- DL manuals

- Jacobsen

- Lawn Mower

- 68082

- Parts & Maintenance Manual

Jacobsen 68082 Parts & Maintenance Manual - Warning

6 MAINTENANCE & LUBRICATION CHARTS

26

6

MAINTENANCE & LUBRICATION CHARTS

6.1 GENERAL ________________________________________________________________

1.

Always clean grease fittings before and after lubrication.

2.

Lubricate with grease that meets or exceeds NLGI

Grade 2 LB specifications. Apply grease with a manual

grease gun and fill slowly until grease begins to seep

out. Do not use compressed air.

3.

For smooth operation of pivot points and other friction

points, apply several drops of SAE 30 oil every 50

hours or as required.

4.

Remove wheels and repack bearings once a year.

6.2

MAINTENANCE CHART ____________________________________________________

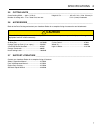

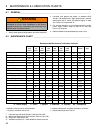

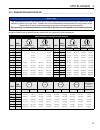

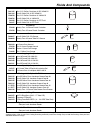

A - Add or Adjust C - Clean I - Inspect L- Lubricate R - Replace AR - As Required

* Indicates initial service for new machines.

** Or yearly, whichever comes first.

*** Inspect visible hoses and tubes for leaks or oil marks.

**** Inspect electrolyte level. See 4.7

I

Pack bearings with NLGI Grade 2 (Service Class GB)

II

Manual grease gun with NLGI Grade 2 (Service Class LB).

III

Engine Oil - See Section 4.3

IV

Jacobsen Hydraulic Oil - SAE 10W30 or Greens Care 68

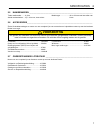

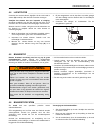

WARNING

Before you clean, adjust, or repair this equipment,

disengage all drives, lower implements to the ground,

engage parking brake, stop engine and remove key from

ignition switch to prevent injuries.

!

Recommended Service and Lubrication Intervals

Every

8-10

Hours

Every

50

Hours

Every

100

Hours

Every

250

Hours

Every

400

Hours

Every

500

Hours

Every

1000

Hours

Yearly

See

Section

Lubricant

Type

Air Cleaner

AR

R

4.4

Battery Charge

I****

4.9

Belt

I-A*

I-A

R

3.3

Brake

I-A*

A

3.4

Cooling System

I-C-A

R

4.15

Engine Oil

I

R*

R

4.2

III

Engine Oil Filter

R*

R

4.3

Fuel Lines and Clamps

I

Fuel Filter

R

4.6

Grease Fittings - F1

L

6.3

II

Grease Fittings - F2

L

6.3

II

Hydraulic Hoses and Tubes

I***

I

4.11

Hydraulic Oil

I-A

R**

4.12

IV

Hydraulic Oil FIlters

R*

R-AR

4.13

Muffler and Exhaust

I

4.10

Radiator Screens

I-C/AR

4.15

Tires

I-A

4.17

Steering System

I*

I-A

Wheel Bearings

L

I

Wiring

I*

I

4.14

Summary of 68082

Page 1

Parts & maintenance manual onderdelen- en onderhoudshandleiding when performance matters. ™ gb nl dutch 19 17 18 13 6 5 9 15 16 7 8 10 4 3 11 1 - includes items 3 - 16 waarschuwing bij verkeerd gebruik kan deze machine ernstig lichamelijk letsel veroorzaken. Degenen die de machine gebruiken en onder...

Page 2

© copyright 2008, textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” this manual contains adjustment, maintenance, troubleshooting instructions and a parts list for your new jacobsen machine. This manual should be stored with the equip...

Page 3

3 table of contents safety 1.1 operating safety ............................................ 4 1.2 important safety notes ..................................5 specifications 2.1 product identification .....................................6 2.2 v2003-m-t engine ...........................................

Page 4: Warning

1 safety 4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manual...

Page 5: Warning

Safety 1 5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6

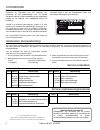

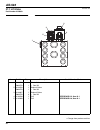

2 specifications 6 2 specifications 2.1 product identification _________________________________________________ 68082 .............................. Ar-522, 5 gang 4wd with rops serial number ................ An identification plate, like the one shown, listing the serial number, is attached to the...

Page 7: Caution

Specifications 2 7 2.5 cutting units ___________________________________________________________ overall cutting width .......90 in. (2.54 m) number of cutting units: ..Five - three front, two rear. Height of cut ................... .3/4 to 5-1/4 in. (19 to 133 mm) in 1/4 in. (6 mm) increments 2.6 a...

Page 8: Warning

3 adjustments 8 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn ...

Page 9

Adjustments 3 9 3.4 brakes _________________________________________________________________ adjust brakes after replacing or servicing brake assembly, or if pedal travel becomes excessive. 1. When installing new brake pads, burnish pads by driving mower at mowing speed while applying a slight press...

Page 10

3 adjustments 10 3.6 forward / reverse speed ______________________________________________ forward and reverse speeds are adjusted at the traction pedal. Set forward speed before adjusting reverse. To adjust forward speed: 1. Make sure drive pump has been set to neutral and engine throttle is adjus...

Page 11: Notice

Adjustments 3 11 3.8 cutting height _________________________________________________________ cutting height for decks can be adjusted from 3/4 to 5-1/4 in. (19-133 mm) in 1/4 in. (6 mm) increments. Actual cutting height may vary somewhat from the heights given depending on turf conditions and other...

