- DL manuals

- Jacobsen

- Other

- 2WD

- Parts & Maintenance Manual

Jacobsen 2WD Parts & Maintenance Manual - Lf 3400 / Lf 3800

97

> Change from previous revision

LF 3400 / LF 3800

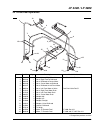

43.1 Reel Motor

Part Number 1002620 (Seven Inch Reel)

Serial No. All

Item

Part No.

Qty.

Description

Serial Numbers/Notes

1

3006021

1

O-Ring

2

5003140

2

Relief Valve

3

5003485

1

Face Plate

4

5003031

1

Seal Kit

Not Shown

5

4102440

1

Shaft, Output

1

2

3

Used on LF 3800 Models.

5

Summary of 2WD

Page 1

Lightweight fairway mower 67945 – lf 3400 ™ , kubota v1305-e, 5 gang, 2wd 67946 – lf 3400 ™ , kubota v1305-e, 5 gang, 4wd 67947 – lf 3800 ™ , kubota v1505-e, 5 gang, 2wd 67948 – lf 3800 ™ , kubota v1505-e, 5 gang, 4wd 67949 – lf 3400 ™ turbo, kubota v1505-te, 5 gang, 4wd 67950 – lf 3800 ™ turbo, kub...

Page 2: To Order Parts

Copyright 1999 textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” to order parts 1. Write your full name and complete address on the order. 2. Explain where and how to make shipment. 3. Give product number, name and serial number that ...

Page 3: Suggested Stocking Guide

Gb-3 suggested stocking guide to keep your equipment fully operational and productive, maintain a stock of the more commonly used maintenance items. We have included part numbers for additional support materials and training aids. A more complete listing of accessories and attachments can be found i...

Page 4: Warning

1 safety gb-4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equip- ment. Never allow minors to operate any equipment. 2. It is your responsibility to read this m...

Page 5: Warning

Safety 1 gb-5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 6

2 specifications gb-6 2 specifications 2.1 product identification _________________________________________________ 67945 .............................. Lf 3400, 5 gang 2wd, uses 5” (127 mm) diameter reel 67946 .............................. Lf 3400, 5 gang 4wd, uses 5” (127 mm) diameter reel 67947 ...

Page 7

Specifications 2 gb-7 2.4 v1505-te engine _________________________________________________________ make................................Kubota model...............................V-1505te diesel, 4 cycle, liquid cooled horsepower .....................44.2 hp (33.0 kw) @ 3000 rpm displacement...........

Page 8

2 specifications gb-8 2.8 lf 3407, lf 3800, lf 3800 turbo cutting units _________________________________ overall cutting width: 5 gang ...................... 100 in. (2.54 m) number of reels: 5 gang ...................... Five - three front, two rear. Reel diameter ................. 7 in. (178 mm) ...

Page 9: Warning

Adjustments 3 gb-9 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be per- formed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, ...

Page 10: Caution

3 adjustments gb-10 3.3 bedknife adjustment ___________________________________________________ read section 3.2 before making the adjustment. Start adjustment at leading end of reel, followed by the trailing end. The leading end of the reel blade is that end which passes over the bedknife first dur...

Page 11

Adjustments 3 gb-11 3.5 flash attach ___________________________________________________________ installing cutting units 1. Place each cutting unit in front of its respective lift arm. Raise lift arm and position cutting unit so that yoke (t) is in line with swivel housing (s). Carefully lower arm ...

Page 12

3 adjustments gb-12 3.7 mow speed _____________________________________________________________ cutting quality is better at speeds well below the transport speed of the tractor. An initial mow speed of five to six mph is set at the factory and should be satisfactory for most cutting conditions. Loc...

Page 13

Adjustments 3 gb-13 3.10 neutral adjustment ___________________________________________________ neutral adjustment can only be made at the drive pump. The neutral adjustment is preset at the factory on all new tractors and replacement pumps. Further adjustment is not required unless the pump has bee...

Page 14

3 adjustments gb-14 3.12 front reel limit switch ________________________________________________ the front left and right lift arms are equipped with proximity switches which signal the controller to turn off the reels.The switches are mounted to the tractor frame directly behind the lift arms. If ...

Page 15: Caution

Adjustments 3 gb-15 3.14 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Caution all torque values included in these charts are approximat...

Page 16: Warning

4 maintenance gb-16 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be per- formed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment o...

Page 17: Warning

Maintenance 4 gb-17 4.4 air filter _______________________________________________________________ check the service indicator daily. If red band appears in the window (b) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk ...

Page 18: Caution

4 maintenance gb-18 4.7 battery ________________________________________________________________ make absolutely certain the ignition switch is “off” and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric ...

Page 19: Warning

Maintenance 4 gb-19 4.10 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engi...

Page 20: Caution

4 maintenance gb-20 4.13 hydraulic filters ______________________________________________________ the hydraulic system is protected by two 10 micron filters; a charge filter (b) and return line filter (a). Flow though the filters is monitored during operation. When pressure drop across the filters i...

Page 21: Warning

Maintenance 4 gb-21 4.15 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiator dra...

Page 22: Warning

4 maintenance gb-22 4.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tig...

Page 23: Warning

Maintenance 4 gb-23 4.20 reel backlapping ______________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, t...

Page 24: Caution

4 maintenance gb-24 4.21 storage________________________________________________________________ general 1. Wash the tractor thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the tractor, tighten all hardware, replace worn or damaged components. 3. Drain and refill radi...

Page 25

Troubleshooting 5 gb-25 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshootijng chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems cont...

