- DL manuals

- Jacobsen

- Lawn Mower

- 63334 - Eclipse 2 118

- Technical Manual

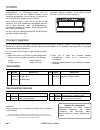

Jacobsen 63334 - Eclipse 2 118 Technical Manual - Fluids And Compounds

Fluids and Compounds

* Refer to the Operator’s manual or the Parts & Maintenance Manual for the correct hydraulic oil requirements for your machine.

Jacobsen offers a High Usage Parts Catalog illustrating commonly used Parts through easy to read line Drawings. See your local

Hydraulic Fluid*

5001405

Two 2-1/2 Gallon Container of ISO VG68 Oil

5001404

One 5 Gallon Pail of ISO VG68 Oil

2500548

Two 2-1/2 Gallon Container of 10W30 Oil

2500546

One 5 Gallon Pail of 10W30 Oil

503409

Two 2-1/2 Gallon Container of ATF Fluid

503407

One 5 Gallon Pail of ATF Fluid

2-Cycle Oil

554599

Twenty Four 8 Ounce Plastic Container

Grease

5000067

One 5 Gallon Pail OO-Grease

5000068

Twenty Four 8 Ounce Tube OO-Grease

Paint

4184140

12 Ounce Orange Aerosol Can

2500789

Twelve 1 Quart Can Orange

546409

Two 1 Gallon Can Orange

5002631

Hunter Green Aerolol Can

838140

16 Ounce Ransomes Green Aerosol Can

4112764

1 Quart Can Ransomes Green

Lapping Compound

5002488

One 10 Pound Pail of 80 Grit

5002490

One 25 Pound Pail of 80 Grit

5002489

One 10 Pound Pail of 120 Grit

5002491

One 25 Pound Pail of 120 Grit

Specialty Compound

365422

5.3 Ounce Tube of Electrical Insulating Gel

5001581

14 Ounce Can of Lubriplate Multi Lube A

523248

Chain Lubricant

4136736

Zinc Spray Corrosion Protection

Biodegradable Hydraulic Fluid*

5003102

One 55 Gallon Drum Jacobsen GreensCare 68

5003103

One 5 Gallon Pail Jacobsen GreensCare 68

5003105

One 55 Gallon Drum Jacobsen GreensCare 46

5003104

One 5 Gallon Pail Jacobsen GreensCare 46

4115976

One 55 Gallon Drum Jacobsen GreensCare 32

4115977

One 5 Gallon Pail Jacobsen Greens Care 32

4114701

GreensCare Bio-Flush

5003106

Twenty Four 14 Ounce Tube Greens Care Grease

O-Ring Kit

5002452

SAE O-Ring Boss (3/32 ~ 2” Tube O.D.)

5002453

Common O-Ring Kit

5002454

O-Ring Face Seal ORFS (-4 ~ -24 ORS Tube Size)

Right Start Kit for New Machines

See your local Jacobsen Dealer

On-Time Maintenance Kit

See your local Jacobsen Dealer

Serial No.

Summary of 63334 - Eclipse 2 118

Page 1

When performance matters. ™ gb united kingdom dk denmark eclipse ® 2 incommand ™ 63334 – eclipse 2 118, 18” 11 blade reel, gen-set 63343 – eclipse 2 118, 18” 11 blade reel, battery pack 63335 – eclipse 2 118, 18” 15 blade reel, gen-set 63344 – eclipse 2 118, 18” 15 blade reel, battery pack 63336 – e...

Page 2

© 2012, jacobsen, a textron company/textron innovations inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” this manual contains safety, operating, adjustment, maintenance, troubleshooting instructions and parts list for your new jacobsen machi...

Page 3

En-3 table of contents 1 safety 1.1 operating safety . . . . . . . . . . . . . . . . . . . . . . 4 1.2 important safety notes . . . . . . . . . . . . . . . . . 5 2 specifications 2.1 product identification . . . . . . . . . . . . . . . . . . 6 2.2 mower . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Warning

1 safety en-4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this man...

Page 5: Warning

Safety 1 en-5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 6

2 specifications en-6 2 specifications 2.1 product identification _________________________________________________ 63334 ............................ Eclipse ® 2 118 base unit with 18 in. (457 mm) 11 blade reel and incommand™ control system. Gen-set power module. 63343 ............................ ...

Page 7

Specifications 2 en-7 2.2 mower__________________________________________________________________ reel..................................7, 9, 11, or 15 blades, hardened high manganese carbon steel. Reel diameter ..................5 in. (127 mm) cutting width ...................18, 22 or 26 in. (457,...

Page 8

2 specifications en-8 2.6 battery power module ________________________________________________ to ensure the longest battery life possible, the batteries are not shipped with the power module and must be ordered separately. For optimum range and performance use batteries that equal or exceed the am...

Page 9: Caution

Specifications 2 en-9 2.7 accessories & support literature _____________________________________ contact your area jacobsen dealer for a complete listing of accessories and attachments. Accessories lapping compound (180 grit) ................................... 554598 orange touch-up paint (12 oz. S...

Page 10

2 specifications en-10 declaration of conformity ƒ ȾȿɄɅȺɊȺɐɂə ɁȺ ɋɔɈɌȼȿɌɋɌȼɂȿ ƒ prohlÁŠenÍ o shodċ ƒ overensstemmelseserklÆring ƒ conformiteitsverklaring ƒ vastavusdeklaratsioon ƒ vaatimustenmukaisuusvakuutus ƒ declaration de conformite ƒ konformitÄtserklÄrung ƒ ǻǾȁȍȈǾ ȈȊȂȂȅȇĭȍȈǾȈ ƒ megfelelėsÉgi ny...

Page 11

Specifications 2 en-11 cutting width ƒ ɒɢɪɨɱɢɧɚ ɧɚ ɪɹɡɚɧɟ ƒ ŠíĜka Ĝezu ƒ skærebredde ƒ maaibreedte ƒ lõikelaius ƒ leikkuuleveys ƒ largeur de coupe ƒ schnittbreite ƒ ȂȒțȠȢ ȝȚıȚȞȑȗĮȢ ƒ vágási szélesség ƒ larghezza di taglio ƒ griešanas platums ƒ pjovimo plotis ƒ tikkonforma mad-direttivi ƒ szerokoĞü c...

Page 12

2 specifications en-12 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. ɉɨɞɩɢɫ ɧɚ ɱɨɜɟɤɚ, ɭɩɴɥɧɨɦɨɳɟɧ ɞɚ ɫɴɫɬɚɜɢ ɞɟɤɥɚɪɚɰɢɹɬɚ ɨɬ ɢɦɟɬ...

Page 13

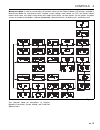

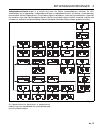

Decals 3 en-13 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4170001 stop 4127335 4169840 rev a danger to prevent injury, ...

Page 14

3 decals en-14 familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4265170 4265171 4172240 read the manual before adjusting front roller weight. Disengaged parking engaged brake reel switch off on 4265172 key switc...