Page 12: Warning

3 adjustments 12 3.9 traction control system calibration _________________________________ the traction control system (tcs) will need to be calibrated when a system component has been replaced or the system is not working correctly. System components include controller, lift valve, lift cylinders, ...

Page 13: Notice

Adjustments 3 13 3.10 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate an...

Page 14: Warning

4 maintenance 14 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 15: Warning

Maintenance 4 15 4.4 air filter _______________________________________________________________ check the service indicator daily. If red band appears in the window (b) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk of ...

Page 16: Caution

4 maintenance 16 4.7 battery ________________________________________________________________ make absolutely certain the ignition switch is off position and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielect...

Page 17: Warning

Maintenance 4 17 4.10 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine ...

Page 18: Notice

4 maintenance 18 4.13 hydraulic filter _______________________________________________________ the hydraulic system is protected by a 10 micron return line filter. Flow though the filters is monitored during operation. When pressure drop across the filters is too high the hydraulic oil filter warnin...

Page 19: Warning

Maintenance 4 19 4.15 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiator drain....

Page 20: Warning

4 maintenance 20 4.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tighte...

Page 21: Warning

Maintenance 4 21 4.20 sharpening blades _____________________________________________________ 1. Place a wooden block between the blade and mower housing to stop the blade from moving. 2. When dressing or sharpening the blade, do not follow the original pattern of grind as shown in (a) . Grind new c...

Page 22: Caution

4 maintenance 22 4.22 storage________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Drain and refill radiator. 4...

Page 23

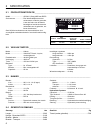

Troubleshooting 5 23 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact ...

Page 24: Notice

5 troubleshooting 24 5.2 controller lamps _____________________________________________________ the controller is a solid state device that monitors and controls electrical functions. The controller receives input signals from various switches and sensors throughout the machine and transmits output ...

Page 25: Notice

Troubleshooting 5 25 5.3 electrical circuits ____________________________________________________ when troubleshooting the machine using the controller always check that program active lamps (2) is on. This indicates that the controller has power and the program is active. Individual circuits can be...

Page 26: Warning

6 maintenance & lubrication charts 26 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubrication. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply gre...

Page 27

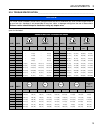

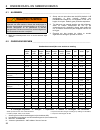

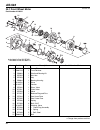

Maintenance & lubrication charts 6 27 6.3 lubrication chart______________________________________________________ 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 5 5 5 5 5 6 7 8 8 9 9 10 10 12 12 12 11 grease fittings f1 - 50 hours (every week) 1 mower pivot (5) 2 lift arm pivot (5) 3 lift cyl...

Page 28

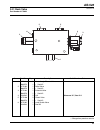

7 parts catalog 28 7 parts catalog 7.1 how to use the parts catalog _________________________________________ abbreviations n/s - not serviced separately, can only be obtained by ordering main component or kit. Ar -variable quantity or measurement is required to obtain correct adjustment. Symbols su...

Page 30

© copyright 2008, textron inc. “alle rechten voorbehouden, inclusief het recht dit boek of gedeelten ervan in wat voor vorm dan ook te reproduceren.” deze handleiding bevat aanpassings-, onderhouds- instructies en instructies voor het oplossen van problemen en een onderdelenlijst voor uw nieuwe jaco...

Page 31

3 inhoud 1 veiligheid 1.1 veiligheidsmaatregels ......................................... 4 1.2 belangrijke veiligheidsoverwegingen ................... 5 2 specificaties 2.1 productidentificatie .............................................. 6 2.2 v2003-m-t motor .......................................

Page 32: Waarschuwing

1 veiligheid 4 1 veiligheid 1.1 veiligheidsmaatregels ________________________________________________ 1. Veiligheid hangt af van de alertheid, zorg en voorzichtigheid van diegenen die de machine bedienen of onderhouden. Laat minderjarigen nooit enig apparaat bedienen. 2. Het is uw verantwoordelijkh...

Page 33: Waarschuwing

Veiligheid 1 5 1.2 belangrijke veiligheidsoverwegingen _________________________________ dit veiligheidssymbool wordt gebruikt om u te attenderen op potentiële gevaren. Gevaar - duidt op dreigende gevaarlijke situatie die, indien niet vermeden, zal resulteren in dood of ernstig letsel. Waarschuwing ...

Page 34

2 specificaties 6 2 specificaties 2.1 productidentificatie___________________________________________________ 68082.............................. Ar-522, 5 gang 4wd met rops serienummer .................. Een identificatieplaat met het serienummer, zoals de getoonde, is aan het frame van de maaier b...

Page 35: Voorzichtig

Specificaties 2 7 2.5 maaieenheden __________________________________________________________ totale maaibreedte .........2,54 m aantal maaieenheden .....Vijf – drie voor, twee achter. Maaihoogte ..................... 19 tot 133 mm met intervallen van 6 mm 2.6 accessoires____________________________...

Page 36: Waarschuwing

3 afstellingen 8 3 afstellingen 3.1 algemeen ______________________________________________________________ 1. Afstellingen en onderhoud moeten altijd door een gekwalificeerde technicus worden uitgevoerd. Als er geen juiste afstelling kan worden gemaakt, neemt u dan contact op met een bevoegde jacob...

Page 37

Afstellingen 3 9 3.4 remmen _________________________________________________________________ na vervanging of onderhoud van de remconstructie moeten de remmen worden bijgesteld. Dit geldt ook wanneer de pedaalweg te lang is geworden. 1. Wanneer u nieuwe remkussens installeert, moet u de kussens pol...

