- DL manuals

- Jacobsen

- Lawn Mower

- AR-5

- Parts & Maintenance Manual

Jacobsen AR-5 Parts & Maintenance Manual

WARNING:If incorrectly used, this machine can cause severe injury. Those who

use and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up, operate,

adjust or service the machine.

5HVHUYHGHOVRJ9HGOLJHKROGHOVHVKnQGERJ

3DUWV0DLQWHQDQFH0DQXDO

AR-5

68080 – AR-5, Kubota V2003-M-T, 5 gang 4WD

4133106-DK (rev.A)

Summary of AR-5

Page 1

Warning:if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the entire manual before attempting to set up, operate, adjust or service the machine. 5hvhuyhghovrj9hgoljhkroghovhvkn...

Page 2: To Order Parts

Copyright 2004 textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” to order parts 1. Write your full name and complete address on the order. 2. Explain where and how to make shipment. 3. Give product number, name and serial number that ...

Page 3: Suggested Stocking Guide

3 suggested stocking guide to keep your equipment fully operational and productive, maintain a stock of the more commonly used maintenance items. We have included part numbers for additional support materials and training aids. A more complete listing of accessories and attachments can be found in t...

Page 4: Warning

1 safety gb-4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equip- ment. Never allow minors to operate any equipment. 2. It is your responsibility to read this m...

Page 5: Warning

Safety 1 gb-5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 6

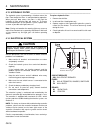

2 specifications gb-6 2 specifications 2.1 product identification _________________________________________________ 68080 .............................. Ar-5, 5 gang 4wd serial number ................ An identification plate, like the one shown, listing the serial number, is attached to the frame of...

Page 7

Specifications 2 gb-7 2.5 cutting units ___________________________________________________________ overall cutting width .......90 in. (2.54 m) number of cutting units: ..Five - three front, two rear. Height of cut ................... .3/4 to 5-1/4 in. (19 to 133 mm) in 1/4 in. (6 mm) increments 2....

Page 8: Warning

3 adjustments gb-8 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be per- formed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, ...

Page 9

Adjustments 3 gb-9 3.4 brakes _________________________________________________________________ adjust brakes after replacing or servicing brake assembly, or if pedal travel becomes excessive. 1. When installing new brake pads, burnish pads by driv- ing tractor at mowing speed while applying a sligh...

Page 10

3 adjustments gb-10 3.6 forward / reverse speed ______________________________________________ forward and reverse speeds are adjusted at the traction pedal. Set forward speed before adjusting reverse. To adjust forward speed: 1. Make sure drive pump has been set to neutral and engine throttle is ad...

Page 11: Warning

Adjustments 3 gb-11 3.8 cutting height _________________________________________________________ cutting height for decks can be adjusted from 3/4 to 5-1/4 in. (19-133 mm) in 1/4 in. (6 mm) increments. Actual cutting height may vary somewhat from the heights given depending on turf conditions and ot...

Page 12: Warning

3 adjustments gb-12 3.9 traction control system calibration _________________________________ the traction control system (tcs) will need to be calibrated when a system component has been replaced, or the system is not working correctly. System components include controller, lift valve, lift cylinde...

Page 13: Caution

Adjustments 3 gb-13 3.10 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Caution all torque values included in these charts are approximat...

Page 14: Warning

4 maintenance gb-14 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be per- formed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment o...

Page 15: Warning

Maintenance 4 gb-15 4.4 air filter _______________________________________________________________ check the service indicator daily. If red band appears in the window (b) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk ...

Page 16: Caution

4 maintenance gb-16 4.7 battery ________________________________________________________________ make absolutely certain the ignition switch is “off” and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric ...

Page 17: Warning

Maintenance 4 gb-17 4.10 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engi...

Page 18: Caution

4 maintenance gb-18 4.13 hydraulic filter _______________________________________________________ the hydraulic system is protected by a 10 micron return line filter. Flow though the filters is monitored during operation. When pressure drop across the filters is too high the hydraulic oil filter war...

Page 19: Warning

Maintenance 4 gb-19 4.15 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiator dra...

Page 20: Warning

4 maintenance gb-20 4.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tig...

Page 21: Warning

Maintenance 4 gb-21 4.20 sharpening blades _____________________________________________________ 1. Place a wooden block between the blade and mower housing to stop the blade from moving. 2. When dressing or sharpening the blade, do not follow the original pattern of grind as shown in (a). Grind new...

Page 22: Caution

4 maintenance gb-22 4.22 storage________________________________________________________________ general 1. Wash the tractor thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the tractor, tighten all hardware, replace worn or damaged components. 3. Drain and refill radi...

Page 23

Troubleshooting 5 gb-23 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems conta...

Page 24

5 troubleshooting gb-24 5.2 controller lamps _____________________________________________________ the controller is a solid state device that monitors and controls electrical functions. The controller receives input signals from various switches and sensors throughout the machine and transmits outp...

Page 25

Troubleshooting 5 gb-25 5.3 electrical circuits ____________________________________________________ when troubleshooting the machine using the controller always check that program active lamps (1, 2 and 3 - 5 gang)(2 and 3 - 7 gang) are on. These indicate that the controller has power and the progr...