Page 15

Decals 3 en-15 to engage traction. 1. Slide bail to the left. 2. Squeeze bail to handle..

Page 16: Warning

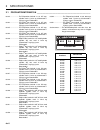

4 controls en-16 4 controls 4.1 icons ___________________________________________________________________ 4.2 handle controls ______________________________________________________ a. Parking brake – used whenever the mower is left unattended or as a service brake while transporting. Always use tran...

Page 17: Warning

Controls 4 en-17 4.3 lcd display _____________________________________________________________ the lcd displays current functional values for the operation of the eclipse 2 mower and sounds one of three types of audible alerts. The lcd operates in one of two modes, operator mode (default), and maint...

Page 18

4 controls en-18 operator mode is used by the operator for system voltage information, travel speed, foc setting, reel speed, and total hours on mower. Press the orange buttons (k and l) on the front handle cover to toggle between the different displays. Operator mode is view only, only screen illum...

Page 19

Controls 4 en-19 maintenance mode is used to set and adjust all functional values for the eclipse 2 mower. Lcd displays available in maintenance mode are, maintenance hours, backlap, system voltage, travel speed, set foc, reel speed, traction motor current draw, reel motor current draw, total motor ...

Page 20

4 controls en-20 display description to enter maintenance mode, press either orange buttons (k or l) until maintenance mode pin screen is on the display and press black button (j). Use the orange buttons (k or l) to select and the black button (j) to enter the digits for the mechanic mode pin. Note:...

Page 21

Controls 4 en-21 gen-set power module - used to indicate the gen-set power module is installed on the mower. This setting is used by system controllers and does not affect operation of mower. Do not operate mower with incorrect power module setting. Press the black button (j) to toggle between the p...

Page 22

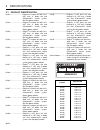

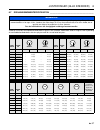

4 controls en-22 4.4 frequency of cut ______________________________________________________ the foc (frequency of cut) is the distance, in inches (mm), the machine travels forward between reel blades contacting the bedknife. The foc can be adjusted either by changing the fixed foc setting or by cha...

Page 23

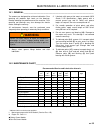

Controls 4 en-23 15 blade reel foc table , product no 63339, 63341, 63335, 63337, 63348, 63350, 63344, 63346 (standard reel) mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.00 0.078 0.076 0.074 0.072 0.070 0.069 0.067 0.065 0.064 (3.22) (1.987) (1.933) (1.882) (1.834) (1.788) (1.74...

Page 24

4 controls en-24 11 blade reel foc table, product no. 63334, 63336, 63338, 63340, 63347, 63349, 63343, 63345 (standard reel) mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 (3.22) 0.107 (2.709) 0.104 (2.636) 0.101 (2.567) 0.098 (2.501) 0.096 (2.438) 0.094 (2.379) 0.091 (2.322) 0....

Page 25

Controls 4 en-25 9 blade reel foc table, product no. 63340, 63349 (optional reel) mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 0.130 0.127 0.124 0.120 0.117 0.114 0.112 0.109 0.107 (3.22) (3.311) (3.222) (3.137) (3.057) (2.98) (2.908) (2.838) (2.772) (2.709) 2.1 0.137 0.133 0....

Page 26

4 controls en-26 7 blade reel foc table, product no. 63342, 63351 (standard reel) and 63340, 63349 (optional reel) mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 0.168 0.163 0.159 0.155 0.151 0.147 0.144 0.140 0.137 (3.22) (4.258) (4.142) (4.033) (3.93) (3.832) (3.738) (3.649) (...

Page 27: Notice

Controls 4 en-27 4.5 gas power module controls ___________________________________________ m. Engine switch – the engine switch enables and disables the engine ignition system. The engine switch must be in the on position for the engine to run. Turning the engine switch to the off position stops the...

Page 28: Caution

5 operation en-28 5 operation 5.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, missing or damaged components. 2. Make sure the mower is adjusted to the required cutting height. 3. M...

Page 29: Caution

Operation 5 en-29 5.3 operating procedures _________________________________________________ 1. Under no circumstances should the unit be started with operator or bystanders standing in front of the reel. 2. Never run the engine in an enclosed area. 3. Keep hands and feet away from moving parts and ...

Page 30

5 operation en-30 5.4 starting/stopping______________________________________________________ 1. Prepare power module to energize unit. Battery power module: disconnect battery charger and connect power connector. Gen-set power module: a. Check oil level and fuel supply then open fuel valve lever (p...

Page 31: Warning

Operation 5 en-31 5.5 mowing _________________________________________________________________ 1. Turn power off. Remove the transport wheels (if installed). 2. Engage the reel switch. Start the unit. 3. Position mower slightly off green. A. Adjust traction speed paddle (b) to provide a safe, comfor...

Page 32: Warning

5 operation en-32 5.6 transport wheels (optional) __________________________________________ transport wheels are optional accessories available through your jacobsen dealer. Traction wheels are recommended when not using the mower caddy to move the mower from green to green. 1. Push and hold the ki...

Page 33: Warning

Operation 5 en-33 5.8 grass catcher _________________________________________________________ 1. When the basket is about two thirds (2/3) full of grass clippings, move the mower off the green. 2. Stop on a flat surface, disengage o.P.C. Bail, engage parking brake, turn key switch off, and disconnec...

Page 34: Warning

6 adjustments (all units) en-34 6 adjustments (all units) 6.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. R...

Page 35: Caution

Adjustments (all units) 6 en-35 6.4 handle _________________________________________________________________ 1. To adjust the angle of the handle bar (f), loosen screw (d) on both sides of the mower and adjust the handle bar to the desired position. 2. After adjusting handle bar, adjust bracket (e) ...

Page 36: Caution

6 adjustments (all units) en-36 6.6 front roller weight ___________________________________________________ the weight on the front roller is adjustable. Adjust the front roller weight as required to meet your turf needs. 1. Battery power module: to adjust front roller weight, disconnect power conne...

Page 37: Notice

Adjustments (all units) 6 en-37 6.7 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are ...

Page 38: Warning

7 fixed head reel adjustments en-38 7 fixed head reel adjustments 7.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen deal...

Page 39: Notice

Fixed head reel adjustments 7 en-39 7.3 bedknife adjustment ___________________________________________________ 1. Adjuster (a) is used to increase or decrease the spring load on the bedknife. Adjuster (b) is used to move the bedknife to the reel or away from the reel. 2. Once the spring is totally ...

Page 40: Warning

8 classic floating head reel adjustments en-40 8 classic floating head reel adjustments 8.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an au...

Page 41: Notice

Classic floating head reel adjustments 8 en-41 8.3 bedknife adjustment ___________________________________________________ 1. Read section 8.2 before making the adjustment. 2. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blades is that en...

Page 42: Notice

8 classic floating head reel adjustments en-42 8.5 cutting height _________________________________________________________ note: always make the reel to bedknife adjustment before adjusting height of cut. (sections 8.2 and 8.3). 1. Push kickstand down and tip mower back on it’s handle. 4. Set desir...