Page 38

3 afstellingen 10 3.6 voorwaartse / achterwaartse snelheid ______________________________ de voor- en achterwaartse snelheden worden afgesteld middels de tractiepedaal. Eerst moet de voorwaartse snelheid worden geregeld en daarna de achterwaartse. Afstelling voorwaartse snelheid: 1. Zorg ervoor dat ...

Page 39: Let Op

Afstellingen 3 11 3.8 maaihoogte ____________________________________________________________ maaihoogte voor dekken kan worden aangepast van 19 tot 133 mm met intervallen van 6 mm. De eigenlijke maaihoogte kan afhankelijk van de toestand van de graszoden en andere factoren iets van de gegeven hoogt...

Page 40: Waarschuwing

3 afstellingen 12 3.9 ijking van het tractiecontrolesysteem _______________________________ het tractiecontrolesysteem (tcs) moet geijkt worden als een systeemcomponent vervangen is of als het systeem niet goed werkt. De systeemcomponenten zijn onder andere de regulateur, hefklep, hefcilinders of sl...

Page 41: Let Op

Afstellingen 3 13 3.10 draaikoppelspecificatie _______________________________________________ jacobsen gebruikt kwaliteit 5 gegalvaniseerde bouten als standaard, tenzij anderszins vermeld. Bij het aandraaien van dergelijke bouten moet de waarde worden gebruikt die voor 'gesmeerd' wordt aangegeven. ...

Page 42: Waarschuwing

4 onderhoud 14 4 onderhoud 4.1 algemeen _______________________________________________________________ 1. Afstelling en onderhoud behoren altijd te worden verricht door een bevoegd monteur. Als de gewenste afstelling niet kan worden uitgevoerd, neem dan contact op met een erkende jacobsen dealer. 2...

Page 43: Waarschuwing

Onderhoud 4 15 4.4 luchtfilter ____________________________________________________________ controleer de service-indicator dagelijks. Als de rode band in venster ( b) verschijnt, dient het filter te worden vervangen. Verwijder het element niet voor inspectie of reiniging. Onnodige verwijdering van ...

Page 44: Voorzichtig

4 onderhoud 16 4.7 accu ___________________________________________________________________ u moet er absoluut zeker van zijn dat de ontstekingsschakelaar in de uit-stand staat en de contactsleutel is verwijderd voordat u de accu een onderhoudsbeurt geeft. Zet de kabels stevig aan de accuklemmen vas...

Page 45: Waarschuwing

Onderhoud 4 17 4.10 geluiddemper en uitlaat _______________________________________________ ter beveiliging tegen koolmonoxidevergiftiging moet het volledige uitlaatsysteem regelmatig worden geïnspecteerd. Een defecte uitlaat moet altijd worden vervangen. Als u een verandering waarneemt in de kleur ...

Page 46: Let Op

4 onderhoud 18 4.13 hydraulische filters __________________________________________________ het hydraulisch systeem wordt beschermd door twee 10 micron filters: een een terugleidingfilter. De stroming door de filters wordt tijdens de operationele werking gecontroleerd. Wanneer de drukdaling in de fi...

Page 47: Waarschuwing

Onderhoud 4 19 4.15 radiator _______________________________________________________________ controleer het koelvloeistofpeil dagelijks. De radiateur moet vol zijn en in de overloopfles dient het koud -streepje te worden bereikt. Het koelsysteem moet jaarlijks worden afgetapt en opnieuw gevuld. Verw...

Page 48: Waarschuwing

4 onderhoud 20 4.18 wielmontageprocedure________________________________________________ 1. Verwijder vuil, gras en olie van de tapboutdraadgangen, maar smeer ze niet. 2. Plaats het wiel op de naaf en controleer of er volledig contact is tussen het montagevlak van het wiel en de naaf of remtrommel. ...

Page 49: Waarschuwing

Onderhoud 4 21 4.20 messen slijpen _________________________________________________________ 1. Plaats een houten blok tussen het mes en de maaibehuizing om het mes stil te zetten. 2. Volg bij het prepareren of slijpen van het mes niet het originele slijppatroon dat in (a) te zien is. Slijp nieuwe m...

Page 50: Voorzichtig

4 onderhoud 22 4.22 stalling _______________________________________________________________ algemeen 1. De maaier dient eerst grondig te worden gewassen en gesmeerd. Repareer en lak beschadigd of blootgesteld metaal. 2. Inspecteer de maaier, draai alle bevestigingen vast en vervang versleten of bes...

Page 51

Foutopsporing 5 23 5 foutopsporing 5.1 algemeen_______________________________________________________________ onderstaande foutopsporingstabel vermeldt basisproblemen die zich kunnen voordoen tijdens start-up en werking. Voor meer gedetailleerde informatie betreffende de hydraulische en elektrische...

Page 52: Let Op

5 foutopsporing 24 5.2 controllerlampjes ___________________________________________________ de controller is een halfgeleiderapparaat dat de elektrische functies controleert en bestuurt. De controller ontvangt ingangssignalen (inputs) van schakelaars en sensors die op diverse plaatsen in de machine...

Page 53: Let Op

Foutopsporing 5 25 5.3 elektrische circuits ___________________________________________________ tijdens foutsporing in de machine met behulp van de controller, dient altijd eerst te worden gecontroleerd of programma actieve lampje (2) branden. Hiermee wordt namelijk aangegeven dat de controller voed...

