- DL manuals

- Jacobsen

- Lawn Mower

- Fairway 67978

- Operation Manual

Jacobsen Fairway 67978 Operation Manual - Warning

CONTROLS 2

5

2

CONTROLS

2.1 ICONS ___________________________________________________________________

WARNING

Never attempt to drive the mower unless you have read the Safety and Operation Manual

and know how to operate all controls correctly.

Familiarize yourself with the icons shown above and what they represent. Learn the

location and purpose of all the controls and gauges before operating this mower.

Read Manual

High

Low

Engine Throttle

Mower Rotation

2-WD

4-WD

Lock

Unlock

Forward

Reverse

Drive

Travel

Cruise Control

Off

Run

Engine

Start

Parking Brake

Forward

(Cut)

Reverse

(Backlap)

Coolant

Temperature

Fuel

Mowers

Lower

Raise

Work Lights

Hour Meter

Oil Level Switch

On

Off/Test

Engine Oil

Pressure

Glow

Plug

Hydraulic

Oil Filter

Battery

Charge

Warning Lights

Hydraulic Oil

Level

D

!

Summary of Fairway 67978

Page 1

Dealer this manual is designed to assist dealer personnel with the proper set up and preparation of the equipment prior to delivery to the customer. You may wish to keep a copy in your customer file. Do not remove the safety & operation manual or parts & maintenance manual from the mower. For additi...

Page 2

2 contents this manual contains safety and operating instructions for your new jacobsen mower. This manual should be stored with the equipment for reference during operation. Before you operate your mower, you and each operator you employ should read the manual carefully in its entirety. By followin...

Page 3: Warning

Safety 1 3 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern, and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manua...

Page 4: Warning

1 safety 4 1.2 important safety notes________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potentia...

Page 5: Warning

Controls 2 5 2 controls 2.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and what...

Page 6

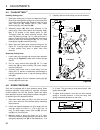

2 controls 6 ! 4131663 a e b f j c g d h k l m n p r w s t u v r a lcd display unit (ldu) b mow switch c parking brake switch d cruise control switch e ignition switch f horn switch g light switch h joystick j fuel cap k air cleaner indicator l backlap switch m steering tilt lever n traction pedal -...

Page 7: Notice

Controls 2 7 2.2 armrest controls _____________________________________________________ a. Lcd display unit (ldu) used to display and set operating conditions. See section 2.4. B. Mow switch enables and disables the reels, and switches lift system between manual mode and mow mode. Pull up on the kno...

Page 8: Caution

2 controls 8 2.3 controls ______________________________________________________________ j. Fuel cap fill fuel tank with fresh, clean, #2 low or ultra low sulfur diesel fuel, minimum cetane rating of 45. K. Air cleaner indicator indicates condition of air cleaner on engine. Clean or replace air filt...

Page 9: Caution

Controls 2 9 r. 12 volt accessory outlet located inside armrest storage compartment. Allows operation of approved 12 volt accessories and attachments. To prevent excessive battery drain, only use 12 volt outlet with engine running. Caution the 12 volt accessory outlet circuit is protected by a 10 am...

Page 10: Caution

2 controls 10 2.4 lcd display unit (ldu) __________________________________________________ the ldu displays current functional values for the operation of the mower, has indicator lights, and sounds audible warning alerts. The ldu operates in one of two modes, operator mode (default) and maintenanc...

Page 11

Controls 2 11 2.4.2 alarm codes _____________________ in addition to the lights on the ldu, there are eight screen displays that are used to alert the operator or mechanic of a problem the needs to be corrected. Figure 2c low oil pressure screen is shown, alarm sounds, reels stop and raise to full u...

Page 12

2 controls 12 2.4.5 maintenance mode maintenance mode is used by the superintendent to set and adjust functional values for the mower. Lcd displays available in maintenance mode are, calibrate pedal, set max mow speed, set travel speed, and set reverse speed. To enter maintenance mode, turn key to r...

