- DL manuals

- Jacobsen

- Tractor

- HR3300T

- Safety, Operation & Maintenance Manual

Jacobsen HR3300T Safety, Operation & Maintenance Manual

RJL 100September 2011

GB

United

Kingdom

Safety, Operation & Maintenance Manual

Jacobsen HR3300T

Series: FY

Product code: JHR33001

24823-GB (rev.3)

WARNING: If incorrectly used this machine can cause

severe injury. Those who use and maintain this

machine should be trained in its proper use, warned of

its dangers and should read the entire manual before

attempting to set up, operate, adjust or service the

machine.

Summary of HR3300T

Page 1

Rjl 100september 2011 gb united kingdom safety, operation & maintenance manual jacobsen hr3300t series: fy product code: jhr33001 24823-gb (rev.3) warning: if incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of...

Page 2

© 2011, ransomes jacobsen limited. All rights reserved.

Page 3

Safety, operators & maintenance manual en-3 1 contents 2.1 important ...........................................................4 2.2 product identification .................................4 2.3 guidelines for the disposal of scrap products .........................................5 2.3.1 during se...

Page 4

Safety, operators & maintenance manual en-4 2 introduction 2.1 important important: this is a precision machine and the service obtained from it depends on the way it is operated and maintained. This safety and operators manual should be regarded as part of the machine. Suppliers of both new and sec...

Page 5

Safety, operators & maintenance manual en-5 2 introduction 2.3 guidelines for the disposal of scrap products 2.3.1 during service life used oil, oil filters and engine coolant are hazardous materials and should be handled in a safe and environmentally responsible way. In the event of a fluid leak, c...

Page 6

Safety, operators & maintenance manual en-6 3 safety instructions this safety symbol indicates important safety mes- sages in this manual. When you see this symbol, be alert to the possibility of injury, carefully read the mes- sage that follows, and inform other operators. 3.1 operating instruction...

Page 7

Safety, operators & maintenance manual en-7 3 safety instructions 3.7 slopes take extra care when working on slopes • local undulations and sinkage will change the general slope. Avoid ground conditions which can cause the machine to slide. • keep machine speeds low on slopes and during tight turns....

Page 8

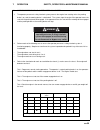

Safety, operators & maintenance manual en-8 3 safety instructions danger: indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning: indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. Ca...

Page 9

Safety, operators & maintenance manual en-9 3 safety instructions when carrying out any welding on the machine the battery and controller must be disconnected before starting. Under no circumstances should the controller be opened as this will invalidate all warranties and could result in a malfunct...

Page 10

Safety, operators & maintenance manual en-10 4 specification 4.1 engine specification type: kubota 24.5kw @ 3000 rpm, 3 cylinder (in line) diesel engine, 4 stroke turbo charged, water cooled, 1123cc with 12v 1kw electric start, 12v 30amp alternator model: d1105-t-e3b-rnuk-3 maximum speed: 3150 ± 50 ...

Page 11

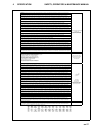

Safety, operators & maintenance manual en-11 4 specification a g b c d e f h j l m k n r s p tyre pressure product front wheel rear wheel tyre size tyre type tyre pressure tyre size tyre type tyre pressure hr3300t 26 x 12.00 - 12 bkt lg306 6pr 1.00 - 1.37 bar 20 x 1 0.00 - 8 bkt lg306 4pr 1.00 - 1.3...

Page 12

Safety, operators & maintenance manual en-12 4 specification 4.4 hydraulic specification description litres / min relief valve pressure test port location transmission forward 95 250bar see section 8.6 reverse 19 250bar see section 8.6 charge - 18bar cutting forward 68 250bar see section 8.6 reverse...

Page 13

Safety, operators & maintenance manual en-13 4 specification 4.7 cutter deck specification 152cm deck 160cm deck 183cm deck construction heavy duty welded pressed steel construction blade length 533mm 559mm 635mm number of blades 3 blade tip speed 4463 m/min 4630 m/min 5318 m/min width of cut 1524mm...

