b” wash arms & manifold detail “a” final rinse arms & manifold 12 10 10 10 10 5 17 17 16 2, 3, 19 5 9, 17 9, 17 1 rinse injector weldment 1 per machine 5700-021-47-65 rinse injector gasket 2...

Page 35

33 wash & rinse arm/manifold assemblies (continued) item qty description mfg. No. 1 1 upper manifold 5700-031-34-82 2 4 nut, 3/8"-16 s/s hex 5310-276-01-00 3 4 lockwasher 3/8 5311-276-01-00 4 2 bolt, hex 3/8-16 x 7/8" lg 5306-011-36-95 5 2 o ring 5330-111-35-15 6 1 positioning bracket, manifold tube...

Page 36

Tempstar sds dispenser assembly 34 1 2 3 4 5 6 7 8 1 see section entitled “cam holder assembly” 9 10 11 see section entitled “dispenser plumbing assembly”. 13 12 see section entitled “feeder pump”. 14 15 16 see section “lower dispenser assembly”..

Page 37

Tempstar sds dispenser assembly (continued) 35 item qty description mfg. No. 1 3 screw, 6-32 x 3/4" long 5305-171-07-00 2 1 lockwasher, #6, external tooth 5311-271-02-00 3 1 rinse cylinder bracket 5700-011-59-72 4 1 rinse additive screen 5930-011-48-66 5 1 rinse cylinder cover 9515-011-49-01 6 1 rin...

Page 38

Tempstar sds dispenser assembly (continued) 36 26 27 28 29 feeder pump item qty description mfg. No. 26 1 plate, solenoid valve mounting 5700-031-58-16 27 1 plate, pump mounting 5700-011-57-88 28 1 peristaltic pump 4320-111-51-03 29 2 ferrule nut, chemical tube connector 4730-609-16-00 30 31 32 33 3...

Page 39

Tempstar sds dispenser assembly (continued) 37 item qty description mfg. No. 30 2 1/4" npt vacuum breaker 4810-011-51-62 31 2 elbow, 3/8" comp. X 1/4" npt, 90 degrees, brass 4730-111-58-18 32 2 nipple, 1/4" x 6" brass 4730-011-79-29 33 1 plug, hunky 5975-011-59-49 34 2 valve, solenoid 4810-011-48-99...

Page 40

Other components not shown: sensor, detergent 6680-011-49-83 kit, detergent sensor mounting 4730-111-51-17 gasket, 1/8” thick 5330-021-51-08 tempstar sds dispenser assembly (continued) 38 item qty description mfg. No. 47 1 jam nut, 1/8"-27 5310-011-58-00 48 1 rinse additive pickup tube 5700-011-50-1...

Page 41

Water pressure regulator kit (wprk) option plumbing 39 1 2 3 4 5 6 7 item qty description mfg. No. 1 1 regulator, water pressure, 3/4" npt 4820-100-01-06 2 1 adapter, 3/4" 4730-401-10-01 3 1 tee, 3/4" x 3/4" x 1/2" c x c x c 4730-411-03-01 4 1 water hammer arrestor, 1/2" npt 6685-100-05-00 5 1 adapt...

Page 42

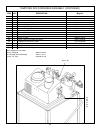

Safety door interlock (sdi) option 40 safety door interlock box bottom 5700-001-21-26 safety door interlock box cover 5700-001-21-27 other safety door interlock (sdi) components (not shown): pipe clamp (found on the side of the machine) 5700-000-35-05 solenoid, electrical interlock option 4810-100-6...

Page 43

Exhaust fan control option 41 delay timer 5945-011-65-44 2” din rail 5700-002-36-09 terminal board 5940-011-84-41.

Page 44

460 volt machine transformer mounting box 42 460v transformer 5950-111-65-93 2 amp circuit breaker 5925-111-64-18 transformer mounting bracket 5700-031-62-82 transformer mounting box 5700-002-10-01 transformer mounting box top (not shown) 5700-000-78-53.

Page 45

Tempstar (side mount) electrical diagram 208 - 230 volt - 50/60 hertz - single/three phase 43.

Page 46

44 tempstar (side mount) electrical diagram 460 volt - 60 hertz - three phase 9905-031-66-00

Page 47

Tempstar (top mount) electrical diagram 208 - 230 volt - 50/60 hertz - single/three phase 45.

Page 48

Tempstar (top mount) electrical diagram 460 volt - 60 hertz - three phase 46.

Page 49

Tempstar nb (side mount) electrical diagram 208 - 230 volt - 50/60 hertz - single/three phase 47.

Page 50

Tempstar nb (side mount) electrical diagram 460 volt - 60 hertz - three phase 48.

Page 51

Tempstar nb (top mount) electrical diagram 208 - 230 volt - 50/60 hertz - single/three phase 49.

Page 52

Tempstar nb (top mount) electrical diagram 460 volt - 60 hertz - three phase 50

Page 53

Tempstar sds electrical diagram 208 - 230 volt - 60 hertz - single/three phase 51.

Page 54

Tempstar sds electrical diagram 460 volt - 60 hertz - three phase 52.

Page 55

Tempstar sds dispenser schematic 53 9905-011-48-52.