- DL manuals

- Jacobsen

- Lawn and Garden Equipment

- GreensAire 24 58234

- Technical Manual

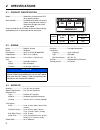

Jacobsen GreensAire 24 58234 Technical Manual - Controls 4

CONTROLS 4

11

4

CONTROLS

4.1

CONTROL DESCRIPTIONS _________________________________________________

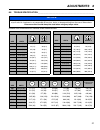

A.

Clutch Control Lever

Clutch control lever engages and disengages power

to tine operation clutch and latches OPC handle.

Pull

lever until OPC handle

(E)

closes for transport. Pull

handle until it clicks and locks in place for tine

operation. Release the OPC handle to disengage.

B.

Throttle

Controls the ground speed of the unit. Position lever

between Slow and Fast to set desired ground speed.

Fully raise lever to Stop position to shut off engine.

C.

Shift Control Lever

Four position lever used to operate different functions

of machine.

R (Reverse)

: Engages reverse traction. Tine

operation is locked out.

N (Neutral)

: Disengages both traction and tine

operation.

H (High)

: Engages transport speed only. Tine

operation is locked out.

L (Low)

: Engages aerating traction speed. Tine

operation can be engaged.

A

L

H

N

R

C

D

B

E

F

G

A

Clutch Control Lever

B

Throttle

C

Shift Control Lever

D

Tine Lever

E

OPC Handle

F

Engine Switch

G

Choke

WARNING

Damage to turf and/or aerator may occur if aerator

head is not fully raised before engaging OPC handle

with shift control lever

(C)

in R (Reverse) or H (High)

position.

!

Summary of GreensAire 24 58234

Page 1

Gb technical manual when performance matters. ™ warning if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers, and should read the entire manual before attempting to set up, operate, adjust, or se...

Page 2

© 2010, jacobsen, a textron company/textron innovations inc. All rights reserved, including the right to reproduce this material or portions thereof in any form. This manual contains safety, operating, adjustment, maintenance, troubleshooting instructions, and parts list for your new jacobsen® aerat...

Page 3: Table Of Contents

3 table of contents 1 safety 1.1 operating safety ................................................ 4 1.2 important safety notes ....................................... 5 2 specifications 2.1 product identification.......................................... 6 2.2 engine ..................................

Page 4: 1 Safety

1 safety 4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern, and prudence of those who operate or service the aerator. Never allow minors to operate any equipment. 2. It is your responsibility to read this manual ...

Page 5: Safety 1

Safety 1 5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

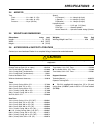

Page 6: 2 Specifications

2 specifications 6 2 specifications 2.1 product identification _________________________________________________ 58234 .............................. Greensaire 24 aerator with opc, 10 hp gasoline engine. Serial number ................ An identification plate, like the one shown, listing the serial ...

Page 7: Specifications 2

Specifications 2 7 2.4 aerator ________________________________________________________________ tires front.......................... 11 x 4.00 - 5 2 ply rear .......................... 16 x 6.50 - 8 4 ply pressure:................... 14 psi (97 kpa) speed: h (transport) ............ 0 - 4.0 mph (6....

Page 8: 2 Specifications

2 specifications 8 2.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shod Ě ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de co...

Page 9: Specifications 2

Specifications 2 9 harmonised standards used ▪ Използвани хармонизирани стандарти ▪ použité harmonizované normy ▪ brugte harmoniserede standarder ▪ gebruikte geharmoniseerde standaards ▪ kasutatud ühtlustatud standardid ▪ käytetyt yhdenmukaistetut standardit ▪ normes harmonisées utilisées ▪ angewand...

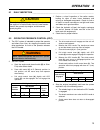

Page 10: 3 Decals and Icons

3 decals and icons 10 3 decals and icons 3.1 decals _________________________________________________________________ familiarize yourself with the decals as they are critical to the safe operation of the aerator. Replace damaged decals immediately. 3.2 icons ________________________________________...

Page 11: Controls 4

Controls 4 11 4 controls 4.1 control descriptions _________________________________________________ a. Clutch control lever clutch control lever engages and disengages power to tine operation clutch and latches opc handle. Pull lever until opc handle (e) closes for transport. Pull handle until it cl...

Page 12: 4 Controls

4 controls 12 d. Tine lever raises and lowers aerator head. Lift lever to raise position to raise head. Push lever to lower position to lower head. E. Opc handle engages and disengages drive clutch. Returns clutch control lever (a) to disengaged position when released. F. Engine switch controls engi...

