- DL manuals

- Jacobsen

- Trimmer

- AR3

- Safety, Operation & Maintenance Manual

Jacobsen AR3 Safety, Operation & Maintenance Manual

Safety, Operation & Maintenance Manual

WARNING: If incorrectly used this machine can cause

severe injury. Those who use and maintain this machine

should be trained in its proper use, warned of its dangers and

should read the entire manual before attempting to set up,

operate, adjust or service the machine.

GB

United

Kingdom

RJL 100 February 2010

Series: EK

Product code: AR30001

Series: FZ

Product code: AR30002

Series: GX

Product code: AR30003

Jacobsen AR3

24715G-GB (rev.4)

Summary of AR3

Page 1

Safety, operation & maintenance manual warning: if incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the entire manual before attempting to set up, operate, adjust or service the m...

Page 2

© 2010, ransomes jacobsen limited. All rights reserved.

Page 3

En-3 jacobsen ar3 safety, operators & maintenance manual 1 contents 2 introduction 2.1 important ................................................................ 4 2.2 product identification...................................... 4 2.3 guidelines for the disposal products ..... 4 3 safety instruction...

Page 4

En-4 jacobsen ar3 safety, operators & maintenance manual 2 introduction 2.1 important important: this is a precision machine and the service obtained from it depends on the way it is operated and maintained. This safety and operators manual should be regarded as part of the machine. Suppliers of bot...

Page 5

En-5 jacobsen ar3 safety, operators & maintenance manual 2 introduction 2.3 guidelines for the disposal of scrap products 2.3.1 during service life used oil, oil filters and engine coolant are hazardous materials and should be handled in a safe and environmentally responsible way. In the event of a ...

Page 6

En-6 jacobsen ar3 safety, operators & maintenance manual 3 safety instructions this safety symbol indicates important safety messages in this manual. When you see this symbol, be alert to the possibility of injury, carefully read the message that follows, and inform other operators. 3.1 operating in...

Page 7

En-7 jacobsen ar3 safety, operators & maintenance manual 3 safety instructions 3.6 leaving the driving position • park the machine on level ground. • before leaving the driving position, stop the engine and make sure all moving parts are stationary. Apply brakes and disengage all drives. Remove the ...

Page 8

En-8 jacobsen ar3 safety, operators & maintenance manual 3 safety instructions • when pressure washing the mower. Turn the engine off and remove the starter key. If the engine has been running, it should be allowed to cool sufficiently to prevent damage to the block and exhaust manifold. Never force...

Page 9

En-9 jacobsen ar3 safety, operators & maintenance manual 4 specifications 4.1 engine specification type: kubota 24.5kw (32.8hp) @ 3000 rpm, 3 cylinder (in line) turbo charged diesel engine, 4 stroke, water cooled, 1123cc (68.53 cu.In) with 12v 1kw electric start, 12v 30amp alternator model: d1105-t-...

Page 10

En-10 jacobsen ar3 safety, operators & maintenance manual 4 specifications 4.4 vibration level when the machine was tested for hand/arm vibration levels. The operator was seated in the normal operating position with both hands on the steering mechanism. The engine was running and the cutting device ...

Page 11

En-11 jacobsen ar3 safety, operators & maintenance manual 4.6 cutting unit specification general: three 686mm (27in) rotary mulching/rear discharge decks. Drive: fixed displacement hydraulic motors directly coupled to cutting unit. Control: cutting unit lift lever with automatic shut off and safety ...

Page 12

En-12 jacobsen ar3 safety, operators & maintenance manual 4 specifications 4.9 conformity certificates business name and full address of the manufacturer ƒ Ɍɴɪɝɨɜɫɤɨ ɢɦɟ ɢ ɩɴɥɟɧ ɚɞɪɟɫ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ ƒ obchodní jméno a plná adresa výrobce ƒ producentens firmanavn og fulde adresse ƒ bedrijfsnaam en ...