Page 54: Waarschuwing

6 onderhouds- en smeerschema’s 26 6 onderhouds- en smeerschema’s 6.1 algemeen ______________________________________________________________ 1. Maak de vetsmeerpunten voor en na het smeren altijd schoon. 2. Smeer met vet dat voldoet aan de nlgi kwaliteit 2 lb specificaties of deze overtreft. Gebruik...

Page 55

Onderhouds- en smeerschema’s 6 27 6.3 smeerschema___________________________________________________________ 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 5 5 5 5 5 6 7 8 8 9 9 10 10 12 12 12 11 smeerfittingen f1 - 50 uur (elke week) 1 maaispil (5) 2 hefarmdraaipen (5) 3 hefcilinders (10) 4 ...

Page 56

7 onderdelencatalogus 28 7 onderdelencatalogus 7.1 de onderdelencatalogus gebruiken __________________________________ afkortingen n/s - non-serviced apart, uitsluitend verkrijgbaar door hoofdonderdeel of set te bestellen. Ar -variabele hoeveelheid of meting is vereist om juiste afstelling te bereik...

Page 57

Parts catalog 7 29 7.3 table of contents______________________________________________________ 1.1 .........Decals ..................................................................... 30 2.1 .........Hood ....................................................................... 32 3.1 .........Seat p...

Page 58: Ar-522

30 2 17 2 4 5 6 7 8 10 12 20 24 25 26 26 20 20 19 19 19 11 14 / 15 17 13 3 11 1 18 9 21 27 27 21 21 13 22 23 23 22 16 important t h i s m a c h i n e u s e s g r e e n s c a r e 6 8 , a b i o d e g r a d a b l e h y d r a u l i c f l u i d . ( o r d e r 5 0 0 3 1 0 3 f o r 5 g a l . P a i l ) u s e ...

Page 59: 105

31 > change from previous revision 7 12 4 5 10 1 18 8 9 6 manufactured under one or more of the following u.S. Patents: xxxxxxx xxxxxxx xxxxxxx xxxxxxx ! Warning radiator is under pressure. Remove cap slowly to avoid personal injury. 365956 340830 1. Leer el manual del operador. No permitir que pers...

Page 60: Ar-522

32 1 2 17 22 5 4 7 9 3 18 15 17 20 22 16 19 10 10 23 24 16 11 14 12 8 16 15 21 6 ar-522 2.1 hood serial no. All lf34-1.

Page 61: Ar-522

33 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4139087 1 hood includes decals 2 4124443 1 • foam, front 3 4124437 1 • foam, right side 4 4124436 1 • foam, left side 5 4124442 1 • foam, top 6 557620 4 • molding 7 4138441 1 • foam, hood mount 8 4129680 ...

Page 62: Ar-522

34 10 3 19 5 6 9 4 30 16 24 25 2 6 9 8 22 23 18 6 9 10 1 20 21 12 7 14 15 13 11 26 27 17 8 28 29 31 33 34 37 38 39 35 36 32 32 40 41 42 42 42 ar-522 3.1 seat pan michigan seat serial no. All.

Page 63: Ar-522

35 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 1004279 1 floor pan 2 3009292 1 seat pan 3 4139241 1 support, seat 4 4131137 1 adjuster, double latching 5 4139237 1 base, seat 6 400258 9 screw, 3/8-16 x 3/4” hex head 7 441602 4 carriage bolt, 5/16-18 x...

Page 64: Ar-522

36 2 3 5 6 7 8 9 34 10 12 11 13 14 16 18 19 20 21 22 32 23 24 27 28 29 30 31 4 33 33 17 15 25 26 1 7 ref 17 ar-522 4.1 control panel serial no. All.

Page 65: Ar-522

37 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4130114 1 instrument panel includes silk screen decals 2 4129683 1 hour meter, quartz reference u-3, see 42.1 3 365943 1 fuel gauge reference u-2, see 42.1 4 3005121 1 water temperature gauge reference u-...

Page 66: Ar-522

38 2 2 3 5 6 6 8 9 10 12 11 13 14 14 16 18 19 20 20 21 21 22 22 23 23 27 27 27 27 27 27 28 28 29 4 25 26 26 26 7 24 30 31 33 17 15 32 1 16 34 35 ar-522 5.1 traction pedal serial no. All.

Page 67: Ar-522

39 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 1003288.7 1 treadle pivot 2 352726 2 • bushing 3 3007230 1 stop, mow speed 4 3003474 1 grip, pedal 5 3003475 1 grip, pedal 6 366974 2 rod end 7 4125831 1 switch, proximity reference sw-7, see 42.1 8 30063...

Page 68: Ar-522

40 3 5 6 7 7 8 9 12 13 13 14 14 16 16 18 18 19 20 21 22 23 27 4 15 15 1 2 10 11 24 17 25 26 28 9 10 28 17 25 29 31 30 ar-522 6.1 brake pedal serial no. All.

Page 69: Ar-522

41 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4142455 1 bracket, brake 2 4125831 1 switch, proximity reference sw-8, see 42.1 3 3006327 1 shaft, turn assist 4 3007606 1 lever, parking brake 5 3006997 1 mount, brake 6 1003616 1 brake arm 7 352726 2 • ...

Page 70: Ar-522

42 1 2 8 9 10 11 7 7 3 6 6 6 5 5 5 3 3 4 20 4 4 5002952 12 13 14 17 18 19 19 16 16 15 15 this structure's proctective capability may be impaired by structural damage, over turn, or alteration. If any of these conditions occur, the structure must be replaced. ! Warning 557844 ar-522 7.1 frame serial ...

