- DL manuals

- Jacobsen

- Lawn Mower

- Eclipse 322

- Operation Manual

Jacobsen Eclipse 322 Operation Manual

Eclipse

®

322 Riding Greens Mower with ROPS

62800 – Battery Power, 3WD

62801 – Battery Power, 2WD

62802 – Gas Hybrid Power, 3WD

62803 – Gas Hybrid Power, 2WD

62804 – Diesel Hybrid Power, 3WD

62805 – Diesel Hybrid Power, 2WD

62825 – Diesel Hybrid Power with Premium Seat, 2WD

62826 – Diesel Hybrid Power with Premium Seat, 3WD

62851 – Diesel Hybrid Power, 2WD

62852 – Diesel Hybrid Power with Premium Seat, 2WD

62853 – Diesel Hybrid Power, 3WD

62854 – Diesel Hybrid Power with Premium Seat, 3WD

WARNING

WARNING: If incorrectly used this machine can cause severe injury. Those

who use and maintain this machine should be trained in its proper use, warned

of its dangers and should read the entire manual before attempting to set up,

operate, adjust or service the machine.

4187720-GB-Rev E

Safety, Operation & Maintenance Manual

GB

United

Kingdom

Summary of Eclipse 322

Page 1

Eclipse ® 322 riding greens mower with rops 62800 – battery power, 3wd 62801 – battery power, 2wd 62802 – gas hybrid power, 3wd 62803 – gas hybrid power, 2wd 62804 – diesel hybrid power, 3wd 62805 – diesel hybrid power, 2wd 62825 – diesel hybrid power with premium seat, 2wd 62826 – diesel hybrid pow...

Page 2

En-2 contents this manual contains adjustment, maintenance, troubleshooting instructions, and parts list for your new jacobsen machine. This manual should be stored with the equipment for reference during operation. Before you operate your machine, you and each operator you employ should read the ma...

Page 3

En-3 7 batteries 7.1 battery safety..................................................... 52 7.2 battery conditioning ...........................................52 7.3 battery systems .................................................54 7.4 battery filling (battery powered mowers) ..........54 7.5 bat...

Page 4: Warning

1 safety en-4 1 safety 1.1 how to operate safely safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and technicians. Manuals in additional languages may b...

Page 5

Safety 1 en-5 e do not use on the slopes greater than the safe slope limit for the equipment. F to guard against over turning or loss of control: – operate the mower up and down on the face of slopes (vertically), but not across the face (horizontally). – do not start or stop suddenly on slopes. – d...

Page 6

1 safety en-6 f refuel outdoors only and do not smoke when you add fuel. Extinguish all types of ignition. G the fuel nozzle must touch the rim of the fuel tank when you add fuel to the mower. Do not use a device to lock the fuel nozzle in the open position. H do not over fill the fuel tank. Leave a...

Page 7: Warning

Safety 1 en-7 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 8

2 specifications en-8 2 specifications 2.1 product identification _________________________________________________ 62800 .............................. Eclipse ® 322, 3wd, 48 volt battery power module, power steering. Without batteries or mowers. 62801 .............................. Eclipse ® 322, ...

Page 9

Specifications 2 en-9 62804, 62805, 62825 and 62826 diesel engine make ............................... Kubota model .............................. Z482-e3b horsepower..................... 13.3 hp (9.3 kw) @3600 rpm displacement .................. 29.3 cu. In. (479 cc) torque ...........................

Page 10

2 specifications en-10 2.4 battery power module ________________________________________________ to ensure the longest battery life possible, the batteries are not shipped with the power module and must be ordered separately. For optimum range and performance use batteries that equal or exceed the a...

Page 11

Specifications 2 en-11 2.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de...

Page 12

2 specifications en-12 net installed power ▪ Нетна инсталирана мощност ▪ Čistý instalovaný výkon ▪ installeret nettoeffekt ▪ netto geïnstalleerd vermogen ▪ installeeritud netovõimsus ▪ asennettu nettoteho ▪ puissance nominale nette ▪ installierte nettoleistung ▪ Καθαρή εγκατεστημένη ισχύς ▪ nettó be...