Page 26: Warning

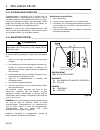

6 maintenance & lubrication charts gb-26 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubrication. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

Page 27

Maintenance & lubrication charts 6 gb-27 6.3 lubrication chart______________________________________________________ 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3 3 3 4 4 4 4 4 5 6 7 7 8 8 9 9 10 11 11 11 grease fittings f1 - 50 hours (every week) 1 mower pivot (5) 2 lift arm pivot (5) 3 lift cylinders (10) 4 caste...

Page 28: Bestilling Af Reservedele

Copyright 2004 textron inc. “alle rettigheder forbeholdes, herunder retten til at reproducere denne bog eller dele heraf uanset form.” bestilling af reservedele 1. Skriv dit fulde navn og fuldstændige adresse på bestillingssedlen. 2. Forklar, hvor og hvordan forsendelse skal finde sted. 3. Opgiv pro...

Page 29: Anbefalet Reservedelslager

Dk-3 anbefalet reservedelslager for at holde udstyret produktivt og i fuld driftsmæssig stand bør du have et lager af de dele, der mest almindeligt bruges i forbindelse med vedligeholdelsen af udstyret. Vi har anført reservedelsnumre på yderligere støttemateriale og uddannelseshjælpemidler. Der er g...

Page 30: Advarsel

1 sikkerhed dk-4 1 sikkerhed 1.1 driftssikkerhed _______________________________________________________ 1. Sikkerheden afhænger af, at de personer, der betjener eller efterser udstyret, udviser opmærksomhed, omtanke og forsigtighed. Tilladaldrigmindreårige at betjene udstyr af nogen art. 2. Det er ...

Page 31: Advarsel

Sikkerhed 1 dk-5 1.2 vigtige bemÆrkninger om sikkerhed ___________________________________ dette sikkerhedsadvarselssymbol advarer om mulige farer. Fare - angiver en overhængende farlig situation, som, hvis den ikke undgås, vil resultere i død eller alvorlig personskade. Advarsel - angiver en potent...

Page 32

2 specifikationer dk-6 2 specifikationer 2.1 identifikation af produkt ______________________________________________ 68080 ............................ Ar-5, 5 gear 4wd serienummer ................ En identifikationsplade - som vist - med serienummeret sidder på traktorens stel på operatørens højre...

Page 33

Specifikationer 2 dk-7 2.5 klippeenheder _________________________________________________________ samlet klippebredde........2,54 m antal klippeenheder.........Fem - tre for og to bag. Klippehøjde ................... 19-133 mm i trin på 6 mm 2.6 tilbehØr ____________________________________________...

Page 34: Advarsel

3 justeringer dk-8 3 justeringer 3.1 generelt _______________________________________________________________ 1. Justeringer og vedligeholdelse skal altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler af jacobsen, hvis korrekt justering ikke kan udføres. 2. Udskift, juster ikke,...

Page 35

Justeringer 3 dk-9 3.4 bremser ________________________________________________________________ juster bremserne efter udskiftning eller servicering af bremsekomponenter, eller hvis pedalvandringen bliver for stor. 1. Når du monterer nye bremseklodser, skal du polere klod- serne ved at køre traktore...

Page 36

3 justeringer dk-10 3.6 forlÆns og bakhastighed _____________________________________________ forlæns og bakhastighed justeres ved traktionspedalen. Indstil forlæns hastighed før justering af bakhastighed. Justering af forlæns hastighed : 1. Sørg for, drivpumpen er indstillet til frigear, og at moto...

Page 37: Advarsel

Justeringer 3 dk-11 3.8 klippehØjde ____________________________________________________________ skjoldenes klippehøjde kan justeres fra 19 til 133 mm i trin på 6 mm. Den faktiske klippehøjde kan variere noget fra de angivne højder afhængigt af plæneforhold og andre faktorer. Bemærk: ved klipning af...

Page 38: Advarsel

3 justeringer dk-12 3.9 kalibrering af traktionskontrolsystemet ___________________________ traktionskontrolsystemet (tcs) skal kalibreres, når en systemkomponent er blevet udskiftet, eller hvis systemet ikke fungerer korrekt. Systemkomponenterne omfatter styringsenhed, løfteventil, løftecylindre el...

Page 39: Forsigtig

Justeringer 3 dk-13 3.10 drejningsmomentspecifikation ________________________________________ jacobsen anvender overfladebehandlede bolte af grad 5 som standard, medmindre andet er angivet. Ved stramning af overfladebehandlede bolte, skal den værdi, der er oplyst for smurte bolte, angives. Forsigti...

Page 40: Advarsel

4 vedligeholdelse dk-14 4 vedligeholdelse 4.1 generelt ________________________________________________________________ 1. Justering og vedligeholdelse skal altid udføres af en uddannet tekniker. Kontakt en autoriseret forhandler af jacobsen, hvis korrekte justeringer ikke kan udføres. 2. Efterse ud...