Page 71: Ar-522

43 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4118092 1 frame 2 366871 2 • bushing 3 4113047 6 screw, 5/8-18 x 1-1/2” hex head grade 8 bolt 4 4140094 6 flat washer, 5/8 5 452016 6 flat washer, 5/8 6 443128 6 nut, 5/8-18 hex 7 445795 2 nut, 5/16-18 sp...

Page 72: Ar-522

44 4 5 6 9 13 14 15 16 17 19 21 21 27 28 29 33 33 33 33 32 32 31 31 20 20 30 30 1 2 3 18 11/12 25/26 10 10 24 22 8 7 23 ar-522 8.1 front axle serial no. All.

Page 73: Ar-522

45 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4133033 2 tire 2 5002574 2 rim 3 360111 2 valve, inflation 4 4118254 2 wheel motor see 35.1 5 557623 2 • key 6 557624 2 • nut, hex 7 446152 6 lockwasher, 1/2 8 400456 6 screw, 1/2-20 x 4” hex head 9 41811...

Page 74: Ar-522

46 1 2 3 4 5 6 7 8 9 10 12 11 13 25 14 15 16 17 18 19 20 21 22 23 24 11 11 ar-522 9.1 tilt steering serial no. All.

Page 75: Ar-522

47 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 5002918 1 actuator, gas spring 2 5002919 1 cable, actuator 3 2811346 1 tower, steering 4 4146776 1 valve, steering see 39.1 339979 3 • adapter, straight 339974 2 • adapter, straight 5 443828 1 • nut, 5/8-...

Page 76: Ar-522

48 > change from previous revision 2 3 5 6 7 8 8 9 9 10 10 12 12 11 11 4 1 ar-522 10.1 tie rod part number 4132688 serial no. All item part no. Qty. Description serial numbers/notes 1 4118210 1 tie rod 2 4121828 1 ball joint, left hand thread 3 4121986 1 • dust cover 4 471214 1 • straight grease fit...

Page 77: Ar-522

49 > change from previous revision 12 16 16 18 17 16 15 10 11 11 13 14 14 1 2 3 8 9 5 6 7 4 ar-522 item part no. Qty. Description serial numbers/notes 1 450190 2 screw, m8-1.25 x 16 mm hex head 4133238 1 kit, remote oil filter included with engine 2 4133239 1 • adapter, engine oil filter 3 4133240 1...

Page 78: Ar-522

50 2 3 5 6 7 8 9 9 9 9 10 12 11 13 14 16 16 18 19 20 21 22 23 23 24 27 28 29 30 30 31 33 34 4 4 4 17 17 15 15 25 26 32 1 ar-522 12.1 rear axle serial no. All.

Page 79: Ar-522

51 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4149337 2 tire, 22.5 x 10-8 4 ply 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 4151058 1 ste...

Page 80: Ar-522

52 2 2 2 2 2 3 5 5 6 7 8 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 24 34 35 27 28 32 28 29 30 31 31 4 4 17 15 33 25 26 1 ar-522 13.1 radiator and air cleaner serial no. All.

Page 81: Ar-522

53 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 3002195 1 elbow, 1/8 npf 90° 2 326112 5 clamp, 1-5/16 to 2-1/4” dia hose 3 345666 1 clamp, 1/2” p hose 4 337229 2 clamp, hose 5 5003447 ar tube, neoprene cut to 33” 6 365398 1 indicator, air cleaner 7 366...

Page 82: Ar-522

54 2 2 2 2 2 2 2 2 3 5 6 6 7 7 8 8 8 8 9 9 10 10 10 10 12 11 13 14 16 18 18 18 18 19 19 20 20 21 22 22 24 17 23 23 23 23 4 27 28 25 15 15 15 15 1 26 24 24 9 ar-522 14.1 engine mounting serial no. All.

Page 83: Ar-522

55 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4118253 1 engine, v2003 mt 4113986 1 • filter, engine oil see 11.1 2 310711 12 washer, isolator 3 362263 1 screw, m10-1.25 x 25mm hex head 4 363485 1 lockwasher, m10 heavy 5 364501 1 temperature sender 6 ...

Page 84: Ar-522

56 2 3 5 6 7 8 9 10 2 8 9 10 12 11 13 14 16 18 19 20 20 21 22 23 24 27 31 4 17 15 25 24 25 26 1 28 view rotated 180° for clarity 29 29 30 30 ar-522 15.1 pump mounting and engine exhaust serial no. All.

Page 85: Ar-522

57 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 362743 1 o-ring seal 2 400264 5 screw, 3/8-16 x 1-1/4” hex head 3 400286 2 screw, 3/8-16 x 2-3/4” hex head 4 400410 2 screw, 1/2-13 x 1-3/4” hex head 5 4118252 1 pump, traction see 40.1 and 41.1 6 4174880...

Page 86: Ar-522

58 a a b b connect to engine fuel injector overflow. Connect to engine fuel pump 1 30 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 19 19 20 21 24 19 18 18 18 15 18 18 18 28 23 27 22 29 25 26 18 18 ar-522 16.1 fuel and hydraulic tanks serial no. All.

Page 87: Ar-522

59 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 132647 1 valve, shut off 2 3001279 1 switch, float reference sw-9, see 42.1 3 3002397 1 plug, magnetic 339899 1 • o-ring 4 3009204 1 fuel tank 5 3005871 1 hydraulic tank 6 3005872 1 shell, tank cover 7 30...

