When performance matters. ™ pgm 22 incommand ™ 63280 – pgm 22, 11 blade reel 63286 – pgm 22, 15 blade reel warning warning: if incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the...

© 2010, jacobsen, a textron company/textron innovations inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” this manual contains safety, operating, adjustment, maintenance, troubleshooting instructions and parts list for your new jacobsen machi...

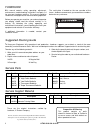

3 > change from previous revision table of contents 1 safety 1.1how to operate safely .............................................. 4 1.2 important safety notes .........................................7 2 specifications 2.1 product identification............................................ 8 2.2 e...

1 safety 4 1 safety 1.1 how to operate safely safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and technicians. Manuals in additional languages may be a...

Safety 1 5 e do not use on the slopes greater than the safe slope limit for the equipment. F to guard against over turning or loss of control: – operate the mower across the face (horizontally), but not up and down on the face of slopes (vertically). – do not start or stop suddenly on slopes. – decr...

1 safety 6 f when you put the mower on a trailer or put the mower in storage, close the fuel valve. Do not keep fuel near flames or drain the fuel inside a building. G disconnect the battery before you service the mower. Always disconnect the negative battery cable before the positive battery cable....

Safety 1 7 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

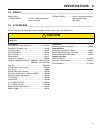

2 specifications 8 2 specifications 2.1 product identification _________________________________________________ 63280......... 22 in., (55.9 cm) 11 blade professional greens mower with incommand™ control system, 4.0 h.P. Gasoline engine (honda), operator presence control, grass catcher, brakes, and...

Specifications 2 9 2.5 weight__________________________________________________________________ weight (mass) 11 blade pgm 22 ................ 187 lb., (85 kg) with catcher, roller, kickstand. 15 blade pgm 22 ............... 194 lb., (88 kg) with catcher, grooved steel roller, kickstand. 2.6 accesso...

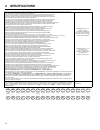

2 specifications 10 2.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de co...

Specifications 2 11 conformity assessment procedure (noise) ▪ Оценка за съответствие на процедурата (Шум) ▪ postup hodnocení plnění podmínek (hluk) ▪ procedure for overensstemmelsesvurdering (støj) ▪ procedure van de conformiteitsbeoordeling (geluid) ▪ vastavushindamismenetlus (müra) ▪ vaatimustenmu...

2 specifications 12 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. Подпис на човека, упълномощен да състави декларацията от името н...

Specifications 2 13 2.8 vibration level_________________________________________________________ when the machine was tested for hand/arm vibration levels, the operator was standing in the normal operating position with both hands on the handle. The engine was running and the cutting device was rota...

3 decals 14 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the decals, they are critical to the safe operation of the mower. Replace damaged decals immediately. To prevent injury and accidental clutch engagement do not adjust engine sp...

Initial inspection 4 15 4 initial inspection 4.1 general ________________________________________________________________ the set-up and testing of the unit should always be performed by a trained technician, familiar with the operation of the equipment. Read each instruction completely and make sur...

5 controls 16 5 controls 5.1 icons ___________________________________________________________________ 5.2 controls ______________________________________________________________ a. Parking brake – used whenever the mower is left unattended or as a service brake while transporting. B. Paddle throttl...

Controls 5 17 e. Reel clutch lever – to disengage, turn handle (e) to point downwards. Always disengage clutch when mower is being transported. F. Choke lever - the choke lever opens and closes the choke valve in the carburetor. The closed position enriches the fuel mixture for starting a cold engin...

6 operation 18 6 operation 6.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, missing, or damaged components. Check for fuel or oil leaks. 2. Check the fuel supply and crankcase oil l...

Operation 6 19 6.3 operating procedures _________________________________________________ 1. Under no circumstances should the engine be started with operator or bystanders standing in front of the reel. 2. Never run the engine in an enclosed area. 3. Keep hands and feet away from moving parts and c...

6 operation 20 6.4 starting/stopping engine ______________________________________________ starting 1. Check oil level and fuel supply, then open fuel valve lever (g). 2. Move the choke lever (f) to the closed position. 3. Set engine switch (d) to on. 4. Make certain the o.P.C. Bail (c) is disengage...

Operation 6 21 6.5 transport wheels (optional kit 62293)__________________________________ 1. Push and hold the kickstand against the ground then pull the mower handle back until the mower rests on the stand (l). 2. To remove wheels, press retaining clip (j) away from the hub and pull wheel off hub....