Page 13

En-13 jacobsen ar3 safety, operators & maintenance manual operator ear noise level ƒ Ɉɩɟɪɚɬɨɪ ɧɚ ɧɢɜɨɬɨ ɧɚ ɞɨɥɨɜɢɦ ɨɬ ɭɯɨɬɨ ɲɭɦ ƒ hladina hluku v oblasti uší operátora ƒ støjniveau i førers ørehøjde ƒ geluidsniveau oor bestuurder ƒ müratase operaatori kõrvas ƒ melutaso käyttäjän korvan kohdalla ƒ ni...

Page 14

En-14 jacobsen ar3 safety, operators & maintenance manual 5 decals 5.2 instruction decals ec description a. Maximum sound power level b. Ignition switch c. Throttle control d. Cutting unit lift e. Fwd/rev traction pedal f. Weight transfer g. Parking brake h. Jacking point j. Slinging point a b c d e...

Page 15: Danger

En-15 jacobsen ar3 safety, operators & maintenance manual 5.3 safety decals usa 5.4 instruction decals usa a. Ignition switch b. Throttle control c. Cutting unit lift d. Fwd/rev traction pedal e. Weight transfer f. Parking brake g. Jacking point h. Slinging point description d b c 5 decals a e tc f ...

Page 16

En-16 jacobsen ar3 safety, operators & maintenance manual 6.1 instrument panel a: starter key switch b: working light switch c: parking brake switch d: cutter switch e: weight transfer switch f: blocked hydraulic filter warning lamp g: charge warning lamp h: engine coolant temperature warning lamp j...

Page 17

En-17 jacobsen ar3 safety, operators & maintenance manual 6.1a starter key switch the starter key (a) should be turned clockwise to the 'pre-heat' (no. 2) position to heat the glowplugs when the green warning lamp goes out, on warning lamp display module, turn the starter key clockwise to the 'start...

Page 18

En-18 jacobsen ar3 safety, operators & maintenance manual 6 controls 6.1e weight transfer switch this switch allows the operator to transfer weight off the cutting units onto the machine. This gives the machine better traction. Depress the rocker switch to transfer weight off the cutting units, the ...

Page 19

En-19 jacobsen ar3 safety, operators & maintenance manual 6.1m throttle control lever the lever should be moved away from the operator to increase the engine speed and towards the operator to decrease the engine speed. Note: engine should be used at full speed. 6.1n joystick unit lift/lower control ...

Page 20

En-20 jacobsen ar3 safety, operators & maintenance manual 6 controls 6.1p multi-function gauge(prior to s/n gx000396) the various functions can be selected using the left hand button the fuel level is displayed on a digital bargraph in the upper segment of the display. The clock, time to service and...

Page 21

En-21 jacobsen ar3 safety, operators & maintenance manual 6 controls 6.2 traction foot pedal a. Forward travel (traction pedal) press front of pedal down for forward travel. Release pedal to slow tractor and stop. Do not press traction pedal when parking brake is set and parking brake light (w) is l...

Page 22

En-22 jacobsen ar3 safety, operators & maintenance manual 6.5 parking brake release valve the parking brake release valve is situated under the operators platform, close to the front axle. It is used to release the parking brake when the engine is not running the parking brake can be released by rot...

Page 23

En-23 jacobsen ar3 safety, operators & maintenance manual 7 operation 7.1 daily inspection 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware and missing or damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and tubes are...

Page 24

En-24 jacobsen ar3 safety, operators & maintenance manual 7 operation 7.2 operator presence and safety interlock system 1. The operator presence & safety interlock system prevents the engine from starting unless the parking brake is on, and the mowing device is switched off. The system also stops th...

Page 25

En-25 jacobsen ar3 safety, operators & maintenance manual 7 operation 7.3 operating procedure 1. Under no circumstances should the engine be started without the operator seated on the tractor. 2. Do not operate tractor or attachments with loose, damaged or missing components. Whenever possible mow w...

Page 26

En-26 jacobsen ar3 safety, operators & maintenance manual 9. Slow down and use extra care on hillsides. Read section 3.7. Use caution when operating near drop off points. 10. Never use your hands to clean cutting units. Use a brush to remove grass clippings from blades. Blades are extremely sharp an...

Page 27

En-27 jacobsen ar3 safety, operators & maintenance manual 7 operation operation of the machine read the safety instructions. Before operating for the first time • check and adjust tyre pressure, if necessary, section 4 specification. • add diesel fuel to tank if neccesary. • check engine oil and top...