Page 43: Warning

Trueset floating head reel adjustments 9 en-43 9 trueset floating head reel adjustments 9.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an au...

Page 44: Notice

9 trueset floating head reel adjustments en-44 9.3 bedknife adjustment __________________________________________________ 1. Read section 8.2 before making the adjustment. 2. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blades is that end...

Page 45: Notice

Trueset floating head reel adjustments 9 en-45 9.5 reel bearing ___________________________________________________________ any radial play or excessive end play indicates bad bearings, a weak tension spring or a backed off nut. 1. Check bearing housing mounting hardware. Tighten or replace componen...

Page 46: Notice

9 trueset floating head reel adjustments en-46 9.9 reel assembly removal ________________________________________________ the reel assembly can be removed for maintenance or to use a different reel. 1. Remove hairpin and washer and slide the lift hangers off the pins. 2. Disconnect motor electrical ...

Page 47: Warning

Battery power module 10 en-47 10 battery power module 10.1 safety __________________________________________________________________ batteries contain dilute sulfuric acid which can result in severe burns. Hydrogen gas is formed within a battery during the charging cycle. Hydrogen in concentrations ...

Page 48

10 battery power module en-48 10.3 maintenance ___________________________________________________________ tool list insulated wrench, 3/8” insulated wrench, 11/32” standard screwdriver before charging batteries inspect the connector housings of the battery charger and battery pack for dirt or debri...

Page 49: Warning

Battery power module 10 en-49 10.5 battery charger _______________________________________________________ the battery charger is designed to fully charge the battery pack. Read the instruction manual included with the charger for proper operating procedure. Before charging, the following should be ...

Page 50: Warning

10 battery power module en-50 10.6 battery installation __________________________________________________ if the batteries have been cleaned and any acid in the battery tray area neutralized, no corrosion to the surrounding area should be present. Any corrosion found should be immediately removed w...

Page 51: Caution

Battery power module 10 en-51 10.7 replacing battery pack________________________________________________ the battery pack (a) is designed to be easily lifted out and replaced. This allows the mower to quickly return to service should the batteries become discharged or fail. Additional battery packs...

Page 52: Notice

11 gen-set power module en-52 11 gen-set power module 11.1 engine _________________________________________________________________ important: a separate engine manual, prepared by the engine manufacturer, is supplied with the power module. Read the engine manual carefully until you are familiar wit...

Page 53

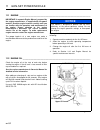

Gen-set power module 11 en-53 11.3 engine oil change ______________________________________________________ perform initial oil change after the first 20 hours of operation. Change oil every 100 hours thereafter. 1. To change engine oil, attach a 7/16 in. (11 mm) i.D. Hose (a) to oil drain valve (b)...

Page 54: Warning

11 gen-set power module en-54 11.5 fuel ____________________________________________________________________ handle fuel with care - it is highly flammable. Use an approved container, the spout must fit inside the fuel filler neck. Avoid using cans and funnels to transfer fuel. • store fuel accordin...

Page 55: Warning

Maintenance 12 en-55 12 maintenance 12.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment ...

Page 56

12 maintenance en-56 12.4 backlapping and grinding _____________________________________________ check for damage to the bedknife and reel blades. Refer to (section 6.2). 1. Determine if backlapping or grinding will restore the proper cutting edge. 2. For optimum performance use a bedknife grinder t...

Page 57: Caution

Maintenance 12 en-57 12.5 storage ________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Clean the tires thoroug...

Page 58

13 troubleshooting en-58 13 troubleshooting 13.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information, contact your area jacobsen dealer. Symptoms poss...

Page 59: Warning

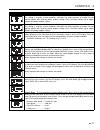

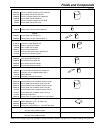

Maintenance & lubrication charts 14 en-59 14 maintenance & lubrication charts 14.1 general ________________________________________________________________ the mower was designed for minimum lubrication. Over greasing will produce high loads on the bearings; thereby reducing the performance of the m...

Page 60

14 maintenance & lubrication charts en-60 14.3 lubrication chart _____________________________________________________ f c d b a l 4 l 6 l 6 l7 e ● ● ● ● ● l 3 l l 5 2 l 1 l l 5 l 5 2 l 2 l 1 l 1 l 1 l 1 l 1 l 1 - reel roller bearing l 2 - reel motor bearing housing l 3 - right side traction drum be...

Page 61

Parts catalog 15 en-61 15 parts catalog 15.1 how to use the parts catalog _________________________________________ abbreviations n/s - not serviced separately, can only be obtained by ordering main component or kit. Ar -variable quantity or measurement is required to obtain correct adjustment. Symb...

Page 62

Denne vejledning indeholder sikkerheds-, drifts-, justerings, vedligeholdelses- og fejlfindingsanvisninger samt en reservedelsliste for din nye jacobsen-maskine. Denne vejledning skal opbevares sammen udstyret, så man kan slå op i den i forbindelse med betjening af maskinen. Inden maskinen tages i b...

Page 63

Da-3 indhold 1 sikkerhed 1.1 sikkerhed ved betjening.................................... 4 1.2 vigtige bemærkninger om sikkerhed .................5 2 specifikationer 2.1 produktidentifikation ..........................................6 2.2 plæneklipper ..................................................

Page 64: Advarsel

1 sikkerhed da-4 1 sikkerhed 1.1 sikkerhed ved betjening _______________________________________________ 1. Sikkerheden afhænger af, at de personer, der betjener eller efterser udstyret, udviser opmærksomhed, omtanke og forsigtighed. Tillad aldrig mindreårige at betjene udstyr af nogen art. 2. Du er...

Page 65: Advarsel

Sikkerhed 1 da-5 1.2 vigtige bemÆrkninger om sikkerhed ___________________________________ dette sikkerhedssymbol bruges til at advare dig om potentielle farer. Fare – angiver en overhængende fare, som, hvis den ikke afværges, vil medføre død eller alvorlig legemsbeskadigelse. Advarsel – angiver en ...

Page 66

2 specifikationer da-6 2 specifikationer 2.1 produktidentifikation _________________________________________________ 63334 ..................... En eclipse ® -basisenhed 2 118, 457 mm, cylinder med 11 knive og incommand™- styringssystem. Effektmodul. 63343 ..................... En eclipse ® -basisen...

Page 67

Specifikationer 2 da-7 2.2 plÆneklipper __________________________________________________________ knivcylinder......................7, 9, 11 eller 15 knive, hærdet kulstofstål med højt manganindhold knivcylinderdiameter........127 mm klippebredde....................457, 559 eller 660 mm klippehøjde...

Page 68

2 specifikationer da-8 2.6 batterimodul __________________________________________________________ for at sikre så lang batterilevetid som muligt sendes batterierne ikke med effektmodulet, og de skal bestilles separat. Med henblik på at opnå optimal rækkevidde og ydeevne skal der bruges batterier, d...

Page 69: Forsigtig

Specifikationer 2 da-9 2.7 dokumentation til tilbehØr og hjÆlp __________________________________ kontakt din lokale jacobsen-forhandler for at få en komplet liste over tilbehør og redskaber. Tilbehør slibemasse (180 korn) .............................................. 554598 orange efterbehandlings...

