- DL manuals

- Jackson

- Dishwasher

- TEMPSTAR

- Installation, operation and service manual

Jackson TEMPSTAR Installation, operation and service manual

INSTALLATION, OPERATION,

AND SERVICE MANUAL

FOR JACKSON MODEL(S):

TEMPSTAR

TEMPSTAR LT

TEMPSTAR NB

TEMPSTAR

WITH VENTLESS

AND ENERGY RECOVERY

STEAM HEATED MODELS:

TEMPSTAR S

TEMPSTAR/LT/NB/ VENTLESS/S Technical Manual • Rev T • P/N 7610-003-61-42 • Issued: 11-11-2008 • Revised: 01-11-16

TEMPSTAR SERIES

UPRIGHT DOOR

DISHMACHINES

Summary of TEMPSTAR

Page 1

Installation, operation, and service manual for jackson model(s): tempstar tempstar lt tempstar nb tempstar with ventless and energy recovery steam heated models: tempstar s tempstar/lt/nb/ ventless/s technical manual • rev t • p/n 7610-003-61-42 • issued: 11-11-2008 • revised: 01-11-16 tempstar ser...

Page 3

Manufacturer's warranty one year limited parts and labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation for a period of (1) one year from date of purchase, but in no event to exceed (18) ...

Page 4: Revision History

I revision letter revision date made by applicable ecns details a 11/11/08 arl 8045 release to production b 04/22/09 arl 8094 added new nsf rating. C 06/22/09 jc 8114 removed nsf rating from steam heated unit. D 07/24/09 arl 8104 added information regarding electrical fi eld conversion. E 02/02/10 r...

Page 5: Nomenclature

Ii model: serial no.: installation date: service rep. Name: phone number: nomenclature jackson wws, inc. Provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please hav...

Page 6: III

Iii table of contents specifications dimensions ................................................................................................................................. 1 table dimensions ..........................................................................................................

Page 7: Table of Contents

Iv table of contents schematics solid state 208 - 230v, 50/60 hz, single/three phase .............................................................. 67 tempstar (ut w/cycle switches) 208 - 230v, 50/60 hz, single/three phase .......................... 68 solid state 460v, 60 hz, three phase .............

Page 8: Specifications

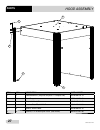

07610-003-61-42-t 1 legend a- water inlet (1/2” npt) b- electrical connection point c- drain (1 1/2” npt) d- standard clearance between machine and wall (with dish table) is 4” (10.2 cm) specifications y-strainer machine dimensions.

Page 9: Specifications

07610-003-61-42-t 25 1/4” (64.1 cm) 32” (81.3 cm) 17 1/2” (44.5 cm) machine opening 34” (86.4 cm) table height 76” (193 cm) w/ door open 14” (35.6 cm) drain to floor 64 3/8” (163.5 cm) 60 5/8” (154 cm) 61 3/4” (156.8 cm) water inlet to floor c 15 1/2” (39.4 cm) 4 7/8” (12.4 cm) b d d a b pressure re...

Page 10: Specifications

07610-003-61-42-t 3 specifications ventless machine dimensions 57 3 4 (1468mm) 24 1 4 (616mm) 82 (2083mm) 17 (432mm) 77 (1956mm) 13 1 4 (335mm) 4 3 4 (120mm) 3 (79mm) 15 1 2 (394mm) 4 60 (1527mm) c a b c a legend a- drain (1 1/2" ips) b- water inlet (3/4") mip c- electrical connections all vertical ...

Page 11: Specifications

07610-003-61-42-t 4 table dimensions specifications 20 1/2” (52.1 cm) opening 25 1/4” (64.1 cm) 20 1/2” (52.1 cm) opening 25 1/4” (64.1 cm) 2 1/2” (6.4 cm) 4” (10.2 cm) minimum 4” (10.2 cm) minimum 2 1/2” (6.4 cm) 3/4” (1.9 cm) 20 1/2” (52.1 cm) 1 1/2” (3.81 cm) roll table dimensions connection to d...