Page 28

En-28 jacobsen ar3 safety, operators & maintenance manual 7 operation 15° maximum 15° maximum 7.9 mowing on slopes the mower has been designed for good traction and stability under normal mowing conditions. Use caution when operating on slopes, especially when the grass is wet. Wet grass reduces tra...

Page 29

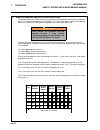

En-29 jacobsen ar3 safety, operators & maintenance manual 7 operation 15° maximum a = maximum allowable slope . How to calculate a slope tools: spirt level 1 metre long. Tape measure. With the spirt level (a) positioned horizontally measure the distance (c) with tape measure (b) use the chart to cal...

Page 30

En-30 jacobsen ar3 safety, operators & maintenance manual 7 operation use either of these columns but not both the result of what you are measuring height c in inches measured with a 1 yard horizontal edge a height c in millimeters measured with a 1 metre horizontal edge a slope angle d measured in ...

Page 31

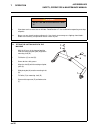

En-31 jacobsen ar3 safety, operators & maintenance manual 7 operation a use of inclinometer when fitted. The inclinometer (a) is located on the left hand side of the footplate forward of the foot rest. When working on slopes the device indicates when the machine is working within stability limits (t...

Page 32

En-32 jacobsen ar3 safety, operators & maintenance manual 8 maintenance & lubrication 8.1 maintenance & lubrication chart maintenance and lubrication chart interval item section first 50 hours change engine oil check fan belt tension change hydraulic filter 82 8.3 8.5 daily 10 hours check engine oil...

Page 33

En-33 jacobsen ar3 safety, operators & maintenance manual 8 maintenance & lubrication.

Page 34

En-34 jacobsen ar3 safety, operators & maintenance manual 8.2 engine lubrication check engine oil level check the engine oil level before starting or more than five minutes after stopping the engine. (a) with the machine on level ground, remove the dipstick, wipe it clean and replace. (b) take the d...

Page 35

En-35 jacobsen ar3 safety, operators & maintenance manual 8.4 engine coolant check engine coolant level (a) the level of coolant in the expansion tank should be between the max and min level indicators when cold. (b) if topping up is required, remove the plastic cap and top up using the correct anti...

Page 36

En-36 jacobsen ar3 safety, operators & maintenance manual 8 maintenance & lubrication change hydraulic oil filter (a) wipe filter canister (a) and housing to remove any dirt present. (b) place a suitable drip tray under the filter. (c) unscrew filter and dispose of safely. (d) replace with new filte...

Page 37

En-37 jacobsen ar3 safety, operators & maintenance manual 8.6 hydraulic test ports if any problems are experienced with the hydraulic system service ports are provided to enable pressures to be checked. All tests, unless stated otherwise, should be carried out with the hydraulic oil at normal workin...

Page 38

En-38 jacobsen ar3 safety, operators & maintenance manual 8.7 fuel system use diesel fuel no.2-d (astm d975) see engine manufacturer's manual for additional information. Bleeding air from fuel system (a) turn the ignition switch to the on position (don't start engine). (b) open air vent (b) on fuel ...

Page 39

En-39 jacobsen ar3 safety, operators & maintenance manual 8.8 air cleaner cleaning the air filter note: after 6 cleanings replace the filter element. (a) raise engine cover. (b) remove end cap of air filter cartridge. (c) remove loose dirt from element with compressed air working from the clean to d...

Page 40

En-40 jacobsen ar3 safety, operators & maintenance manual storage • store petrol or diesel fuel in an approved container in a cool dry place. • keep the machine and fuel containers in a locked storage place to prevent tampering and to keep children from playing with them. • do not store fuel or petr...

Page 41

En-41 jacobsen ar3 safety, operators & maintenance manual 9.1 traction control pedal adjustment to eliminate wheel creep. 1. Lift and support both front and rear wheels. 2. Remove ball joint a from foot pedal c to allow damper b to set pedal neutral position. 3. Start engine, manually move the pump ...