Page 70

2 specifikationer da-10 2.8 overensstemmelseserklÆring ________________________________________ declaration of conformity ƒ ȾȿɄɅȺɊȺɐɂə ɁȺ ɋɔɈɌȼȿɌɋɌȼɂȿ ƒ prohlÁŠenÍ o shodċ ƒ overensstemmelseserklÆring ƒ conformiteitsverklaring ƒ vastavusdeklaratsioon ƒ vaatimustenmukaisuusvakuutus ƒ declaration de c...

Page 71

Specifikationer 2 da-11 cutting width ƒ ɒɢɪɨɱɢɧɚ ɧɚ ɪɹɡɚɧɟ ƒ ŠíĜka Ĝezu ƒ skærebredde ƒ maaibreedte ƒ lõikelaius ƒ leikkuuleveys ƒ largeur de coupe ƒ schnittbreite ƒ ȂȒțȠȢ ȝȚıȚȞȑȗĮȢ ƒ vágási szélesség ƒ larghezza di taglio ƒ griešanas platums ƒ pjovimo plotis ƒ tikkonforma mad-direttivi ƒ szerokoĞü ...

Page 72

2 specifikationer da-12 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. ɉɨɞɩɢɫ ɧɚ ɱɨɜɟɤɚ, ɭɩɴɥɧɨɦɨɳɟɧ ɞɚ ɫɴɫɬɚɜɢ ɞɟɤɥɚɪɚɰɢɹɬɚ ɨɬ ɢɦɟ...

Page 73

MÆrkater 3 da-13 3 mÆrkater 3.1 mÆrkater ______________________________________________________________ gør dem bekendt med overføringsbillederne, da de er af afgørende betydning for sikker betjening af maskinen. Udskift straks beskadigede overfØringsbilleder. Fare for at undgå personsonskade skal d...

Page 74

3 mÆrkater da-14 gør dem bekendt med overføringsbillederne, da de er af afgørende betydning for sikker betjening af maskinen. Udskift straks beskadigede overfØringsbilleder. 4265170 4265171 4172240 læs vejledningen, inden den forreste valsevægt justeres udkoblet parkerings- aktiveret bremse knivcyli...

Page 75

MÆrkater 3 da-15 tryk traktion: 1. Skub grebet til venstre. 2. Tryk grebet mod håndtaget..

Page 76: Advarsel

4 betjeningsanordninger da-16 4 betjeningsanordninger 4.1 ikoner _________________________________________________________________ 4.2 hÅndtagets betjeningsanordninger___________________________________ a. Parkeringsbremse – skal bruges hver gang maskinen efterlades ubevogtet, eller som en driftsbre...

Page 77: Advarsel

Betjeningsanordninger 4 da-17 4.3 lcd-skÆrm _____________________________________________________________ lcd-skærmen viser de aktuelle, funktionelle værdier for driften af eclipse 2-plæneklipperen, og har tre forskellige typer lydalarmer. Lcd-skærmen fungerer i en af to tilstande – operatørtilstand...

Page 78

4 betjeningsanordninger da-18 operatørtilstand bruges af operatøren til at få oplysning om systemspænding, kørselshastighed, klippefrekvens-indstilling og knivcylinderhastighed. Tryk på de orange knapper (k og l) på det forreste håndtagsdæksel for at skifte mellem de forskellige skærme. Operatørtils...

Page 79

Betjeningsanordninger 4 da-19 vedligeholdelsestilstand bruges til at indstille og justere alle eclipse 2-plæneklipperens funktioner. De lcd- skærmbilleder, der er tilgængelige i vedligeholdelsestilstand, er vedligeholdelsestimer, selvslibning, systemspænding, kørehastighed, indstillet klippefrekvens...

Page 80

4 betjeningsanordninger da-20 skærmbillede beskrivelse for at aktivere vedligeholdelsestilstand skal du trykke på én af de orange knapper (k eller l), indtil skærmbilledet for pinkode til vedligeholdelsestilstand vises. Tryk herefter på den sorte knap (j). Tryk på de orange knapper (k eller l) for a...

Page 81

Betjeningsanordninger 4 da-21 generatordrevet effektmodul - bruges til at indikere, at det generatordrevne effektmodul er installeret på plæneklipperen. Denne indstilling bruges af systemets styreenheder og har ingen indflydelse på driften af plæneklipperen. Betjen ikke plæneklipperen, hvis effektmo...

Page 82

4 betjeningsanordninger da-22 4.4 klippefrekvens ________________________________________________________ klippefrekvensen er den afstand i mm, som maskinen flytter sig fremad, når knivcylindrene berører bundkniven. Klippefrekvensen kan justeres enten ved at ændre den faste klippefrekvensindstilling...

Page 83

Betjeningsanordninger 4 da-23 tabel for cylinder med 15 knive, produktnr. 63339, 63341, 63335, 63337, 63348, 63350, 63344, 63346 (tandard knivcylinder) klippe- hastighed knivcylinderomdrejninger 1800 1850 1900 1950 2000 2.00 0.078 0.076 0.074 0.072 0.070 0.069 0.067 0.065 0.064 (3.22) (1.987) (1.933...

Page 84

4 betjeningsanordninger da-24 tabel for cylinder med 11 knive, produktnr. 63334, 63336, 63338, 63340, 63347, 63349, 63343, 63345 (standard knivcylinder) klippe- hastighed knivcylinderomdrejninger 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 (3.22) 0.107 (2.709) 0.104 (2.636) 0.101 (2.567) 0.098 ...

Page 85

Betjeningsanordninger 4 da-25 tabel for klippefrekvens for cylinder med ni knive, produktnr. 63340, 63349 (valgfri knivcylinder) klippe- hastighed knivcylinderomdrejninger 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 0.130 0.127 0.124 0.120 0.117 0.114 0.112 0.109 0.107 (3.22) (3.311) (3.222) (3...

Page 86

4 betjeningsanordninger da-26 tabel for klippefrekvens for knivcylinder med syv knive, produktnr. 63342, 63351 (standard knivcylinder) og 63340, 63349 (valgfri knivcylinder) klippe- hastighed knivcylinderomdrejninger 1800 1850 1900 1950 2000 2050 2100 2150 2200 2.0 0.168 0.163 0.159 0.155 0.151 0.14...

Page 87: Bemærk

Betjeningsanordninger 4 da-27 4.5 betjeningsanordninger til benzinmotormodul ________________________ m. Tændingskontakt – kontakten sidder på motoren og skal være tændt for at motoren kan starte. Den tændingskontakt skal være i den on (til) holdning nemlig den maskine hen til opstille. Når motorkon...

Page 88: Forsigtig

5 betjening da-28 5 betjening 5.1 dagligt eftersyn ______________________________________________________ 1. Foretag et visuelt eftersyn af maskinen, se efter tegn på slid, løse monteringsdele og manglende eller beskadigede dele. 2. Sørg for at klippeenheden er justeret til den ønskede klippehøjde. ...