6 operation 22 6.7 mowing_________________________________________________________________ 1. Stop engine. Place mower on kickstand and remove the transport wheels if installed. See section 6.5. 2. Engage the reel lever (e) and push mower off the kickstand. Start the engine. 3. Position mower slight...

Operation 6 23 6.8 daily maintenance______________________________________________________ 1. Park the mower on a flat, level surface, engage parking brake, and stop the engine. 2. Grease and lubricate all points if required. 3. To prevent fires, wash the mower after each use. Clean all grass clippi...

7 adjustments 24 7 adjustments 7.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Adjustments 7 25 7.3 bedknife _______________________________________________________________ 1. Read section 7.2 before making the adjustment. 2. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blade is the end that passes over the bedknife...

7 adjustments 26 7.5 cutting height _________________________________________________________ note: make sure the bedknife is properly adjusted before setting the cutting height. (section 7.3). 1. Tip mower back on traction drum or tires. Do not leave the mower tipped back for an extended length of ...

Adjustments 7 27 7.7 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. When tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate an...

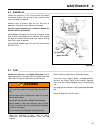

8 maintenance 28 8 maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen. 2. Inspect the equipment on a regular ...

Maintenance 8 29 8.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap, and add oil as required. Perform initial oil change after the first 20 hours of op...

8 maintenance 30 8.5 bedknife shoe removal ________________________________________________ 1. To remove the shoe (e), loosen nut (a), and turn nuts (b) counterclockwise 1/4 turn or more to bring the bedknife into light contact with the reel blades. 2. Remove mounting hardware (d) from both sides of...

Maintenance 8 31 8.8 wheel bearing _________________________________________________________ the bearing has the word lock and an arrow stamped on the face. When replacing the bearing, make absolutely certain that the bearing is installed in the proper direction of rotation. For the right wheel, ins...

8 maintenance 32 8.10 troubleshooting ______________________________________________________ before making any adjustments or performing maintenance, read maintenance section for procedures and warnings. Symptoms probable causes solution engines does not start. Choke in wrong position. Empty fuel ta...

Maintenance 8 33 8.11 lubrication ____________________________________________________________ the mower was designed for minimum lubrication. Over greasing will produce high loads on the bearings and engine, thereby reducing the performance of the machine. 1. Always clean the grease fitting before ...

9 notes 34 9 notes.

Parts catalog 10 35 10 parts catalog 10.1 how to use the parts catalog _________________________________________ abbreviations n/s - not serviced separately, can only be obtained by ordering main component or kit. Ar -variable quantity or measurement is required to obtain correct adjustment. Symbols...

36 1 15 2 3 4 5 6 7 8 8 9 10 11 12 13 l wa 98 db 14 14 1. Slide bail to the left. To engage traction 2. Squeeze bail to handle. 16 16 pgm 1.1 decals serial no. All be sure the traction clutch lever is in neutral before starting the engine. Caution 1 reel clutch control engage disengage j-t-3001792 1...

37 > change from previous revision pgm item part no. Qty. Description serial numbers/notes 1 362764 1 decal, caution 2 3001790 1 decal, caution 3 4125685 1 decal, pgm 22 4 2811102 1 decal, eu 5 340830 1 decal, spanish 6 361854 1 decal, caution 7 4127335 1 decal, danger 8 4131528 1 decal, noise 98 db...

38 a a b b c c 1 1 2 3 4 5 5 5 6 6 7 7 8 8 9 10 11 12 13 14 15 16 17 / 18 19 / 20 21 22 23 24 25 26 27 27 28 29 30 31 32 33 34 35 36 37 38 39 pgm 2.1 handle and controls serial no. All.

39 > change from previous revision item part no. Qty. Description serial numbers/notes 1 366708 2 flanged bearing 2 400262 2 screw, 3/8-16 x 1” hex head 3 400268 1 screw, 3/8-16 x 1-3/4” hex head 4 434029 4 screw, 1/4-20 x 1” socket head 5 443102 7 nut, 1/4-20 hex 6 443110 2 nut, 3/8-16 hex 7 444718...

40 8 9 10 11 18 4 3 4 5 6 7 18 20 1 2 19 20 12 13 14 15 16 17 pgm 3.1 left chain cover serial no. All.