Page 13

Specifications 2 en-13 technical standards and specifications used ▪ Използвани технически стандарти и спецификации ▪ použité technické normy a specifikace ▪ brugte tekniske standarder og specifikationer ▪ gebruikte technische standaards en specificaties ▪ kasutatud tehnilised standardid ja spetsifi...

Page 14

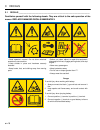

2 specifications en-14 2.8 vibration level ________________________________________________________ the mower was tested for hand and arm vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The engine was in operation and the cutt...

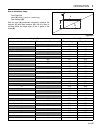

Page 15: Caution

Specifications 2 en-15 2.9 weights and dimensions ________________________________________________ dimensions: inches (cm) length - grass catchers on ......................... 101 (256.5) height - top of rops .................................. 79.3 (201.4) wheel base....................................

Page 16

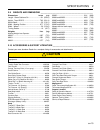

3 decals en-16 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4181865 4181864 • read operator's manual. Do not allow untrai...

Page 17

Decals 3 en-17 familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4182520 4181860 danger to prevent injury, disengage all drives, engage parking brake, stop engine, and remove key before working on machine or empt...

Page 18

3 decals en-18 4181863 warning read manual before performing maintenance. 4181861 important do not use starting assist fluids use of starting assist fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition. This could result in serious engine damage. 4181862...

Page 19

Decals 3 en-19 familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4216820 rev a disconnect steering chain before towing mower..

Page 20

3 decals en-20 i / a ev er y 100 engine oil - diesel.......................2.6 qt (2.5 liter) r r r (0.97 - 1.10 bar) i universal reel set-up clean debr is from radiator vi i / c item radiator screens chec k saf e ty inter loc k functions batter y fluid (distilled w a ter) l diesel muffler and exhau...

Page 21

Decals 3 en-21 familiarize yourself with the following decals. They are critical to the safe operation of the mower. Replace damaged decals immediately. 4225602 2x f2 (po wer br ush if eq uipped) 6x f2 6x f2 (gr oomer if eq uipped) f1 f1 2x f1 4x f5 springs f5 chain 2x f5 springs f1 f1 ser vice f1: ...

Page 22: Warning

4 controls en-22 4 controls 4.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and ...

Page 23

Controls 4 en-23 4.2 instrument panel ______________________________________________________ a. Lcd display unit (ldu) used to display and set operating conditions. See section 4.5. B. Mow switch enables and disables the three reel switches (c, d and e), and switches lift system between service mode...

Page 24: Caution

4 controls en-24 4.3 operator controls ____________________________________________________ k. Forward traction pedal press forward traction pedal down to move the mower forward. The further the pedal is pressed, the faster the mower will travel. L. Reverse traction pedal press reverse traction peda...

Page 25

Controls 4 en-25 4.4 operator convenience _________________________________________________ t. Mcu access panel remove thumbscrew and lift up on front of access panel to view mcu diagnostic lights. Always secure access panel with thumbscrew when operating. U. Cup holder used to hold a beverage cup f...

Page 26: Caution

4 controls en-26 4.5 lcd display unit (ldu) __________________________________________________ the ldu displays current functional values for the operation of the eclipse mower, has indicator lights, and sounds audible warning alerts. The ldu operates in one of two modes, operator mode (default) and...

Page 27

Controls 4 en-27 4.5.2 display operating hours ___________ to check operating hours when system power switch is in the off position, press the center (black) button. Operating hours will be displayed for 1 minute. Figure 4e 4.5.3 start up screen __________________ the jacobsen start up screen will d...

Page 28

4 controls en-28 4.5.6 operator mode ____________________ operator mode is used by the operator to view attachment mode, system voltage information, travel speed, reel motor current, reel motor speed, switch status, operation hours, and stored alarms. Press the orange buttons (am and an) on the ldu ...

Page 29: Notice

Controls 4 en-29 4.5.7 maintenance mode ________________ maintenance mode is used by the superintendent to set and adjust all functional values for the eclipse mower. Lcd displays available in maintenance mode are, mower attachment mode, system voltage, travel speed, reel motor current, reel motor s...