Page 26

5 troubleshooting gb-26 lamp 1 2 3 4 5 6 7 8 9 1 0 11 12 1 3 14 15 1 6 17 18 19 20 21 22 23 24 25 26 27 28 29 30 3 1 32 33 inputs outputs 5.2 controller lamps _____________________________________________________ the controller is a solid state device that monitors and controls electrical functions....

Page 27

Troubleshooting 5 gb-27 5.3 electrical circuits ____________________________________________________ when troubleshooting the machine using the controller always check that program active lamp (1) is on. These indicate that the controller has power and the program is active. Note: the controller req...

Page 28: Warning

6 maintenance & lubrication charts gb-28 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubrication. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

Page 29

Maintenance & lubrication charts 6 gb-29 6.3 lubrication chart______________________________________________________ 2 3 3 5 6 7 7 8 8 9 10 12 12 11 13 11 13 14 14 14 4 15 1 9 grease fittings f1 - 50 hours (every week) 1 swivel housing 2 lift arm 3 lift cylinders 4 lift arm pivot 5 brake pedal pivot...

Page 30: Indice

Copyright 1999 textron inc. “se reservan todos los derechos, incluido el derecho para reproducir este material y porciones del mismo en cualquier forma” para hacer pedidos de piezas 1. Escribir el nombre y dirección completos en el pedido. 2. Explicar a dónde y cómo hacer el envío. 3. Facilitar el n...

Page 31: Cómo Usar Este Manual

Es-3 guía de inventario sugerido para mantener su equipo en perfecta operación y producción, mantenga un inventario de los componentes usados con más frecuencia en el mantenimiento. Hemos incluido los números de piezas de materiales auxiliares y ayudas de capacitación. Una lista más completa de piez...

Page 32: Advertencia

1 seguridad es-4 1 seguridad 1.1 manipulacion segura ________________________________________________________ 1. La seguridad depende del conocimiento, la preocupación y la prudencia de aquellos que manipulen o pongan en servicio el equipo. Nunca se debe permitir a menores manipular ningún equipo. 2...

Page 33: Advertencia

Seguridad 1 es-5 1.2 avisos importantes sobre seguridad __________________________________ este símbolo de seguridad sirve para alertarle de posibles peligros. Peligro - indica una situación de inminente peligro que, de no ser evitada, provocara la muerte o graves lesiones. Advertencia - indica una ...

Page 34

2 especificaciones es-6 2 especificaciones 2.1 identificacion del articulo ___________________________________________ 67945 .............................. Lf 3400, 5 gang 2wd, carrete de 127 mm de diámetro 67946 .............................. Lf 3400, 5 gang 4wd, carrete de 127 mm de diámetro 67947...

Page 35

Especificaciones 2 es-7 2.4 motor v1505-te _________________________________________________________ marca ..............................Kubota modelo.............................V1505te diesel, 4 ciclos, enfriado por líquido potencia ..........................33 kw @ 3000 rpm desplazamiento...........

Page 36

2 especificaciones es-8 2.8 unidades de corte lf 3407, lf 3800, lf 3800 turbo ________________________ ancho corte total 5 unidades ...................... 2,54 m número de carretes 5 unidades ...................... Cinco - tres delante, dos detrás. Diámetro carrete ...................... 178 mm anch...

Page 37: Advertencia

Ajustes 3 es-9 3 ajustes 3.1 generalidades _________________________________________________________ 1. Los ajustes y las tareas de mantenimiento siempre deben ser acometidas por un técnico cualificado. Si no se puede realizar el ajuste deseado, póngase en con- tacto con un distribuidor jacobsen aut...

Page 38: Precaucion

3 ajustes es-10 3.3 ajuste de la cuchilla fija _____________________________________________ lea la sección 3.2 antes de realizar ningún ajuste. Comience el ajuste en el extremo de ataque del carrete y después en el extremo de cola. El extremo de ataque de las cuchillas de los carretes es aquel que ...

Page 39

Ajustes 3 es-11 3.5 flash attach ___________________________________________________________ instalación de las unidades de corte 1. Colocar la unidad de corte frente a su respectivo brazo de elevación. Levantar el brazo de elevación y poner la unidad de corte para que el yugo (t) esté en línea con ...

Page 40

3 ajustes es-12 3.6 presion descendente __________________________________________________ cada carrete está equipado con un muelle de presión descendente. La presión descendente mejora la calidad de corte mejora la calidad de corte asegurando un contacto constante entre el carrete y el terreno. Rev...

Page 41

Ajustes 3 es-13 3.9 frenos _________________________________________________________________ ajustar los frenos después de cambiar o revisar la unidad de frenos, o si la carrera del pedal es excesiva. 1. Al instalar pastillas de freno nuevas, cnducir el tractor a velocidad de corte y aplicar algo de...

Page 42

3 ajustes es-14 3.11 velocidad de marcha hacia delante / marcha atras___________________ las velocidades de dirección y reversa están ajustadas en el pedal de tracción. Ajustar la velocidad de dirección antes de ajustar la reversa. Para ajustar la velocidad hacia delante: 1. Comprobar que la bomba d...

Page 43

Ajustes 3 es-15 3.12 interruptor de limite de carrete delantero___________________________ los brazos delanteros y derechos de elevación están equipados con interruptores de láminas que indican al controlador desconectar los carretes. Los interruptores están montados en el bastidor del tractor direc...

Page 44: Precaucion

3 ajustes es-16 3.14 especificaciones del par de torsion ___________________________________ jacobsen utiliza pernos metalizados grado 5 de serie, a menos que se cite lo contrario. Para tensar pernos metalizados, utilice el valor dado para los lubricados. Precaucion los valores de par de torsión de ...