Page 42

En-42 jacobsen ar3 safety, operators & maintenance manual 9 adjustments 9.3 height of cut cutting height for decks can be adjusted from 3/4 to 4 in. (19-101.6 mm) in 1/2 in. (13 mm) increments. Actual cutting height may vary somewhat from the heights given depending on turf conditions and other fact...

Page 43

En-43 jacobsen ar3 safety, operators & maintenance manual 3. To lower height of cut, remove all three snap lock pins (a). Lift outer spindle shaft (b) slightly and remove 13mm (1/2") spacers (d) and / or 6mm (1/4") spacer (e) from bottom one at a time until desired height is obtained. Carefully remo...

Page 44

En-44 jacobsen ar3 safety, operators & maintenance manual 9 adjustments 9.5 blade sharpening blades may be sharpened by filing or grinding. When sharpening, maintain blade balance within 19.4 g/cm (5/8 oz/in). Failure to keep the blade balanced causes excess vibration, blade wear and shortened blade...

Page 45

En-45 jacobsen ar3 safety, operators & maintenance manual 9 adjustments 9.7 seat (milsco ce-200) the seat can be adjusted for operator's weight and leg reach to provide a comfortable position for operating the machine. A. Adjustment for operator weight to adjust: whilst sitting on the seat push knob...

Page 46

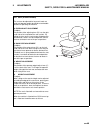

En-46 jacobsen ar3 safety, operators & maintenance manual 9.8 seat (michigan v5300) the seat can be adjusted for operator's weight and leg reach to provide a comfortable position for operating the machine. A. Adjustment for operator weight to adjust: whilst standing in front of the machine, rotate k...

Page 47

En-47 jacobsen ar3 safety, operators & maintenance manual 9.9 general instructions for grammer seats • the operating instructions must be read in full before use. • the operating instructions must be kept in the vehicle and always be at hand. • the driver’s seat may only be fitted, serviced and repa...

Page 48

En-48 jacobsen ar3 safety, operators & maintenance manual 9 adjustments do not hold onto the covers for lifting the driver’s seats. If you do so anyway, there is an increased risk of injury due to loosening or breaking covers. Before you remove the driver’s seat, disconnect all plug-in connections b...

Page 49

En-49 jacobsen ar3 safety, operators & maintenance manual 9.10 seat (grammer msg85) the seat can be adjusted for leg reach, back rest angle and operator weight to provide a comfortable position for operating the machine. A. Fore and aft adjustment to adjust: the position of the adjusting lever (b) i...

Page 50

En-50 jacobsen ar3 safety, operators & maintenance manual 9.11.1 weight adjustment the seat is adjusted for the driver’s weight by pulling or pressing the lever for seat weight adjustment and with the driver sitting on the seat. The driver’s weight is adjusted correctly when the arrow is in the midd...

Page 51

En-51 jacobsen ar3 safety, operators & maintenance manual a 9.11.3 backrest extension * ** the backrest extension can be individually adjusted by pulling it upwards or pushing it downwards over the various locking increments up the end stop. To remove the backrest extension, pull it upwards over the...

Page 52

En-52 jacobsen ar3 safety, operators & maintenance manual 9 adjustments 9.11.6armrests * ** the armrests can be folded up if required and the height individually adjusted. To adjust the armrests for height, separate the round cap (see arrow) from the cover, loosen the hexagon nut (size 13 mm) behind...

Page 53

En-53 jacobsen ar3 safety, operators & maintenance manual 9.11.9maintenance dirt can impair the function of the seat, so make sure you keep your seat clean! Upholstery does not need to be removed from the seat frame for cleaning. Caution: take care with the backrest - it may jerk forward and cause i...

Page 54

En-54 jacobsen ar3 safety, operators & maintenance manual 10 accessories 10.1 ops frame (lmac164) warning when an ops frame is fitted to a machine, a seat belt must be fitted and worn by the operator. 10.2 transport latch kit (lmac174) a transport latch kit is available for the front lift arms 10.3 ...

Page 55

En-55 jacobsen ar3 safety, operators & maintenance manual 11.1 general the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact your area jacobsen distributor. 11 troublesho...

Page 56

En-56 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2 quality of cut troubleshooting it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area should ...