Page 30: Notice

4 controls en-30 switch status: displays the current switch settings, and is used to diagnose switch problems. A status of 0 indicates the switch is in the off position. A status of 1 indicates the switch is in the on position. Check the wiring and operation of any switch that is not displaying the ...

Page 31

Controls 4 en-31 figure 4j select reset to factory defaults confirm reset mower attachment mode maintenance mode factory reset? Reset? No yes travel speed 00 mph system volts 48.0 vdc 00 reel 00 00 amps 1900 reel 1900 1900 rpm actuator calibrate? Set reel speed ? Acuator amps 00 00 00 2200 rpm displ...

Page 32: Notice

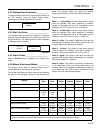

4 controls en-32 4.6 frequency of cut ______________________________________________________ the foc (frequency of cut) is the distance, in inches (cm), the machine travels forward between reel blades contacting the bedknife. The foc can be adjusted either by changing the fixed foc setting or by cha...

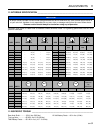

Page 33

Controls 4 en-33 15 blade reel foc table mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 mph (kph) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) 1.0 0.039 0.038 0.037 0.036 0.035 0.034 0.034 0.033 0.032 (1.61) (0.993) (0.967) (0.941) (0.917...

Page 34

4 controls en-34 11 blade reel foc table mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 mph (kph) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) 1.0 0.053 0.052 0.051 0.049 0.048 0.047 0.046 0.045 0.044 (1.61) (1.355) (1.318) (1.283) (1.250...

Page 35

Controls 4 en-35 9 blade reel foc table mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 mph (kph) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) 1.0 0.065 0.063 0.062 0.060 0.059 0.057 0.056 0.055 0.053 (1.61) (1.656) (1.611) (1.569) (1.528)...

Page 36

4 controls en-36 7 blade reel foc table mow speed reel rpm 1800 1850 1900 1950 2000 2050 2100 2150 2200 mph (kph) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) inch (cm) 1.0 0.084 0.082 0.079 0.077 0.075 0.074 0.072 0.070 0.069 (1.61) (2.129) (2.071) (2.017) (1.965)...

Page 37: Caution

Controls 4 en-37 4.7 electronic traction control system __________________________________ the eclipse is equipped with an electronic traction control system which utilizes a controller and software to regulate speed and optimize the driveability of the unit. A speed sensor in the drive motor report...

Page 38: Caution

5 operation en-38 5 operation 5.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hos...

Page 39: Warning

Operation 5 en-39 5.3 operating procedures _________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. 2. Do not operate mower or attachments with loose, damaged, or missing components. Whenever possible mow when ...

Page 40: Warning

5 operation en-40 5.4 starting _______________________________________________________________ important: do not use starting assist fluids. Use of such fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition and could result in serious engine damage. 1. Si...

Page 41: Notice

Operation 5 en-41 5.5 stopping / parking ______________________________________________________ to stop: remove your foot from traction pedal, regen braking will start, bringing the mower to a complete stop. To increase regen braking, slowly depress the brake pedal. When mower stops, the automatic p...

Page 42: Caution

5 operation en-42 5.7 to drive / transport____________________________________________________ read and follow all safety notes contained in this manual when driving or transporting mower. Refer to section 5.3 for general operating instructions. When operating in reverse, look behind you to ensure y...

Page 43: Warning

Operation 5 en-43 5.10 mowing _________________________________________________________________ operators should practice mowing in a clear area to become familiar with raising and lowering the reels. Practicing, by turning reel motors off (see section 4.5.6), will help the operator become proficien...

Page 44: Warning

5 operation en-44 5.11 hillside operation _____________________________________________________ the mower has been designed for good traction and stability under normal mowing conditions; however, use caution when operating on slopes, especially over rough terrain or when the grass is wet. Wet grass...

Page 45

Operation 5 en-45 how to calculate a slope: tools required: level (a), either 1 yard, or 1 meter long. Tape measure (b). With the level (a) positioned horizontally, measure the distance (c) with tape measure (b). Use the chart to calculate either the slope angle or the % grade of the slope (d). Figu...