Page 45: Advertencia

Mantenimiento 4 es-17 4 mantenimiento 4.1 generalidades _________________________________________________________ 1. Los ajustes y las tareas de mantenimiento siempre deben ser acometidas por un técnico cualificado. Si no es posible realizar los ajustes deseados, póngase en contacto con un distribui...

Page 46: Advertencia

4 mantenimiento es-18 4.4 filtro de aire __________________________________________________________ compruebe el indicador de mantenimiento diariamente. Si en la ventana (b) aparece la banda roja reemplace el filtro. No extraiga el filtro para inspeccionarlo o limpiarlo. Si se extrae innecesariament...

Page 47: Precaucion

Mantenimiento 4 es-19 4.7 bateria _________________________________________________________________ esté absolutamente seguro de que el interruptor de encendido esté «apagado» y que se haya retirado la llave de contacto antes de poner en servicio la batería. Apriete los cables a los terminales de la...

Page 48: Advertencia

4 mantenimiento es-20 4.10 escape y silenciador __________________________________________________ para protegerse del monóxido de carbono, inspeccione todo el sistema de escape regularmente y sustituya siempre el silenciador si está dañado. Si advierte un cambio de color y de sonido del escape, par...

Page 49

Mantenimiento 4 es-21 4.12 aceite hidraulico ______________________________________________________ consulte en la sección 6.2 los intervalos específicos de mantenimiento. Drene y reemplace el aceite hidráulico si ha tenido lugar un fallo de componentes grave, si advierte la presencia de agua o espu...

Page 50: Precaucion

4 mantenimiento es-22 4.14 sistema electrico______________________________________________________ a continuación se enumeran las precauciones que deben tomarse para reducir posibles problemas eléctricos: 1. Asegúrese de que todos los terminales y conexiones están limpias y correctamente fijadas. 2....

Page 51: Advertencia

Mantenimiento 4 es-23 4.15 radiador _______________________________________________________________ revisar el nivel del refrigerante diariamente. El radiador deberá estar lleno y la botella de recuperación hasta la marca frío. Vaciar y rellenar anualmente. Quitar la tapa del radiador, abrir el tapó...

Page 52: Advertencia

4 mantenimiento es-24 4.18 montaje de las ruedas_________________________________________________ 1. Limpie la suciedad, la grasa y el aceite de la rosca de los pernos sin cabeza. No lubrique las roscas. 2. Coloque la rueda en el cubo y preste atención para que la superficie de la rueda esté totalme...

Page 53: Advertencia

Mantenimiento 4 es-25 4.20 amolado del carrete __________________________________________________ revisar el carrete y la cuchilla fija para determinar si el amolado o afilado restauran el filo. Si el desgaste o daño es superior al punto donde el filo se puede corregir por el proceso de amolado, se ...

Page 54: Precaucion

4 mantenimiento es-26 4.21 almacenamiento _______________________________________________________ generalidades 1. Lave el tractor a fondo y lubríquelo. Repare y pinte el metal dañado o desnudo. 2. Inspeccione el tractor, apriete todos los elementos, sustituya los componentes desgastados o dañados. ...

Page 55

Resolucion de problemas 5 es-27 5 resolucion de problemas 5.1 generalidades _________________________________________________________ en el siguiente cuadro se enumeran los problemas más comunes que pueden ocurrir durante el arranque y funcionamiento. Para más información detallada acerca de los sis...

Page 56

5 resolucion de problemas es-28 5.2 lamparas del controlador ___________________________________________ el controlador es una unidad sólida que dirige y controla las funciones eléctricas. El controlador recibe la señales de entrada desde diversos interruptores y sensores de la máquina y transmite s...

Page 57

Resolucion de problemas 5 es-29 5.3 circuitos electricos ___________________________________________________ al tratar de averiguar un problema en la máquina usando el controlador, comprobar siempre que la lámpara de programa activo (1) esté conectada. Esta indica que el controlador tiene potencia y...

Page 58: Advertencia

6 cuadros de mantenimiento y lubricacion es-30 6 cuadros de mantenimiento y lubricacion 6.1 generalidades _________________________________________________________ 1. Limpie siempre el accesorio engrasador antes y después de lubricar. 2. Use grasa que cumpla o supere las especificaciones nlgi grado ...

Page 59

Cuadros de mantenimiento y lubricacion 6 es-31 6.3 cuadro de lubricacion _________________________________________________ 2 3 3 5 6 7 7 8 8 9 10 12 12 11 13 11 13 14 14 14 4 15 1 9 accesorios de engrase f1 - 50 horas (cada semana) 1 bastidor giratorio 2 brazo elevación 3 cilindros elevación 4 pivot...

Page 60

7 parts catalog 7 parts catalog 7.1 table of contents _____________________________________________________ 1.1 ........ Decals ..................................................................... 32 2.1 ........ Hood ....................................................................... 34 3.1 .....

Page 62: Lf 3400 / Lf 3800

32 2 17 2 3 4 5 6 7 8 10 12 11 22 19 3 14 / 15 17 13 16 21 11 1 18 20 9 1. Read operators manual. Do not allow untrained operators to use machine. 2. Keep shields in place and hardware securely fastened. 3. Before you clean, adjust or repair this equiptment, disengage all drives, engage parking brak...

Page 63: 105

33 > change from previous revision to avoid injury when working with battery 1. Always connect the black ground (–) cable last and remove it first. 2. Keep sparks and flames away, and avoid contatc with acid. To avoid injury when jumping battery 1. Connect positive (+) terminal to positive (+) termi...