Page 13: Operation 5

Operation 5 13 5 operation 5.1 daily inspection ________________________________________________________ 1. Perform a visual inspection of the entire aerator, looking for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and...

Page 14: 5 Operation

5 operation 14 5.3 operating procedures_________________________________________________ 1. Before starting engine, always release opc handle. 2. Do not operate aerator or attachments with loose, damaged, or missing components. 3. First aerate in a test area to become thoroughly familiar with the op...

Page 15: Operation 5

Operation 5 15 5.5 stopping / parking ______________________________________________________ to stop: release opc handle (e) to bring unit to a complete stop. To park the aerator under normal conditions: 1. Release opc handle (e) , raise the aerator head (d) . Move shift control lever (c) to h posit...

Page 16: 5 Operation

5 operation 16 5.8 aerating _______________________________________________________________ to aerate: 1. Start the engine and raise aerator head. 2. Move shift control lever to l position. 3. Move throttle lever to slow. Stand to the side of aerator and slowly engage opc handle. A. Adjust throttle ...

Page 17: Operation 5

Operation 5 17 how to calculate a slope: tools required: level (a) , either 1 yard, or 1 meter long. Tape measure (b) . With the level (a) positioned horizontally, measure the distance (c) with tape measure (b) . Use the chart to calculate either the slope angle or the % grade of the slope (d) . Fig...

Page 18: 6 Adjustments

6 adjustments 18 6 adjustments 6.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust , wor...

Page 19: Adjustments 6

Adjustments 6 19 6.4 traction drive idler cable _____________________________________________ 1. Engage opc handle. [ see section 4.1] 2. Adjust cable nuts (e) as necessary to obtain 0.18 inch (3.3 mm) deflection with a 4.4 lb (2.0 kg) push for new belt or 3.0 lb (1.4 kg) push for used belt at locat...

Page 20: 6 Adjustments

6 adjustments 20 6.6 shift control cable ___________________________________________________ if traction drive system does not shift properly, adjustment of the shift control cable may be required. 1. Disconnect clevis (n) from shift lever (p) . 2. Place the shift control lever in the l position. 3....

Page 21: Adjustments 6

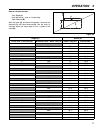

Adjustments 6 21 6.8 torque specification ___________________________________________________ jacobsen uses grade 5 bolts as standard, unless otherwise noted. Notice all torque values included in these charts are approximate and are for reference only. Use of these torque values is at your sole risk...

Page 22: 7 Maintenance

7 maintenance 22 7 maintenance 7.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the aerator on a dai...

Page 23: Maintenance 7

Maintenance 7 23 7.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap, and add oil as necessary. Perform initial oil change after the first 5 hours of op...

Page 24: 7 Maintenance

7 maintenance 24 7.6 hydraulic hoses _______________________________________________________ 1. Always disengage all drives, lower aerator head to ground, stop engine, and disconnect spark plug wire before inspecting or disconnecting hydraulic lines or hoses. 2. With engine stopped, move tine lever ...

Page 25: Maintenance 7

Maintenance 7 25 7.8 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and immediately replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the eng...

Page 26: 7 Maintenance

7 maintenance 26 7.12 pushrod installation __________________________________________________ whenever the push rods are removed for service or replaced, a pushrod installation tool (a) (jacobsen part no. 517693 ) is required to prevent damage to triple lip seals. [see figure 7b] figure 7b 7.13 stor...

Page 27: Troubleshooting 8

Troubleshooting 8 27 8 troubleshooting 8.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems, contact...

Page 28: Warning

9 maintenance & lubrication charts 28 9 maintenance & lubrication charts 9.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply gre...

Page 29: Tine Selection Guide 10

Tine selection guide 10 29 10 tine selection guide 11 original and duratine™ hole/core size type duty part number wall thickness mount diameter hole/core length total length application 1/4 in. (6 mm) side eject original 523864 solid side eject 1/2 in. (13 mm) 2.50 in. (64 mm) 4.00 in. (102 mm) prim...

Page 30: 12 Parts Catalog

12 parts catalog 30 12 parts catalog 12.1 how to use the parts catalog _________________________________________ abbreviations n/s - not serviced separately, can only be obtained by ordering main component or kit. Ar -variable quantity or measurement is required to obtain correct adjustment. Symbols...