Page 88: Ar-522

60 > change from previous revision 9 3 6 4 7 2 5 1 2 1 1 7 8 ar-522 17.1 pump suction hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 3008673 5 clamp, constant torque hose 2 4148857 2 hose, gear pump suction 3 340090 1 fitting, 24-24 90° 4 4122538 1 hose, charge pump ...

Page 89: Ar-522

61 > change from previous revision 1 3 5 6 7 8 9 10 2 11 4 1 ar-522 item part no. Qty. Description serial numbers/notes 1 339999 2 fitting, 16-16 straight 2 4129037 1 hose, 4wd return 3 340077 1 fitting, 16-16 90° 4 340123 1 fitting, 16-16-16 swivel run tee 5 340039 1 fitting, 16-16 45° 6 4123166 1 ...

Page 90: Ar-522

62 > change from previous revision 2 3 5 5 5 5 6 6 6 6 7 8 9 10 4 1 1 1 1 ar-522 19.1 hydraulic valves and filter serial no. All item part no. Qty. Description serial numbers/notes 1 400258 8 screw, 3/8-16 x 3/4” hex head 2 409811 4 screw, 5/16-18 x 5/8” thread cutting 3 4121554 1 hydraulic filter a...

Page 91: Ar-522

63 > change from previous revision 2 2 3 5 5 6 7 8 9 10 12 11 11 13 4 4 4 4 4 4 4 4 4 4 4 1 10 ar-522 item part no. Qty. Description serial numbers/notes 1 339985 2 fitting, 8-10 straight 2 339989 3 fitting, 10-10 straight 3 340009 1 fitting, 10-10 straight 4 340070 11 fitting, 10-10 90° 5 340030 2 ...

Page 92: Ar-522

64 2 3 3 5 6 7 8 9 27 28 29 29 29 29 9 10 12 11 13 14 16 25 28 27 26 18 19 19 20 21 22 22 23 24 4 4 17 15 1 1 1 1 1 21 ar-522 21.1 traction hydraulics serial no. All.

Page 93: Ar-522

65 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 339994 5 adapter, 12-12 straight fitting 2 4129035 1 hose, 4wd valve to traction pump 4wd valve port i 3 339993 2 adapter, 12-10 straight fitting 4 4128977 2 hose, front tube to rear tube 5 4134921 1 tube...

Page 94: Ar-522

66 > change from previous revision 2 2 2 2 3 3 5 5 5 6 7 8 9 10 11 4 4 4 4 1 1 1 ar-522 22.1 front lift hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 3000953 3 disk, orifice 2 339979 6 fitting, 6-6 straight 3 340026 2 fitting, 6-6 45° 4 340061 4 fitting, 6-6 90° 5 r...

Page 95: Ar-522

67 > change from previous revision 2 2 3 6 7 8 9 10 12 11 6 5 4 4 4 4 1 1 ar-522 item part no. Qty. Description serial numbers/notes 1 3000953 2 disk, orifice 2 339979 4 fitting, 6-6 straight 3 339985 1 fitting, 8-10 straight 4 340061 4 fitting, 6-6 90° 5 340376 1 fitting, 8-8 90° swivel 6 ref 2 lif...

Page 96: Ar-522

68 > change from previous revision 2 3 5 6 7 8 9 10 10 12 11 13 13 14 4 1 8 ar-522 24.1 wheel motor case drains serial no. All item part no. Qty. Description serial numbers/notes 1 4137634 1 hose, lh rear motor to drain tube included in hose bundle 4137625 2 4137624 1 hose, rh rear motor to drain tu...

Page 97: Ar-522

69 > change from previous revision 2 3 5 5 5 5 7 8 9 10 10 10 10 5 10 6 4 1 1 ar-522 item part no. Qty. Description serial numbers/notes 1 4137561 2 hose, front motor to front motor 2 4137562 1 hose, front motors to drain tube 3 4129600 1 hose, rear motors to drain tube 4 4129603 1 hose, rear motor ...

Page 98: Ar-522

70 > change from previous revision to return tube (3) from pump (2) to steering cylinder (4) to steering cylinder (5) aux in out lt rt to lift valve (1) 6 2 3 5 7 7 4 1 ar-522 26.1 steering hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 4129028 1 hose, lift valve to ...

Page 99: Ar-522

71 > change from previous revision steering hoses 3 2 1 4 5 9 10 6 6 7 ar-522 item part no. Qty. Description serial numbers/notes 1 1004541 1 bracket, hose retaining 2 403770 2 screw, 5/16-18 x 3/4” flange head 3 445795 2 nut, 5/16-18 spiralock flange 4 4131862 2 clamp, two hose 5 4131864 2 plate, c...

Page 100: Ar-522

72 a b c d e f g h j k l m a - headlight b - lift arm limit switch c - fuel level sender/ instrument panel d - seat switch e - oil float switch f - glow plugs g - fuel solenoid h - charge filter switch j - engine oil pressure switch k - temperature sender l - 4wd valve (4wd only) m - reel valve 2 3 ...

Page 101: Ar-522

73 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 2810424 1 cable, engine ground engine mount to frame 2 4122840 2 headlight reference l-1 & l-2, see 42.1 4123183 1 • bulb 3 4122841 1 controller reference u-6, see 42.1 4 5003282 2 • fuse, 20 amp referenc...

Page 102: Ar-522

74 2 3 3 3 5 5 5 6 7 7 8 9 30 9 9 9 30 10 10 10 12 12 12 11 11 11 11 11 11 13 14 16 18 18 18 18 18 18 19 20 20 21 22 23 23 29 29 24 27 27 27 28 28 4 4 4 4 4 4 17 17 17 15 25 25 25 26 26 26 1 1 31 32 31 32 ar-522 29.1 front lift arms serial no. All.