Page 41: Advarsel

Vedligeholdelse 4 dk-15 4.4 luftfilter ______________________________________________________________ check serviceindikatoren dagligt. Hvis rød stribe vises i vinduet (b), skal elementet skiftes. Fjern ikke elementet med henblik på inspektion eller rensning. Unødig fjernelse af filteret øger risiko...

Page 42: Forsigtig

4 vedligeholdelse dk-16 4.7 batteri_________________________________________________________________ sørg med absolut sikkerhed for, at tændingslåsen står på „slukket“, og at nøglen er fjernet, før batteriet serviceres. Spænd kabler sikkert fast til batteripoler, og påfør poler og kabelender et tynd...

Page 43: Advarsel

Vedligeholdelse 4 dk-17 4.10 lyddÆmper og udstØdning _____________________________________________ efterse hele udstødningssystemet regelmæssigt, og udskift altid en defekt lyddæmper for at beskytte mod kulilteforgiftning. Stands omgående motoren, hvis du bemærker en forandring i udstødningens farve...

Page 44: Forsigtig

4 vedligeholdelse dk-18 4.13 hydrauliske oliefiltre ________________________________________________ hydrauliksystemet er beskyttet af to 10 mikrons-filtre; et tilbageløbsliniefilter. Gennemstrømning gennem filtrene overvåges under drift. Når trykfaldet over filtrene er for højt, tændes det hydrauli...

Page 45: Advarsel

Vedligeholdelse 4 dk-19 4.15 kØler __________________________________________________________________ efterse kølervæskestanden dagligt. Køleren bør være fuld, og genindvindingsflasken bør være fyldt op til kold- mærket. Tap og genopfyld køleren en gang om året. Fjern kølerdækslet, åben motorblokafl...

Page 46: Advarsel

4 vedligeholdelse dk-20 4.18 hjulmonteringsprocedure ____________________________________________ 1. Fjern snavs, fedt og olie fra pindbolten. Smør ikke gevind. 2. Placer hjul på nav, og efterse for at sikre fuld kontakt mellem monteringsoverfladen på hjul og nav eller bremsetromle. 3. Fingerspænd a...

Page 47: Advarsel

Vedligeholdelse 4 dk-21 4.20 slibning af knivene _____________________________________________________ 1. Anbring en træklods mellem kniven og plæneklipperhuset for at forhindre kniven i at bevæge sig. 2. Ved tilhugning eller slibning af knivene skal du ikke følge det oprindelige slibemønster som vi...

Page 48: Forsigtig

4 vedligeholdelse dk-22 4.22 opbevaring ____________________________________________________________ generelt 1. Vask traktoren grundigt, og smør den. Reparer og mal beskadiget eller blotlagt metal. 2. Efterse traktoren, spænd alle beslag, udskift slidte eller beskadigede komponenter. 3. Tøm og geno...

Page 49

Fejlfinding 5 dk-23 5 fejlfinding 5.1 generelt _______________________________________________________________ nedenstående fejlfindingsskema nævner grundlæggende problemer, som kan opstå under opstart og betjening. Kontakt den lokale jacobsen-distributør for at få flere oplysninger om de hydraulisk...

Page 50

5 fejlfinding dk-24 5.2 kontrollamper ________________________________________________________ styreenheden er en faststofindretning, som overvåger og styrer de elektriske funktioner. Styreenheden modtager indgangssignaler fra forskellige kontakter og sensorer i hele maskinen og transmitterer udgang...

Page 51

Fejlfinding 5 dk-25 5.3 elektriske kredslØb ___________________________________________________ når du foretager fejlfinding på maskinen, skal du altid se efter, at program aktiv-lampe (1, 2 og 3 - 5 gear) (2 og 3 - 7 gear) tændt. Disse angiver, at styreenheden har strøm på, og at programmet er akti...

Page 52: Advarsel

6 vedligeholdelses- og smØringsplaner dk-26 6 vedligeholdelses- og smØringsplaner 6.1 generelt _______________________________________________________________ 1. Rengør altid fedtfittingen før og efter smøring. 2. Smør med fedt, som opfylder eller er bedre end nlgi grad 2 lb-specifikationerne. Tilfø...

Page 53

Vedligeholdelses- og smØringsplaner 6 dk-27 6.3 smØringsplan __________________________________________________________ 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3 3 3 4 4 4 4 4 5 6 7 7 8 8 9 9 10 11 11 11 smørenipler f1 - 50 timer (hver uge) 1 klippeenhedens drejetap (5) 2 løftearmens drejetap (5) 3 løftecylinde...

Page 54

7 parts catalog 7 parts catalog 7.1 table of contents _____________________________________________________ 1.1 ........ Decals ..................................................................... 30 2.1 ........ Hood ....................................................................... 32 3.1 .....

Page 55

Parts catalog 7.

Page 56: Ar-5

30 2 17 2 4 5 6 7 8 10 12 20 20 20 19 19 19 11 22 14 / 15 17 13 16 3 11 1 18 9 1. Read operators manual. Do not allow untrained operators to use machine. 2. Keep shields in place and hardware securely fastened. 3. Before you clean, adjust or repair this equiptment, disengage all drives, engage parki...