Page 14

Safety, operators & maintenance manual en-14 4 specification business name and full address of the manufacturer ƒ Ɍɴɪɝɨɜɫɤɨ ɢɦɟ ɢ ɩɴɥɟɧ ɚɞɪɟɫ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ ƒ obchodní jméno a plná adresa výrobce ƒ producentens firmanavn og fulde adresse ƒ bedrijfsnaam en volledig adres van de fabrikant ƒ tootja ä...

Page 15

Safety, operators & maintenance manual en-15 4 specification operator ear noise level ƒ Ɉɩɟɪɚɬɨɪ ɧɚ ɧɢɜɨɬɨ ɧɚ ɞɨɥɨɜɢɦ ɨɬ ɭɯɨɬɨ ɲɭɦ ƒ hladina hluku v oblasti uší operátora ƒ støjniveau i førers ørehøjde ƒ geluidsniveau oor bestuurder ƒ müratase operaatori kõrvas ƒ melutaso käyttäjän korvan kohdalla ƒ...

Page 16

Safety, operators & maintenance manual en-16 4 specification ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt product code serial number lmac266 fs000301 - fs999999 lmac364 ga000317 - ga999999 lmac294 ga000301 - ga000316 lmac320 gb000301 - gb999999 lmac267 fx000301 -...

Page 17

Safety, operators & maintenance manual en-17 4 specification ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt 4th january 2010 the place and date of the declaration ƒ Ɇɹɫɬɨ ɢ ɞɚɬɚ ɧɚ ɞɟɤɥɚɪɚɰɢɹɬɚ ƒ místo a datum prohlášení ƒ sted og dato for erklæringen ƒ plaats en d...

Page 18

Safety, operators & maintenance manual en-18 4 specification business name and full address of the manufacturer ƒ Ɍɴɪɝɨɜɫɤɨ ɢɦɟ ɢ ɩɴɥɟɧ ɚɞɪɟɫ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ ƒ obchodní jméno a plná adresa výrobce ƒ producentens firmanavn og fulde adresse ƒ bedrijfsnaam en volledig adres van de fabrikant ƒ tootja ä...

Page 19

Safety, operators & maintenance manual en-19 4 specification operator ear noise level ƒ Ɉɩɟɪɚɬɨɪ ɧɚ ɧɢɜɨɬɨ ɧɚ ɞɨɥɨɜɢɦ ɨɬ ɭɯɨɬɨ ɲɭɦ ƒ hladina hluku v oblasti uší operátora ƒ støjniveau i førers ørehøjde ƒ geluidsniveau oor bestuurder ƒ müratase operaatori kõrvas ƒ melutaso käyttäjän korvan kohdalla ƒ...

Page 20

Safety, operators & maintenance manual en-20 4 specification business name and full address of the manufacturer ƒ Ɍɴɪɝɨɜɫɤɨ ɢɦɟ ɢ ɩɴɥɟɧ ɚɞɪɟɫ ɧɚ ɩɪɨɢɡɜɨɞɢɬɟɥɹ ƒ obchodní jméno a plná adresa výrobce ƒ producentens firmanavn og fulde adresse ƒ bedrijfsnaam en volledig adres van de fabrikant ƒ tootja ä...

Page 21

Safety, operators & maintenance manual en-21 4 specification operator ear noise level ƒ Ɉɩɟɪɚɬɨɪ ɧɚ ɧɢɜɨɬɨ ɧɚ ɞɨɥɨɜɢɦ ɨɬ ɭɯɨɬɨ ɲɭɦ ƒ hladina hluku v oblasti uí operátora ƒ støjniveau i førers ørehøjde ƒ geluidsniveau oor bestuurder ƒ müratase operaatori kõrvas ƒ melutaso käyttäjän korvan kohdalla ƒ...

Page 22

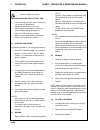

Safety, operators & maintenance manual en-22 5 decals 5.1 safety decals ec a. 009034910 read operator's manual. B. 009034890 keep a safe distance from the machine. C. 009034920 stay clear of hot surfaces. D. 009034880 do not open or remove safety shields while the engine is running. E. 009034960 cau...