Page 64: Lf 3400 / Lf 3800

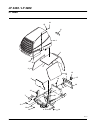

34 1 2 17 22 5 4 9 3 18 15 17 20 22 16 19 10 10 7 16 11 14 12 8 16 15 21 6 lf 3400 / lf 3800 2.1 hood serial no. All lf34-1.

Page 65: Lf 3400 / Lf 3800

35 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 4123226 1 hood assembly, lf 3400/3800 includes items 13 ~ 16 on illustration 1.1 2 4124443 1 • foam, front 3 4124437 1 • foam, right side 4 4124436 1 • foam, left side 5 4124442 1 • foam, top 6...

Page 66: Lf 3400 / Lf 3800

36 10 3 19 5 6 9 4 7 16 19 24/25 2 6 9 8 22 23 6 9 10 1 18 20 21 12 7 14 15 13 19 11 8 26 27 17 8 28 29 lf 3400 / lf 3800 3.1 seat pan serial no. All.

Page 67: Lf 3400 / Lf 3800

37 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 1004279 1 floorpan 2 3009292 1 seat pan 3 4129685 1 support, seat 4 4131337 1 adjuster, double latching 5 4130641 1 base, seat 6 400258 9 screw, 3/8-16 x 3/4” hex head 7 441602 8 carriage bolt,...

Page 68: Lf 3400 / Lf 3800

38 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 27 28 29 30 31 4 17 15 25 26 1 7 ref 17 lf 3400 / lf 3800 4.1 instrument panel serial no. All.

Page 69: Lf 3400 / Lf 3800

39 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 4130114 1 instrument panel includes silk screen decals 2 4129683 1 hour meter, quartz reference u-3, see 45.1 3 365943 1 fuel gauge reference u-2, see 45.1 4 3005121 1 water temperature gauge r...

Page 70: Lf 3400 / Lf 3800

40 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 27 28 29 4 17 15 25 26 1 27 26 20 2 26 27 14 21 27 23 27 22 27 6 28 lf 3400 / lf 3800 5.1 traction pedal linkage serial no. All lf34-4.

Page 71: Lf 3400 / Lf 3800

41 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 1003288 1 treadle pivot 2 352726 2 • bushing 3 3007230 1 stop, mow speed 4 3003474 1 grip, pedal 5 3003475 1 grip, pedal 6 366974 2 rod end 7 4125831 1 switch, proximity reference sw-7, see 45....

Page 72: Lf 3400 / Lf 3800

42 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 22 23 4 17 15 1 13 18 15 9 14 16 7 24 lf 3400 / lf 3800 6.1 brake pedal linkage serial no. All lf34-5.

Page 73: Lf 3400 / Lf 3800

43 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 4118395 1 bracket, brake 2 4125831 1 switch, proximity reference sw-8, see 45.1 3 3006327 1 shaft, turn assist 4 3007606 1 lever, parking brake 5 4129466 1 mount, brake 6 1003616 1 brake arm 7 ...

Page 74: Lf 3400 / Lf 3800

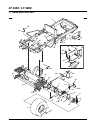

44 4 5 6 7 8 9 10 13 14 15 16 17 19 20 21 22 23 27 28 29 30 31 33 1 2 3 18 10 11/12 25/26 32 10 23 23 20 16 17 24 34 35 35 36 37 39 35 40 41 38 34 34 lf 3400 / lf 3800 7.1 frame and front axle serial no. All.

Page 75: Lf 3400 / Lf 3800

45 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 5002573 2 tire 2 5002574 2 rim 3 360111 2 valve, inflation 4 1001757 2 wheel motor see 39.1 5 557623 2 • key 6 557624 2 • nut, hex 7 4130197 1 frame includes four (4) of item 10 8 366871 2 • bu...

Page 76: Lf 3400 / Lf 3800

46 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 9 9 9 4 16 15 17 15 20 15 25 29 31 31 26 32 lf 3400 / lf 3800 8.1 2wd steering 2wd units only serial no. 67866,67868.

Page 77: Lf 3400 / Lf 3800

47 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 3006981 2 tire 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 117139 1 steering axl...

Page 78: Lf 3400 / Lf 3800

48 lf 3400 / lf 3800 9.1 4wd steering 4wd units only serial no. 67915, 67916-1601 and up serial no. 67867 -1601 and up serial no. 67869-1601 and up serial no. 67889-1601 and up lf34-8 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 18 20 21 22 23 4 4 9 9 9 11 16 17 20 15 15 15 24 25 26 27 28 29 30 31 32 33 3...

Page 79: Lf 3400 / Lf 3800

49 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 3006981 2 tire 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 117139 1 steering axl...

Page 80: Lf 3400 / Lf 3800

50 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 11 11 lf 3400 / lf 3800 10.1 tilt steering serial no. All.

Page 81: Lf 3400 / Lf 3800

51 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 5002918 1 actuator, gas spring 2 5002919 1 cable, actuator 3 2811346 1 tower, steering 4 1003458 1 valve, steering see 44.1 339979 3 • adapter, straight 339974 2 • adapter, straight 5 443828 1 ...

Page 82: Lf 3400 / Lf 3800

52 lf 3400 turbo, lf 3800 turbo, units only 2 3 5 6 7 8 9 10 12 11 ref 13 14 16 18 19 20 21 22 23 24 27 28 29 30 31 34 4 17 15 26 25 26 32 1 11 7 ref 22 12 22 28 30 26 24 20 29 33 lf 3400 / lf 3800 11.1 radiator and air cleaner serial no. All lf34-10

Page 83: Lf 3400 / Lf 3800

53 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 3001965 1 air filter 5000919 1 • air cleaner element 5000920 1 • cover 5000921 1 • valve 2 3001388 1 bracket, air filter 3 4119873 1 shroud, rear frame 4 4121722 1 bracket, air cleaner mounting...