Page 57: 105

31 > change from previous revision to avoid injury when working with battery 1. Always connect the black ground (–) cable last and remove it first. 2. Keep sparks and flames away, and avoid contatc with acid. To avoid injury when jumping battery 1. Connect positive (+) terminal to positive (+) termi...

Page 58: Ar-5

32 1 2 17 22 5 4 9 3 18 15 17 20 22 16 19 10 10 7 16 11 14 12 8 16 15 21 6 ar-5 2.1 hood serial no. All lf34-1.

Page 59: Ar-5

33 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4123226 1 hood 2 4124443 1 • foam, front 3 4124437 1 • foam, right side 4 4124436 1 • foam, left side 5 4124442 1 • foam, top 6 557620 4 • molding 7 4129679 1 seal, left side air 8 4129680 1 seal, right sid...

Page 60: Ar-5

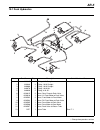

34 10 3 19 5 6 9 4 30 16 19 24/25 2 6 9 8 22 23 18 6 9 10 1 20 21 12 7 14 15 13 19 11 8 26 27 17 8 28 29 31 33 34 37 38 39 35 36 32 32 ar-5 3.1 seat pan serial no. All.

Page 61: Ar-5

35 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 1004279 1 floorpan 2 3009292 1 seat pan 3 4129685 1 support, seat 4 4131137 1 adjuster, double latching 5 4130641 1 base, seat 6 400258 9 screw, 3/8-16 x 3/4” hex head 7 441602 4 carriage bolt, 5/16-18 x 3/...

Page 62: Ar-5

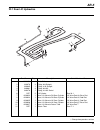

36 2 3 5 6 7 8 9 34 10 12 11 13 14 16 18 19 20 21 22 32 23 24 27 28 29 30 31 4 33 33 17 15 25 26 1 7 ref 17 ar-5 4.1 control panel serial no. All.

Page 63: Ar-5

37 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4130114 1 instrument panel includes silk screen decals 2 4129683 1 hour meter, quartz reference u-3, see 41.1 3 365943 1 fuel gauge reference u-2, see 41.1 4 3005121 1 water temperature gauge reference u-1,...

Page 64: Ar-5

38 2 2 3 5 6 6 7 8 9 10 12 11 13 14 14 16 18 19 20 20 21 21 22 22 23 23 24 27 27 27 27 27 27 28 28 29 30 31 33 4 17 15 25 26 26 26 32 1 ar-5 5.1 traction pedal serial no. All.

Page 65: Ar-5

39 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 1003288.7 1 treadle pivot 2 352726 2 • bushing 3 3007230 1 stop, mow speed 4 3003474 1 grip, pedal 5 3003475 1 grip, pedal 6 3004384 2 rod end 7 4125831 1 switch, proximity reference sw-7, see 41.1 8 300632...

Page 66: Ar-5

40 2 3 5 6 7 7 8 9 9 10 12 11 13 13 14 14 16 16 18 18 19 20 21 22 23 24 27 4 17 15 15 25 26 1 ar-5 6.1 brake pedal serial no. All.

Page 67: Ar-5

41 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 3006838 1 bracket, brake 2 4125831 1 switch, proximity reference sw-8, see 41.1 3 3006327 1 shaft, turn assist 4 3007606 1 lever, parking brake 5 3006997 1 mount, brake 6 1003616 1 brake arm 7 352726 2 • bu...

Page 68: Ar-5

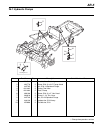

42 4 5 6 7 8 9 13 14 15 16 17 19 20 21 21 22 23 27 28 29 33 33 33 33 32 32 31 31 40 40 38 38 30 30 1 2 3 18 11/12 25/26 10 10 23 23 20 24 35 36 37 39 34 34 ar-5 7.1 frame and front axle serial no. All.

Page 69: Ar-5

43 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4133033 2 tire 2 5002574 2 rim 3 360111 2 valve, inflation 4 4118254 2 wheel motor see 34.1 5 557623 2 • key 6 557624 2 • nut, hex 7 4118092 1 frame 8 366871 2 • bushing 9 4118134 1 front axle 10 4133054 2 ...

Page 70: Ar-5

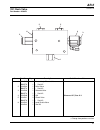

44 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 11 11 ar-5 8.1 tilt steering serial no. All.

Page 71: Ar-5

45 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 5002918 1 actuator, gas spring 2 5002919 1 cable, actuator 3 2811346 1 tower, steering 4 1003458 1 valve, steering see 38.1 339979 3 • adapter, straight 339974 2 • adapter, straight 5 443828 1 • nut, 5/8-18...

Page 72: Ar-5

46 2 3 5 6 7 8 9 9 9 9 10 12 11 13 14 16 16 18 19 20 21 22 23 23 24 27 28 29 30 30 31 33 34 4 4 4 17 17 15 15 25 26 32 1 ar-5 9.1 rear axle serial no. All.

Page 73: Ar-5

47 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 178032-01 2 tire 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 117139 1 steering axle 9 363562 ...

