- DL manuals

- Jacobsen

- Lawn Mower

- 67069

- Operating Manual

Jacobsen 67069 Operating Manual - Caution

ADJUSTMENTS 9

43

9.17 REMOVING THE CUTTING UNIT ______________________________________________

1.

To prevent contamination of the hydraulic system, as

well as loss of oil, do not disconnect the hoses from

the motor.

2.

Raise and lock the lift arms in transport mode

(Section 3.4) and disconnect the down pressure

springs.

3.

Remove transport pin then lower the lift arms to the

ground.

4.

Remove hardware securing motor to drive housing

and carefully pull the motor away.

5.

Place motor in a clean plastic bag and cover the

opening in the gear box.

6.

Remove pin and collar from center (rear) lift arm

and pull the center cutting unit away from the

mower.

7.

Remove the hardware securing the front lift arms to

the cutting units, and slide the mowers out of the

way.

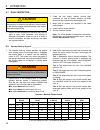

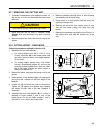

9.18 CUTTING HEIGHT - FIXED MODE _____________________________________________

Follow the procedures outlined in Section 9.16.

1.

Reposition the rear roller adjuster.

a.

For cutting heights from 3/8 to 1-3/4 in. (9 to

44 mm), use holes (M) on the mower frame, and

two holes (shown in black) of the height adjuster

(F) as shown.

b.

For cutting heights greater than 1-3/4 inches

(44 mm), disassemble adjuster (F) and turn the

mounting bracket upside down; then use holes

(N) of the frame, and the two holes (shown in

black) of the adjuster (F).

2.

Remove the tether, and lower the cutting units to the

ground.

3.

Place spacers of the desired height (J) under each

end of the reel, adjacent to the front edge of the

bedknife.

4.

Loosen nut (G) and lower rear roller to the ground.

Tighten nut (E) against the adjuster then recheck

the setting on both side of the reel. Readjust if

necessary.

5.

Assemble the front roller adjuster (B) (If a roller is

required) to holes number 2 and 4 only of the

mower frame. Do not use holes number 1 and 3.

Set roller to 1/4 in. (6 mm) above rear roller.

Figure 9Q

Figure 9R

CAUTION

Disconnect lift springs before removing mowers.

!

1

2

3

4

5

6

7

8

N

M

N

M

U

T

S

R

B

E

F

G

G

J

F

E

A

B

Summary of 67069

Page 1

Safety, operation, & maintenance manual warning warning: if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers, and must read the entire manual before attempting to set up, operate, adjust, or ser...

Page 2

2 this manual contains safety and operating instructions for your new jacobsen machine. This manual should be stored with the equipment for reference during operation. Before you operate your machine, you and each operator you employ should read the manual carefully in its entirety. By following the...

Page 3

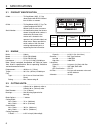

Contents 1 3 1 contents 2 safety 2.1 operating safety ............................................ 4 2.2 important safety notes ..................................5 3 specifications 3.1 product identification ..................................... 6 3.2 engine ............................................

Page 4: Warning

2 safety 4 2 safety 2.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern, and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manua...

Page 5: Warning

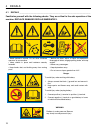

Safety 2 5 2.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6

3 specifications 6 3 specifications 3.1 product identification _________________________________________________ 67069 .............................. Tri-king mower, 3wd, 17.7 hp diesel engine with rops. Without front lift arms or mowers. 67146 .............................. Tri-king mower, 3wd, 17....

Page 7: Caution

Specifications 3 7 3.4 mower __________________________________________________________________ tires: front ......................... 20 x 10 - 10 tubeless rear ......................... 20 x 10 - 8 tubeless pressure: front.......................... 10-12 psi (0.69-0.82 bar) rear .....................

Page 8

3 specifications 8 3.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de con...

Page 9

Specifications 3 9 harmonised standards used ▪ Използвани хармонизирани стандарти ▪ použité harmonizované normy ▪ brugte harmoniserede standarder ▪ gebruikte geharmoniseerde standaards ▪ kasutatud ühtlustatud standardid ▪ käytetyt yhdenmukaistetut standardit ▪ normes harmonisées utilisées ▪ angewand...