Page 12: Specifications

07610-003-61-42-t model designation: tempstar performance/capabilities operating capacity: high temperature racks per hour 58 dishes per hour 1450 glasses per hour 1450 low temperature racks per hour 50 dishes per hour 1250 glasses per hour 1250 operating cycle (seconds): minimum (other cycle times ...

Page 13: Specifications

07610-003-61-42-t electrical requirements specifications note: typical electrical circuit is based upon (1) 125% of the full amperage load of the machine and (2) typical fi xed-trip circuit breaker sizes as listed in the nec 2002 edition. Local codes may require more stringent protection than what i...

Page 14: Specifications

7 07610-003-61-42-t electrical requirements specifications volts phase hz rinse heater ratings total amps typical electrical circuit 208 1 50 n/a 28 a 35 amp 230 1 50 n/a 30 a 100 amp tempstar lt/tempstar nb electrical characteristics: 208 3 50 n/a 20a 25 amp 230 3 50 n/a 21 a 30 amp 380 3 50 n/a 10...

Page 15: Installation

8 07610-003-61-42-t instructions installation before installing the unit, check the container and machine for damage. A damaged container is an indicator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away the container. The dishmachi...

Page 16: Installation

9 07610-003-61-42-t instructions installation take care not to confuse static pressure with fl ow pressure! Chemical dispensing equipment steam line connection plumbing check ensure that you have read the section entitled “plumbing the dishmachine” above before proceeding. Install the water supply l...

Page 17: Installation

10 07610-003-61-42-t instructions installation electrical power connections electrical and grounding connections must comply with the applicable portions of the national electrical code ansi/nfpa 70 (latest edition) and/or other electrical codes. Disconnect electrical power supply and place a tag at...

Page 18: Installation

11 07610-003-61-42-t false panel installation installation rack rail removed & repositioned for a corner operation. Insert this side fi rst. False panel positioned in unit..

Page 19: Installation

12 07610-003-61-42-t 1. Remove the rack assembly from the unit. 2. False panel will mount inside the dishmachine. 3. Position panel in unit on side to be closed. 4. Hold panel against side of dishmachine and push up. 5. Panel will clip in at the top, inside unit. 6. Holes in false panel will line up...

Page 20: Operation

13 07610-003-61-42-t operating instructions operation before proceeding with the start-up of the unit, verify the following: 1. The pan strainer and pump suction strainer are in place and are clean. 2. The overfl ow tube and o-ring are installed. 3. That the wash and rinse arms are screwed securely ...

Page 21: Operation

14 07610-003-61-42-t operating instructions operation warm-up cycles for a typical daily start-up, it may be necessary to run the machine through 3 cycles to ensure that all of the cold water is out of the system and to verify that the unit is operating correctly. To cycle the machine, ensure that t...

Page 22: Detergent

15 07610-003-61-42-t detergent control detergent usage and water hardness are two factors that contribute greatly to how effi ciently your dishmachine will operate. Using detergent in the proper amount can become, in time, a source of substantial savings. A qualifi ed water treatment specialist can ...

Page 23: Operation

16 07610-003-61-42-t detergent control certain dishmachine models require that chemicals be provided for proper operation and sanitization. Some models even require the installation of third-party chemical feeders to introduce those chemicals to the machine. Jackson does not recommend or endorse any...

Page 24: Operation

17 07610-003-61-42-t delime instructions operation to proceed with the delime operation, fi ll the dishmachine with the correct amount of delime solution as recommended by the chemical manufacturer. The tank capacities of the machine can be found in the specifi cations section of this manual. After ...

Page 25: Maintenance

18 07610-003-61-42-t preventative maintenance maintenance the dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However, this does not mean that some items will not wear out in time. Jackson highly recommends that any maintenance and repairs...

Page 26: Maintenance

19 07610-003-61-42-t preventative maintenance maintenance preventative maintenance (continued) by following the operating and cleaning instructions in this manual, you should get the most effi cient results from your machine. As a reminder, here are some steps to take to ensure that you are using th...

Page 27: Troubleshooting

20 07610-003-61-42-t common problems troubleshooting problem possible cause remedy dishmachine will not fi ll after the door is close. Power “on” light is illuminated. 1. Faulty rinse solenoid valve. 2. Faulty door switch. 3. Fouled/faulty high level probe. 1. Repair or replace valve as required. 2....

