- DL manuals

- Jacobsen

- Lawn Mower

- LF 3400

- Parts And Maintenance Manual

Jacobsen LF 3400 Parts And Maintenance Manual - Lf 3400 / Lf 3800

Summary of LF 3400

Page 1

Rj 100 012003 warnhinweis: wenn diese maschine nicht ordnungsgemäß verwendet wird, können ernsthafte verletzungen verursacht werden. Personen, die diese maschine verwenden und warten, müssen in ihrer richtigen verwendung ausgebildet sein, auf die gefahren aufmerksam gemacht worden sein und die anlei...

Page 2: To Order Parts

Copyright 1999 textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” to order parts 1. Write your full name and complete address on the order. 2. Explain where and how to make shipment. 3. Give product number, name and serial number that ...

Page 3: Suggested Stocking Guide

Gb-3 suggested stocking guide to keep your equipment fully operational and productive, maintain a stock of the more commonly used maintenance items. We have included part numbers for additional support materials and training aids. A more complete listing of accessories and attachments can be found i...

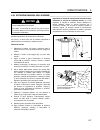

Page 4: Warning

1 safety gb-4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equip- ment. Never allow minors to operate any equipment. 2. It is your responsibility to read this m...

Page 5: Warning

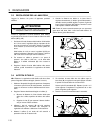

Safety 1 gb-5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 6

2 specifications gb-6 2 specifications 2.1 product identification _________________________________________________ 67866 .............................. Lf 3800, 5 gang 2 wheel drive, uses 7” (178 mm) diameter reel 67867 .............................. Lf 3800, 5 gang 4 wheel drive, uses 7” (178 mm) ...

Page 7

Specifications 2 gb-7 2.4 v1505-te engine _________________________________________________________ make................................Kubota model...............................V-1505te diesel, 4 cycle, liquid cooled horsepower .....................44.2 hp (33.0 kw) @ 3000 rpm displacement...........

Page 8

2 specifications gb-8 2.7 cutting units___________________________________________________________ lf 3400, lf3400 turbo, lf 4675 overall cutting width: 5 gang ...................... 100 in. (2.54 m) 7 gang ...................... 139 in. (3.53 m) number of reels: 5 gang ...................... Five -...

Page 9: Warning

Adjustments 3 gb-9 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be per- formed by a qualified technician. If proper adjustment cannot be made, contact an authorized textron turf care and specialty products dea...

Page 10: Caution

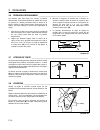

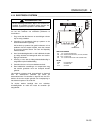

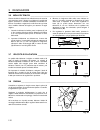

3 adjustments gb-10 3.3 bedknife adjustment ___________________________________________________ read section 3.2 before making the adjustment. Start adjustment at leading end of reel, followed by the trailing end. The leading end of the reel blade is that end which passes over the bedknife first dur...

Page 11

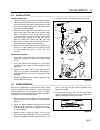

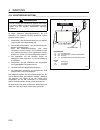

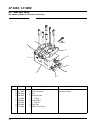

Adjustments 3 gb-11 3.5 flash attach ___________________________________________________________ installing cutting units 1. Place each cutting unit in front of its respective lift arm. Raise lift arm and position cutting unit so that yoke (t) is in line with swivel housing (s). Carefully lower arm ...

Page 12

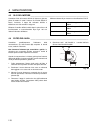

3 adjustments gb-12 3.7 mow speed _____________________________________________________________ cutting quality is better at speeds well below the transport speed of the tractor. An initial mow speed of five to six mph is set at the factory and should be satisfactory for most cutting conditions. Loc...

Page 13

Adjustments 3 gb-13 3.10 neutral adjustment ___________________________________________________ neutral adjustment can only be made at the drive pump. The neutral adjustment is preset at the factory on all new tractors and replacement pumps. Further adjustment is not required unless the pump has bee...

Page 14

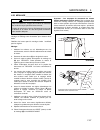

3 adjustments gb-14 3.12 reel limit switch _______________________________________________________ the front left and right lift arms are equipped with reed switches which signal the controller to turn off the reels.The switches are mounted to the tractor frame directly behind the lift arms. If reel...

Page 15: Caution

Adjustments 3 gb-15 3.14 torque specification ___________________________________________________ textron turf care and specialty products uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Caution all torque values include...

Page 16: Warning

4 maintenance gb-16 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be per- formed by a qualified technician. If proper adjustments cannot be made, contact an authorized textron turf care and specialty products de...

Page 17: Warning

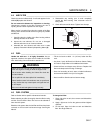

Maintenance 4 gb-17 4.4 air filter _______________________________________________________________ check the service indicator daily. If red band appears in the window (b) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk ...