Page 13: Notice

Controls 2 13 calibrate pedal: to calibrate the traction pedal, press forward or backward on the joystick (h) until the calibrate pedal screen is on the lcd display. With traction pedal in neutral, press the black button (j) to enter set mode. Press traction pedal all the way in the forward directio...

Page 14

2 controls 14 figure 2g engine temp 120f 50c pedal reverse 000 traction configuration. Calibrate reverse pedal movement. Calibrate traction pedal. Calibrate forward pedal movement. Press and hold black button. Enter pin. Change max mow speed. Mow speed setting. Mow speed set max mow speed enter pin?...

Page 15: Caution

Set-up 3 15 3 set-up 3.1 general ________________________________________________________________ the set-up and testing of the unit should always be performed by a trained technician, familiar with the operation of this equipment. Read each instruction completely and make sure you understand it bef...

Page 16

3 set-up 16 3.3 reels __________________________________________________________________ 1. If installing five inch reels, apply moly ep grease to female spline on reel, and insert reel coupler (n) into the bearing housing before attaching reel motor. 2. Remove hardware (p) from the outside front ro...

Page 17: Warning

Set-up 3 17 3.5 interlock system ______________________________________________________ 1. The interlock system prevents the engine from starting unless the parking brake switch is engaged, the traction pedal is in neutral, and the mow switch is off. The sys- tem also stops the engine if the operato...

Page 18: Warning

4 adjustments 18 4 adjustments 4.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 19: Caution

Adjustments 4 19 4.3 bedknife adjustment ___________________________________________________ read section 4.2 before making the adjustment. Start adjustment at leading end of reel, followed by the trailing end. The leading end of the reel blade is that end which passes over the bedknife first during...

Page 20

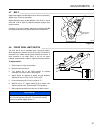

4 adjustments 20 4.5 flash attach ™ _________________________________________________________ installing cutting units 1. Place each cutting unit in front of its respective lift arm. Raise lift arm and position cutting unit so that yoke (t) is in line with swivel housing (s). Carefully lower arm ont...

Page 21: Notice

Adjustments 4 21 4.7 belt ____________________________________________________________________ inspect and adjust new belt after first ten hours of operation. Adjust every 100 hours thereafter. Adjust alternator pulley so belt deflects 1/4 to 5/16 in. (6 to 8 mm) with a 20 lb. Push at midpoint betwe...

Page 22

4 adjustments 22 4.9 steering toe-in _________________________________________________________ 1. Turn wheels to straight ahead position. 2. Loosen jam nuts (j) on both sides of tie rod (m). 3. Turn tie rod (m) to provide proper toe-in. Toe-in must not exceed +1/16 in. (1.5 mm) (k). Retighten jam nu...

Page 23

Adjustments 4 23 4.11 armrest pivot __________________________________________________________ 1. Tighten or loosen pivot plunger (w) as required so plunger button stops the armrest at both ends of armrest pivot slots, and plunger body does not contact armrest pivot. Do not use plunger to increase p...

Page 24: Notice

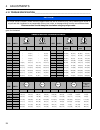

4 adjustments 24 4.12 torque specification___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate and...

Page 25

Troubleshooting 5 25 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact ...

Page 26

6 lubrication 26 6 lubrication 6.1 lubrication chart 2 3 3 5 6 7 7 8 8 9 10 12 12 11 13 11 13 14 14 14 4 15 1 9 grease fittings f1 - 50 hours (every week) 1 swivel housing 2 lift arm 3 lift cylinders 4 lift arm pivot 5 brake pedal pivot 6 traction pedal pivot 7 ball joint 8 steering pivot 9 steering...

Page 27

Pre-delivery checklist product no. 67978 - lf 550 2wd product no. 67979 - lf 550 4wd product no. 67980 - lf 550 turbo 4wd product no. 67981 - lf 570 2wd product no. 67982 - lf 570 4wd product no. 67983 - lf 570 turbo 4wd mower _________________________ check: ❏ wheel lug torque 85 - 95 ft. Lb. (115 ...

Page 30

When performance matters. ™ jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacobsen.Com 800-848-1636 ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com +44 (0) 1473 270000 world cla...