- DL manuals

- Jacobsen

- Tiller

- GA 24

- Technical Manual

Jacobsen GA 24 Technical Manual

TECHNICAL MANUAL

TEKNISK VEJLEDNING

When Performance Matters.

™

ADVARSEL

Denne maskine kan forårsage alvorlig personskade, hvis den bruges forkert.

Alle, der bruger og vedligeholder denne maskine, skal være korrekt

uddannet til dette, skal advares om farerne og læse hele instruktionsbogen,

før maskinen forberedes, bruges, justeres eller serviceres.

WARNING

If incorrectly used, this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up,

operate, adjust or service the machine

GB

DK

Danish

GA 24

Model 58230

4144214-DK (Rev.C)

Summary of GA 24

Page 1

Technical manual teknisk vejledning when performance matters. ™ advarsel denne maskine kan forårsage alvorlig personskade, hvis den bruges forkert. Alle, der bruger og vedligeholder denne maskine, skal være korrekt uddannet til dette, skal advares om farerne og læse hele instruktionsbogen, før maski...

Page 2

© copyright 2007, textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” this manual contains safety, operating, adjustment, maintenance, troubleshooting instructions and parts list for your new jacobsen machine. This manual should be stor...

Page 3: Table of Contents

3 table of contents 1 safety 1.1 operating safety ................................................ 4 1.2 important safety notes ....................................... 4 2 specifications 2.1 product identification.......................................... 6 2.2 engine ..................................

Page 4: 1 Safety

1 safety 4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manual...

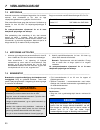

Page 5: Safety 1

Safety 1 5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

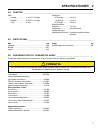

Page 6: 2 Specifications

2 specifications 6 2 specifications 2.1 product identification_________________________________________________ 58230.............................. Ga 24 aerator with opc, 8 hp gasoline engine. Serial number ................ An identification plate, like the one shown, listing the serial number, is ...

Page 7: Specifications 2

Specifications 2 7 2.4 aerator ________________________________________________________________ tires front.......................... 11 x 4.00 - 5 2 ply rear .......................... 16 x 6.50 - 6 4 ply pressure:................... 14 psi (97 kpa) speed: h (transport) ........... 0 - 4.0 mph (6.4...

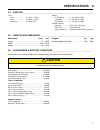

Page 8: 3 Decals and Icons

3 decals and icons 8 3 decals and icons 3.1 decals _________________________________________________________________ familiarize yourself with the decals they are critical to the safe operation of the machine. Replace damaged decals immediately. 3.2 icons ____________________________________________...

Page 9: Controls 4

Controls 4 9 4 controls 4.1 control descriptions __________________________________________________ a. Clutch control lever clutch control lever engages and disengages power to tine operation clutch and latches opc handle. Pull lever until opc handle (e) closes for transport. Pull handle until it cl...

Page 10: 4 Controls

4 controls 10 d. Tine lever raises and lowers aerator head. Lift lever to raise position to raise head. Push lever to lower position to lower head. E. Opc handle engages and disengages drive clutch. Returns clutch control lever (a) to disengaged position when released. F. Engine switch controls engi...

Page 11: Operation 5

Operation 5 11 5 operation 5.1 daily inspection ________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses...

Page 12: 5 Operation

5 operation 12 5.3 operating procedures_________________________________________________ 1. Before starting engine, always release opc handle. 2. Do not operate aerator or attachments with loose, damaged or missing components. 3. First aerate in a test area to become thoroughly familiar with the ope...

Page 13: Operation 5

Operation 5 13 5.5 stopping / parking______________________________________________________ to stop: release opc handle (e) to bring unit to a complete stop. To park the aerator under normal conditions: 1. Release opc handle (e), raise the aerator head (d). Move shift control lever (c) to h position...

Page 14: 5 Operation

5 operation 14 5.8 aerating _______________________________________________________________ to aerate: 1. Start the engine raise aerator head. 2. Move shift control lever to l position. 3. Move throttle lever to slow, stand to the side of unit and slowly engage opc handle. A. Adjust throttle to desi...

Page 15: Adjustments 6

Adjustments 6 15 6 adjustments 6.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 16: 6 Adjustments

6 adjustments 16 6.4 traction drive idler cable_____________________________________________ 1. Engage opc handle. [ see 4.1] 2. Adjust cable nuts (e) as required to obtain 0.18 inch (3.3 mm) deflection with a 4.4 lb (2.0 kg) push for new belt or 3.0 lb (1.4 kg) push for used belt at location shown....