Page 23

Safety, operators & maintenance manual en-23 5 decals 5.2 instruction decals ec description a. Maximum sound power level b. Parking brake c hourmeter d beacon e cutting unit drive f throttle g traction pedal, forward / reverse h diff lock switch j mow / transport lever k power socket 12 volt l heigh...

Page 24

Safety, operators & maintenance manual en-24 6 controls stop 1234 a p e b j s h d r f l k m n c g 6.1 instrument panel (after serial no. Fr000322 & fy000312) a: starter key switch b: throttle control lever c: parking brake switch d: cutter switch e: emergency stop switch (optional) f: fuel gauge g: ...

Page 25

Safety, operators & maintenance manual en-25 6 controls stop 1234 a p g f r e c b h d s j l k n m 6.1.1 instrument panel (before serial no. Fr000323 & fy000313) a: starter key switch b: throttle control lever c: parking brake switch d: cutter switch e: emergency stop switch f: fuel gauge g: engine c...

Page 26

Safety, operators & maintenance manual en-26 6 controls 1 6.1a starter key switch the starter key (a) should be turned clockwise to the 'start' position to start the engine. After starting, the key should be released and allowed to return automatically to the 'on' position for normal running. Note:t...

Page 27

Safety, operators & maintenance manual en-27 6 controls stop 6.1e emergency stop switch (optional) this switch allows the operator to stop the machine in an emergency. To reset the switch rotate the button. 6.1f fuel gauge indicates the amount of fuel in the fuel tank. 6.1g engine coolant temperatur...

Page 28

Safety, operators & maintenance manual en-28 6 controls a b k c d l 6.1j blocked hydraulic filter indicator lamp. Monitors hydraulic filter condition. Coloured red, illuminates prior to filter bypass valve operating, when illuminated filter requires changing. The red lens should illuminate while the...

Page 29

Safety, operators & maintenance manual en-29 6 controls 6.1n fault indicator lamp colour red, illuminates when there is a fault in the operator presence and interlock system. The lamp will flash during the start cycle to identify that the glow plugs are operating. 6.1p rotating beacon switch (option...

Page 30

Safety, operators & maintenance manual en-30 6 controls a b c d a 6.2 traction pedal a. Forward travel (traction pedal c) press the front of pedal down for forward travel. To slow and stop - gently return the fwd/rev foot pedal to the neutral position. Do not press traction pedal when parking brake ...

Page 31

Safety, operators & maintenance manual en-31 6 controls a d a b 6.5 diff lock the diff lock switch (a) is situated on the foot plate to the left of the steering tower. The diff lock is operated by depressing the foot switch. When the foot switch is released the diff lock ceases to operate. The diff ...

Page 32

Safety, operators & maintenance manual en-32 6 controls b a c d e a b 6.10 lighting kit (optional) lighting control stalk a push away from operator to turn lights on. B pull towards operator to flash headlights. C move stalk up to indicate left turn. D move stalk down to indicate right turn. E push ...

Page 33

Safety, operators & maintenance manual en-33 6 controls a b c d e x y z 6.11 seat right hand arm rest & pod the right hand arm rest of the seat has an extension mounted to it which carries the control pod. To obtain a comfortable operating position: a release hand wheel (a). B using both hands grip ...

Page 34

Safety, operators & maintenance manual en-34 7 operation 7.1 daily inspection 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware and missing or damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and tubes are in good cond...

Page 35

Safety, operators & maintenance manual en-35 7 operation 7.2 operator presence and safety interlock system 1. The operator presence & safety interlock system prevents the engine from starting unless the parking brake is on, and the mowing device is switched off. The system stops the engine if the op...

Page 36

Safety, operators & maintenance manual en-36 7 operation 7.3 operating procedure 1. Under no circumstances should the engine be started without the operator seated on the tractor. 2. Do not operate tractor or attachments with loose, damaged or missing components. Whenever possible mow when grass is ...

Page 37

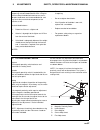

Safety, operators & maintenance manual en-37 7 operation a b c 9. Under no circumstances should the engine be started without the operator seated on the tractor. 10. Do not operate tractor or attachments with loose, damaged or missing components. 7.4 fitting the cutting unit to the machine 1. With t...