Page 46: Notice

5 operation en-46 5.12 loading mower on trailer _____________________________________________ use care when loading and unloading mower onto trailer. Fasten mower to trailer, using tie downs on left and right side and rear of mower (ae - figure 4c), to prevent mower from rolling or shifting during t...

Page 47: Warning

Operation 5 en-47 5.13 towing mower __________________________________________________________ if the mower experiences problems and a trailer is not available, the unit can be towed slowly short distances. 1. Automatic parking brake under right side of floorboard must be disengaged. A. Remove two o...

Page 48

5 operation en-48 figure 5f zu zv zw.

Page 49: Notice

Operation 5 en-49 5.14 daily maintenance______________________________________________________ important: for more detailed maintenance information, adjustments and maintenance/lubrication charts, see the parts & maintenance manual. 1. Park the mower on a flat, level surface. Fully lower the reels t...

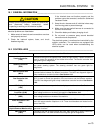

Page 50: Warning

6 maintenance & lubrication charts en-50 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. App...

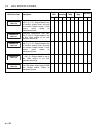

Page 51

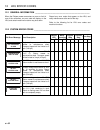

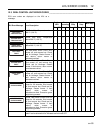

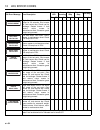

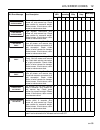

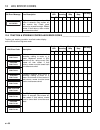

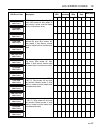

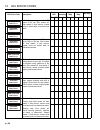

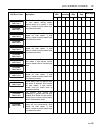

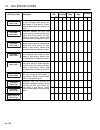

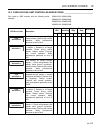

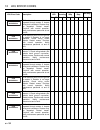

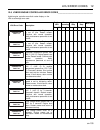

Maintenance & lubrication charts 6 en-51 6.3 maintenance charts____________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** not required unless engine problems occur. I - manual...

Page 52: Warning

7 batteries en-52 7 batteries 7.1 battery safety ________________________________________________________ batteries contain dilute sulfuric acid which can result in severe burns. Hydrogen gas is formed within a battery during the charging cycle. Hydrogen in concentrations of 4% and higher are explos...

Page 53

Batteries 7 en-53 the conditioning process can be monitored by checking the specific gravity of the battery cells. After the battery set has been recharged, spot check two or more battery cells. A fully charged fully conditioned battery with an electrolyte temperature of 80° f (27° c) has a gravity ...

Page 54: Notice

7 batteries en-54 7.3 battery systems _______________________________________________________ the eclipse mower is available with either a battery power module, a gas engine hybrid power module, or a diesel engine hybrid power module. 1. The battery powered eclipse has six, 8 vdc batteries wired in ...

Page 55

Batteries 7 en-55 7.5 battery maintenance __________________________________________________ a regularly scheduled maintenance program is vital to the performance and maximum life of the batteries. 1. Keep the batteries clean at all times. Make sure the cell caps are in place to prevent water of deb...

Page 56: Warning

7 batteries en-56 7.8 battery charger ______________________________________________________ the battery charger is designed to fully charge the battery pack and will shut off automatically when the batteries are fully charged. Read the instruction manual included with the charger for proper operati...

Page 57: Warning

Batteries 7 en-57 7.9 battery charger algorithm ___________________________________________ three algorithms are programmed into the delta-q charger. Make sure correct algorithm is set for the batteries being charged. Checking charge algorithm 1. Make sure system power switch is in off position and ...

Page 58

7 batteries en-58 7.10 cleaning batteries ____________________________________________________ when cleaning the batteries, do not use a water hose without first spraying with a solution of sodium bicarbonate (baking soda) and water to neutralize any acid deposits. Use of a water hose without first ...

Page 59

Batteries 7 en-59 7.11 specific gravity (62801 only) ____________________________________________ the normal specific gravity readings for a fully charged battery should be between 1.250 and 1.280 after correcting for temperature. Check the specific gravity after the batteries have been charged and ...

Page 60: Warning

7 batteries en-60 7.13 discharge test (62801 only)_____________________________________________ battery serviceability can be tested using a battery discharge tester of the same voltage as the system to be tested (48 volts for the eclipse 322). The battery discharge tester will discharge the batteri...