Page 17: Adjustments 6

Adjustments 6 17 6.6 shift control cable ___________________________________________________ if traction drive system does not shift properly, adjustment of the shift control cable may be required. 1. Disconnect clevis (n) from shift lever (p). 2. Place the shift control lever in the l position. 3. ...

Page 18: 6 Adjustments

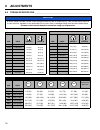

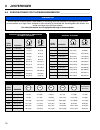

6 adjustments 18 6.8 torque specification __________________________________________________ jacobsen uses grade 5 bolts as standard, unless otherwise noted. Notice all torque values included in these charts are approximate and are for reference only. Use of these torque values is at your sole risk....

Page 19: Maintenance 7

Maintenance 7 19 7 maintenance 7.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 20: 7 Maintenance

7 maintenance 20 7.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap and add oil as required. Perform initial oil change after the first 5 hours of oper...

Page 21: Maintenance 7

Maintenance 7 21 7.6 hydraulic hoses _______________________________________________________ 1. Always disengage all drives, lower aerator head to ground, stop engine and disconnect spark plug wire before inspecting or disconnecting hydraulic lines or hoses. 2. With engine stopped, move tine lever t...

Page 22: 7 Maintenance

7 maintenance 22 7.8 muffler and exhaust __________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine im...

Page 23: Maintenance 7

Maintenance 7 23 7.12 pushrod installation __________________________________________________ whenever the push rods are replaced or removed for service, a pushrod installation tool (a) (jacobsen part no. 517693) is required to prevent damage to triple lip seals. Figure 7b 7.13 storage _____________...

Page 24: 8 Troubleshooting

8 troubleshooting 24 8 troubleshooting 8.1 general________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact y...

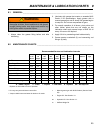

Page 25: Warning

Maintenance & lubrication charts 9 25 9 maintenance & lubrication charts 9.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

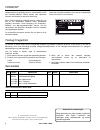

Page 26: 10 Ce Conformity

10 ce conformity 26 jacobsen, a textron company charlotte, north carolina u.S.A. • hereby declares that • erklärt hiermit, daß • por la presente declara q ue • déclare par la présente que • erklærer hermed at • dic h iara che il prodotto qui di seguito descritto • pela pres e n te, declara que • ver...

Page 28

© copyright 2007, textron inc. “alle rettigheder forbeholdes, herunder retten til at mangfoldiggøre denne bog eller dele af den i nogen som helst form”. Denne manual indeholder instruktioner i justering, vedligeholdelse og fejlfinding samt en reservedelsliste til din nye jacobsen-maskine. Denne manu...

Page 29

3 indhold 1 sikkerhed 1.1 driftssikkerhed .................................................... 4 1.2 vigtige bemærkninger om sikkerhed ...................5 2 specifikationer 2.1 produktidentifikation ............................................6 2.2 motor ...............................................

Page 30: 1 Sikkerhed

1 sikkerhed 4 1 sikkerhed 1.1 driftssikkerhed _______________________________________________________ 1. Sikkerheden afhænger af, at de personer, der betjener eller efterser udstyret, udviser opmærksomhed, omtanke og forsigtighed. Tillad aldrigmindreårige at betjene udstyr af nogen art. 2. Det er di...

Page 31: Sikkerhed 1

Sikkerhed 1 5 1.2 vigtige bemÆrkninger om sikkerhed ___________________________________ dette sikkerhedssymbol bruges til at advare dig om potentielle farer. Fare – angiver en overhængende fare, som, hvis den ikke afværges, vil medføre død eller alvorlig legemsbeskadigelse. Advarsel – angiver en pot...

Page 32: 2 Specifikationer

2 specifikationer 6 2 specifikationer 2.1 produktidentifikation _________________________________________________ 58230............................ Ga 24 dybdelufter med dødemandsgreb, 6 kw benzinmotor. Serienummer ............... Serienummeret findes på en identificeringsplade, som vist, som er fas...

Page 33: Specifikationer 2

Specifikationer 2 7 2.4 traktor ________________________________________________________________ dæk fordæk ....................11 x 4,00 - 5 2-lags bagdæk ...................16 x 6,50 - 6 4-lags tryk: ........................97 kpa hastighed: h (fremad) ............. 6,4 km/t l (luftning) ............