Page 38

Safety, operators & maintenance manual en-38 7 operation 7.5 operation of the machine read the safety instructions. Before operating for the first time • check and adjust tyre pressure, if necessary, see section 4.2 specification. • add diesel fuel to tank if neccesary. • check engine oil and top-up...

Page 39

Safety, operators & maintenance manual en-39 7 operation b a 7.10 unblocking cutter decks 1. Switch off cutter deck, lift out of work and move machine to flat level ground. 2. Switch engine off and remove the ignition key. 3. Pivot deck see section 9.4. 4. Using a piece of wood and personal protecti...

Page 40

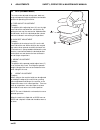

Safety, operators & maintenance manual en-40 7 operation a 7.13 mowing on slopes the mower has been designed for good traction and stability under normal mowing conditions. Use caution when operating on slopes, especially when the grass is wet. Wet grass reduces traction and steering control. 1. Alw...

Page 41

Safety, operators & maintenance manual en-41 7 operation ####### a d c if it is necessary to mow across a short slope, ensure the right hand cutting unit is the lowest. When the machine is being used, whether cutting grass or not, on slopes, the rops frame should be deployed and the seat belt used. ...

Page 42

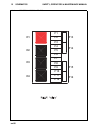

Safety, operators & maintenance manual en-42 7 operation slope calculation chart use either of these columns but not both the result of what you are measuring height ‘c’ in inches measured with a 1 yard horizontal edge ‘a’ height ‘c’ in millimeters measured with a 1 metre horizontal edge ‘a’ slope a...

Page 43

Safety, operators & maintenance manual en-43 7 operation.

Page 44

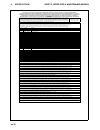

Safety, operators & maintenance manual en-44 8 maintenance & lubrication 8.1 maintenance & lubrication chart maintenance and lubrication chart interval item section first 50 hours change engine oil check fan belt tension change hydraulic filter 8.2 8.3 8.5 daily 10 hours check engine oil level. Chec...

Page 45

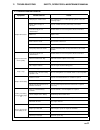

Safety, operators & maintenance manual en-45 8 maintenance & lubrication a b c d e g f 8.2 8.2 8.2 8.3 8.4 8.5 8.5 8.7 8.7 8.8 8.9.

Page 46

Safety, operators & maintenance manual en-46 8 maintenance & lubrication a b c d 8.2 engine lubrication check engine oil level check the engine oil level before starting or more than five minutes after stopping the engine. (a) with the machine on level ground, remove the dipstick d, wipe it clean an...

Page 47

Safety, operators & maintenance manual en-47 8 maintenance & lubrication 8.3 engine: fan belt check & adjust fan belt. The fan belt is adjusted so that it has sufficient tension to avoid undue stress on alternator bearings but does not slip on the alternator pulley. Use the following procedure to ch...

Page 48

Safety, operators & maintenance manual en-48 8 maintenance & lubrication b a 8.4 engine coolant check engine coolant level (a) the level of coolant in the expansion tank should be between the max and min level indicators when cold. (b) if topping up is required, remove the plastic cap and top up usi...

Page 49

Safety, operators & maintenance manual en-49 8 maintenance & lubrication a c b 8.5 hydraulic system check hydraulic oil level check hydraulic oil level using sight gauge (c). Change hydraulic oil (a) clean around hose (a) in bottom of hydraulic tank and remove. (b) allow tank to drain into a suitabl...

Page 50

Safety, operators & maintenance manual en-50 8 maintenance & lubrication c b a 8.7 hydraulic test ports if any problems are experienced with the hydraulic system service ports are provided to enable pressures to be checked. All tests, unless stated otherwise, should be carried out with the hydraulic...

Page 51

Safety, operators & maintenance manual en-51 8 maintenance & lubrication a b c d e f 8.8 fuel system use diesel fuel no.2-d (astm d975) see engine manufacturer's manual for additional information. Bleeding air from fuel system (a) turn the ignition switch to the on position (don't start engine). (b)...

Page 52

Safety, operators & maintenance manual en-52 8 maintenance & lubrication 8.9 air cleaner cleaning the air filter note:after 6 cleanings replace the filter element. (a) raise engine cover. (b) remove end cap of air filter cartridge. (c) remove loose dirt from element with compressed air working from ...