Page 84: Lf 3400/ Lf 3800

54 ref. Negative battery cable 1 2 3 14 15 18 19 20 21 22 23 24 25 26 27 28 29 30 31 24 24 6 7 10 12 13 21 16 17 4/5 16 17 8 9 11 22 30 2 20 a a 32 33 34 lf 3400/ lf 3800 12.1 engine assembly and mounting serial no. All.

Page 85: Lf 3400 / Lf 3800

55 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 1002855 1 engine, kubota v1305-e lf 3400 1 1002856 1 engine, kubota v1505-e lf 3800 1 1002857 1 engine, kubota v1505-te lf 3400 turbo, lf 3800 turbo 2 366879 3 isolator, engine 3 1003239 1 fron...

Page 86: Lf 3400 / Lf 3800

56 > change from previous revision 1 2 3 4 5 6 7 8 9 10 3 7 lf 3400 / lf 3800 13.1 engine exhaust serial no. All item part no. Qty. Description serial numbers/notes 1 1004653 1 muffler lf 3400 & 3800 only 1 1002931 1 muffler lf 3400 turbo, lf 3800 turbo 2 1004598 1 tailpipe 3 363586 6 screw, m8-1.25...

Page 87: Lf 3400 / Lf 3800

57 > change from previous revision 1 2 4 10 12 11 14 15 16 17 10 3 5 6 7 8 9 13 lf 3400 / lf 3800 14.1 pump mounting serial no. All item part no. Qty. Description serial numbers/notes 1 2810006 1 pump, traction 5003034 1 • seal kit 5003432 1 • control kit 5003433 1 • shaft seal kit 5003434 1 • syste...

Page 88: Lf 3400 / Lf 3800

58 a a b b connect to engine fuel injector overflow. Connect to engine fuel pump 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 26 20 21 22 22 23 23 24 25 22 23 19 18 18 18 13 15 17 18 18 lf 3400 / lf 3800 15.1 fuel and hydraulic tanks serial no. All.

Page 89: Lf 3400 / Lf 3800

59 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 132647 1 valve, shut off 2 3001279 1 switch, float reference sw-9, see 45.1 3 3002397 1 plug, magnetic 339899 1 • o-ring 4 3009204 1 fuel tank 5 3005871 1 hydraulic tank 6 3005872 1 shell, tank...

Page 90: Lf 3400 / Lf 3800

60 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 3 6 lf 3400 / lf 3800 16.1 2wd traction hydraulics serial no. 67915-1601 and up serial no. 67868-1601 and up item part no. Qty. Description serial numbers/notes 1 1003462 1 hose, pump to upper traction tee 2 339994 4 adaptor, straight 3 339999...

Page 91: Lf 3400 / Lf 3800

61 > change from previous revision 2 3 5 6 7 8 9 10 12 11 13 14 16 4 15 1 2 13 12 2 13 13 8 7 2 2 3 lf 3400 / lf 3800 17.1 4wd traction hydraulics serial no. 67916-1601 and up serial no. 67869-1601 and up item part no. Qty. Description serial numbers/notes 1 1003440 1 hose, pump to reverse 4wd tee 2...

Page 92: Lf 3400 / Lf 3800

62 > change from previous revision a b a b p t g 10 9 8 1 2 3 front lift valve rear reel valve 1 2 3 4 5 5 6 8 9 10 12 11 14 16 16 7 17 1 15 15 13 17 9 to lift valve p port to lift valve t port from gear pump to steering cylinder aux in out lt rt charge (inner) filter lf 3400 / lf 3800 18.1 charge p...

Page 93: Lf 3400 / Lf 3800

63 > change from previous revision lf 3400 / lf 3800 19.1 gear pump hydraulics serial no. All 1 2 3 16 4 5 6 7 8 9 10 13 15 12 11 14 6 9 6 9 5 item part no. Qty. Description serial numbers/notes 1 365959 1 strainer, tank mounted 362743 1 • o-ring 2 340090 1 adapter, 90° 3 1003992 1 tube, gear pump i...

Page 94: Lf 3400 / Lf 3800

64 1 2 3 4 5 6 8 9 10 11 8 12 14 13 15 16 4 7 19 20 18 17 lf 3400 / lf 3800 20.1 return hydraulics serial no. All.

Page 95: Lf 3400 / Lf 3800

65 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 4129656 1 hose, oil cooler 2 2812271 1 tube, drain 3 1004312 1 tube, right front motor drain 4 339999 2 adapter, straight 5 4123166 1 check valve, tee assembly 6 4129642 1 hose, oil cooler 7 41...

Page 96: Lf 3400 / Lf 3800

66 > change from previous revision 6 7 10 12 11 7 1 2 3 4 5 7 6 6 7 8 11 10 6 12 9 10 11 lf 3400 / lf 3800 21.1 hydraulic valve & filter mounting item part no. Qty. Description serial numbers/notes 1 123015 1 charge filter 556417 1 • head 2811255 1 • oil filter cartridge 556419 1 • charge pressure s...

Page 97

67 > change from previous revision 1 2 3 4 5 6 9 7 8 10 10 10 10 10 2 7 9 7 9 7 4 7 9 9 right front cylinder center front cylinder left front cylinder g 10 9 8 1 2 3 lift valve 5 gang units 22.1 front lift hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 1003344 1 hose...

Page 98: Lf 3400 / Lf 3800

68 > change from previous revision 9 8 1 2 13 9 8 5 3 3 4 10 11 12 6 7 9 9 4 9 lf 3400 / lf 3800 23.1 rear lift hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 1003352 1 hose, left rear to right rear base ports 2 1003351 1 hose, left rear to right rear rod ports 3 100...