Page 18: Caution

4 maintenance gb-18 4.7 battery ________________________________________________________________ make absolutely certain the ignition switch is “off” and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric ...

Page 19: Warning

Maintenance 4 gb-19 4.10 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engi...

Page 20: Caution

4 maintenance gb-20 4.13 hydraulic filters ______________________________________________________ the hydraulic system is protected by two 10 micron filters; a charge filter (b) and return line filter (a). Flow though the filters is monitored during operation. When pressure drop across the filters i...

Page 21: Warning

Maintenance 4 gb-21 4.15 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiator dra...

Page 22: Warning

4 maintenance gb-22 4.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tig...

Page 23: Warning

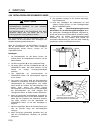

Maintenance 4 gb-23 4.20 reel backlapping ______________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, t...

Page 24: Caution

4 maintenance gb-24 4.21 storage________________________________________________________________ general 1. Wash the tractor thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the tractor, tighten all hardware, replace worn or damaged components. 3. Drain and refill radi...

Page 25

Troubleshooting 5 gb-25 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshootijng chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems cont...

Page 26

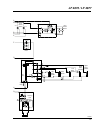

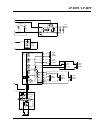

5 troubleshooting gb-26 5.2 controller lamps _____________________________________________________ the controller is a solid state device that monitors and controls electrical functions. The controller receives input signals from various switches and sensors throughout the machine and transmits outp...

Page 27

Troubleshooting 5 gb-27 5.3 electrical circuits ____________________________________________________ when troubleshooting the machine using the controller always check that program active lamps (1, 2 and 3 - 5 gang)(2 and 3 - 7 gang) are on. These indicate that the controller has power and the progr...

Page 28: Warning

6 maintenance & lubrication charts gb-28 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubrication. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

Page 29

Maintenance & lubrication charts 6 gb-29 6.3 lubrication chart______________________________________________________ grease fittings f1 - 50 hours (every week) 1 swivel housing 2 lift arm 3 lift cylinders 4 lift arm pivot 5 brake pedal pivot 6 traction pedal pivot 7 ball joint 8 steering pivot 9 ste...

Page 30

7 notes gb-30 7 notes.

Page 32: Table Des Matières

Copyright 1999 textron inc. ‘tous droits réservés. Il est interdit de reproduire tout ou en partie de ce document’ commande des pièces de rechange 1. Inscrivez votre nom et adresse sur le bordereau de com- mande. 2. Indiquez l’adresse et le mode de transport pour l’expédi- tion. 3. Indiquez le numér...

Page 33: Utilisation Du Manuel

F-3 stockage des pièces de rechange afin d’assurer le fonctionnement et la rentabilité maximum de la machine, ransomes recommande de conserver les pièces de rechange les plus courantes. Les numéros de certaines pièces sont également inclus pour les manuels et aides à la formation. Utilisation du man...

Page 34: Avertissement

1 securite f-4 1 securite 1.1 consignes de securite relatives au fonctionnement __________________ 1. Les utilisateurs de ces machines doivent être vigilants et consciencieux quand ils s'en servent ou effectuent des services de révision afin que la sécurité soit opti- male. Les mineurs ne doivent ja...

Page 35: Avertissement

Securite 1 f-5 1.2 consignes de securite importantes ____________________________________ ce symbole sert à vous signaler la présence de dangers éventuels. Danger - indique un danger immédiat avec risque de mort ou de blessures graves. Avertissement - indique un danger avec risque eventuel de mort o...

Page 36

2 specifications f-6 2 specifications 2.1 description ____________________________________________________________ 67866 ................................ Lf 3800, 5 unités de coupe, 2 rm, rouleau de 178 mm Ø 67867 ................................ Lf 3800, 5 unités de coupe, 4 rm, rouleau de 178 mm Ø...

Page 37

Specifications 2 f-7 2.4 moteur v1505-te ________________________________________________________ constructeur....................Kubota modèle.............................Diesel v1505te, 4 cycles, refroidi par liquide puissance........................33 kw @ 3 000 tr/min cylindrée ....................

Page 38

2 specifications f-8 2.7 unites de coupe ________________________________________________________ lf 3400, lf3400 turbo, lf 4675 largeur de coupe hors tout : 5 unités de coupe ........ 2,54 m 7 unités de coupe ........ 3,53 m nombre de rouleaux : 5 unités de coupe ........ Cinq – trois en avant, deu...