Page 74: Ar-5

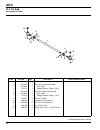

48 > change from previous revision 2 3 5 6 7 8 8 9 9 10 10 12 12 11 11 4 1 ar-5 10.1 tie rod part number 4132688 serial no. All item part no. Qty. Description serial numbers/notes 1 4118210 1 tie rod 2 4121828 1 ball joint, left hand thread 3 4121986 1 • dust cover 4 471214 1 • straight grease fitti...

Page 75: Ar-5

49 > change from previous revision 12 16 16 18 17 16 15 10 11 11 13 14 14 1 2 3 8 9 5 6 7 4 ar-5 item part no. Qty. Description serial numbers/notes 1 450190 2 screw, m8-1.25 x 16 mm hex head 4133238 1 kit, remote oil filter included with engine 2 4133239 1 • adapter, engine oil filter 3 4133240 1 •...

Page 76: Ar-5

50 2 2 2 2 2 3 5 5 6 7 8 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 24 24 27 28 32 28 29 30 31 31 4 4 17 15 33 25 26 1 ar-5 12.1 radiator and air cleaner serial no. All.

Page 77: Ar-5

51 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 3002195 1 elbow, 1/8 npf 90° 2 326112 5 clamp, 1-5/16 to 2-1/4” dia hose 3 345666 1 clamp, 1/2” p hose 4 337229 2 clamp, hose 5 5003447 ar tube, neoprene cut to 33” 6 365398 1 indicator, air cleaner 7 36652...

Page 78: Ar-5

52 2 2 2 2 2 2 2 2 3 5 6 6 7 7 8 8 8 8 9 9 10 10 10 10 12 11 13 14 16 18 18 18 18 19 19 20 20 21 22 22 24 23 23 23 23 4 17 25 25 15 15 15 15 1 26 24 24 9 ar-5 13.1 engine mounting serial no. All.

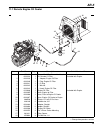

Page 79: Ar-5

53 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4118253 1 engine, v2003 mt 4113986 1 • filter, engine oil see 11.1 2 310711 12 washer, isolator 3 362263 1 screw, m10-1.25 x 25mm hex head 4 363485 1 lockwasher, m10 heavy 5 364501 1 temperature sender 6 36...

Page 80: Ar-5

54 2 3 5 6 7 8 9 10 2 8 9 10 12 11 13 14 16 18 19 20 20 21 22 23 24 27 28 4 17 15 25 24 27 25 26 1 28 view rotated 180˚ for clarity ar-5 14.1 pump mounting and engine exhaust serial no. All.

Page 81: Ar-5

55 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 362743 1 o-ring seal 2 400264 5 screw, 3/8-16 x 1-1/4” hex head 3 400286 2 screw, 3/8-16 x 2-3/4” hex head 4 400410 2 screw, 1/2-13 x 1-3/4” hex head 5 4118252 1 pump, traction see 39.1 and 40.1 6 4131571 1...

Page 82: Ar-5

56 a a b b connect to engine fuel injector overflow. Connect to engine fuel pump 1 30 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 19 19 20 21 24 19 18 18 18 15 18 18 18 28 23 27 22 29 25 26 18 18 ar-5 15.1 fuel and hydraulic tanks serial no. All.

Page 83: Ar-5

57 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 132647 1 valve, shut off 2 3001279 1 switch, float reference sw-9, see 41.1 3 3002397 1 plug, magnetic 339899 1 • o-ring 4 3009204 1 fuel tank 5 3005871 1 hydraulic tank 6 3005872 1 shell, tank cover 7 3006...

Page 84: Ar-5

58 > change from previous revision 9 3 6 4 7 2 5 1 2 1 1 7 8 ar-5 16.1 pump suction hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 3008673 5 clamp, constant torque hose 2 3008745 2 hose, gear pump suction 3 340090 1 fitting, 24-24 90° 4 4122538 1 hose, charge pump su...

Page 85: Ar-5

59 > change from previous revision 1 3 5 6 7 8 9 10 2 11 4 1 ar-5 item part no. Qty. Description serial numbers/notes 1 339999 2 fitting, 16-16 straight 2 4129037 1 hose, 4wd return 3 340077 1 fitting, 16-16 90° 4 340123 1 fitting, 16-16-16 swivel run tee 5 340039 1 fitting, 16-16 45° 6 4123166 1 fi...

Page 86: Ar-5

60 > change from previous revision 2 3 5 5 5 5 6 6 6 6 7 8 9 10 4 1 1 1 1 ar-5 18.1 hydraulic valves and filter serial no. All item part no. Qty. Description serial numbers/notes 1 400258 8 screw, 3/8-16 x 3/4” hex head 2 409811 4 screw, 5/16-18 x 5/8” thread cutting 3 4121554 1 hydraulic filter ass...

Page 87: Ar-5

61 > change from previous revision 2 2 3 5 5 6 7 8 8 9 10 12 11 13 4 4 4 4 4 4 4 4 4 4 4 1 10 ar-5 item part no. Qty. Description serial numbers/notes 1 339985 2 fitting, 8-10 straight 2 339989 3 fitting, 10-10 straight 3 340009 1 fitting, 10-10 straight 4 340070 11 fitting, 10-10 90° 5 340030 2 fit...