Page 10

4 decals 10 4 decals 4.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181865 4181864 4181862 • read operator's manual. Do not allow...

Page 11

Decals 4 11 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. Gages 3 3 7.5 7.5 spare spare spare spare 3wd valve reel clutch lights (optional) 3003606 4199140 4181863 4182520 warning to prevent burns, do not t...

Page 12: Important

4 decals 12 3003348 3003349 press down on pedal to lower and engage reels. Lift up on pedal to raise and disengage reels. Press down on pedal for forward travel. Lift up on pedal for reverse travel. 1 4 3004207 3 2 see section 5.3 for hood opening procedure. Important t h i s m a c h i n e u s e s g...

Page 13

Decals 4 13 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 3003350 fast engine throttle slow disengage reels and 3wd engage reels and 3wd circuit breaker glow plug keyswitch off run start 4141266 engine oil ...

Page 14: Warning

5 controls 14 5 controls 5.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and wha...

Page 15

Controls 5 15 2811597 3003350 77 93 ° c 170 200 ° f 10 16 12 14 volts solid state hours 0 0 0 0 0 e l m 2 u u y f j r v g k s w a b c d h n 2 m 1 n 1 p t x a throttle lever b glow plug switch c circuit breaker d water temperature e engine oil f voltmeter g hour meter h ignition switch j reel / 3wd s...

Page 16

5 controls 16 5.2 controls ______________________________________________________________ a. Throttle lever used to regulate engine speed. B. Glow plug switch used to energize the glow plugs (refer to section 6.4). C. Circuit breaker if the gauges or ignition system fail to operate properly, check t...

Page 17

Controls 5 17 5.3 opening the hood ______________________________________________________ the “right” and “left”, “front” and “rear” of the machine are referenced from the operator’s right and left when seated in the mower’s seat in the normal operating position. 1. To open the hood, unhook latch (r...

Page 18: Caution

6 operation 18 6 operation 6.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses ...

Page 19: Warning

Operation 6 19 6.3 operating procedures _________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. 2. Do not operate mower or attachments with loose, damaged, or missing components. Whenever possible mow when gra...

Page 20

6 operation 20 6.4 starting _______________________________________________________________ important: do not use starting assist fluids. Use of such fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition and could result in serious engine damage. 1. Make ...

Page 21: Notice

Operation 6 21 6.6 to drive / transport ____________________________________________________ read and follow all safety notes contained in this manual when driving or transporting mower. Refer to section 6.3 for general operating instructions. When operating in reverse look behind you to ensure you ...

Page 22: Warning

6 operation 22 6.7 hillside operation _____________________________________________________ the mower has been designed for good traction and stability under normal mowing conditions; however, use caution when operating on slopes, especially over rough terrain or when the grass is wet. Wet grass red...

Page 23

Operation 6 23 how to calculate a slope: tools required: level (a), either 1 yard, or 1 meter long. Tape measure (b). With the level (a) positioned horizontally, measure the distance (c) with tape measure (b). Use the chart to calculate either the slope angle or the % grade of the slope (d). Figure ...

Page 24: Warning

6 operation 24 6.8 mowing _________________________________________________________________ to mow: 1. Disengage transport lock. See section 6.6. 2. Start the engine and lower the mowers to the ground. The lift cylinder must be fully extended for the mowers to float properly. 3. Turn reel/3wd switch...

Page 25: Notice

Operation 6 25 6.10 daily maintenance______________________________________________________ important: for more detailed maintenance information, adjustments, and maintenance/lubrication charts, see the parts & maintenance manual. 1. Park the mower on a flat, level surface. Fully lower the implement...

Page 26: Warning

7 maintenance & lubrication charts 26 7 maintenance & lubrication charts 7.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

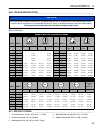

Page 27

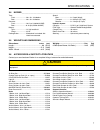

Maintenance & lubrication charts 7 27 7.3 maintenance charts ___________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** every 250 hours, or yearly whichever comes first. *** in...

Page 28: Warning

8 maintenance 28 8 maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 29

Maintenance 8 29 8.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap, and add oil as required. Perform initial oil change after first 50 hours of operat...

Page 30: Warning

8 maintenance 30 8.5 fuel ____________________________________________________________________ handle fuel with care - it is highly flammable. Use an approved container, the spout must fit inside the fuel filler neck. Avoid using cans and funnels to transfer fuel. • fill the fuel tank to within 1 in...