Page 31: Parts Catalog 12

Parts catalog 12 31 12.1 table of contents______________________________________________________ 1.1 ......... Decals ................................................................ 32 2.1 ......... Chassis .............................................................. 34 3.1 ......... Aerator encl...

Page 32: Greensaire 24

32 1 2 3 3 11 13 13 12 14 8 10 11 8 6 5 5 7 4 4 2 1 8 5 9 10 important this machine uses greenscare 68, biodegrable hydraulic fluid. (order 5003103 for 5 gal. Pail) 15 15 16 17 105 db l wa 4164381 4164381 4164281 greensaire 24 greensaire 24 greensaire 24 important emissions information evaporative e...

Page 33: Greensaire 24

33 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 4132318 1 decal, throttle 2 4116118 1 decal, gear selector 3 4132147 1 decal, tine raise/lower 4 4132281 2 decal, no step 5 4124712 2 decal, product id, ga 24 6 4152417 1 decal, ga 24 new stripe-le...

Page 34: Greensaire 24

34 2 3 28 6 7 8 8 9 9 10 12 23 13 14 16 18 19 20 21 4 17 15 1 8 9 10 11 7 27 26 3 2 6 25 24 22 27 26 greensaire 24 2.1 chassis serial no. All.

Page 35: Greensaire 24

35 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 446116 8 lockwasher, #10 2 446128 5 lockwasher, 1/4 3 400104 5 screw, 1/4-20 x 1/2 in. Hex head 4 444310 8 nut, #10-24 hex 5 452002 4 flat washer, 3/16 6 453023 5 flat washer, 1/4 7 404014 5 screw,...

Page 36: Greensaire 24

36 3 11 5 9 8 7 10 6 5 1 ref 1 2 2 4 greensaire 24 3.1 aerator enclosure serial no. All.

Page 37: Greensaire 24

37 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 2703142.7 1 plate, rear 2 2703714.7 2 plate, cover seal 3 403746 2 screw, #10-24 x 3/4 in. Hex head 4 548900 4 screw, #10-24 x 1/2 in. Hex flange 5 800521 6 nut, #10-24 hex flange 6 521050 6 boot 7...

Page 38: Greensaire 24

38 1 21 24 26 26 1 5 10 21 24 29 37 1 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 21 1 22 23 24 43 27 28 29 ref 30 31 33 4 44 17 15 26 34 37 38 39 40 35 36 32 42 1 19 19 21 24 25 1 41 21 10 21 greensaire 24 4.1 controls serial no. All.

Page 39: Greensaire 24

39 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 453009 6 flat washer, 5/16 2 460014 1 pin, cotter 3 460010 1 pin, cotter 4 443102 1 nut, 1/4-20 hex 5 400190 2 screw, 5/16-18 x 1-1/4 in. Hex head 6 402118 2 screw, #10-24 x 1/2 in. Pan head 7 4600...

Page 40: Greensaire 24

40 8 7 7 7 5 5 4 4 2 6 6 3 3 1 22 10 9 13 12 14 11 15 16 17 18 19 20 21 greensaire 24 5.1 chassis serial no. All.

Page 41: Greensaire 24

41 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 1 chassis, front service 2 2703216 2 cam case 3 4113007 2 cylinder assembly, hydraulic lift 4 4113032.7 2 mount, outer cylinder 5 4113031.7 2 mount, inner cylinder 6 400410 4 screw, 1/2-13 1-3/4 in...

Page 42: Greensaire 24

42 2 3 5 6 6 7 8 8 9 10 33 33 32 21 21 12 12 11 11 13 13 14 16 16 18 19 19 20 20 20 21 21 22 22 23 24 28 29 30 31 4 4 17 17 15 15 15 25 26 / 27 1 9 37 34 36 35 part of front chassis 38 39 40 greensaire 24 6.1 transaxle serial no. All.

Page 43: Greensaire 24

43 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 446140 2 lockwasher, 3/8 2 2702438 1 transaxle 3 2702591 2 rear hub 4116957 2 • bearing, ball 816320 4 • wheel bolt, 7/16-14 x 1-1/8 in. 4 2702673 2 sprocket, #40 16 tooth 5 2702965 1 gearbox, 90° ...

Page 44: Greensaire 24

44 25 3 3 18 19 20 21 2 16 17 5 12 9 10 14 14 15 15 17 18 8 8 11 11 13 25 1 5 4 30 7 6 22 24 23 26 27 28 29 greensaire 24 7.1 steering axle serial no. All.