Page 99: Lf 3400 / Lf 3800

69 > change from previous revision 2 3 5 6 7 8 9 10 12 11 13 14 16 4 15 1 12 10 15 13 14 15 11 10 10 16 10 11 16 10 lf 3400 / lf 3800 24.1 front reel hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 1003337 1 hose, valve to right front motor front reel valve port a 2 1...

Page 100: Lf 3400 / Lf 3800

70 > change from previous revision 2 3 5 6 7 8 9 10 4 1 10 7 7 6 3 10 9 7 10 1 lf 3400 / lf 3800 25.1 rear reel hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 1003336 1 hose, valve to right rear motor 2 1003443 1 hose, right rear to left rear motor 3 1003335 1 hose, ...

Page 101

71 > change from previous revision.

Page 102: Lf 3400 / Lf 3800

72 lift cylinder hoses steering hoses reel motor hoses reel motor hoses fuel hoses steering hoses front reel drain 6 7 4 9 3 5 6 4 5 15 7 10 8 9 17 1 3 1 2 3 4 5 reel motor hoses 16 15 7 8 traction hoses traction hoses 4wd 2wd 5 10 1 5 10 11 10 12 10 5 5 3 14 10 3 2wd 6 6 fuel lines steering hoses l...

Page 103: Lf 3400 / Lf 3800

73 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 445795 ar nut, 5/16-18 spiralock flange 2 441614 1 carriage bolt, 5/16-18 x1” 3 3007558 ar clamp, double tube 4 345666 ar clamp, 1/2” i.D. 5 409811 ar screw, 5/16-18 x 5/8” thread cutting 6 445...

Page 104: Lf 3400 / Lf 3800

74 30 outside yokes only. 31 32 32 1 2 5 6 7 8 9 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 18 11 11 6 6 17 19 7 7 8 8 10 17 19 28 17 19 9 19 32 19 19 32 32 3 4 10 11 11 8 8 7 7 19 19 6 6 32 17 19 6 32 17 31 30 lf 3400 / lf 3800 27.1 lift arms serial no. All.

Page 105: Lf 3400 / Lf 3800

75 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 4130337 1 left front lift arm 2 4130338 1 right front lift arm 3 4130339 1 left rear lift arm 4 4130340 1 right rear lift arm 5 4130341 1 center lift arm 6 3006539 10 • bushing 2 per lift arm 7...

Page 106: Lf 3400 / Lf 3800

76 a b c d e f g h j k l m a - headlight b - lift arm limit switch c - fuel level sender/ instrument panel d - seat switch e - oil float switch f - glow plugs g - fuel solenoid h - charge filter switch j - engine oil pressure switch k - temperature sender l - 4wd valve (4wd only) m - reel valve 11 2...

Page 107: Lf 3400 / Lf 3800

77 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 ------------ 1 tray, battery see 7.1 2 4122840 2 headlight 4123183 1 • bulb reference l-1 and l-2, see 45.1 3 4122841 1 controller reference u-6, see 45.1 4 5003282 2 • fuse, 20 amp reference f...

Page 108: Lf 3400/ Lf 3800

78 to prevent cuts use socket wrench or turf groomer knob to turn reel. ! Warning to prevent injury, disengage all drives, engage parking brake and stop engine before working in machine or emptying grass catchers. ! Danger 2 3 5 6 7 8 9 12 11 13 14 16 18 19 20 21 22 23 24 27 28 29 31 33 4 17 15 25 2...

Page 109: Lf 3400 / Lf 3800

79 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 5003087 1 frame, reel 2 361877 2 • decal, danger 3 1000997 1 • decal, warning 4 5003053 1 7 blade left hand reel 4 5003054 1 7 blade right hand reel 5 1004786 1 bearing housing 6 500534 1 • bea...

Page 110: Lf 3400 / Lf 3800

80 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21/22 23 24 28 29 4 17 15 25 26/27 1 12 8 19 lf 3400 / lf 3800 30.1 five inch reel assembly lf 3400, lf 3400 turbo serial no. All.

Page 111: Lf 3400 / Lf 3800

81 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 1000770 1 rear roller see 35.1 2 1002224 2 zerk bolt 3 446142 2 lockwasher, 3/8 heavy 4 400264 2 screw, 3/8-16 x 1-1/4” hex head 5 453011 2 flat washer, 3/8 6 345510 2 spacer 7 2000065 1 castin...

Page 112: Lf 3400 / Lf 3800

82 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 22 20 21 40 23 24 27 28 29 30 31 33 4 17 15 25 26 34 37 38 39 35 36 32 1 18 18 34 27 38 39 33 35 36 26 14 lf 3400 / lf 3800 31.1 seven inch reel assembly and lf 3407 serial no. All.

Page 113: Lf 3400 / Lf 3800

83 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 2810472 1 reel, 11 blade used on 67848 1 2810471 1 reel, 9 blade used on 67858 2 5002609 1 frame, 7” reel 3 361877 2 • decal, danger 4 2811399 1 bedknife backing assembly 5 503460 1 • bedknife ...

Page 114: Lf 3400 / Lf 3800

84 3 5 7 12 13 14 18 19 20 21 22 4 17 15 25 2 6 8 9 10 11 13 14 16 23 24 27 28 29 26 lf 3400 / lf 3800 32.1 seven inch reel assembly lf 3800 and lf 3407 serial no. All.