Page 28: Troubleshooting

21 07610-003-61-42-t common problems troubleshooting problem possible cause remedy machine doesn’t drain when power button is pressed. 1. Drain clogged. 2. Standpipe not removed prior to drain. 3. Defective drain valve. 1. Remove obstruction. 2. Remove standpipe and run drain cycle again. 3. Replace...

Page 29: Parts

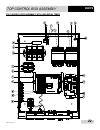

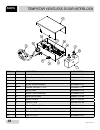

22 07610-003-61-42-t top control box assembly parts 17 18 6 20 8 2 7 6 6 6 5 32 16 6 6 23 24 4 4 6 6 31 37 39 top control box assembly with universal timer.

Page 30: Parts

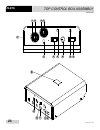

23 07610-003-61-42-t top control box assembly parts (continued) 10 9 13 14 15 12 11 27 41 42 40 25 21 21 21 22 22.

Page 31: Parts

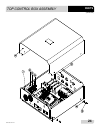

24 07610-003-61-42-t top control box assembly parts (continued) 26 1 29 28 30 33 34 36.

Page 32: Parts

25 07610-003-61-42-t top control box assembly parts item qty description part number 1 1 control box weldment 05700-003-30-14 2 1 timer bracket 05700-003-02-08 3 2 lock nut 6-32 05310-373-03-00 4 2 heater contactor 05945-109-01-69 5 1 terminal block 05940-011-48-27 6 17 lock nut 10-24 05310-373-01-0...

Page 33: Parts

26 07610-003-61-42-t top control box assembly parts item qty description part number 31 1 decal,ground 09905-011-86-86 32 1 decal,l1, l2 09905-002-78-67 33 1 bracket, fuse strip 05700-002-42-03 34 1 fuse holder, 6 pole 05920-002-42-13 35 2 screw, 6-32 x 3/8” w/ext tooth washer 05305-002-25-91 36 1 d...

Page 34: Parts

27 07610-003-61-42-t hood assembly parts 2 1 3 4 item qty description part number 1 1 hood weldment (tempstar/tempstar lt/tempstar nb) 05700-002-29-79 2 2 hood support 05700-002-78-99 3 6 bolt, 1/4”-20 x 1/2” lon 05305-274-21-00 4 6 washer, flat, ss, 1/4”-20 id 05311-174-01-00 5 4 spacer, sleeve hoo...

Page 35: Parts

28 07610-003-61-42-t cantilever arm/door assemblies parts 14 11 12 10 1 2 3 4 5 6 7 8 16 15 18 24 18 17 11 12 19 20 11 12 19 22 18 23 3d 3c 3f 3b 3a 3e.

Page 36: Parts

29 07610-003-61-42-t cantilever arm/door assemblies parts 29 item qty description part number 1 1 cantilever arm 05700-031-50-67 2 2 spring pin, 1/4" x 1 1/8" 05315-407-06-00 3 2 yoke assembly 05700-000-75-77 3a 1 cotter pin 05315-207-01-00 3b 1 yoke 05700-000-75-78 3c 1 clevis pin, 5/16” x 1 3/8” 0...

Page 37: Parts

30 07610-003-61-42-t 30 item qty description part number 24 1 door, left side (complete assembly) 05700-002-30-87 1 door, left side (complete assm) (door interlock) (not shown) 05700-004-24-32 24a 1 door only, left side 05700-002-29-86 1 door only, left side (door interlock) (not shown) 05700-004-24...

Page 38: Parts

31 07610-003-61-42-t tub assembly parts 12 11 10 13 15 11 14 34 37 36 33 26 35 32 31 30 29 27 28 24 25 22 23 21 4 20 19 18 16 16 17 3 1 2 3 5 6 7 8 bracket, motor support weldment 05700-002-68-31 pump support adjustable bracket 05700-002-20-41 nut, 1/4”-20 serrated nut 05310-011-66-49 pump support a...