Page 89: Forsigtig

Betjening 5 da-29 5.3 betjeningsprocedurer ________________________________________________ 1. Motoren må under ingen omstændigheder startes, mens operatøren eller omkringstående står foran tromlen. 2. Lad aldrig motoren køre i et lukket rum. 3. Hold hænder og fødder væk fra bevægelige dele og klipp...

Page 90

5 betjening da-30 5.4 start/stop _____________________________________________________________ 1. Klargør effekmodulet til at aktivere enheden. Batterimodul: frakobl batteriopladeren, og tilkobl strømledningen. Effektmodul: a. Kontroller oliestanden og brændstoftilførslen, og åbn så brændstofventile...

Page 91: Advarsel

Betjening 5 da-31 5.5 klipning ________________________________________________________________ 1. Sluk motoren. Placer plæneklipperen på støtteben, og fjern transporthjulene (hvis monteret). 2. Tænd knivcylinderkontakten. Skub plæneklipperen fremad, så den kommer fri af støttebenet. Start enheden. ...

Page 92: Advarsel

5 betjening da-32 5.6 transporthjulene (ekstraudstyr) ____________________________________ transporthjulene er ekstra tilbehør, der kan købes hos en jacobsen-forhandler. Det anbefales at bruge drivhjul, når du ikke bruger en plæneklippervogn til at flytte plæneklipperen fra green til green. 1. Skub,...

Page 93: Advarsel

Betjening 5 da-33 5.8 grÆsfang ______________________________________________________________ 1. Når opsamleren er omkring to-tredjedele (2/3) fyldt med græsaffald tages maskinen af green'en. 2. Stop på et jævnt underlag, udløs dødemandsgrebet, aktiver parkeringsbremsen og frakoble strømled- ningen....

Page 94: Advarsel

6 justeringer (alle enheder) da-34 6 justeringer (alle enheder) 6.1 generelt_______________________________________________________________ 1. Justeringer og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler af jacobsen, hvis korrekt justering ikke kan udfø...

Page 95: Forsigtig

Justeringer (alle enheder) 6 da-35 6.4 hÅndtag ________________________________________________________________ 1. For at justere vinklen på håndtaget (f), skal skruen (d) løsnes på begge sider af maskinen. Indstil håndtaget til den ønskede position. 2. Når håndtaget er justeret, justeres beslaget (...

Page 96: Forsigtig

6 justeringer (alle enheder) da-36 6.6 forreste valsevÆgt ___________________________________________________ vægten på den forreste valse kan justeres. Juster den forreste valsevægt i det omfang, det er nødvendigt, for at opfylde dine krav til plænen. 1. Batterimodul: for at justere den forreste va...

Page 97: Bemærk

Justeringer (alle enheder) 6 da-37 6.7 drejningsmomentspecifikation ________________________________________ jacobsen anvender overfladebehandlede bolte af grad 5 som standard, medmindre andet er angivet. Ved tilspænding af overfladebehandlede bolte skal den oplyste værdi for smurte bolte benyttes. ...

Page 98: Advarsel

7 justering af fast hoved til cylinder da-38 7 justering af fast hoved til cylinder 7.1 generelt _______________________________________________________________ 1. Justeringer og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler af jacobsen, hvis korrekt ju...

Page 99: Forsigtig

Justering af fast hoved til cylinder 7 da-39 7.3 bundknivjustering _____________________________________________________ 1. Stilleskruen (a) anvendes til at øge eller sænke fjederbelastningen på underkniven. Stilleskruen (b) anvendes til at flytte underkniven hen til tromlen eller væk fra tromlen. 2...

Page 100: Advarsel

8 justering af flydende hoved til cylinder - classic da-40 8 justering af flydende hoved til cylinder - classic 8.1 generelt_______________________________________________________________ 1. Justeringer og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler a...

Page 101: Bemærk

Justering af flydende hoved til cylinder - classic 8 da-41 8.3 bundknivjustering _____________________________________________________ 1. Læs afsnit 8.2 før justeringen udføres. 2. Start justeringen ved knivcylinderens forreste del efterfulgt af den bageste del. Knivcylinderskærenes forreste del er ...

Page 102: Bemærk

8 justering af flydende hoved til cylinder - classic da-42 8.5 klippehØjde ____________________________________________________________ bemærk: foretag altid justering af bundkniv i forhold til knivcylinder før justering af klippehøjden. (afsnit 8.2 og 8.3). 1. Skub støttefoden ned og vip maskinen t...

Page 103: Advarsel

Justering af flydende hoved til cylinder - trueset 9 da-43 9 justering af flydende hoved til cylinder - trueset 9.1 generelt _______________________________________________________________ 1. Justeringer og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler ...

Page 104: Bemærk

9 justering af flydende hoved til cylinder - trueset da-44 9.3 bundknivjustering _____________________________________________________ 1. Læs afsnit 8.2 før justeringen udføres. 2. Start justeringen ved knivcylinderens forreste del efterfulgt af den bageste del. Knivcylinderskærenes forreste del er ...

Page 105: Bemærk

Justering af flydende hoved til cylinder - trueset 9 da-45 9.5 knivcylinderleje _______________________________________________________ endeslør eller radialslør angiver dårlige lejer, en svag strammefjeder eller en løsnet møtrik. 1. Kontroller lejehusets monteringsanordninger. Stram eller udskift k...

Page 106: Bemærk

9 justering af flydende hoved til cylinder - trueset da-46 9.9 afmontering af knivcylinderenheden _________________________________ knivcylinderenheden kan afmonteres med henblik på vedligeholdelse eller brug af en anden knivcylinder. 1. Fjern låseclipsen og skiven, og skub løftestropperne af clipse...

Page 107: Advarsel

Batterimodul 10 da-47 10 batterimodul 10.1 sikkerhed ______________________________________________________________ batterier indeholder fortyndet svovlsyre, som kan forårsage alvorlige forbrændinger. Der dannes hydrogengas i batteriet under opladningsprocessen. Hydrogen i koncentrationer på 4 % og ...

Page 108

10 batterimodul da-48 10.3 vedligeholdelse _______________________________________________________ værktøjsliste isoleret skruenøgle, 3/8” tommer isoleret skruenøgle, 11/32” tommer almindelig skruetrækker inden ladning af batterierne kontroller, om der er snavs og affald i batteriopladerens stikhuse...

Page 109: Advarsel

Batterimodul 10 da-49 10.5 batterioplader ________________________________________________________ batteriopladeren er beregnet til at oplade batteripakken helt. Læs vejledningen, der følger med opladeren, for at bruge den korrekt. Før opladningen skal du overholde følgende sikkerhedsforanstaltninge...

Page 110: Advarsel

10 batterimodul da-50 10.6 isÆtning af batterier __________________________________________________ hvis batterierne er blevet renset, og syre i batteribakkens område er blevet neutraliseret, bør der ikke genereres korrosion i det omgivende område. Enhver registreret korrosion skal straks fjernes me...