Page 115: Lf 4675 / Lf 4677

85 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 123268 1 front roller see 34.1 2 1002446 1 rear roller, 24” serial no. 67848-1601 ~ 1899,see 36.1 2 1003728 1 rear roller, 22” serial no. 67848-1900 and up,see 36.1 2 1003728 1 rear roller, 22”...

Page 116: Lf 3400 / Lf 3800

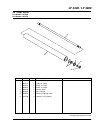

86 > change from previous revision 2 3 5 6 7 8 9 10 11 4 1 lf 3400 / lf 3800 33.1 down pressure spring serial no. All item part no. Qty. Description serial numbers/notes 1 461397 1 roll pin, 1/4 x 1-1/4” 2 453017 1 flat washer, 1/2 3 400268 1 screw, 3/8-16 x 1-3/4” hex head 4 3008593 1 tube, down pr...

Page 117: Lf 3400 / Lf 3800

87 > change from previous revision 2 3 5 6 7 8 9 10 12 11 4 1 lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 3003416 1 shaft 2 3000115 1 tube ◆ 3 500534 2 bearing, cup and cone 4 471214 2 grease fitting ◆ 5 338647 2 grease seal ◆ 6 n/s 16 spacer ◆ 7 3004882 2 grease seal 8 3...

Page 118: Lf 3400 / Lf 3800

88 > change from previous revision 2 3 5 6 7 8 4 1 lf 3400 / lf 3800 35.1 rear roller part number 1000770 serial no. All item part no. Qty. Description serial numbers/notes 1 3001654 1 shaft, roller 2 3001655 1 tube, roller 3 3001656 2 seal, grease 4 5000625 2 bearing, cup and cone 5 3000983 2 seal,...

Page 119: Lf 3400 / Lf 3800

89 > change from previous revision 2 3 5 6 4 1 lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 1002445 1 tube, 24” roller 1 1003727 1 tube, 22” roller 2 3005318 1 shaft, 24” roller 2 3008027 1 shaft, 22” roller 3 3005156 2 sleeve, wear 4 3004882 2 seal, grease 5 500534 2 bear...

Page 120: Lf 3400 / Lf 3800

90 > change from previous revision 1 2 3 4 5 6 7 8 9 7 6 lf 3400 / lf 3800 37.1 brake assemblies serial no. All item part no. Qty. Description serial numbers/notes 1 340603 2 bracket, brake mounting 503308 1 disk brake, r.H. 2500722 1 disk brake, l.H. 2 590259 4 • nut, 3/8-24 3 549441 2 • v-plate 4 ...

Page 121: Lf 3400 / Lf 3800

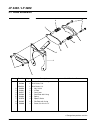

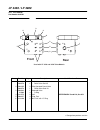

91 > change from previous revision 1 / 7 2 3 4 5 3 a b g 6 lf 3400 / lf 3800 38.1 reel valve part number 2822502 serial no. All item part no. Qty. Description serial numbers/notes 1 5003080 1 flow control 5003579 1 • flow control seal kit 2 5003032 1 solenoid vlave 339909 4 • o-ring 3 5003033 2 coil...

Page 122: Lf 3400 / Lf 3800

92 > change from previous revision 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 1 2 3 4 5 6 lf 3400 / lf 3800 39.1 front wheel motor part number 1001757 serial no. All item part no. Qty. Description serial numbers/notes 1 558066 8 screw, torx 2 5002110 1 front retainer 3 558063 1 shaft and bearing kit ...

Page 123: Lf 3400 / Lf 3800

93 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 lf 3400 / lf 3800 40.1 rear wheel motor part number 390859 serial no. All item part no. Qty. Description serial numbers/notes 1 a 1 seal exclusion 2 a 4 seal, 3” i.D. 3 a 1 back up ring 4 a 1 shaft seal 5 554781 1 shaft and bearing kit...

Page 124: Front

94 > change from previous revision 1 2 3 4 5 8 9 10 g p t 5 1 t 6 4 front rear 2 3 2 2 2 used with lf 3400 and 3400 turbo models. 6 lf 3400 / lf 3800 41.1 lift valve part number 2822501 serial no. All item part no. Qty. Description serial numbers/notes 1 5003144 1 relief valve 5003579 1 • relief val...

Page 125: Top View

95 > change from previous revision 1 1 2 2 f r t top view front view 1 2 3 4 5 6 7 8 8 8 8 8 8 9 8 8 7 1 8 9 7 item part no. Qty. Description serial numbers/notes 1 5003507 2 coil reference k-1 and k-2, see 45.1 2 5003096 1 solenoid valve 5003578 1 • solenoid valve seal kit 3 5003121 1 solenoid valv...

Page 126: Lf 3400 / Lf 3800

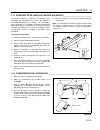

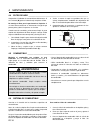

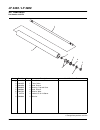

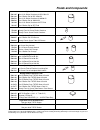

96 > change from previous revision lf 3400 / lf 3800 42.1 reel motor part number 2822503 (five inch reel) serial no. All item part no. Qty. Description serial numbers/notes 1 5001068 1 o-ring 2 5003140 2 relief valve 3 5003688 1 face plate 5003589 1 seal kit 1 2 3.

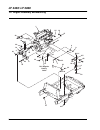

Page 127: Lf 3400 / Lf 3800

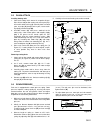

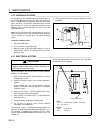

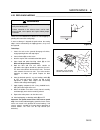

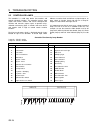

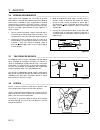

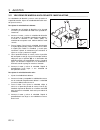

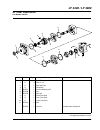

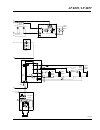

97 > change from previous revision lf 3400 / lf 3800 43.1 reel motor part number 1002620 (seven inch reel) serial no. All item part no. Qty. Description serial numbers/notes 1 3006021 1 o-ring 2 5003140 2 relief valve 3 5003485 1 face plate 4 5003031 1 seal kit not shown 5 4102440 1 shaft, output 1 ...