Page 34: 3 Mærkater Og Symboler

3 mÆrkater og symboler 8 3 mÆrkater og symboler 3.1 mÆrkater______________________________________________________________ lær mærkaterne at kende. De er altafgørende for sikker betjening af maskinen. Udskift beskadigede mÆrkater omgÅende. 3.2 symboler _______________________________________________...

Page 35: Betjeningsanordninger 4

Betjeningsanordninger 4 9 4 betjeningsanordninger 4.1 beskrivelser af styreenheder_________________________________________ a. Koblingshåndtag koblingshåndtaget til- og frakobler kraftoverføringen til pibeaktiveringskoblingen og låser dødemands- grebet. Træk i håndtaget, indtil dødemandsgrebet (e) l...

Page 36: 4 Betjeningsanordninger

4 betjeningsanordninger 10 d. Pibeindstillingshåndtag hæver og sænker dybdelufterens hoved. Træk håndtaget opad til positionen raise (hÆve) for at hæve hovedet. Skub håndtaget nedad til positionen lower (sÆnke) for at sænke hovedet . E. Dødemandsgreb til- og frakobler drivkoblingen. Sætter koblings-...

Page 37: Betjening 5

Betjening 5 11 5 betjening 5.1 dagligt eftersyn_______________________________________________________ 1. Udfør et visuelt eftersyn af hele enheden, se efter tegn på slid, løse beslag og manglende eller beskadigede dele. Kontroller, om der er brændstof- eller olielækager for at sikre, at tilslutning...

Page 38: 5 Betjening

5 betjening 12 5.3 betjeningsprocedurer ________________________________________________ 1. Udløs altid dødemandsgrebet, før motoren startes. 2. Betjen ikke dybdelufteren eller redskaberne med løse, beskadigede eller manglende dele. 3. Luft først i et testområde for at blive helt fortrolig med betje...

Page 39: Betjening 5

Betjening 5 13 5.5 standsning / parkering_________________________________________________ for at stoppe: udløs dødemandsgrebet (e) for at standse enheden helt. Parkering af traktoren ved normale forhold: 1. Udløs dødemandsgrebett (e), hæv dybdelufterens hoved (d). Sæt gearskiftehåndtaget (c) på h, ...

Page 40: 5 Betjening

5 betjening 14 5.8 luftning _______________________________________________________________ for at lufte: 1. Start motoren, hæv dybdelufterens hoved. 2. Sæt gearstangen i stilling l. 3. Flyt gashåndtaget til slow (langsom), stil dig ved siden af enheden, og aktiver langsomt dødemandsgrebet. A. Stil ...

Page 41: Justeringer 6

Justeringer 6 15 6 justeringer 6.1 generelt _______________________________________________________________ 1. Justeringer og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret jacobsen- forhandler, hvis du ikke kan foretage de korrekte justeringer. 2. Udskift slidte e...

Page 42: 6 Justeringer

6 justeringer 16 6.4 traktionsdrevets frilØbskabel _______________________________________ 1. Aktiver dødemandsgrebet. [ se 4.1] 2. Juster kablets møtrikker (e) efter behov, indtil der på det viste sted opnås en afbøjning på 3,3 mm med et tryk på 1,81 kg på en ny rem eller med et tryk på 1,36 kg på ...

Page 43: Justeringer 6

Justeringer 6 17 6.6 gearskiftekabel _______________________________________________________ hvis gearskiftet til traktionsdrevet ikke fungerer korrekt, kan det være nødvendigt at justere gearskiftekablet. 1. Afmonter gaffelbolten (n) på gearstangen (p). 2. Stil gearskiftehåndtaget på l. 3. Drej gea...

Page 44: 6 Justeringer

6 justeringer 18 6.8 specifikationer for tilspÆndingsmomenter ___________________________ jacobsen bruger grad 5-bolte som standard, medmindre andet er angivet. BemÆrk alle de angivne momentværdier i disse tabeller er omtrentlige og er kun beregnet til opslagsbrug. Brug af disse momentværdier er for...

Page 45: Vedligeholdelse 7

Vedligeholdelse 7 19 7 vedligeholdelse 7.1 generelt _______________________________________________________________ 1. Justering og vedligeholdelse bør altid udføres af en uddannet tekniker. Kontakt en autoriseret jacobsen- forhandler, hvis du ikke kan foretage de korrekte justeringer. 2. Efterse ud...