Page 103: Ar-522

75 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 548905 9 screw, 3/8-16 x 1” serrated flange 2 ref 3 deck assembly see 31.1 3 4125547 3 front deck pivot 4 4127480 2 • bushing 5 471214 1 • straight grease fitting 6 4125919 1 center lift arm 7 3010489 2 •...

Page 104: Ar-522

76 6 13 15 21 8 8 11 12 10 14 14 22 9 19 18 19 1 17 16 25 4 4 23 24 2 5 3 7 27 27 20 13 15 21 8 8 14 14 22 19 18 26 28 19 1 17 16 25 4 4 23 24 2 3 7 20 ar-522 30.1 rear lift arms serial no. All.

Page 105: Ar-522

77 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4131422 2 pin, rear cylinder 2 4131420 2 pin, rear lift arm 3 4126450 2 pin, cylinder 4 445783 10 nut, 3/8-16 whizlock flange 5 548905 4 screw, 3/8-16 x 1” serrated flange 6 ref 2 deck assembly see 31.1 7...

Page 106: Ar-522

78 2 3 5 6 7 8 9 9 9 10 12 11 31 13 13 14 16 18 19 20 21 22 23 29 24 4 17 17 15 25 26 1 30 27 28 ar-522 31.1 deck housing and caster wheels serial no. All.

Page 107: Ar-522

79 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 3004894 2 pin, 7/16 x 1-3/4” snap ring 2 3007764 1 washer, blade 3 3008388 1 adapter, blade 4 400410 1 screw, 1/2-13 x 1-3/4” hex head 5 400426 2 screw, 1/2-13 x 5” hex head 6 4117807 3 spacer 7 4163107 1...

Page 108: Ar-522

80 2 3 3 5 5 5 5 6 6 7 8 9 10 10 12 12 11 11 13 14 16 16 18 18 19 19 20 20 22 23 30 32 32 30 24 26 27 28 28 29 26 27 28 28 29 31 24 25 30 4 17 / 21 15 15 1 ar-522 32.1 deck frame serial no. All.

Page 109: Ar-522

81 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 400404 4 screw, 1/2-13 x 1” hex head 2 400408 2 screw, 1/2-13 x 1-1/2” hex head 3 400418 4 screw, 1/2-13 x 3” hex head 4 4137665 1 deck frame front decks 4 4137674 1 deck frame rear decks 5 4127478 4 • fl...

Page 110: Ar-522

82 > change from previous revision 1 2 3 4 5 6 7 8 9 7 6 ar-522 33.1 brake assemblies serial no. All item part no. Qty. Description serial numbers/notes 1 340603 2 bracket, brake mounting 503308 1 disk brake, r.H. 2500722 1 disk brake, l.H. 2 590259 4 • nut, 3/8-24 3 549441 2 • v-plate 4 502517 1 • ...

Page 111: Ar-522

83 > change from previous revision 1 2 3 4 5 5 6 ar-522 34.1 deck valve part number 4175022 serial no. All item part no. Qty. Description serial numbers/notes 1 4175181 2 vented logic element valve 5003579 1 • seal kit 2 4175183 1 relief valve 5003578 1 • seal kit 3 4175184 1 solenoid valve 5003578 ...

Page 112: Ar-522

84 > change from previous revision 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 1 2 3 4 5 6 ar-522 35.1 front wheel motor part number 4118254 serial no. All item part no. Qty. Description serial numbers/notes 1 558066 8 screw, torx 2 5002110 1 front retainer 3 558063 1 shaft and bearing kit 4 557624 1 ...

Page 113: Ar-522

85 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 ar-522 36.1 rear wheel motor part number 4118255 serial no. All item part no. Qty. Description serial numbers/notes 1 a 1 seal exclusion 2 a 4 seal, 3” i.D. 3 a 1 back up ring 4 a 1 shaft seal 5 4134525 1 shaft and bearing kit 6 554780...

Page 114: Ar-522

86 > change from previous revision 1 2 3 4 5 ar-522 37.1 lift valve part number 4129069 serial no. All item part no. Qty. Description serial numbers/notes 1 4134528 1 check valve 5003579 1 • seal kit 2 4134529 1 solenoid valve 5003579 1 • seal kit 3 4136067 1 solenoid valve 5003578 4 • seal kit 4 41...

Page 115: Ar-522

87 > change from previous revision 1 1 2 ar-522 38.1 4wd valve part number 4129071 serial no. All item part no. Qty. Description serial numbers/notes 1 4134541 2 check valve 5003579 1 • seal kit 2 4134535 1 pilot operated internal vent valve 5003579 1 • seal kit.

Page 116: Ar-522

88 39 38 29 31 32 34 33 37 35 36 6 7 16 17 4 4 18 19 20 21 22 23 24 25 26 27 28 11 1 2 3 30 5 8 11 4 12 13 4 10 15 11 9 14 ar-522 39.1 steering valve part number 4138567 serial no. All.

Page 117: Ar-522

89 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 443108 4 locknut, 5/16-18 center 2 n/s 1 port cover 3 c 1 seal, o-ring 4 c 4 seal, o-ring 5 c 4 seal, o-ring 6 443828 1 nut, 5/8-18 hex jam 7 n/s 4 special bolt 8 n/s 1 port manifold 9 b 3 spring, port si...

Page 118: Ar-522

90 22 19 20 2 1 3 4 18 21 6 15 5 22 21 17 23 14 13 13 8 8 9 9 16 10 11 12 7 16 ar-522 40.1 traction pump (front half) part number 4118252 serial no. All.