Page 39: Parts

32 07610-003-61-42-t tub assembly parts item qty description part number 1 1 tub weldment 05700-002-12-59 2 1 rack assembly 05700-002-01-00 3 2 bulk head plug 04730-609-05-00 4 1 see page entitled “wash motors” n/a 5 1 gasket 05700-111-35-03 6 1 o-ring 05330-400-05-00 7 4 bolt, hex 3/8”-16 x 1 1/4" ...

Page 40: Parts

33 07610-003-61-42-t item qty description part number 27 4 lockwasher, 5/16", s/s, split 05311-275-01-00 28 4 nut, hex, 5/16"-18, s/s 05310-275-01-00 29 4 locknut, 10-24 with nylon insert 05310-373-01-00 30 1 cover, wash heater 05700-031-47-57 31 1 decal, warning-disconnect power 09905-100-75-93 32 ...

Page 41: Parts

34 07610-003-61-42-t steam tub assembly parts 12 11 10 13 15 11 14 24 29 27 28 25 22 23 21 4 20 19 18 16 16 17 3 1 2 3 5 6 7 8 26 30 bracket, motor support weldment 05700-002-68-31 pump support adjustable bracket 05700-002-20-41 nut, 1/4”-20 serrated nut 05310-011-66-49 pump support adjustable brack...

Page 42: Parts

35 07610-003-61-42-t steam tub assembly parts item qty description part number 1 1 tub weldment 05700-002-12-59 2 1 rack assembly 05700-002-01-00 3 2 bulk head plug 04730-609-05-00 4 1 see page entitled “wash motors” n/a 5 1 gasket 05700-111-35-03 6 1 o-ring 05330-400-05-00 7 4 bolt, hex 3/8”-16 x 1...

Page 43: Parts

36 07610-003-61-42-t steam tub assembly parts item qty description part number 25 1 probe, high water 06680-200-02-68 26 1 thermostat, regulating 05930-510-02-79 1 kit, wash thermostat replacement (includes: thermostat, brass fi tting, 2 jumper wires & instructions) 06401-003-18-67 27 1 cover, wash ...

Page 44: Parts

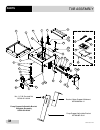

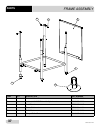

07610-003-61-42-t 37 frame assembly parts item qty description part number 1 4 bolt, 1/4”-20 x 1/2” 05305-274-02-00 2 4 locknut, 1/4”-20 s/s hex with nylon insert 05310-374-02-00 3 1 front panel 05700-002-36-65 4 1 frame weldment 05700-031-48-01 5 4 bullet foot 05340-108-01-03 6 4 flanged bullet foo...

Page 45: Parts

07610-003-61-42-t 38 rinse tank assembly parts item qty description part number 1 1 booster tank weldment 05700-001-22-02 2 2 locknut, 10-24 with nylon insert 05310-373-01-00 3 2 washer, #10 s/s flat 05311-173-01-00 4 1 decal, warning - disconnect power 09905-100-75-93 5 1 booster tank cover weldmen...

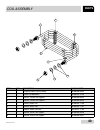

Page 46: Parts

39 07610-003-61-42-t rinse tank & round flange heater assm parts 1 4 5 6 10 11 2 3 9 12 see page entitled “wash heaters/rinse heaters”. 7 8 13 item qty description part number 1 1 booster tank weldment 05700-003-58-41 2 2 locknut, 10-24 with nylon insert 05310-374-01-00 3 2 washer, #10 s/s flat 0531...

Page 47: Parts

40 07610-003-61-42-t coil assembly item qty description part number complete steam coil assembly 05700-002-08-62 1 1 steam coil weldment 05700-021-41-38 2 1 stand c, steam coil support 05700-002-08-52 3 1 stand d, steam coil support 05700-002-08-53 4 4 gasket, steam coil 05700-001-17-86 5 2 washer, ...

Page 48: Parts

41 07610-003-61-42-t incoming steam plumbing assemblies parts item qty description part number complete assembly 05700-002-01-55 1 1 union, 3/4’’ npt, black iron 04730-912-01-00 2 1 bushing, reducing, 3/4’’ to 1/2’’ 04730-911-02-34 3 2 elbow, 3/4” 90° street 04730-011-87-37 4 1 nipple, close, 3/4’’ ...