Page 46: 7 Vedligeholdelse

7 vedligeholdelse 20 7.3 motorolie______________________________________________________________ kontroller motorolien ved dagens begyndelse, før du starter motoren. Hvis oliestanden er lav, skal du tage oliepåfyldningsdækslet af og påfylde olie efter behov. Olien skal skiftes første gang efter de f...

Page 47: Vedligeholdelse 7

Vedligeholdelse 7 21 7.6 hydraulikslanger _____________________________________________________ 1. Frakobl altid alle drev, sænk dybdelufterens hoved ned på jorden, stop motoren og frakobl tændrørskablet, før du undersøger eller frakobler hydraulikledninger eller –slanger. 2. Når motoren er stoppet,...

Page 48: 7 Vedligeholdelse

7 vedligeholdelse 22 7.8 lydpotte og udstØdning _______________________________________________ efterse hele udstødningssystemet regelmæssigt med henblik på beskyttelse mod kulilteforgiftning, og udskift altid en defekt lydpotte. Hvis du bemærker en ændring i udstødningens farve eller lyd, skal moto...

Page 49: Vedligeholdelse 7

Vedligeholdelse 7 23 7.12 installation af stempel________________________________________________ når stemplerne skiftes eller fjernes ved serviceeftersyn, skal der bruges et stempel-installationsværktøj (a) (jacobsen reservedelsnr. 517693) for at modvirke beskadigelse af de trerandede tætninger. Fi...

Page 50: 8 Fejlfinding

8 fejlfinding 24 8 fejlfinding 8.1 generelt_______________________________________________________________ nedenstående fejlfindingsskema viser de grundlæggende problemer, der kan opstå i forbindelse med start og drift. Kontakt den lokale jacobsen-distributør for at få mere detaljerede oplysninger o...

Page 51: Advarsel

Vedligeholdelses- og smØringsoversigter 9 25 9 vedligeholdelses- og smøringsoversigter 9.1 generelt _______________________________________________________________ 1. Rengør altid fedtfittingerne før og efter smøring. 2. Smør med fedt, der opfylder eller overstiger nlgi grad 2 lb-specifikationerne. ...

Page 52

10 ce overensstemmelseserklÆring 26 jacobsen, a textron company charlotte, north carolina u.S.A. • hereby declares that • erklärt hiermit, daß • por la presente declara q ue • déclare par la présente que • erklærer hermed at • dic h iara che il prodotto qui di seguito descritto • pela pres e n te, d...

Page 53: Parts Catalog 11

Parts catalog 11 27 11 parts catalog 11.1 how to use the parts catalog _________________________________________ abbreviations n/s - not serviced seperately, can only be obtained by ordering main component or kit. Ar -variable quantity or measurement is required to obtain correct adjustment. Symbols...

Page 54: Danger

28 keep hands and feet away danger ga 24 opc ga 24 opc 1 2 3 3 13 11 15 15 14 16 10 12 13 4 9 7 6 6 8 5 keep hands and feet away danger ga 24 opc 5 2 1 9 6 operation read manual before operating. Replacement manual available from: local dealer 4 11 1. Leer el manual del operador. No permitir que per...

Page 55: Ga 24

29 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 4132318 1 decal, throttle 2 4116118 1 decal, gear selector 3 4132147 1 decal, tine raise/lower 4 4116785 1 decal, operating instructions 5 4132281 2 decal, no step 6 4124712 2 decal, product id, ga 24 7 41...

Page 56: Ga 24

30 2 3 28 6 7 8 8 9 9 10 12 23 13 14 16 18 19 20 21 4 17 15 1 8 9 10 11 7 27 26 3 2 6 25 24 22 27 26 ga 24 2.1 chassis serial no. All.

Page 57: Ga 24

31 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 446116 8 lockwasher. .194 x .337 x .047 2 446128 5 lockwasher, 255 x .493 x .062 3 400104 5 screw, 1/4-20 x 1/2” hex head 4 444310 8 nut, #10-24 hex 5 452002 4 washer, flat .24 x .54 x .05 6 453023 5 washe...

Page 58: Ga 24

32 3 11 5 9 8 7 10 6 5 1 ref 1 2 2 4 ga 24 3.1 aerator enclosure serial no. All.