Page 88: Ar-5

62 2 3 3 5 6 7 8 9 9 9 9 9 9 9 9 10 12 11 13 14 16 16 18 19 19 20 21 22 22 23 24 4 4 17 17 15 1 1 1 1 1 21 ar-5 20.1 traction hydraulics serial no. All.

Page 89: Ar-5

63 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 339994 5 adapter, 12-12 straight fitting 2 4129035 1 hose, 4wd valve to traction pump 4wd valve port i 3 339993 2 adapter, 12-10 straight fitting 4 4128939 2 hose, 4wd valve to wheel motor 4wd valve port b ...

Page 90: Ar-5

64 > change from previous revision 2 2 2 2 3 3 5 5 5 6 7 8 9 10 11 4 4 4 4 1 1 1 ar-5 21.1 front lift hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 3000953 3 disk, orifice 2 339979 6 fitting, 6-6 straight 3 340026 2 fitting, 6-6 45° 4 340061 4 fitting, 6-6 90° 5 ref...

Page 91: Ar-5

65 > change from previous revision 2 2 3 6 7 8 9 10 11 12 6 5 4 4 4 4 1 1 ar-5 item part no. Qty. Description serial numbers/notes 1 3000953 2 disk, orifice 2 339979 4 fitting, 6-6 straight 3 339985 1 fitting, 8-10 straight 4 340061 4 fitting, 6-6 90° 5 340376 1 fitting, 8-8 90° swivel 6 ref 2 lift ...

Page 92: Ar-5

66 > change from previous revision 2 3 5 6 7 8 8 9 10 10 12 11 13 13 14 4 1 ar-5 23.1 wheel motor case drains serial no. All item part no. Qty. Description serial numbers/notes 1 4129038 1 hose, lh rear motor to drain tube 2 4129039 1 hose, rh rear motor to drain tube 3 4129040 1 hose, rh front moto...

Page 93: Ar-5

67 > change from previous revision 2 3 5 5 5 5 6 7 8 8 9 10 10 10 10 10 11 4 1 1 ar-5 item part no. Qty. Description serial numbers/notes 1 4129593 2 hose, front motor to front motor 2 4129599 1 hose, front motors to drain tube 3 4129600 1 hose, rear motors to drain tube 4 4129603 1 hose, rear motor...

Page 94: Ar-5

68 > change from previous revision to return tube (3) from pump (2) to steering cylinder (4) to steering cylinder (5) aux in out lt rt to lift valve (1) 6 2 3 5 7 7 4 1 ar-5 25.1 steering hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 4129028 1 hose, lift valve to st...

Page 95: Ar-5

69 > change from previous revision steering hoses 3 2 1 4 5 9 10 6 6 7 ar-5 item part no. Qty. Description serial numbers/notes 1 1004541 1 bracket, hose retaining 2 403770 2 screw, 5/16-18 x 3/4” flange head 3 445795 2 nut, 5/16-18 spiralock flange 4 4131862 2 clamp, two hose 5 4131864 2 plate, cla...

Page 96: Ar-5

70 2 3 3 3 5 5 5 6 7 7 8 9 9 9 9 9 9 10 10 10 12 12 12 11 11 11 11 11 11 13 14 16 18 18 18 18 18 18 19 20 20 21 22 23 23 29 29 24 27 27 27 28 28 4 4 4 4 4 4 17 17 17 15 25 25 25 26 26 26 1 1 ar-5 27.1 front lift arms serial no. All.

Page 97: Ar-5

71 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 548905 9 screw, 3/8-16 x 1” serrated flange 2 ref 3 deck assembly see 30.1 3 4125547 3 front deck pivot 4 4127480 2 • bushing 5 471214 1 • straight grease fitting 6 4125919 1 center lift arm 7 3010489 2 • b...

Page 98: Ar-5

72 6 13 15 21 8 8 11 12 10 14 14 22 9 19 18 19 1 17 16 25 4 4 23 24 2 5 3 7 27 27 20 13 15 21 8 8 14 14 22 19 18 26 19 1 17 16 25 4 4 23 24 2 3 7 20 ar-5 28.1 rear lift arms serial no. All.

Page 99: Ar-5

73 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4131422 2 pin, rear cylinder 2 4131420 2 pin, rear lift arm 3 4126450 2 pin, cylinder 4 445783 6 nut, 3/8-16 whizlock flange 5 548905 4 screw, 3/8-16 x 1” serrated flange 6 4123167 2 deck assembly see 30.1 ...

Page 100: Ar-5

74 a b c d e f g h j k l m a - headlight b - lift arm limit switch c - fuel level sender/ instrument panel d - seat switch e - oil float switch f - glow plugs g - fuel solenoid h - charge filter switch j - engine oil pressure switch k - temperature sender l - 4wd valve (4wd only) m - reel valve 2 3 ...