Page 49: Parts

42 07610-003-61-42-t incoming steam plumbing assemblies parts item qty description part number complete assembly 05700-002-01-60 1 1 bushing, reducing, 3/4’’ to 1/2’’ 04730-911-02-34 2 2 union, 3/4’’ npt, black iron 04730-912-01-01 3 1 elbow, 90b 3/4” npt black iron 04730-906-10-34 4 4 nipple, close...

Page 50: Parts

43 07610-003-61-42-t wash motors parts model volts hz phase wash motor assembly tempstar/tempstar nb 208 50 1 06105-002-19-87 tempstar/tempstar nb 208 50 3 06105-002-19-87 tempstar/tempstar nb 208 60 1 06105-002-69-78 tempstar/tempstar nb 208 60 3 06105-002-69-78 tempstar/tempstar nb 230 50 1 06105-...

Page 51: Parts

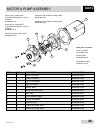

44 07610-003-61-42-t item qty description part number 1 1 motor only, 50hz 06105-002-85-36 motor only, 60hz 06105-002-79-61 2 1 case o-ring, 60hz 05330-002-81-83 seal plate, 60hz 05700-002-81-87 gasket, 50hz 05330-002-41-48 3 1 mechanical seal, 60hz 05330-002-34-22 seal, 50hz 05330-002-06-21 4 1 cas...

Page 52: Parts

45 07610-003-61-42-t parts wash heaters/rinse heaters model volts hz phase wash heater rinse heater (12 kw) rinse heater (14 kw) tempstar 208 50 1 04540-121-47-39 04540-121-47-40 04540-121-63-38 tempstar 208 50 3 04540-121-47-39 04540-121-47-40 04540-121-63-38 tempstar 208 60 1 04540-121-47-39 04540...

Page 53: Parts

46 07610-003-61-42-t parts round flanged rinse heater model volts hz phase wash heater rinse heater (12 kw) rinse heater (14 kw) tempstar 208 50 1 04540-003-58-27 04540-003-58-28 tempstar 208 50 3 04540-003-58-27 04540-003-58-28 tempstar 208 60 1 04540-003-58-27 04540-003-58-28 tempstar 208 60 3 045...

Page 54: Parts

47 07610-003-61-42-t parts incoming/outlet plumbing assembly 16 5 17 6 18 19 17 7 5 5 5 tempstar outlet plumbing (complete assembly) 05700-003-60-75 tempstar incoming plumbing (complete assembly) 05700-003-60-74 tube length chart item # length (inches) 8 1/2” x 2 1/2” long 9 1/2” x 37” long 10 1/2” ...

Page 55: Parts

48 07610-003-61-42-t parts incoming/outlet plumbing assembly item qty description part number 1 1 fitting, tee, 1/2” x 1/2” x 1/4” 04730-411-25-01 2 2 adapter, 1/2” mnpt x cu male 04730-011-59-53 3 1 strainer, y 1/2” 04730-217-01-10 4 1 vave, ball test cock 1/4” bronze 04810-011-72-67 5 6 adapter, 1...

Page 56: Parts

49 07610-003-61-42-t parts inlet plumbing 5 7 2 1 2 3 6 4 8 9 10 11 2 item qty description part number complete assembly 05700-003-60-73 1 1 tee, brass, 1/2" x 1/2" x 1/4" npt 04730-411-25-01 2 3 adapter, 1/2” mnpt x cu male 04730-011-59-53 3 1 strainer, y 1/2” 04730-217-01-10 4 1 valve, ball, bronz...

Page 57: Parts

50 07610-003-61-42-t parts incoming/outlet plumbing assembly pressure regulator option 7 12 13 11 19 8 19 11 10 8 18 11 17 12 5 9 4 9 1 3 2 14 12 17 8 15 12 16 12 17 12 7.

Page 58: Parts

51 07610-003-61-42-t parts incoming/outlet plumbing assembly item qty description part number 1 1 water pressure regulator, 1/2" npt 05700-100-04-07 2 1 valve, ball, 1/4" npt 04810-011-72-67 3 1 gauge, pressure, 0-100 psi 06685-111-88-34 4 1 tee, brass, 1/2" npt x 1/2" x 1/4" 04730-411-25-01 5 1 val...