Page 53

Safety, operators & maintenance manual en-53 8 maintenance & lubrication a b d c 8.12 machine maintenance other regular service. • verify proper operation of safety interlock switches (seat switch, etc.) • ensure nuts and bolts remain tight. • visually inspect for hydraulic leaks. • keep engine bay ...

Page 54

Safety, operators & maintenance manual en-54 9 adjustments a 9.1 traction control pedal the lpv transmission pump has an internal neutralising mechanism which cannot be adjusted. If the machine does however creep carry out the following. 1. Lift and support both front and rear wheels. 2. Remove ball...

Page 55

Safety, operators & maintenance manual en-55 9 adjustments 9.3 height of cut cutting height for decks can be adjusted from 25- 115mm. Actual cutting height may vary somewhat from the heights given depending on turf conditions and other factors. Note: when cutting undulating areas, lower cutting heig...

Page 56

Safety, operators & maintenance manual en-56 9 adjustments e d 9.4 blade change 1. Raise the deck so it is just clear of the ground. This will allow the setting pin d to lift clear of the arm and be easier to remove. 2. Remove the pins at position d on both sides of the machine which lock the deck i...

Page 57

Safety, operators & maintenance manual en-57 9 adjustments b c a e d blades may be sharpened by filing or grinding. When sharpening, maintain blade balance within 19.4 g/cm. Failure to keep the blade balanced causes excess vibration, blade wear and shortened blade life, and may harm other mechanical...

Page 58

Safety, operators & maintenance manual en-58 9 adjustments 9.7 general instructions for grammer seats • the operating instructions must be read in full before use. • the driver’s seat may only be fitted, serviced and repaired by specialist personnel, in accordance with national regulations and the v...

Page 59

Safety, operators & maintenance manual en-59 9 adjustments do not hold onto the covers for lifting the driver’s seats. If you do so anyway, there is an increased risk of injury due to loosening or breaking covers. Before you remove the driver’s seat, disconnect all plug-in connections between the se...

Page 60

Safety, operators & maintenance manual en-60 9 adjustments 9.8 seat (grammer msg85) the seat can be adjusted for leg reach, back rest angle and operator weight to provide a comfortable position for operating the machine. A. Fore and aft adjustment to adjust: the position of the adjusting lever (a) i...

Page 61

Safety, operators & maintenance manual en-61 9 adjustments 9.9 air suspension seat (grammer msg75 -521) 9.9.1 weight adjustment the seat is adjusted for the driver’s weight by pulling or pressing the lever for seat weight adjustment and with the driver sitting on the seat. The driver’s weight is adj...

Page 62

Safety, operators & maintenance manual en-62 9 adjustments 9.9.3 backrest extension * ** the backrest extension can be individually adjusted by pulling it upwards or pushing it downwards over the various locking increments up the end stop. To remove the backrest extension, pull it upwards over the e...

Page 63

Safety, operators & maintenance manual en-63 9 adjustments 9.9.6 armrests * ** the armrests can be folded up if required and the height individually adjusted. To adjust the armrests for height, separate the round cap (see arrow) from the cover, loosen the hexagon nut (size 13 mm) behind it and adjus...

Page 64

Safety, operators & maintenance manual en-64 9 adjustments 9.9.9 maintenance dirt can impair the function of the seat, so make sure you keep your seat clean! Upholstery does not need to be removed from the seat frame for cleaning. Caution: take care with the backrest - it may jerk forward and cause ...

Page 65

Safety, operators & maintenance manual en-65 10 accessories 0 4 10.1 152 cm rear discharge deck kit number lmac266. 10.2 183 cm rear discharge deck kit number lmac267. 10.3 152 cm mulching deck kit number lmac294. 10.4 152 cm mulching deck conversion kit kit number lmac293. To convert a standard 152...

Page 66

Safety, operators & maintenance manual en-66 10 accessories 10.8 rops frame kit number lmac259. Oecd code 4 compliant. Stability angle rotary cutter deck 12° 10.9 rotary beacon kit kit number lmac290..