Page 111: Forsigtig

Batterimodul 10 da-51 10.7 udskiftning af batteripakken __________________________________________ batteripakken (a) er konstrueret således, at den nemt kan tages ud og udskiftes med en ny. Det betyder, at plæneklipperen hurtigt kan tages i brug igen, hvis batterierne aflades eller svigter. Flere ba...

Page 112: Bemærk

11 benzinmotormodul da-52 11 benzinmotormodul 11.1 motor _________________________________________________________________ vigtigt: der leveres en separat motorvejledning fra motorproducenten sammen med denne traktor. Læs motorvejledningen grundigt, indtil du er bekendt med betjeningen og vedligehol...

Page 113

Benzinmotormodul 11 da-53 11.3 skift af motorolie _____________________________________________________ skift olie første gang efter 20 driftstimer. Skift olie for hver 100 timer derefter. 1. For at skifte motorolie skal du montere en slange med en indvendig diameter på 7/16" (11 mm) (a) til olieaft...

Page 114: Advarsel

11 benzinmotormodul da-54 11.5 brÆndstof_____________________________________________________________ brændstof er meget brandfarligt og skal håndteres med forsigtighed. Brug en godkendt beholder. Tuden skal passe til påfyldningsstudsen. Undgå brug af dunke og tragte til overførsel af brændstof. • o...

Page 115: Advarsel

Vedligeholdelse 12 da-55 12 vedligeholdelse 12.1 generelt _______________________________________________________________ 1. Justering og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler af jacobsen, hvis korrekte justeringer ikke kan udføres. 2. Efterse u...

Page 116

12 vedligeholdelse da-56 12.4 backlapning og slibning _______________________________________________ undersøg om der er skader på bundkniv og cylinderknive. Se afsnit 6.2. 1. Bestem om backlapning eller slibning vil genoprette det korrekte skær. 2. For optimal ydelse skal der bruges en bundknivssli...

Page 117: Forsigtig

Vedligeholdelse 12 da-57 12.5 lagring ________________________________________________________________ generelt 1. Smør klippeaggregatet, og smør det. Reparer og mal beskadiget eller blotlagt metal. 2. Undersøg maskinen, stram alle monteringsdele, udskift slidte eller beskadigede dele. 3. Rengør dæk...

Page 118

13 fejlfinding da-58 13 fejlfinding 13.1 generelt_______________________________________________________________ nedenstående fejlfindingsskema viser de grundlæggende problemer, der kan opstå i forbindelse med start og drift. Kontakt den lokale jacobsen-distributør for at få flere oplysninger om de ...

Page 119: Advarsel

Vedligeholdelses- og smØringstabeller 14 da-59 14 vedligeholdelses- og smØringstabeller 14.1 generelt _______________________________________________________________ klipperens konstruktion gør, at den skal smøres minimalt. Hvis den smøres for meget, bliver lejerne og motoren belastet, og maskinens ...

Page 120

14 vedligeholdelses- og smØringstabeller da-60 14.3 smØringsoversigt _____________________________________________________ f c d b a l 4 l 6 l 6 l7 e l 3 l l 5 2 l 1 l l 5 l 5 2 l 2 l 1 l 1 l 1 l 1 l 1 l 1 - knivcylinders rulleleje l 2 - cylindermotorens lejehus l 3 - højre side af traktionstromlens...

Page 121

Reservedelskatalog 15 da-61 15 reservedelskatalog 15.1 sÅdan bruges reservedelskataloget _________________________________ forkortelser n/s - serviceres ikke separat, kan kun skaffes ved at bestille hovedkomponent eller sæt. Ar - variabel mængde eller mål påkrævet for at opnå korrekt justering (som ...

Page 122: Eclipse 2

62 ® dry erase marker only 1 2 3 4 5 6 6 29 7 8 9 9 10 11 12 13 14 15 16 17 18 19 20 21 21 22 22 23 23 24 24 25 25 26 27 28 4265172 4265171 4265170 eclipse 2 1.1 handle covers serial no. All.

Page 123: Eclipse 2

63 > change from previous revision item part no. Qty. Description serial numbers/notes 1 ref 1 handle assembly see 2.1 2 4254050 1 control lever 3 4127340 1 knob 4 453017 1 flat washer, 1/2 5 454025 ar spring washer, 1/2 6 366708 2 bearing, flanged 7 461381 1 roll pin, 3/16 x 13/16” 8 2000067 1 leve...

Page 124: Eclipse 2

64 1 2 3 4 5 6 6 7 8 9 10 11 12 13 14 26 15 16 17 18 19 20 21 22 24 25 23 27 27 eclipse 2 2.1 handle assembly serial no. All.

Page 125: Eclipse 2

65 > change from previous revision item part no. Qty. Description serial numbers/notes 1 4256578 1 handle 2 4136328 1 plate, tilt 3 434029 4 screw, 1/4-20 x 1” hex socket 4 453023 4 flat washer, 1/4 5 446130 4 lockwasher, 1/4 heavy 6 443102 6 nut, 1/4-20 hex 7 4136325 1 bail 8 4147696 1 handle, over...

Page 126: Eclipse 2

66 1 1 2 2 3 3 4 5 6 7 8 8 9 9 10 10 11 11 12 12 1 1 2 2 3 3 4 5 6 7 8 8 9 10 10 11 11 12 12 13 eclipse 2 118 and 118f 63334 63343 63335 63344 63336 63345 63337 63346 eclipse 2 122, 122f, and 126 63338 63347 63339 63348 63340 63349 63341 63350 63342 63351 handle assembly 12 eclipse 2 3.1 handle to f...

Page 127: Eclipse 2

67 > change from previous revision item part no. Qty. Description serial numbers/notes 1 2811559 2 bolt, handle mount 2 447224 2 lockwasher, 5/8 internal tooth 3 443828 2 nut, 5/8-18 hex jam 4 4257813 1 handle stop, right side 5 4257814 1 handle stop, left side 6 2809900 1 torsion spring, handle ecl...

Page 128: Eclipse 2

68 1 2 3 4 37 5 5 6 6 7 8 8 9 9 10 10 10 10 11 12 13 19 20 15 16 16 16 16 17 36 12 4172240 14 18 a b a b a b a b a b 21 gen-set battery 22 23 23 24 24 24 24 25 25 26 26 27 28 28 29 30 31 31 32 33 33 38 34 35 eclipse 2 4.1 power module mounting plate serial no. All fixed head frame shown. Floating he...

Page 129: Eclipse 2

69 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 63305 1 gen-set power module see 19.1 2 63306 1 battery power module see 20.1 3 4253190 2 controller, motor reference u1, u2, see 21.1 4 800271 8 screw, #10-24 x 1/2” pan head 5 404016 2 screw, 1/4-20 ...

Page 130: Eclipse 2

70 96 db l wa manufactured under one or more of the following u.S. Patents: xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx 96 db l wa manufactured under one or more of the following u.S. Patents: xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx 1 1 2 2 3 3 3 3 4 4 4 4 4 4 4 4 5 5 5 5 5 5 5 5 6 6 6 6...