Page 128: Lf 3400 / Lf 3800

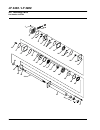

98 lf 3400 / lf 3800 44.1 steering valve part number 1003458 serial no. All 1 2 3 4 5 6 7 8 10 9 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 31 32 33 34 35 36 37 4 4 4 11 11 38 30

Page 129: Lf 3400 / Lf 3800

99 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 443108 4 locknut, 5/16-18 center 2 n/s 1 port cover 3 c 1 seal, o-ring 4 c 4 seal, o-ring 5 c 4 seal, o-ring 6 443828 1 nut, 5/8-18 hex jam 7 n/s 4 special bolt 8 n/s 1 port manifold 9 b 3 spri...

Page 130: Lf 3400 / 3800

100 a b c d e f g h j k l m n sw-6 sw-13 1 1 2 2 2 3 r db og/wh og/bk lb/wh pk/bu ye/bu gy/rd og/wh ye ye og/y e db pu/gn pk dg dg tn/bk db pu/gn tn/bk + – k-11 k-10 u-7 sw-2 sw-3 cb-1 l-1 l-3 l-5 l-4 l-6 l-2 r-3 m-1 b-1 r-2 u-1 u-2 u-3 r-3 k-1 k-2 l l b s s g g i og/wh og/wh og/wh og/wh og/bk og/wh...

Page 131: Lf 3400 / 3800

101 bk 1-5 1-4 3-2 3-8 grd-1 4-1 4-2 4-3 4-4 2-1 3-12 2-12 1-2 1-7 1-8 1-9 1-10 1-11 1-12 1-1 2-2 2-6 2-5 2-8 2-11 1-6 1-3 3-4 3-5 3-3 3-6 3-7 pk/bu y e/bu og/y e og/y e og/pk og/pk select 3 select 4 select 2 select 1 star t rela y glo w plug rela y 4wd glo w plug light lights hyd le v el light swit...

Page 132: Lf 3400 / 3800

102 lf 3400 / 3800 item reference illustration part number description serial numbers/notes b-1 see 28.1 366931 battery cb-1 see 28.1 361439 50 amp circuit breaker (alternator) f-1 see 28.1 5003282 20 amp fuse (ignition circuit) included in controller f-2 see 28.1 5003282 20 amp fuse (lights) includ...

Page 133: Lf 3400 / 3800

103 lf 3400 / 3800 sw-16 see 27.1 4125831 left reel level proximity switch u-1 see 4.1 3005121 temperature gauge u-2 see 4.1 365943 fuel gauge u-3 see 4.1 4129683 hour meter u-4 see 4.1 366670 horn u-5 not shown cruise control module (option) u-6 see 28.1 4122841 controller u-7 not shown n/s alterna...

Page 134: Lf 3400 / Lf 3800

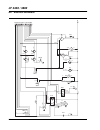

104 a b p g t a b p t .5 ci .5 ci .5 ci 3625 psi 3625 psi supply .036 drain .031 285 psi 2.81 ci displacement control tow valve reverse diag. Forward diag 3000 rpm a b traction pump gear pump rear reel valve g front reel valve 1167 psi 1167 psi lr reel motor rr reel motor * * 1167 psi lf reel motor ...

Page 135: Lf 4675 / Lf 4677

105 1 2 3 4 6 8 9 10 g p t t left front cylinder center cylinder left rear cylinder right rear cylinder right front cylinder steering unit in out aux lt rt 4.13 ci 1450 psi 450 psi .026 .040 .040 .040 .040 .040 .040 .040 .040 .052 one way 25 psi 25 psi 10 micron charge filter 19.0 ci 19.0 ci front w...

Page 136: Lf 3400/ Lf 3800

106 x w w w x w x w w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size w-x o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face se...

Page 137: Lf 3400 / Lf 3800

107 > change from previous revision lf 3400 / lf 3800 adapter part number. Dash size adapter type (w) o-ring (x) o-ring (y) o-ring (z) o-ring 339974 4-6 straight adapter 339908 339897 339979 6-6 straight adapter 339909 339897 339985 8-10 straight adapter 339910 339899 339989 10-10 straight adapter 3...

Page 138: Fluids And Compounds

Fluids and compounds * refer to the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Textron golf, turf & specialty products offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See your local tgtsp dealer for a...

Page 139: Index

109 index 1000480 ...................... 79 1000770 ...................... 81 1000997 ...................... 79 1001757 ...................... 45 1002031 ................ 47 , 49 1002032 ................ 47 , 49 1002153 ...................... 57 1002154 ...................... 57 1002224 ...............

Page 140: Index

110 index 3007719.......................55 3007776.......................77 3007777.......................77 3007798.......................75 3007889.......................56 3007970.......................45 3007989.......................75 3008027.......................89 3008193......................

Page 141: Index

111 index 4131337 ...................... 37 4131618 ...................... 39 4131663 ...................... 33 4131828 ...................... 33 5000097 ...................... 87 5000318 ...................... 92 5000415 ...................... 79 5000625 ...................... 88 5000919 .............

Page 144

Textron golf, turf & specialty products po box 7708, charlotte, nc 28241-7708 www.Ttcsp.Com equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and factory trained technicians backed b...