Page 61: Warning

Batteries 7 en-61 7.14 buffer battery wiring _________________________________________________ refer to the following diagram for buffer battery wiring. After battery cables are properly installed and torqued, the use of standard battery terminal anti corrosion spray is recommended. Figure 7e 7.15 b...

Page 62

7 batteries en-62 c. Any battery that is 0.5 volt lower than the highest battery voltage, may have failed. Make a note of the battery location in the pack..

Page 63: Warning

Batteries 7 en-63 7.16 battery power module wiring__________________________________________ refer to the following diagrams for battery power module wiring. 1. Label four battery cables with numbers 1~4. 2. Slide cable 1 and cable 3 through grommet at rear of battery tray. Slide cable 2 and cable 4...

Page 64: Warning

8 hybrid engine maintenance en-64 8 hybrid engine maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. ...

Page 65

Hybrid engine maintenance 8 en-65 8.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap, and add oil as required. Diesel engine: perform initial oil chang...

Page 66: Warning

8 hybrid engine maintenance en-66 8.5 diesel air filter________________________________________________________ do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk of injecting dust and other impurities into the engine. When service is required,...

Page 67: Caution

Hybrid engine maintenance 8 en-67 8.8 12 volt engine battery _________________________________________________ make absolutely certain the system power switch is off and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of sili...

Page 68: Warning

8 hybrid engine maintenance en-68 8.11 muffler and exhaust __________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, ...

Page 69: Warning

Maintenance 9 en-69 9 maintenance 9.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on ...

Page 70: Notice

9 maintenance en-70 9.3 lift actuator calibration _____________________________________________ the actuators need to be calibrated at initial setup, whenever an actuator or the rdu was replaced, or when switching from reels to vertical mowers. Before calibrating, reels or vertical mowers must be pr...

Page 71

Maintenance 9 en-71 9.4 backlapping and grinding ______________________________________________ to backlap: 1. Park the mower on a flat and level surface. 2. Enter maintenance mode. [see section 4.7]. 3. Press either of the orange buttons (am or an) on the ldu until the backlap enable? Screen is on ...

Page 72: Notice

9 maintenance en-72 9.5 tires ___________________________________________________________________ 1. Keep tires properly inflated to prolong tire life. Check inflation pressure while the tires are cool. Inspect tread wear. 2. Check the pressure with an accurate, low pressure tire gauge. 3. Keep tire...

Page 73: Warning

Maintenance 9 en-73 warning never use your hands to clean cutting units. Use a brush to remove grass clippings from blades. Blades are extremely sharp and can cause serious injuries. !.

Page 74: Caution

9 maintenance en-74 9.8 storage________________________________________________________________ general 1. Clean the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Drain and refill radiator...

Page 75: Caution

Electrical system 10 en-75 10 electrical system 10.1 general information ___________________________________________________ general precautions that can be taken to reduce electrical problems are listed below. 1. Make certain all terminals and connections are clean and properly secured. 2. Check th...

Page 76

10 electrical system en-76 10.3 pdu and controller locations ________________________________________ a. Power distribution unit (pdu) circuit breakers used to protect electrical system. Three manual reset circuit breakers located on the pdu are accessible by opening the hood and looking towards the...

Page 77

Electrical system 10 en-77 10.4 rcu controller lights _________________________________________________ the rcu controller is a solid state device that monitors and controls reel and lift electrical functions. The rcu communicates with the mcu via the can network. Each input and output signal is dis...

Page 78

10 electrical system en-78 10.5 mcu controller lights ________________________________________________ the mcu controller is a solid state device that monitors and controls mower functions. The mcu communicates with the other controllers via the can network. Each input and output signal is displayed...

Page 79

Electrical system 10 en-79 10.6 olm controller lights (early units) ___________________________________ the olm controller is a solid state device that monitors and controls resistor functions. The controller communicates with the mcu controller via the can network. Each input and output signal is d...

Page 80

10 electrical system en-80 10.8 pdu (later units) _______________________________________________________ the pdu is located to the left of the operator seat, under the mcu, and is used to switch 48v and 12v motor/ controller outputs on or off. Three circuit breakers are located on the rear of the p...