Page 45: Greensaire 24

45 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 4113476 1 steering column 2 4113562 1 shaft assembly, steering 3 522011 2 bearing, nylon 4 400268 2 screw, 3/8-16 x 1-3/4 in. Hex head 5 445796 3 nut, 3/8-16 spiralock flange 6 440078 2 bolt, carri...

Page 46: Greensaire 24

46 15 19 19 19 19 19 19 19 3 5 6 18 21 17 16 6 1 8 3 4 14 2 9 10 11 12 13 7 20 22 23 24 25 26 a b a b 27 28 29 30 31 32 33 34 35 36 37 greensaire 24 8.1 engine and pump serial no. All.

Page 47: Greensaire 24

47 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 n/s 1 engine, 10 hp b & s vanguard 2 2704105.7 1 bracket, hydraulic pump 3 446136 7 lockwasher, 5/16 4 400226 3 screw, 5/16-24 x 1 in. Hex head 5 453009 4 flat washer, 5/16 6 306501 5 screw, 5/16-1...

Page 48: Greensaire 24

48 2 3 5 6 7 8 9 10 12 11 13 14 16 18 19 20 21 22 23 24 27 28 29 30 31 33 41 42 43 44 4 17 15 25 26 34 37 38 39 35 40 36 32 1 11 16 4 4 12 11 11 10 16 26 25 27 27 27 31 34 37 38 greensaire 24 9.1 belts & pulleys serial no. All.

Page 49: Greensaire 24

49 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 4112767 1 pulley, 8.83 in. Od, 1 in. Bore, 3v includes items 3 and 4 2 4113436 1 belt, 3v, mechanism 3 4112381 1 pulley, 8.83 in. Od, 1 in. Bore, 2-3v 4 463021 4 key, woodruff 5 4112766 1 pulley, 4...

Page 50: Greensaire 24

50 2 3 3 3 3 5 5 6 6 7 7 7 7 8 8 9 9 10 10 12 12 11 11 13 13 14 14 16 16 18 18 19 / 20 / 21 19 / 20 / 21 22 22 23 24 27 28 30 30 29 29 31 4 4 4 4 4 4 17 17 15 15 25 26 1 32 33 greensaire 24 10.1 cam case serial no. All.

Page 51: Greensaire 24

51 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 2703216 1 cam case 2 2703105 1 shaft, cam 3 521302 6 cam 4 463021 6 key, woodruff 5 520237 2 liner, bearing 6 520232 2 bearing, needle 7 520228 4 race, inner 8 520458 2 spacer, 1/4 in. 9 520456 2 s...

Page 52: Greensaire 24

52 2 2 3 3 3 5 6 6 7 7 8 20 9 20 10 12 10 11 11 20 19 13 14 16 16 14 18 25 17 21 21 22 22 23 26 26 26 27 28 29 28 29 28 29 4 4 4 13 15 part of 15 24 25 1 33 32 35 34 30 31 32 37 36 36 27 27 greensaire 24 11.1 aerator crankshaft serial no. All.

Page 53: Greensaire 24

53 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 545520 1 support, left side crankshaft includes items 3 and 4 2 544792 2 support, right side crankshaft 3 548815 1 • bearing, needle 4 548224 1 • grease fitting 5 548811 6 dowel pin 6 520458 2 spac...

Page 54: Greensaire 24

54 2 8 10 7 14 14 13 12 7 a 1 30 32 31 5 17 17 3 4 9 5 4 1 16 16 13 12 15 11 6 6 a 18 19 20 21 22 5 23 24 25 26 27 28 34 33 29 greensaire 24 12.1 hydraulic system serial no. All.

Page 55: Greensaire 24

55 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 400108 3 screw, 1/4-20 x 3/4 in. Hex head 2 522113 1 hose, pump to lift/lower valve 3 522127 1 adapter, straight to 90° elbow 4 522650 3 clamp 5 445794 7 nut, 1/4-20 spiralock flange 6 823118 2 fit...

Page 56: Greensaire 24

56 2 1 1 3 2 1 4 5 6 9 3 8 7 8 10 11 12 13 14 13 15 greensaire 24 13.1 slide and glide assembly serial no. All.

Page 57: Greensaire 24

57 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 540094 1 slide and guide assembly 540095 1 • slide assembly 1 2702293 1 • • slide assembly 2 800766 2 • • seal, oil pushrod installation tool, part no. 517693, is required to install push rod through...