Page 59: Ga 24

33 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 2703142.7 1 plate, rear 2 2703714.7 2 plate, cover seal 3 403746 2 screw, #10-24 x 3/4” hex head 4 548900 4 screw, #10-24 x 1/2” ys hsf g5 5 800521 6 nut, #10-24 ys hsf 6 521050 6 boot 7 545371 6 ring asse...

Page 60: Ga 24

34 1 21 24 26 26 1 5 10 21 24 29 37 1 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 21 22 23 24 43 27 28 29 ref 30 31 33 4 17 15 26 34 37 38 39 40 35 36 32 42 1 19 19 21 24 25 1 41 21 10 21 ga 24 4.1 controls serial no. All.

Page 61: Ga 24

35 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes > 1 453009 6 flat washer, .31 x .69 x .06 > 2 460014 1 pin, cotter 3 460010 1 pin, cotter 4 443102 1 nut, 1/4-20 hex 5 400190 2 screw, 5/16-18 x 1-1/4” hex head 6 402118 2 screw, #10-24 x 1/2” 7 460026 1 pin...

Page 62: Ga 24

36 8 7 7 7 5 5 4 4 2 6 6 3 3 1 22 10 9 13 12 14 11 15 16 17 18 19 20 21 ga 24 5.1 chassis serial no. All.

Page 63: Ga 24

37 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 4144385 1 chassis, front service 2 2703216 2 cam case 3 4113007 2 cylinder assembly, hydraulic lift 4 4113032.7 2 mount, outer cylinder 5 4113031.7 2 mount, inner cylinder 6 400410 4 screw, 1/2-13 1-3/4 he...

Page 64: Ga 24

38 2 3 5 6 6 7 8 8 9 10 33 33 32 21 21 12 12 11 11 13 13 14 16 16 18 19 19 20 20 20 21 21 22 22 23 24 28 29 30 31 4 4 17 17 15 15 15 25 26 / 27 1 9 37 34 36 35 part of front chassis 38 39 40 ga 24 6.1 transaxle serial no. All.

Page 65: Ga 24

39 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 446140 2 lockwasher, 3/8 2 2702438 1 transaxle 3 2702591 2 rear hub 4116957 2 • bearing, ball 816320 4 • wheel bolt, 7/16-14 x 1-1/8” 4 2702673 2 sprocket, #40 16 tooth 5 2702965 1 gearbox, 90° 6 400144 2 ...

Page 66: Ga 24

40 25 3 3 18 19 20 21 2 16 17 5 12 9 10 14 14 15 15 17 18 8 8 11 11 13 25 1 5 4 30 7 6 22 24 23 26 27 28 29 ga 24 7.1 steering axle serial no. All.

Page 67: Ga 24

41 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 4113476 1 steering column 2 4113562 1 shaft assembly, steering 3 522011 2 bearing, nylon 4 400268 2 screw, 3/8-16 x 1-3/4” hex head 5 445796 3 nut, 3/8-16 flange crownlock 6 440078 2 bolt, carriage 5/16-18...

Page 68: Ga 24

42 15 1 19 19 3 5 6 18 21 17 16 6 1 8 3 4 14 2 9 10 11 12 13 7 20 22 23 24 25 26 ga 24 8.1 engine and pump serial no. All.

Page 69: Ga 24

43 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 n/s 1 engine, 8 hp intek pro 2 2704105.7 1 bracket, hydraulic pump 3 446140 2 lockwasher, .319 .591 .078 ys 4 400226 2 screw, 5/16-24 x 1 ys hx g5 5 453009 4 washer, flat .32 .63 .06 ys 6 402118 5 screw, 5...

Page 70: Ga 24

44 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 27 28 29 30 31 33 41 42 43 44 4 17 15 25 26 34 37 38 39 35 40 36 32 1 11 16 4 4 12 11 11 10 16 26 25 27 27 27 31 34 37 38 ga 24 9.1 belts & pulleys serial no. All.

Page 71: Ga 24

45 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 4112767 1 pulley, 8.83” od, 1” bore, 3v includes items 3 and 4 2 4113436 1 belt, 3v, mechanism 3 4112381 1 pulley, 8.83” od, 1” bore, 2-3v 4 463021 4 key, woodruff 5 4112766 1 pulley, 4.75” od, 1” bore, 3v...