Page 81: Warning

Adjustments 11 en-81 11 adjustments 11.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust...

Page 82: Notice

11 adjustments en-82 11.3 bedknife adjustment __________________________________________________ 1. Read section 11.2 before making the adjustment. 2. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blades is that end which passes over the b...

Page 83

Adjustments 11 en-83 11.5 reel assembly _________________________________________________________ 1. Slide splined end of coupler (ac) onto reel shaft 2. Assemble o-ring (ad) onto motor adapter on reel. 3. Insert key (ae) into motor shaft. 4. Slide motor (af) into coupler (ac), and secure to reel us...

Page 84

11 adjustments en-84 11.6 reel bearing ___________________________________________________________ any radial play or excessive end play indicates bad bearings, a weak tension spring or a backed off nut. 1. Check bearing housing mounting hardware. Tighten or replace components as required. Carefully...

Page 85: Notice

Adjustments 11 en-85 11.8 bedknife adjuster spring ______________________________________________ for proper operation, bedknife adjuster spring should be compressed to a dimension of 1-7/16 - 1-1/2 in. (3.65-3.8 cm). To adjust spring compression, loosen or tighten nut (r) to obtain a distance of 1-...

Page 86

11 adjustments en-86 11.12 armrest height adjustment ___________________________________________ the armrest has three available height settings for operator convenience. To adjust armrest height: 1. Shut mower off and remove key. 2. Remove three bolts (v) from bracket on right side of seat. 3. Rais...

Page 87

Adjustments 11 en-87 11.15 hood stops _____________________________________________________________ 1. Adjust position of hood stop bumpers (z) as required so hood contacts bumpers with approximately 1/8 in. (0.3 cm) clearance between hood and cowlings. 2. Adjust left and right side bumpers as requi...

Page 88

11 adjustments en-88 11.17 diesel engine alternator belt ________________________________________ 1. Inspect and adjust new alternator belt after the first 10 hours of operation. Check and adjust every 100 hours thereafter. 2. Adjust the alternator pulley so the belt deflects 9/32 to 11/32 in. (0.7 ...

Page 89: Notice

Adjustments 11 en-89 11.20 steering proximity switches ___________________________________________ only used on 2wd mowers with the following serial numbers: 6280101601~6280102499 6280301601~6280302499 6280501601~6280502499 6282501601~6282502499 1. Clean any dirt or debris off sensing portion of ste...

Page 90: Notice

11 adjustments en-90 11.23 gas throttle actuator adjustment ___________________________________ 1. Open hood. 2. With mower off, remove air filter cover (bd), element (be), and base housing (bf) from engine. 3. Disconnect spring (ay) from spring clip (az) at the carburetor. 4. Unlatch the spring cli...

Page 91: Notice

Adjustments 11 en-91 11.24 torque specification ___________________________________________________ jacobsen uses grade 5 plated bolts as standard unless otherwise noted. For tightening plated bolts use the value given for lubricated. 11.25 specific torque ___________________________________________...

Page 92

12 ldu error codes en-92 12 ldu error codes 12.1 general information __________________________________________________ when the eclipse mower encounters an error or fault in one of the controllers, an error code will display on the ldu, and certain machine functions may shut down. Record any error ...

Page 93

Ldu error codes 12 en-93 12.3 reel control unit error codes ________________________________________ rcu error codes are displayed on the ldu as a message. Ldu error message error description caution led alarm sounding engine stop traction stop mow stop on off yes no yes no yes no yes no left reel m...

Page 94

12 ldu error codes en-94 right reel motor current over 35 amps for 30 seconds. Shut mower off, and remove key. Check reel for blockage. Restart mower. If fault returns, return mower to maintenance shed. Excessive grass height being mowed. 4 4 4 4 4l left reel motor fuse blown. Return mower to mainte...

Page 95

Ldu error codes 12 en-95 center actuator overcurrent. Shut mower off, and remove key. Check grass catcher for excessive weight. Restart mower. If fault returns, return mower to maintenance shed. 4 4 4 4 4l right actuator overcurrent. Shut mower off, and remove key. Check grass catcher for excessive ...