Page 59: Parts

52 07610-003-61-42-t parts inlet plumbing - pressure regulator 5 7 2 1 2 3 6 4 8 9 10 11 2 item qty description part number 1 1 tee, brass, 1/2" x 1/2" x 1/4" npt 04730-411-25-01 2 3 adapter, 1/2” mnpt x cu male 04730-011-59-53 3 1 water pressure regulator, 1/2" npt 04820-100-04-07 4 1 valve, ball, ...

Page 60: Parts

53 07610-003-61-42-t parts tempstar - ventless plumbing rinse injector 09515-004-22-73 2 1 4 5 6 7 3 hose pac, assembly (tempstar) 05700-004-20-01 hose pac, assembly (tempstar hh) 05700-004-20-02 item qty description part number 1 1 vac breaker 1/2 brass 04820-003-06-13 2 1 elbow, 90 degree 1/2 stre...

Page 61: Parts

54 07610-003-61-42-t parts tempstar - ventless plumbing 1 2 3 4 5 6 2 2 item qty description part number 1 1 bushing, hex 3/4"m to 1/2" brass 04730-002-56-27 2 3 nipple, brass 1/2" x 3" npt 04730-004-20-10 3 1 elbow, 1/2 npt 90 brass 04730-011-42-96 4 1 tee, 1/2 fnpt x 1/2 fnpt 1/4 fnpt 04730-002-22...

Page 62: Parts

55 07610-003-61-42-t parts tempstar - ventless plumbing item qty description part number 1 1 bushing, hex 3/4"m to 1/2" brass 04730-002-56-27 2 3 elbow, 3/4 street brass 90 degress 04730-206-04-34 3 1 regulator, pressure 3/4 06685-011-58-22 4 1 nipple, 3/4 npt x 1-3/8 closed brass 04730-207-34-00 5 ...

Page 63: Parts

56 07610-003-61-42-t parts solenoid valve & vacuum breaker 1/2” solenoid valve & 1/2” npt vacuum breaker repair parts kits 4810-200-03-18 complete 110 volt solenoid valve assembly, 1/2” 04810-100-12-18 coil & housing only 06401-003-07-43 complete 240 volt solenoid valve assembly, 1/2” 04810-100-09-1...

Page 64: Parts

57 07610-003-61-42-t parts wash & rinse arm/manifold assemblies rinse injector weldment 1 per machine 05700-002-56-75 plug, 1/8” npt, brass 3 per rinse injector 04730-209-07-37 rinse injector gasket 2 per machine 05330-111-42-81 10 18 15 14 20 13 11 10 10 10 9 17 16 5 7 7 6 10 19 3 2 6 8 9 17 3 17 1...

Page 65: Parts

58 07610-003-61-42-t parts wash & rinse arm/manifold assemblies item qty description part number 1 1 upper manifold 05700-031-34-82 2 4 nut, 3/8"-16 s/s hex 05310-276-01-00 3 4 lockwasher,3/8 05311-276-01-00 4 2 bolt, hex 3/8”-16 x 7/8" long 05306-011-36-95 5 2 o ring 05330-111-35-15 6 1 positioning...

Page 66: Parts

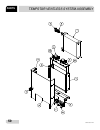

59 07610-003-61-42-t parts tempstar ventless system assembly.

Page 67: Parts

60 07610-003-61-42-t parts tempstar ventless system assembly item qty description part number 1 1 coil, heat exchanger 04420-004-19-61 2 1 inlet, cold water 05700-004-19-01 3 1 ring, water inlet 05700-004-19-24 4 1 plate, fan mounting 05700-004-18-07 5 1 upper shroud 05700-004-18-06 6 1 exhaust box ...

Page 68: Parts

61 07610-003-61-42-t parts tempstar ventless door interlock item qty description part number door interlock assembly 05700-004-23-06 1 1 guide block, door lock 09330-004-22-72 2 1 f-cover, door lock mounting 05700-004-22-80 3 1 w-rod, interlock weldment 05700-004-23-15 4 1 soleniod, horizontal 1" pu...