Page 72: Ga 24

46 2 3 3 3 3 5 5 6 6 7 7 7 7 8 8 9 9 10 10 12 12 11 11 13 13 14 14 16 16 18 18 19 / 20 / 21 19 / 20 / 21 22 22 23 24 27 28 30 30 29 29 31 4 4 4 4 4 4 17 17 15 15 25 26 1 32 33 ga 24 10.1 cam case serial no. All.

Page 73: Ga 24

47 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 2703216 1 cam case 2 2703105 1 shaft, cam 3 521302 6 cam 4 463021 6 key, woodruff 5 520237 2 liner, bearing 6 520232 2 bearing, needle 7 520228 4 race, inner 8 520458 2 spacer, 1/4” 9 520456 2 spacer, 15/3...

Page 74: Ga 24

48 2 2 3 3 3 5 6 6 7 7 8 20 9 20 10 12 10 11 11 20 19 13 14 16 16 14 18 25 17 21 21 22 22 23 26 26 26 27 28 29 28 29 28 29 4 4 4 13 15 part of 15 24 25 1 33 32 35 34 30 31 32 36 36 27 27 ga 24 11.1 aerator crankshaft serial no. All.

Page 75: Ga 24

49 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 545520 1 support, left side crankshaft includes items 3 and 4 2 544792 2 support, right side crankshaft 3 548815 1 • bearing, needle 4 548224 1 • grease fitting 5 548811 6 dowel pin 6 520458 2 spacer, 1/4”...

Page 76: Ga 24

50 2 8 10 7 14 14 13 12 7 a 1 30 32 31 5 17 17 3 4 9 5 4 1 16 16 13 12 15 11 6 6 a 18 19 20 21 22 5 23 24 25 26 27 28 34 33 29 ga 24 12.1 hydraulic system serial no. All.

Page 77: Ga 24

51 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 400108 3 screw, 1/4-20 x 3/4” hex head 2 522113 1 hose, pump to lift/lower valve 3 522127 1 adapter, straight to 90° elbow 4 522650 3 clamp 5 445794 7 nut, 1/4-20 crownlock 6 823118 2 fitting, straight 7 8...

Page 78: Ga 24

52 2 1 1 3 2 1 4 5 6 9 3 8 7 8 10 11 12 13 14 13 15 ga 24 13.1 slide and glide assmebly serial no. All.

Page 79: Ga 24

53 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 540094 1 slide and guide assembly 540095 1 • slide assembly 1 2702293 1 • • slide assembly 2 800766 2 • • seal, oil pushrod installation tool, part no. 517693, is required to install push rod through slide s...

Page 80: Ga 24

54 1 2 3 4 5 10 12 6 11 11 8 9 7 13 13 14 ga 24 14.1 turf guard assembly serial no. All.

Page 81: Ga 24

55 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 1 4115936 1 mounting plate 2 4115939 1 guard, turf 3 4115931 2 bar, turf guard 4 4115935 2 bracket, connecting 5 4115944 2 link, adjustment 6 518510 2 spring, compression 7 809265 2 pin, hair .78 x 2.69 x .1...

Page 82: Ga 24

56 2 / 3 / 4 5 6 7 8 9 9 10 10 10 12 11 13 14 16 18 19 20 21 22 23 33 33 34 31 37 35 36 32 32 17 15 1 / 24 38 38 40 41 42 39 25 26 28 27 / 29 / 30 39 standard tine holder optional quad tine accessory 1/2" o.D. Tines optional tine holder 5/8" o.D. Tines (use with item 31) 3/4" o.D. Tines (use with it...

Page 83: Ga 24

57 > change from previous revision ga 24 item part no. Qty. Description serial numbers/notes 4116986 1 accessory, quad tine (coring) (optinal) includes items 2 through 24 4116987 1 accessory, quad tine (solid) (optional) includes items 1 through 23 1 523863 24 • tine, 1/4” solid 1/2” mounting o.D. 2...

Page 84: Index

58 index 1003815.......................35 22372 .. ........................43 2700335.......................39 2702104.......................53 2702293.......................53 2702438.......................39 2702591.7....................39 2702667.......................37 2702668.....................

Page 85: Index

59 index 548869 ........................53 548880 ..................39 , 41 548882 ........................35 548891 ........................49 548900 ........................51 548902 ........................47 548926 ........................47 800113 ........................47 800766 ................

Page 88

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ kvalitet, præstation og understøttelse i verdensklasse world class quality, performance and support equipment from jacobsen is built to exacting standards ensured by iso 900...