Page 39

Specifications 2 f-9 2.9 documents _____________________________________________________________ adressez-vous au concessionnaire de textron turf care and specialty products pour obtenir la liste des documents de support. Manual de securite et de fonctionnement ............. 4100740 nomenclature des...

Page 40: Avertissement

3 reglages f-10 3 reglages 3.1 generalites ____________________________________________________________ 1. Les réglages et services d’entretien doivent toujours être effectués par un technicien agréé. Quand il est impossible d’obtenir les réglages requis, adressez-vous au concessionnaire agréé textr...

Page 41: Attention

Reglages 3 f-11 3.3 reglages de la contrelame ___________________________________________ lisez le chapitre 3.2 avant de procéder aux réglages. Le réglage doit s'effectuer, en premier, sur l'extrémité avant du cylindre puis l'extrémité longitudinale. L'extrémité longitudinale des lames de cylindre e...

Page 42

3 reglages f-12 3.4 hauteur de coupe ______________________________________________________ remarque: ajustez toujours le cylindre à la contrelame avant de régler la hauteur de coupe. (chapitres 3.2 et 3.3). 1. Levez les accessoires pour placer la machine en posi- tion de transport, serrez le frein ...

Page 43

Reglages 3 f-13 3.5 flash attach ___________________________________________________________ pose des unités de coupe 1. Placez chaque unité de coupe en face de sa biellette de levage. Levez manuellement la biellette et faites glisser l'unité de coupe de façon à ce que la fourche (t) s'aligne au log...

Page 44

3 reglages f-14 3.6 pression d’ecrasement ________________________________________________ les rouleaux sont tous munis d’un ressort à pression d’écrasement. L’écrasement améliore la qualité de la coupe en assurant un contact permanent entre le rouleau et le terrain. Vérifiez et réglez cette pressio...

Page 45

Reglages 3 f-15 3.9 freins __________________________________________________________________ réglez les freins si vous remplacez l’unité complète ou s’il faut effectuer une révision ou si la course de la pédale est excessive. 1. Desserrez les écrous de réglage (c). 2. Ajustez le câble de façon à ce...

Page 46

3 reglages f-16 3.11 vitesse de marche avant / arriere _____________________________________ ces vitesses se règlent sur la pédale de traction et la marche avant se règle d’abord. Réglage de la marche avant : 1. Veillez à ce que la pompe motrice soit au point mort et que le papillon des gaz soit rég...

Page 47

Reglages 3 f-17 3.12 interrupteurs de fin de course des rouleaux _________________________ les biellettes de levage gauche et droite sont munies d’un interrupteur de fin de course pour permettre au contrôleur d’arrêter les rouleaux. Ils sont posés sur le châssis de la machine, derrière les biellette...

Page 48: Attention

3 reglages f-18 3.14 specifications des couples de serrage ________________________________ textron turf care and specialty products recommande l’utilisation, en standard, de boulons métallisés de qualité 5, à moins qu’indiqué différemment. Pour coupler ces boulons, se reporter aux valeurs indiquées...

Page 49: Avertissement

Maintenance 4 f-19 4 maintenance 4.1 generalites ____________________________________________________________ 1. Les réglages et services d'entretien doivent toujours être effectués par un technicien agréé. Quand il est impossible d'obtenir les réglages requis, adressez-vous au concessionnaire agréé...

Page 50

4 maintenance f-20 4.3 huile moteur ___________________________________________________________ vérifiez quotidiennement l'huile moteur avant de démarrer le moteur. Quand son niveau est bas, retirez le bouchon de remplissage pour le rétablir. Changez l'huile après les 50 premières heures de fonction...

Page 51: Avertissement

Maintenance 4 f-21 4.5 carburant _____________________________________________________________ attention au carburant car il est très inflammable. Utilisez un récipient adapté dont le bec arrive à s'introduire à l'intérieur du goulot de remplissage de carburant. Evitez de vous servir de burettes et ...

Page 52: Avertissement

4 maintenance f-22 4.8 demarrage par connexion volante ____________________________________ avant de “démarrer par connexion volante” la machine, vérifiez l'état de charge de la batterie (chapitre 4.7). Raccordement des cavaliers: 1. Arrêtez le moteur de la machine dont la batterie est bien chargée....

Page 53: Avertissement

Maintenance 4 f-23 4.11 flexibles hydrauliques ________________________________________________ 1. Abaissez toujours les accessoires au sol, débrayez tous les entraînements, serrez le frein de stationnement, arrêtez le moteur et retirez la clé de contact avant de vérifier ou débrancher les conduites...