Page 119: Ar-522

91 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4134588 1 shim kit ● 2 n/s 1 o-ring 3 4134589 1 charge relief spring 4 4134590 1 charge relief valve 5 4134591 2 o-ring 6 4134592 1 needle bearing 7 4134594 1 roller bearing 8 4134595 2 retaining ring 9 4...

Page 120: Ar-522

92 11 5 13 16 10 15 17 12 14 9 8 1 4 3 7 1 2 6 6 10 11 ar-522 41.1 traction pump (rear half) part number 4118252 (cont) serial no. All.

Page 121: Ar-522

93 > change from previous revision ar-522 item part no. Qty. Description serial numbers/notes 1 4134615 1 o-ring 2 4134616 1 o-ring ● 3 ns 1 o-ring ● 4 ns 1 temper load ring 5 4134617 1 neutral return spring ● 6 4134618 1 piston ring kit 7 4134619 1 gerotor ● 8 ns 1 suction filter adapter seal 9 413...

Page 122: Ar-522

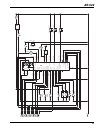

94 a b c d e f g h j k l m n sw-6 sw-13 2 3 r db og/wh og/bk lb/wh pk/bu ye/bu gy/rd og/wh ye ye og/y e db pu/gn og dg dg tn/bk db pu/gn tn/bk + – k-2 k-1 u-7 sw-2 sw-3 cb-1 l-1 l-3 l-5 l-4 l-6 l-2 r-3 m-1 b-1 r-2 u-1 u-2 u-3 r-3 l l b s s g g i og/wh og/wh og/wh og/wh og/bk og/wh lb/tn tn lb/tn lb/...

Page 123: Ar-522

95 bk 1-5 1-4 3-2 3-8 grd-1 4-1 4-2 4-3 4-4 2-1 3-12 2-12 1-2 1-7 1-8 1-9 1-10 1-11 1-12 1-1 2-2 2-6 2-5 2-8 2-11 1-6 1-3 3-4 3-5 3-3 3-6 3-7 pk/bu ye /b u og/y e og/y e og/pk og/pk select 3 select 4 select 2 select 1 star t rela y glo w plug rela y glo w plug light lights hyd le v el light switches...

Page 124: Ar-522

96 ar-522 item reference illustration part number description serial numbers/notes b-1 see 28.1 366931 battery cb-1 see 28.1 361439 50 amp circuit breaker (alternator) f-1 see 28.1 5003282 20 amp fuse (ignition circuit) included in controller f-2 see 28.1 5003282 20 amp fuse (lights) included in con...

Page 125: Ar-522

97 ar-522 u-1 see 4.1 3005121 temperature gauge u-2 see 4.1 365943 fuel gauge u-3 see 4.1 4129683 hour meter u-4 see 4.1 366670 horn u-5 not shown cruise control module (option) u-6 see 28.1 4122841 controller u-7 not shown 5000938 alternator included in engine item reference illustration part numbe...

Page 126: Ar-522

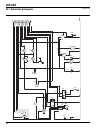

98 p2 g2 g1 m2 m1 r2 r1 p1 t .88 ci .88 ci .5 ci 3625 psi 2600 psi 3625 psi supply .028 drain .031 285 psi 2.81 ci displacement control tow valve 3000 rpm a b traction pump gear pump rr deck motor deck valve lr deck motor rf deck motor 10 micron 25 psi crack bypass 30 psi crack bypass 100 mesh scree...

Page 127: Ar-522

99 p t c1 c2 c3 c4 c5 c6 c10 c9 c8 c7 left front cylinder steering unit in out aux lt rt 4.13 ci 1740 psi 30.0 ci 30.0 ci front wheel motors rear wheel motors 24.0 ci 24.0 ci lift valve a b c d e f g 4wd valve f a g b h c i d e .040 .050 right front cylinder .040 center front cylinder .040 right rea...

Page 128: Ar-522

100 x w w w x w x w w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size w-x o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face se...

Page 129: Ar-522

101 > change from previous revision ar-522 adapter part number. Dash size adapter type (w) o-ring (x) o-ring (y) o-ring (z) o-ring 339974 4-6 straight adapter 339908 339897 339977 6-4 straight adapter 339909 339896 339979 6-6 straight adapter 339909 339897 339985 8-10 straight adapter 339910 339899 ...

Page 130: Fluids And Compounds

Fluids and compounds * refer to the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Jacobsen offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See your local jacobsen dealer for a copy. Hydraulic fluid* 5001...

Page 131: Index

103 index 1002657 ...................... 47 1002810 ...................... 37 1003047 ...................... 45 1003048 ...................... 45 1003288 ...................... 39 1003616 ...................... 41 1003638 ...................... 51 1003872 ...................... 41 1004279 .............

Page 132: Index

104 index 4125831.................39 , 41 4125919.......................75 4126082.......................73 4126447.......................75 4126450.................75 , 77 4127192.................75 , 77 4127478.......................81 4127480.................75 , 77 4127556.................75 , 7...

Page 133: Index

105 index 4163121 ...................... 81 4163122 ...................... 81 4163124 ...................... 79 4163125 ...................... 79 4171883 ...................... 75 4171884 ...................... 75 4173042 ...................... 55 4173922 ...................... 79 4173923 .............

Page 136

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ kwaliteit, prestatie en ondersteuning van wereldklasse world class quality, performance and support equipment from jacobsen is built to exacting standards ensured by iso 900...