Page 57

En-57 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2.2step cutting note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a cutting unit than the other or on one side of mower to the other. This is usually caused by mechani...

Page 58

En-58 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2.3scalping note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is usuall...

Page 59

En-59 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2.4stragglers note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy dull cutting blade(s). Sharpen blade(s). (refer to parts & maintenance manual.)...

Page 60

En-60 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting probable cause remedy damaged blade(s). Replace blade(s). Turning too aggressively. Cutting units don’t overlap during turns or on side hills. Turn less aggressively to allow cutting units to overlap. Change mowing directio...

Page 61

En-61 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2.6windrowing note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between cutting units, forming line(s) in the direction of travel. Probable ca...

Page 62

En-62 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting 11.2.7mismatched cutting units note: arrow indicates direction of travel. Mismatched cutting units is a pattern of varying cutting heights, resulting in a stepped cut appearance, usually due to mismatched hoc (height-of-cut...

Page 63

En-63 jacobsen ar3 safety, operators & maintenance manual 11 troubleshooting.

Page 64

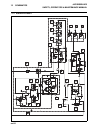

En-64 jacobsen ar3 safety, operators & maintenance manual 12.1 hydraulic circuit 12 schematics.

Page 65

En-65 jacobsen ar3 safety, operators & maintenance manual key to hydraulic diagram 1 transmission pump 2 hydraulic wheel motor front 3 hydraulic wheel motor front 4 hydraulic wheel motor rear 5 hydraulic flushing valve 6 hydraulic filter 7 hydraulic cutter & brake valve 8 hydraulic deck motor 9 hydr...

Page 66

En-66 jacobsen ar3 safety, operators & maintenance manual 12.2 electrical circuit instrument 12 schematics to sp#19 to sp#19 2 to sp#19 b p/y 1.0 1.0 1 to sp#11.

Page 67

En-67 jacobsen ar3 safety, operators & maintenance manual key to wiring diagram 1 split to main harness 2 split to main harness 3 split to main harness 54 key switch 55 fuse box 1 56 fuse box 2 57 battery, positive 58 weight transfer switch 59 start relay 60 mow switch 61 parking brake switch 62 wor...

Page 68

En-68 jacobsen ar3 safety, operators & maintenance manual 12.3 electrical circuit main 12 schematics.

Page 69

En-69 jacobsen ar3 safety, operators & maintenance manual key to wiring diagram 1 split to console 2 split to console 3 split to console 4 glow plugs 5 split to cab 6 working lamp 7 working lamp 8 glow plug relay 9 brake solenoid 10 lower solenoid 11 cutter solenoid 12 engine oil pressure switch 13a...

Page 70

En-70 jacobsen ar3 safety, operators & maintenance manual 12.4 electrical circuit fuses and relays fuses & relays under control panel 1 fuse - 15 amp-start relay 2 fuse - 7.5 amp- fuel pump 3 fuse - 5 amp - warning lamps 4 fuse - 5 amp - warning lamps 5 fuse - 10 amp - safety module 6 fuse - 15 amp ...

Page 71

En-71 jacobsen ar3 safety, operators & maintenance manual 12.4 electrical circuit fuses and relays 12 schematics fuses & relays in engine compartment b relay - glow plugs c strip fuse - 40 amp top - cab bottom - glow plugs.

Page 72

En-72 jacobsen ar3 safety, operators & maintenance manual 13.1 torques s d a e r h t c i r t e m h c t i p e s r o c a i d ) m m ( e d a r g 6 . 4 e d a r g 8 . 4 e d a r g 8 . 8 e d a r g 9 . 0 1 e d a r g 9 . 2 1 ) m n ( ) m n ( ) m n ( ) m n ( ) m n ( 6 5 6 2 1 7 1 1 2 8 1 1 5 1 0 3 2 4 1 5 0 1 2...

Page 73: Guarantee

En-73 jacobsen ar3 safety, operators & maintenance manual 14 guarantee / sales & service guarantee we guarantee that should any defect in workmanship or material occur in the goods within two years or two thousand hours (on models equipped with hour meters), or whichever occurs first. Exception to t...

Page 76

Ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacobsen.Com.