41 > change from previous revision pgm item part no. Qty. Description serial numbers/notes ●▲ 1 207480 1 cover, chain 2 472201 1 plug, 1/8 pipe,square head ◆ 3 400102 1 screw, 1/4-20 x 3/8” hex head 4 446130 4 lockwasher, 1/4 heavy 5 304756 1 retainer 6 503438 1 lever, shift 7 339910 1 • o-ring ◆ 8 ...

42 17 8 7 37 36 23 24 21 20 18 34 24 39 35 33 32 22 31 31 30 30 26 27 5 2 15 16 38 25 6 13 12 14 1 28 29 19 5 4 11 10 9 40 3 pgm 4.1 left side frame serial no. All.

43 > change from previous revision pgm item part no. Qty. Description serial numbers/notes ● 1 2811557 1 frame, l.H. 2 337677 1 • seal, oil 3 2811124 1 • stud, handle 4 336962 1 • seal, oil 5 500534 2 • bearing cup and cone 6 2500759 2 • bushing 7 365753 1 • seal, grease 8 303490 1 • bearing 9 30795...

44 8 9 6 5 1 2 4 7 21 13 20 19 18 3 4 10 11 12 13 14 15 16 17 pgm 5.1 right side frame serial no. All.

45 > change from previous revision pgm item part no. Qty. Description serial numbers/notes 1 2811558 1 frame, r.H. 2 337677 1 • seal, oil 3 336962 1 • seal, oil 4 500534 2 • bearing cup and cone 5 2811124 1 • stud, handle 6 2500759 1 • bushing 7 307377 1 spacer, shaft 8 471223 1 fitting, grease 9 47...

46 38 39 34 31/33 36 1 20 22 12 23 18 19 11 8 13 39 3 4 12 22 21 35 16 37 15 14 6 7 4 3 5 30 16 9 2 27 40 29 28 26 17 25 24 32 10 503477 22" high profile 503478 22" low profile 503479 22" tournament 5002887 22" special tournament standard bedknife options 4131369 22" high profile 4131001 22" low pro...

47 > change from previous revision pgm item part no. Qty. Description serial numbers/notes ●▲ 1 122544 1 cross bar, front 2 122545 1 cross bar, rear 3 400266 8 screw, 3/8-16 x 1-1/2” 4 446142 8 lockwasher, 3/8 heavy 5 304740 1 tie rod, front 6 443114 2 nut, 7/16-14 hex 7 446148 2 lockwasher, 7/16 8 ...

48 1 2 3 32 4 5 6 7 8 9 10 11 11 12 13 14 31 15 17 18 21 23 29 24 25 26 19 throttle cable installation 20 22 part of engine part of engine 27 16 27 28 29 pgm 7.1 engine and clutch serial no. All.

49 > change from previous revision pgm item part no. Qty. Description serial numbers/notes 1 303873 1 washer 2 309756 1 sprocket, 3 365658 4 spacer, engine mounting 4 400194 4 screw, 5/16-18 x 1-3/4” hex head 5 306369 1 screw, 5/16-24 x 1” hex head 6 434029 3 screw, 1/4-20 x 1” socket head 7 441677 ...

50 10 8 7 4 2 3 1 6 5 21 20 5 6 3 2 4 7 9 11 12 8 13 14 15 16 15 11 17 18 19 pgm 8.1 traction rollers serial no. All.

51 > change from previous revision item part no. Qty. Description serial numbers/notes 1 3004026 1 shaft, roller 2 163801 2 gear, differential 3 325656 2 • bushing 4 344745 2 washer, thrust 5 202947 2 pinion 6 308030 2 washer, pinion thrust 7 103862 2 housing, differential 8 308033 2 • bushing 9 400...

52 17 14 15 12 13 10 20 21 11 5 5 3 18 19 23 16 2 3 1/4 6 7 8 9 22 22 pgm 9.1 transport wheels serial no. All.

53 > change from previous revision pgm item part no. Qty. Description serial numbers/notes 1 1000477 1 hub, l.H. Wheel 2 338766 1 • bearing 3 366705 2 • seal 4 1000476 1 hub, r.H. Wheel (includes 2 and 3) 5 366697 4 bushing 6 366718 1 collar, latching 7 445801 1 nut, 5/8-18 hex jam lock 8 361451 1 w...

54 index 1000476 ........................53 1000477 ........................53 1001308 ........................45 1001309 ........................41 1004944 ........................43 103399 ..........................47 103862 ..........................51 106790 ..........................43 122544 ....

55 index 503478 ........................... 2 503479 ........................... 2 503532 ......................... 49 62293 ........................... 53.

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...