Page 101: Ar-5

75 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 2810424 1 cable, engine ground engine mount to frame 2 4122840 2 headlight reference l-1 & l-2, see 41.1 4123183 1 • bulb 3 4122841 1 controller reference u-6, see 41.1 4 5003282 2 • fuse, 20 amp reference ...

Page 102: Ar-5

76 2 3 5 6 7 8 9 9 9 10 12 11 13 14 16 18 19 20 21 22 23 24 4 17 17 15 25 26 1 27 28 ar-5 30.1 deck housing and caster wheels serial no. All.

Page 103: Ar-5

77 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 3004894 2 pin, 7/16 x 1-3/4” snap ring 2 3007764 1 washer, blade 3 3008388 1 adapter, blade 4 400410 1 screw, 1/2-13 x 1-3/4” hex head 5 400426 2 screw, 1/2-13 x 5” hex head 6 4117807 3 spacer 7 4123171 1 d...

Page 104: Ar-5

78 2 2 3 3 5 5 5 5 6 6 7 8 9 10 10 12 12 11 11 13 14 16 16 18 18 19 19 20 20 22 23 23 24 24 25 23 4 17 / 21 15 15 1 ar-5 31.1 deck frame serial no. All.

Page 105: Ar-5

79 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 400404 4 screw, 1/2-13 x 1” hex head 2 400408 4 screw, 1/2-13 x 1-1/2” hex head 3 400418 4 screw, 1/2-13 x 3” hex head 4 4123168 1 deck frame 5 4127478 4 • flanged bushing 6 471214 2 • straight grease fitti...

Page 106: Ar-5

80 > change from previous revision 1 8 3 4 4 2 5 5 6 7 7 6 ar-5 32.1 brake assemblies serial no. All item part no. Qty. Description serial numbers/notes 1 340603 2 bracket, brake mounting 4118913 1 disk brake, r.H. 4118912 1 disk brake, l.H. 2 4118987 1 • bracket, housing 3 4118986 1 • cam, lever 4 ...

Page 107: Ar-5

81 > change from previous revision 1 2 3 4 5 5 6 ar-5 33.1 deck valve part number 4129070 serial no. All item part no. Qty. Description serial numbers/notes 1 4134537 2 vented logic element valve 5003579 1 • seal kit 2 4134538 1 relief valve 5003578 1 • seal kit 3 4134539 1 solenoid valve 5003578 1 ...

Page 108: Ar-5

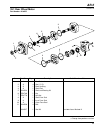

82 > change from previous revision 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 1 2 3 4 5 6 ar-5 34.1 front wheel motor part number 4118254 serial no. All item part no. Qty. Description serial numbers/notes 1 558066 8 screw, torx 2 5002110 1 front retainer 3 558063 1 shaft and bearing kit 4 557624 1 nu...

Page 109: Ar-5

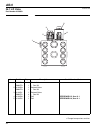

83 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 ar-5 35.1 rear wheel motor part number 4118255 serial no. All item part no. Qty. Description serial numbers/notes 1 a 1 seal exclusion 2 a 4 seal, 3” i.D. 3 a 1 back up ring 4 a 1 shaft seal 5 4134524 1 shaft and bearing kit 6 554780 1...

Page 110: Ar-5

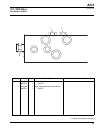

84 > change from previous revision 1 2 3 4 5 ar-5 36.1 lift valve part number 4129069 serial no. All item part no. Qty. Description serial numbers/notes 1 4134528 1 check valve 5003579 1 • seal kit 2 4134529 1 solenoid valve 5003579 1 • seal kit 3 4134531 1 solenoid valve 5003578 4 • seal kit 4 4134...

Page 111: Ar-5

85 > change from previous revision 1 1 2 ar-5 37.1 4wd valve part number 4129071 serial no. All item part no. Qty. Description serial numbers/notes 1 4134533 2 check valve 5003579 1 • seal kit 2 4134535 1 pilot operated internal vent valve 5003579 1 • seal kit.

Page 112: Ar-5

86 ar-5 38.1 steering valve part number 1003458 serial no. All 1 2 3 4 5 6 7 8 10 9 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 31 32 33 34 35 36 37 4 4 4 11 11 38 30

Page 113: Ar-5

87 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 443108 4 locknut, 5/16-18 center 2 n/s 1 port cover 3 c 1 seal, o-ring 4 c 4 seal, o-ring 5 c 4 seal, o-ring 6 443828 1 nut, 5/8-18 hex jam 7 n/s 4 special bolt 8 n/s 1 port manifold 9 b 3 spring, port side...

Page 114: Ar-5

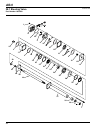

88 6 15 22 19 20 2 1 3 4 18 21 14 13 13 8 8 9 9 163 10 11 12 5 22 21 23 17 7 16 ar-5 39.1 traction pump (front half) part number 4118252 serial no. All.

Page 115: Ar-5

89 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4134588 1 shim kit ● 2 n/s 1 o-ring 3 4134589 1 charge relief spring 4 4134590 1 charge relief valve 5 4134591 2 o-ring 6 4134592 1 needle bearing 7 4134594 1 roller bearing 8 4134595 2 retaining ring 9 413...