Page 96

12 ldu error codes en-96 12.4 traction & steering controller error codes _________________________ traction and steering controller error/fault codes display on the ldu as a four digit error code. Right actuator did not reach position within 6 seconds. Shut mower off, and remove key. Check grass cat...

Page 97

Ldu error codes 12 en-97 dc voltage is above the high trip level. Shut mower off, then restart. If fault returns, mower must be towed back to maintenance shed. 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 dc voltage is above the hardware defined trip level. Shut mower off, then restart. If fault returns, mower mus...

Page 98

12 ldu error codes en-98 15 v supply voltage on the dsp board is too low. Shut mower off, then restart. If fault returns, mower must be towed back to maintenance shed. 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5v supply voltage on the dsp board is too high or too low. Shut mower off, then restart. If fault retu...

Page 99

Ldu error codes 12 en-99 throttle sensor error. Shut mower off, then restart, making certain traction pedal is in neutral. If fault returns, mower must be towed back to maintenance shed. 4 4 4 4 4 4 4 4 4 4 reverse alarm test failed. Shut mower off, then restart. If fault returns, mower must be towe...

Page 100

12 ldu error codes en-100 reference generator not connected or short circuited. Shut mower off, then restart. If fault returns, mower must be towed back to maintenance shed. 4 4 4 4 4 difference between set value and actual value for current regulator are above limit. Shut mower off, then restart. I...

Page 101

Ldu error codes 12 en-101 12.5 over-voltage limit controller error codes __________________________ only used on 2wd mowers with the following serial numbers: 6280101601~6280102499 6280301601~6280302499 6280501601~6280502499 6282501601~6282502499 ldu error code description caution led alarm sounding...

Page 102

12 ldu error codes en-102 olm detects less current than expected through resistor 2. Inspect wiring and connectors. Resistor may be degraded. Restart mower. Continue with normal operation. Notify maintenance personnel at end of shift. 4 4 4 4 4 olm detects a short circuit to ground in resistor 3. Re...

Page 103

Ldu error codes 12 en-103 12.6 hybrid engine controller error codes________________________________ hybrid engine controller error/fault codes display on the ldu as a two digit error code. Ldu error code description caution led alarm sounding engine stop traction stop mow stop on off yes no yes no y...

Page 104

12 ldu error codes en-104 generator temperature greater than 340° f (171° c). Engine speed is set to idle.Shut mower down and wait ten minutes. Restart mower. If fault returns, return mower to maintenance shed. 4 4 4 4 4 generator temperature less than -20° f (-29° c). Engine speed is set to idle. A...

Page 105

Troubleshooting 13 en-105 13 troubleshooting 13.1 trouble shooting ______________________________________________________ problem possible cause/items to check additional items to check key switch on - no power to ldu 48vdc battery or 48vdc buffer battery not connected or discharged. Check battery c...

Page 106

13 troubleshooting en-106 no glowplug operation ensure diesel genset is selected. Check mcu led #17 should be on. Check engine harness connections. Check mcu led #6 should be on when glowplugs should be on (i.E. Pre-glow, during cranking, and post-glow) if not on check to see if circuit breaker 6 is...

Page 107

Troubleshooting 13 en-107 no steering (electric steer- ing system) check if seat switch is functioning. Check mcu led #24 should be on when on seat and off when off seat. Check switch and harness connection. Scu does not have power. Check to see if circuit breaker 5 is tripped. Fault code on ldu rev...

Page 108

14 quality of cut en-108 14 quality of cut 14.1 quality of cut troubleshooting _______________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area s...

Page 109

Quality of cut 14 en-109 14.3 marcelling _____________________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-t...

Page 110

14 quality of cut en-110 14.4 step cutting ___________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to another. This is usually caused by mechanical wea...

Page 111

Quality of cut 14 en-111 14.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. Thi...

Page 112

14 quality of cut en-112 14.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull ree...

Page 113

Quality of cut 14 en-113 14.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged ...

Page 114

14 quality of cut en-114 14.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. ...

Page 115

Quality of cut 14 en-115 14.9 rifling or tramlining ___________________________________________________ 14.10mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in ...

Page 116

When performance matters. ™ equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and factory trained technicians backed by genuine jacobsen parts provide reliable, high-quality product ...