Page 54: Attention

4 maintenance f-24 4.13 filtres a huile hydraulique____________________________________________ deux filtres de 10 microns protègent le circuit hydraulique : un filtre de charge (b) et un filtre de conduite de retour (a). Le débit traversant les filtres est toujours contrôlé lors du fonctionnement. ...

Page 55: Avertissement

Maintenance 4 f-25 4.15 radiateur ______________________________________________________________ vérifiez quotidiennement le niveau du refroidisseur. Le radiateur doit être rempli et un flacon de rechange rempli jusqu'au point de repère maxi. Vidangez le radiateur et reremplissez-le annuellement. Dé...

Page 56: Attention

4 maintenance f-26 4.17 pneus __________________________________________________________________ 1. Veillez à ce qu'ils soient gonglés correctement afin de prolonger leur vie utile. Vérifiez leur gonflage quand ils sont froids et l'absence d'usure des chapes. 2. Contrôlez leur pression toutes les 50...

Page 57: Avertissement

Maintenance 4 f-27 4.20 meulage ________________________________________________________________ vérifiez les cylindres et la contrelame pour déterminer si le meulage ou l'affûtage sont nécessaires pour restaurer leurs bords. Réaffûtez les lames quand le meulage s'avère insuffisant pour les aiguiser...

Page 58: Attention

4 maintenance f-28 4.21 entreposage ___________________________________________________________ généralités 1. Nettoyez entièrement la machine et graissez-la. Réparez et peignez ses surfaces métalliques extérieures ou endommagées. 2. Examinez la machine, serrez les composants et remplacez ceux qui s...

Page 59

Depistage des defauts 5 f-29 5 depistage des defauts 5.1 generalites ____________________________________________________________ le tableau suivant de dépistage des défauts indique les problèmes rencontrés couramment lors de la mise en marche et du fonctionnement. Pour tous renseignements concernan...

Page 60

5 depistage des defauts f-30 5.2 voyants du controleur ________________________________________________ le contrôleur ressemble à un bloc dur qui surveille et contrôle les fonctions électriques. Il reçoit des entrées de divers interrupteurs et capteurs de la machine et transmet les sorties permettan...

Page 61

Depistage des defauts 5 f-31 5.3 circuits electriques ___________________________________________________ au cours du dépistage des défauts de la machine en utilisant le contrôleur, veillez à ce que les voyants 1, 2 et 3 soient allumés. Ils prouvent que le contrôleur est sous tension et que le progr...

Page 62: Avertissement

6 tableaux de maintenance et de graissage f-32 6 tableaux de maintenance et de graissage 6.1 generalites ____________________________________________________________ 1. Nettoyez toujours les graisseurs avant et après les avoir utilisés. 2. Utilisez toujours de la graisse répondant aux spécifi- catio...

Page 63

Tableaux de maintenance et de graissage 6 f-33 6.2 tableau de maintenance _______________________________________________ a - ajouter ou régler c - nettoyer i - vérifier l- graisser r - remplacer ar - s'il y a lieu * indique le premier service d'une nouvelle machine. ** ou tous les deux ans, ce qui ...

Page 64

6 tableaux de maintenance et de graissage f-34 6.3 tableau de graissage__________________________________________________ raccords de graissage f1 – 50 heures (hebdomadairement) 1 logement d’articulation 2 biellette de levage 3 vérins de levage 4 pivot de biellette de levage 5 pivot de pédale de fre...

Page 65

Remarques 7 f-35 7 remarques.

Page 66: Bestellen Van Onderdelen

Copyright 1999 textron inc. "alle rechten voorbehouden inclusief het recht op reproductie in enigerlei vorm van dit materiaal of gedeelten ervan". Bestellen van onderdelen 1. Vul uw volledige naam en adres op de order in. 2. Maak duidelijk waar en hoe moet worden geleverd. 3. Vermeld het productnumm...

Page 67: Aanbevolen Voorraadvorming

Nl-3 aanbevolen voorraadvorming om uw machine altijd en volledig operationeel en productief te houden, wordt u aangeraden om een voorraad aan te leggen van de regelmatig gebruikte onderdelen t.B.V. Onderhoud. We hebben stuknummers vermeld van aanvullende ondersteuningsmaterialen en trainingshulpmidd...

Page 68: Waarschuwing

1 veiligheid nl-4 1 veiligheid 1.1 operationele veiligheid ________________________________________________ 1. Veiligheid hangt af van de alertheid, zorg en voorzichtig- heid van degenen die de machine bedienen of onder- houden. Minderjarigen mag nooit worden toegestaan om enig deel van de apparatuu...