Page 131: Eclipse 2

71 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4253156 1 frame, l.H. Side fixed head eclipse 2 118, 122, and 126 1 4253154 1 frame, l.H. Side floating head eclipse 2 118f and 122f 2 4253155 1 frame, r.H. Side fixed head eclipse 2 118, 122, and 126 ...

Page 132: Eclipse 2

72 1 2 2 3 3 3 3 4 4 5 5 6 6 6 6 7 7 7 7 8 8 9 9 10 10 11 12 13 13 13 14 15 15 16 17 18 19 20 21 22 23 24 25 26 27 28 28 29 30 31 eclipse 2 6.1 lower unit fixed head units serial no. 63334 - all serial no. 63335 - all serial no. 63338 - all serial no. 63339 - all serial no. 63342 - all serial no. 63...

Page 133: Eclipse 2

73 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 ref 1 reel and bedknife assembly see 7.1 2 400264 2 screw, 3/8-16 x 1-1/4” hex head 3 446142 8 lockwasher, 3/8 heavy 4 400258 6 screw, 3/8-16 x 3/4” hex head 5 3001610 2 block, bedknife adjuster 6 3667...

Page 134: Eclipse 2

74 optional magknife bedknives part number description 4131005 22” medium section 4131369 22” high profile 4131001 22” low profile 4131370 22” tournament 4131003 22” super tournament standard style bedknives (secured with screws) part number description 5000098 18” low profile ● 5002888 18” super to...

Page 135: Eclipse 2

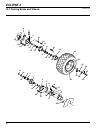

75 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 see chart 1 reel 2 4105281 1 bearing housing 3 366650 1 • grease seal 4 545940 1 • bushing 5 500534 1 • bearing cup and cone 6 4179720 1 bearing housing 7 366650 1 • seal 8 545940 1 • bushing 9 500534 ...

Page 136: Eclipse 2

76 1 2 2 2 20 3 4 5 5 6 9 6 7 7 8 9 10 11 12 13 14 14 14 15 11 12 13 14 15 16 16 16 16 17 17 19 19 18 18 8 10 4127335 eclipse 2 8.1 grass shield and roller brackets fixed head units only serial no. 63334 - all serial no. 63335 - all serial no. 63338 - all serial no. 63339 - all serial no. 63342 - al...

Page 137: Eclipse 2

77 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4139661 1 grass shield, 18 inch used on 63334, 63343, 63335, and 63344 1 4139660 1 grass shield, 22 inch used on 63338, 63347, 63339, and 63348 1 4139662 1 grass shield, 26 inch used on 63342 and 63351...

Page 138: Eclipse 2

78 4 3 1 2 5 6 7 7 8 8 8 8 9 9 10 10 11 11 12 13 14 15 15 15 15 16 17 18 19 20 21 22 22 23 24 25 25 26 27 29 29 30 30 30 30 31 32 36 37 37 38 35 33 34 34 29 29 30 30 28 28 39 40 eclipse 2 9.1 floating head reel connection floating head units only serial no. 63336 - 1651 ~ 2599 serial no. 63337 - 165...

Page 139: Eclipse 2

79 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4175221 1 rear roller - 18” used on 63336, 63345, 63337, 63346 1 1004990 1 rear roller - 22” used on 63340, 63349, 63341, 63350 2 4175220 1 • shaft, 18” used on 63336, 63345, 63337, 63346 2 3010422 1 •...

Page 140: Eclipse 2

80 4 3 1 2 5 6 7 7 8 8 8 8 9 9 10 10 11 11 12 13 14 15 15 15 15 16 17 18 19 20 21 22 22 23 24 25 25 26 27 29 29 30 30 30 30 31 32 36 37 37 38 35 33 34 34 29 29 30 30 28 28 eclipse 2 9.2 floating head reel connection floating head units only serial no. 63336 - 2600 and up serial no. 63337 - 2600 and ...

Page 141: Eclipse 2

81 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4175221 1 rear roller - 18” used on 63336, 63345, 63337, 63346 1 1004990 1 rear roller - 22” used on 63340, 63349, 63341, 63350 2 4175220 1 • shaft, 18” used on 63336, 63345, 63337, 63346 2 3010422 1 •...

Page 142: Eclipse 2

82 10 12 8 13 11 5 18 14 20 20 27 20 16 17 12 15 12 15 19 9 8 7 4 3 1 2 6 6 21 22 23 24 25 26 28 28 28 4127335 eclipse 2 10.1 outer reel assembly floating head units only serial no. 63336 - 1651 ~ 2599 serial no. 63337 - 1651 ~ 2599 serial no. 63340 - 1651 ~ 2599 serial no. 63341 - 1651 ~ 2599 seria...

Page 143: Eclipse 2

83 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4175221 1 rear roller, 18” used on 63336, 63345, 63337, and 63346 1 1004990 1 rear roller, 22” used on 63340, 63349, 63341, and 63350 2 4175220 1 • shaft, 18” roller used on 63336, 63345, 63337, and 63...

Page 144: Eclipse 2

84 10 12 12 8 8 13 13 11 11 5 5 18 18 14 14 20 20 27 29 3031 32 20 16 17 12 15 12 15 19 19 9 8 7 4 3 1 2 6 6 21 22 23 24 25 26 28 28 28 33 33 4127335 4181863 eclipse 2 11.1 outer reel assembly floating head units only serial no. 63336 - 2600 and up serial no. 63337 - 2600 and up serial no. 63340 - 2...

Page 145: Eclipse 2

85 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4175221 1 rear roller, 18” used on eclipse 2 118f 1 1004990 1 rear roller, 22” used on eclipse 2 122f 2 4175220 1 • shaft, 18” roller used on eclipse 2 118f 2 3010422 1 • shaft, 22” roller used on ecli...

Page 146: Eclipse 2

86 25 5 24 18 10 1 9 21 8 17 16 17 14 15 4 7 6 12 23 22 26 11 19 28 13 29 27 3 2 20 2 optional magknife bedknives part number description 4131369 22” high profile 4131004 18” super tournament 4131373 18” tournament 4131371 18” low profile 4131001 22” low profile 4131370 22” tournament 4131003 22” su...

Page 147: Eclipse 2

87 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4170204 1 frame, 18” reel used on 63336, 63345, 63337, and 63346 1 5002577 1 frame, 22” reel used on 63340, 63349, 63341, and 63350 2 400192 8 screw, 5/16-18 x 1-1/2” hex head 3 446142 1 lockwasher, 3/...

Page 148: Eclipse 2

88 optional magknife bedknives part number description 4131369 22” high profile 4131004 18” super tournament 4131373 18” tournament 4131371 18” low profile 4131001 22” low profile 4131370 22” tournament 4131003 22” super tournament standard style bedknives (secured with screws) part number descripti...

Page 149: Eclipse 2

89 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4256224 1 18” reel frame 1 4256225 1 22” reel frame 2 4170220 1 reel, 18” 11 blade used on 63336 and 63345 2 4225504 1 reel, 18” 15 blade used on 63337 and 63346 2 5003053 1 reel, 22” 7 blade optional ...