Page 69: Parts

62 07610-003-61-42-t parts door interlock, exhaust fan, transformer box door interlock (sdi) /exhaust fan control/transformer mounting box door interlock box bottom 05700-001-21-26 door interlock box cover 05700-001-21-27 description part number pipe clamp (found on the side of the machine) 05700-00...

Page 70: Parts

63 07610-003-61-42-t parts go*box components a go*box is a kit of the most needed parts for a particular model or model family to successfully effect a repair in the fi rst call 90% or more of the time. The following components may be ordered together using the following mfg. No.: 06401-003-62-04 it...

Page 71: Parts

64 07610-003-61-42-t parts drain quench assembly item qty description part number 1 1 nipple, 1/4 npt x 3 brass 04730-004-08-07 2 1 nipple, 1/4 npt x 3 brass 04730-004-08-07 3 1 reducer, 1-1/2 x 1/2 hex brass 04730-002-55-75 4 1 nipple, 1-1/12 brass close 04730-207-40-00 5 1 tee, 1-1/2 brass 04730-0...

Page 72: Parts

65 07610-003-61-42-t parts drain quench assembly (continued) item qty description part number 1 1 wash heater cover 05700-004-07-92 2 1 liquid tight fitting (large) 05975-011-65-51 3 1 conduit fitting, 45°-1/2" 05975-011-45-23 4 2 lock nut, 6-32 hex 05310-373-03-00 5 1 thermostat 05930-003-13-65 6 1...

Page 73: Parts

66 07610-003-61-42-t parts drain quench assembly (continued) connect 1 1/2” drain plumbing (elbow can be removed if not needed) connect 1/4” cold water line.

Page 74: Schematics

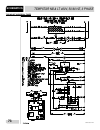

07610-003-61-42-t 67 schematics solid state 208-230v, 50/60 hz, 1 & 3 phase tempstar (top mount w/ cycle switches).

Page 75: Schematics

07610-003-61-42-t tempstar 208-230v, 50/60 hz, 1 & 3 phase schematics tempstar (top mount w/ cycle switches) 68.

Page 76: Schematics

69 07610-003-61-42-t schematics solid state 460 v, 60 hz, 3 phase tempstar (top mount w/ cycle switches).

Page 77: Schematics

70 tempstar 460 v, 60 hz, 3 phase schematics tempstar (top mount w/ cycle switches).

Page 78: Schematics

71 07610-003-61-42-t schematics solid state lt & nb 208-230v, 50/60hz,1 & 3 phase tempstar (top mount w/ cycle switches).

Page 79: Schematics

72 tempstar lt & nb 208-230v, 50/60hz, 1 & 3 phase schematics tempstar (top mount w/ cycle switches).

Page 80: Schematics

73 07610-003-61-42-t schematics tempstar nb & lt 460v, 50/60 hz, 3 phase top mount universal timer.

Page 81: Schematics

74 07610-003-61-42-t tempstar s 208-230v, 50/60 hz, 1 & 3 phase schematics top mount universal timer tempstar steam tempstar steam elctrical diagram elctrical diagram 208/230 volt 50/60 hz 1/3 phase 208/230 volt 50/60 hz 1/3 phase.

Page 82: Schematics

75 07610-003-61-42-t schematics sdi options.

Page 83: Schematics

76 07610-003-61-42-t drain quench options schematics.

Page 84: Jackson Technical

07610-003-61-42-t 77 serial number: model: tempstar made in the usa jackson wws, inc. P.O. Box 1060 barbourville, ky. 40906 (606) 523-9795 09905-003-69-11d 460v wash motor 230v 208v 3/4 hp 5.7 a 3/4 hp 5.7 a 3/4 hp 1.8 a wash heater 4.1 kw 11.4 a 5 kw 12.6 a 5 kw 6.3 a rinse heater 9 kw 25.0 a 11 kw...

Page 86

79 tempstar/lt/nb/ ventless/s technical manual • rev t • p/n 7610-003-61-42 • issued: 11-11-08 • revised: 01-11-16 jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com.