Page 67

Safety, operators & maintenance manual en-67 10 accessories 10.10 light kit kit number lmac260 for 152cm decks. Kit number lmac297 for 160cm & 183cm decks. Storage racks, kit number lmac272 are included in the light kit. Maximum capacity per rack is 5kg. 10.11 mirror kit kit number lmac270..

Page 68

Safety, operators & maintenance manual en-68 10 accessories 10.12 storage racks kit number lmac272. Maximum capacity per rack is 5kg. 10.13 storage pod kit number lmac271 cannot be used with rops cab fitted. 10.14 auxiliary hydraulic services kit kit number lmac307 fitting instructions 24836g this k...

Page 69

Safety, operators & maintenance manual en-69 10 accessories 10.15 rotary brush kit number lmac322 fitting instructions 24844g 10.16 snow blade kit number lmac268 fitting instructions 24845g 10.17 weight kit for rotary brush 33.2 kgs kit number lmac269 0 0

Page 70

Safety, operators & maintenance manual en-70 10 accessories 10.18 e stop kit kit number lmac291 10.19 slave battery lead kit kit number lmac292.

Page 71

Safety, operators & maintenance manual en-71 11 troubleshooting 11.1 troubleshooting general symptons posible causes action engine will not start glow plug has not timed out reset ignition switch and allow glow plug to time out before cranking engine. Battery low on charge or defective. Inspect cond...

Page 72

En-72 12 quality of cut it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area should provide known and consistent turf conditions to allow accurate evaluation of the mower’s ...

Page 73

En-73 12 quality of cut 12.2 step cutting note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a cutting unit than the other or on one side of mower to the other. This is usually caused by mechanical wear or an incorrect roller or deck caster adjustm...

Page 74

En-74 12 quality of cut 12.3 scalping note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is usually caused by an excessively low height-of-cut (hoc) set...

Page 75

En-75 12 quality of cut 12.4 stragglers note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy dull cutting blades(s). Sharpen or replace blade. Mowing (ground) speed is too fast. Reduce mowing (ground) speed. Grass is too tall....

Page 76

En-76 12 quality of cut 12.5 streaks note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a damaged blade. Probable cause remedy damaged blade(s). Replace blade(s). Turning too aggressively. Cutting units don’t overlap during turns or on side hills....

Page 77

En-77 12 quality of cut 12.6 windrowing note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Probable cause remedy grass is too tall. Mow more often. Mowin...

Page 78

En-78 12 quality of cut 12.7 mismatched cutting units note: arrow indicates direction of travel. Mismatched cutting units is a pattern of varying cut- ting heights, resulting in a stepped cut appearance, usually due to mismatched hoc (height-of-cut) ad- justment from one cutting unit to another. Pro...

Page 79

En-79 12 quality of cut.

Page 80

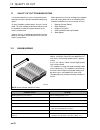

Safety, operators & maintenance manual en-80 13 schematics r1 r2 r3 r4 f1 f2 f3 f4 f5 f6 f7 f8 f9 f10 f11 f12 f13 f14 f15 f16 13.1 electrical fuses & relays.

Page 81

Safety, operators & maintenance manual en-81 13 schematics 13.1 electrical fuses & relays fuse no. Rating function 1 5 amp left hand side lamps 2 5 amp right hand side lamps 3 10 amp left hand head lamps 4 10 amp right hand head lamps 5 5 amp beacon 6 10 amp controller supply 7 2 amp ignition on cir...

Page 82

Safety, operators & maintenance manual en-82 14 torques 14.1 torques fine pitch metric threads dia (mm) grade 4.6 grade 4.8 grade 8.8 grade 10.9 grade 12.9 (nm) (nm) (nm) (nm) (nm) 6 0 0 0 0 0 8 12 16 32 45 54 10 24 31 63 88 106 12 42 57 113 159 191 14 67 90 179 252 302 16 103 137 274 385 462 20 209...

Page 83: Guarantee

Safety, operators & maintenance manual en-83 15 guarantee guarantee we guarantee that should any defect in workmanship or material occur in the goods within two years or two thousand hours (on models equipped with hour meters), or whichever occurs first. Exception to this warranty will be aeration p...

Page 86

Ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacobsen.Com.