Page 150: Eclipse 2

90 1 1 2 3 4 5 6 7 8 9 10 11 12 12 13 13 14 14 15 15 16 17 18 19 19 20 21 22 23 24 24 25 25 26 27 28 28 29 30 31 32 33 34 eclipse 2 14.1 differential and rollers serial no. All.

Page 151: Eclipse 2

91 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 1000024 2 18” smooth roller 1 132655 2 22” smooth roller 1 1000027 2 26” dimpled roller 2 366699 1 • differential gear bushing 3 366698 1 • drum bushing 4 366701 1 • grease seal 5 366700 1 • grease sea...

Page 152: Eclipse 2

92 7 8 1 24 16 16 13 17 25 33 6 4 2 9 5 3 3 18 17 35 35 36 34 28 29 19 32 14 14 22 23 16 16 13 21 20 12 11 12 10 15 15 31 27 30 26 4 eclipse 2 15.1 parking brake and wheels serial no. All.

Page 153: Eclipse 2

93 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 1000476 1 r.H. Hub 2 338766 1 • bearing 3 366705 2 • grease seal 4 164056 2 brake band 5 132663 1 brake mounting bracket 6 132658 1 seal housing 7 365753 1 • grease seal 8 4128725 1 • grease fitting 9 ...

Page 154: Eclipse 2

94 8 12 18 18 18 27 31 15 17 17 17 19 19 19 20 20 20 11 13 16 16 21 1 2 3 4 5 6 7 9 14 14 17 22 23 24 25 26 28 29 30 32 32 33 33 10 eclipse 2 16.1 belts and drive motors serial no. All fixed head frame shown. Floating head similar.

Page 155: Eclipse 2

95 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 446116 2 lockwasher, #10 2 2000148 1 bracket, bearing 3 2811070 1 belt, polychain, 80 tooth 4 2811223 1 pully, 18 tooth 5 2811107 1 pully, 112 tooth 6 3001273 1 shaft 7 4140154 1 floating head pulley c...

Page 156: Eclipse 2

96 sw1reel switch j14 can diagnostic connector r1 hand throttle potentiometer r2 rotary switch sw2 ignition switch f230 amp fuse j1 and j2 controller connection j6 and j7 reel motor controller connection j10 and j11 reel motor connection j12 and 13 traction motor connection m1 reel motor m2 traction...

Page 157: Eclipse 2

97 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4254330 1 harness, main 4262910 1 • 30 amp mini fuse reference f1, see 21.1 2 4253190 1 controller, reel motor reference u1, see 21.1, 4.1 3 4261470 1 motor, brushless bi-directional reference m1, see ...

Page 158: Eclipse 2

98 1 2 22 3 4 5 6 7 8 9 harness ground 10 11 12 13 14 15 16 16 17 17 18 19 20 20 21 ® eclipse 2 18.1 genset power source 63305 serial no. 63334 - all serial no. 63335 - all serial no. 63336 - all serial no. 63337 - all serial no. 63337 - all serial no. 63338 - all serial no. 63339 - all serial no. 6...

Page 159: Eclipse 2

99 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 4258930 1 engine, honda gx-120 2 320774 1 • key, 3/16 x1-1/2” square 3 4170500 1 trim, muffler 4 4172080 1 valve, oil drain 5 4187840 1 gasket, oil drain valve 6 4253595 1 mount, power source 7 441674 ...

Page 160: Eclipse 2

100 1 2 2 2 3 3 3 3 4 4 5 5 6 7 8 9 10 11 12 13 14 eclipse 2 19.1 battery power source 63306 serial no. 63343 - all serial no. 63344 - all serial no. 63345 - all serial no. 63346 - all serial no. 63347 - all serial no. 63348 - all serial no. 63349 - all serial no. 63350 - all serial no. 63341 - all.

Page 161: Eclipse 2

101 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 1 2809837 2 spring, extension 2 444708 6 locknut, 1/4-20 center 3 443102 8 nut, 1/4-20 hex 4 446130 4 lockwasher, 1/4 heavy 5 441604 4 carriage bolt, 1/4-20 x 1” 6 400108 2 screw, 1/4-20 x 3/4 hex head ...

Page 162: Eclipse 2

102 battery post style terminal hardware 8 10 10 to battery gauge 10 10 10 10 12 22 11 23 21 13 14 15 26 27 24 6 6 18 19 20 20 16 17 25 p n key battery and battery monitor connections 7 9 9 9 9 14 see above 7 4170001 stop 2 5 4 1 6 6 3 a a eclipse 2 20.1 battery case serial no. All.

Page 163: Eclipse 2

103 > change from previous revision eclipse 2 item part no. Qty. Description serial numbers/notes 68668 1 battery case does not include batteries 1 4105660 1 • screw, 5/16-18 x 1-1/4” nylon 2 452004 2 • flat, washer 1/4 3 4105800 1 • fuse, 50a reference f1, see 21.1 4 447214 1 • lockwasher, 5/16 int...

Page 164: Eclipse 2

104 run start off e f d a j2-25 j24 j22 j23- – j23- + j23- – j23- + p n key j2-24 red wht/red j2-15 j2-16 j2-28 b wht/red red sw2 key switch gc1 yel on off sw1 mow switch r3 5 Ω resistor r2 bail potentiometer r1 throttle potentiometer sw3 engine on/off switch t1 ignition coil e1 spark plug f1 50a b1...

Page 165: Eclipse 2

105 > change from previous revision u2 traction motor controller u1 reel motor controller m1 reel motor red blk shld sw4 light switch l1 work light optional work light kit on off blk grn blu wht red brn grn blu wht red brn grn blu wht red brn grn blu wht red brn blk red red red blk yel blk j6-8 j6-9...

Page 166: Eclipse 2

106 eclipse 2 item reference illustration part number description serial numbers/notes b1 see 20.1 n/s 12 volt sla battery obtain batteries localy or through your jacobsen dealer battery power module only b2 see 20.1 n/s 12 volt sla battery b3 see 20.1 n/s 12 volt sla battery b4 see 20.1 n/s 12 volt...

Page 167: Fluids And Compounds

Fluids and compounds * refer to the operator’s manual or the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Jacobsen offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See your local hydraulic fluid* 5001405...

Page 168: Index

108 index 1000024.......................91 1000027.......................91 1000476.......................93 1000477.......................93 1000480.................87 , 89 1002224.................83 , 85 1004756.......................87 1004990.... 79 , 81 , 83 , 85 132655............................

Page 169: Index

109 index 417242 ........................ 79 4172945 ...................... 75 4174640 ................ 83 , 85 4175220 .... 79 , 81 , 83 , 85 4175221 .... 79 , 81 , 83 , 85 4175240 ...................... 83 4179720 ...................... 75 4179780 ...................... 73 4181863 ...................

Page 171

When performance matters. ™ jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacobsen.Com 800-848-1636 ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt, england engelsk virksomhedsregistreringsnr. 1070731 www.Ransomesjacobsen.Com +44 (0) 1473 2700...