Page 58: Greensaire 24

58 1 2 3 4 5 10 12 6 11 11 8 9 7 13 13 14 greensaire 24 14.1 turf guard assembly serial no. All.

Page 59: Greensaire 24

59 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 4115936 1 mounting plate 2 4115939 1 guard, turf 3 4115931 2 bar, turf guard 4 4115935 2 bracket, connecting 5 4115944 2 link, adjustment 6 518510 2 spring, compression 7 809265 2 pin, hair .78 x 2...

Page 60: Greensaire 24

60 1 2 3 4 5 8 8 9 10 11 7 7 13 13 15 16 17 14 14 standard 5/8 in. O.D.Tine holder 1/2 in. O.D. Tine holder optional 3/4 in. O.D.Tine holder greensaire 24 15.1 tines and holders optional accessories serial no. All.

Page 61: Greensaire 24

61 > change from previous revision greensaire 24 item part no. Qt y. Description serial numbers/notes 1 547849 6 tine holder for 1/2 in. Mounting o.D. Tines optional 2 446136 1 • lockwasher, 5/16 3 800512 1 • screw, 5/16-18 x 1-1/14 in. Socket hd 4 800694 2 • screw, 5/16-18 x 2-1/2 in. Grade 8 5 829...

Page 62: Greensaire 24

62 greensaire 24 2 / 3 / 4 5 6 7 8 9 9 10 10 10 12 11 13 14 16 17 15 optional quad tine accessory 18 19 20 21 22 23 1 / 24 1/2 in. O.D. Tines 15.1 quad tine accessory part numbers 58231, 4116986 and 4116987.

Page 63: Greensaire 24

63 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 4116986 1 accessory, quad tine (coring) (optional) includes items 1 through 23 4116987 1 accessory, quad tine (solid) (optional) includes items 3 through 24 1 523863 24 • tine, 1/4 in. Solid 1/2 in. ...

Page 64: Greensaire 24

64 1 2 3 4 5 6 7 8 9 10 11 12 12 1 3 14 15 16 17 1 8 1 8 19 20 21 21 21 21 22 2 3 24 25 25 26 27 2 8 29 3 0 3 1 3 2 33 3 4 3 5 3 6 3 7 38 3 9 40 46 47 4 8 49 50 41 42 4 3 44 44 45 45 56 57 57 5 8 5 8 59 59 60 60 51 52 5 3 54 55 66 67 6 8 6 8 69 69 70 70 61 62 6 3 64 65 76 76 77 7 8 79 79 8 0 71 71 7...

Page 65: Greensaire 24

65 > change from previous revision greensaire 24 item part no. Qty. Description serial numbers/notes 1 556331 1 case, top transaxle 2 556333 1 case, bottom transaxle 3 556350 17 screw, 5/16-18 x 1-3/4” 4 556351 1 retaining ring 5 551171 1 ball bearing 6 556371 1 input shaft 7 556332 1 needle bearing...

Page 66: Greensaire 24

66 1 2 3 4 5 6 7 8 9 10 11 12 12 1 3 14 15 16 17 1 8 1 8 19 20 21 21 21 21 22 2 3 24 25 25 26 27 2 8 29 3 0 3 1 3 2 33 3 4 3 5 3 6 3 7 38 3 9 40 46 47 4 8 49 50 41 42 4 3 44 44 45 45 56 57 57 5 8 5 8 59 59 60 60 51 52 5 3 54 55 66 67 6 8 6 8 69 69 70 70 61 62 6 3 64 65 76 76 77 7 8 79 79 8 0 71 71 7...

Page 67: Greensaire 24

67 > change from previous revision greensaire 24 46 556390 1 washer 47 556376 1 roller chain, no. 41 chain, 22 link 48 556341 1 bevel gear, 33 tooth 49 4144271 1 spur gear, 30 tooth 50 4144270 1 spur gear, 12 tooth steel 51 5003333 4 spacer, 1-1/8 x 3/8 52 551434 1 thrust bearing 53 590294 2 washer,...

Page 68: Index

68 index 1003815 ......................35 22372.. ........................43 2700335.......................39 2702060.......................57 2702104 ......................53 2702293.......................53 2702438.......................39 2702591.7....................39 2702667......................

Page 69: Index

69 index 545801 ....................... 41 547132 ....................... 57 547293 ....................... 49 547596 ....................... 49 547849 ................. 57, 59 547860 ....................... 57 547861 ....................... 57 547896 ....................... 51 548224 ........... 37...

Page 70

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and f...