Page 116: Ar-5

90 10 10 2 3 4 1 7 1 8 9 11 11 15 17 16 5 12 13 6 6 14 ar-5 40.1 traction pump (rear half) part number 4118252 (cont) serial no. All.

Page 117: Ar-5

91 > change from previous revision ar-5 item part no. Qty. Description serial numbers/notes 1 4134615 1 o-ring 2 4134616 1 o-ring ● 3 ns 1 o-ring ● 4 ns 1 temper load ring 5 4134617 1 neutral return spring ● 6 4134618 1 piston ring kit 7 4134619 1 gerotor ● 8 ns 1 suction filter adapter seal 9 41346...

Page 118: Ar-5

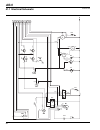

92 a b c d e f g h j k l m n sw-6 sw-13 2 3 r db og/wh og/bk lb/wh pk/bu ye/bu gy/rd og/wh ye ye og/y e db pu/gn og dg dg tn/bk db pu/gn tn/bk + – k-2 k-1 u-7 sw-2 sw-3 cb-1 l-1 l-3 l-5 l-4 l-6 l-2 r-3 m-1 b-1 r-2 u-1 u-2 u-3 r-3 l l b s s g g i og/wh og/wh og/wh og/wh og/bk og/wh lb/tn tn lb/tn lb/...

Page 119: Ar-5

93 bk 1-5 1-4 3-2 3-8 grd-1 4-1 4-2 4-3 4-4 2-1 3-12 2-12 1-2 1-7 1-8 1-9 1-10 1-11 1-12 1-1 2-2 2-6 2-5 2-8 2-11 1-6 1-3 3-4 3-5 3-3 3-6 3-7 pk/bu y e/bu og/y e og/y e og/pk og/pk select 3 select 4 select 2 select 1 star t rela y glo w plug rela y glo w plug light lights hyd le v el light switches ...

Page 120: Ar-5

94 ar-5 item reference illustration part number description serial numbers/notes b-1 see 29.1 366931 battery cb-1 see 29.1 361439 50 amp circuit breaker (alternator) f-1 see 29.1 5003282 20 amp fuse (ignition circuit) included in controller f-2 see 29.1 5003282 20 amp fuse (lights) included in contr...

Page 121: Ar-5

95 ar-5 u-1 see 4.1 3005121 temperature gauge u-2 see 4.1 365943 fuel gauge u-3 see 4.1 4129683 hour meter u-4 see 4.1 366670 horn u-5 not shown cruise control module (option) u-6 see 29.1 4122841 controller u-7 not shown 5000938 alternator included in engine item reference illustration part number ...

Page 122: Ar-5

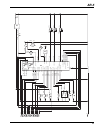

96 p2 g2 g1 m2 m1 r2 r1 p1 t .5 ci .5 ci .5 ci 3625 psi 2600 psi 3625 psi supply .028 drain .031 285 psi 2.81 ci displacement control tow valve 3000 rpm a b traction pump gear pump rr deck motor deck valve lr deck motor rf deck motor 10 micron 25 psi crack bypass 30 psi crack bypass 100 mesh screen ...

Page 123: Ar-5

97 p t c1 c2 c3 c4 c5 c6 c10 c9 c8 c7 left front cylinder steering unit in out aux lt rt 4.13 ci 1450 psi 30.0 ci 30.0 ci front wheel motors rear wheel motors 24.0 ci 24.0 ci lift valve a b c d e f g 4wd valve f a g b h c i d e .040 .050 right front cylinder .040 center front cylinder .040 right rea...

Page 124: Ar-5

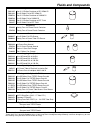

98 x w w w x w x w w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size w-x o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face sea...

Page 125: Ar-5

99 > change from previous revision ar-5 adapter part number. Dash size adapter type (w) o-ring (x) o-ring (y) o-ring (z) o-ring 339974 4-6 straight adapter 339908 339897 339977 6-4 straight adapter 339909 339896 339979 6-6 straight adapter 339909 339897 339985 8-10 straight adapter 339910 339899 339...

Page 126: Fluids And Compounds

Fluids and compounds * refer to the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Textron golf, turf & specialty products offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See your local tgtsp dealer for a...

Page 127: Index

101 index 1002657 ...................... 45 1002810 ...................... 37 1003047 ...................... 43 1003048 ...................... 43 1003288 ...................... 39 1003458 ...................... 45 1003616 ...................... 41 1003638 ...................... 47 1003872 .............

Page 128: Index

102 index 4124076.......................77 4124087.......................77 4124129.......................79 4124166.......................53 4124204.......................48 4124395.......................79 4124423.......................79 4124425.......................79 4124436......................

Page 129: Index

103 index 5000318 ...................... 82 5002110 ...................... 82 5002574 ...................... 43 5002918 ...................... 45 5002919 ...................... 45 5003034 ................ 89 , 91 5003076 ...................... 35 5003219 ...................... 87 5003220 ..............

Page 130

Textron golf, turf & specialty products po box 7708, charlotte, nc 28241-7708 www.Ttcsp.Com equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and factory trained technicians backed b...