Page 31: Warning

Maintenance 8 31 8.8 jump starting __________________________________________________________ before attempting to “jump start” the mower, check the condition of the discharged battery. Section 8.7 when connecting jumper cables: 1. Stop the engine on the vehicle with a good battery. 2. Connect red j...

Page 32: Caution

8 maintenance 32 8.11 hydraulic oil __________________________________________________________ refer to section 6.3 for specific maintenance intervals. The hydraulic reservoir on this machine is filled with jacobsen greens care 68 biodegradable fluid. Drain and replace the hydraulic oil after a majo...

Page 33: Warning

Maintenance 8 33 8.14 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine ...

Page 34: Notice

8 maintenance 34 8.17 care and cleaning _____________________________________________________ wash the mower and implements after each use. Keep the equipment clean. 1. Use compressed air to clean engine and radiator fins. A special blow gun is available through jacobsen dealer. 2. Use only fresh wa...

Page 35: Warning

Maintenance 8 35 8.19 backlapping____________________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, they...

Page 36: Caution

8 maintenance 36 8.20 storage________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Drain and refill radiator. 4...

Page 37: Warning

Adjustments 9 37 9 adjustments 9.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 38

9 adjustments 38 9.4 neutral and 3wd switches _____________________________________________ 1. Check traction pedal adjustment. 2. Use a volt/ohm meter to determine when switch opens or closes. A. Adjust switch (g) so “finger” of actuating arm (f) is centered over sensing portion of switch. Switch c...

Page 39

Adjustments 9 39 9.7 traction pedal neutral ________________________________________________ 1. If the mower “creeps” in either direction when the engine is running, but the traction pedal is not depressed, adjust spring tension so that the pedal always returns to neutral when released. Note: the mo...

Page 40: Caution

9 adjustments 40 9.10 parking brake _________________________________________________________ 1. Check linkage cables and pivots to ensure they are operating smoothly. 2. Park the mower on a 30% slope (16.7°) near the bottom of the hill, with the front of the mower facing downhill. Engage the parkin...

Page 41: Caution

Adjustments 9 41 9.13 reel to bedknife _______________________________________________________ (pre-adjustment check) 1. Check the reel bearings for end play or radial play. If there is any abnormal movement of the reel, up and down or side to side, adjust or replace components as needed. 2. Inspect...

Page 42

9 adjustments 42 9.15 cutting modes _________________________________________________________ 1. The mower may be operated in the fixed mode or the floating mode. 2. Fixed mode is generally used for cutting heights greater than 1 in. (25 mm) and the mower does not require a front roller unless the t...

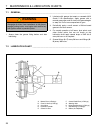

Page 43: Caution

Adjustments 9 43 9.17 removing the cutting unit ______________________________________________ 1. To prevent contamination of the hydraulic system, as well as loss of oil, do not disconnect the hoses from the motor. 2. Raise and lock the lift arms in transport mode (section 3.4) and disconnect the d...

Page 44

9 adjustments 44 9.19 cutting height - floating mode ________________________________________ follow the procedures outlined in section 9.16. 1. Assemble the front roller adjuster (b) to holes num- ber 2 and 4 only of the mower frame. Do not use hole numbers 1 and 3. Refer to the chart below for cor...

Page 45: Notice

Adjustments 9 45 9.20 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. 9.21 specific torque _______________________________________________...

Page 46

10 problem solving 46 10 problem solving 10.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems conta...

Page 47

Quality of cut 11 47 11 quality of cut 11.1 quality of cut troubleshooting _______________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area shoul...

Page 48

11 quality of cut 48 11.3 marcelling_____________________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip di...

Page 49

Quality of cut 11 49 11.4 step cutting____________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to another. This is usually caused by mechanical wear or...

Page 50

11 quality of cut 50 11.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is...

Page 51

Quality of cut 11 51 11.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or...

Page 52

11 quality of cut 52 11.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or u...

Page 53

Quality of cut 11 53 11.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Prob...

Page 54

11 quality of cut 54 11.9 rifling or tramlining __________________________________________________ 11.10mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wav...

Page 55

Notes 12 55 12 notes.

Page 56

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and f...