Page 69: Waarschuwing

Veiligheid 1 nl-5 1.2 belangrijke veiligheidsoverwegingen _________________________________ dit veiligheidssymbool wordt gebruikt om u te attenderen op potentiële gevaren. Gevaar - duidt op dreigende gevaarlijke situatie die, indien niet vermeden, zal resulteren in dood of ernstig letsel. Waarschuwi...

Page 70

2 specificaties nl-6 2 specificaties 2.1 productidentificatie ___________________________________________________ 67866 ..................Lf 3800, 5 maaieenheden, tweewiel- aandrijving, gebruikt kooi met doorsnee van 178 mm 67867 ..................Lf 3800, 5 maaieenheden, vierwiel- aandrijving, gebr...

Page 71

Specificaties 2 nl-7 2.4 v1505-te motor _________________________________________________________ merk ..................................... Kubota model.................................... V1505te diesel, viertakt, vloeistofkoeling paardekrachtvermogen ........ 33 kw @ 3000 rpm capaciteit ............

Page 72

2 specificaties nl-8 2.7 maaieenheden __________________________________________________________ lf 3400, lf3400 turbo, lf 4675 totale maaibreedte: 5 maaieenheden 2,54 m 7 maaieenheden 3,53 m totale maaibreedte: 5 maaieenheden vijf - drie voorzijde, twee achterzijde 7 maaieenheden zeven - drie voorz...

Page 73: Waarschuwing

Afstellingen 3 nl-9 3 afstellingen 3.1 algemeen_______________________________________________________________ 1. Afstellingen en onderhoud behoren altijd te worden ver- richt door een bevoegd monteur. Als de gewenste afs- telling niet kan worden uitgevoerd, neem dan contact op met een erkende textr...

Page 74: Voorzichtig

3 afstellingen nl-10 3.3 ondermesafstelling ___________________________________________________ lees eerst sectie 3.2 alvorens de afstelling uit te voeren. Begin de afstelling aan de oplopende kant van de kooimessen, gevolgd door de aflopende kant. De oplopende kant is het gedeelte dat tijdens norma...

Page 75

Afstellingen 3 nl-11 3.4 maaihoogte ____________________________________________________________ n.B. De afstelling tussen kooimessen en ondermes moet altijd eerst worden uitgevoerd voordat de maaihoogte wordt afgesteld (secties 3.2 en 3.3). 1. Breng de maaieenheden omhoog in de transportstand. Trek...

Page 76

3 afstellingen nl-12 3.5 flash attach___________________________________________________________ installatie van de maaieenheden 1. Plaats iedere maaieenheid voor zijn eigen hefarm. Til de hefarm op en positioneer de maaieenheid zodanig dat juk (t) in lijn is met het draaihuis (s). Laat de arm zorgv...

Page 77

Afstellingen 3 nl-13 3.6 neerwaartse druk _____________________________________________________ iedere kooi is voorzien van een neerwaartse drukveer. Neerwaartse druk verbetert de knipkwaliteit doordat hiermee wordt gezorgd voor consistent contact tussen de kooi en de grond. Om de beste maaiprestati...

Page 78

3 afstellingen nl-14 3.8 riem ____________________________________________________________________ een nieuwe riem moet na de eerste tien bedrijfsuren worden geïnspecteerd en bijgesteld. Vervolgens na iedere 100 bedrijfsuren. Regel de poelie van de wisselstroomdynamo zodanig dat de riem onder een dr...

Page 79

Afstellingen 3 nl-15 3.10 neutraalafstelling____________________________________________________ neutraalafstelling kan uitsluitend aan de drijfpomp worden uitgevoerd. De neutraalstand is een fabriekinstelling die geldt voor alle nieuwe tractors en vervangingspompen. Verdere bijstelling is overbodig...

Page 80

3 afstellingen nl-16 3.11 voorwaartse/achterwaartse snelheid _______________________________ de voor- en achterwaartse snelheden worden afgesteld middels de tractiepedaal. Eerst moet de voorwaartse snelheid worden geregeld en daarna de achterwaartse. Afstelling voorwaartse snelheid: 1. Zorg ervoor d...

Page 81

Afstellingen 3 nl-17 3.12 kooiafslagschakelaar ________________________________________________ de voorste hefarmen links en rechts zijn voorzien van tongenschakelaars die de controller het signaal geven om de kooien stil te zetten. De schakelaars zijn op het tractorframe gemonteerd, direct achter d...

Page 82: Voorzichtig

3 afstellingen nl-18 3.14 draaikoppelspecificatie _______________________________________________ textron turf care and specialty products gebruikt kwaliteit 5 gegalvaniseerde bouten als standaard, tenzij anderszins vermeld. Bij het aandraaien van dergelijke bouten moet de waarde worden gebruikt die...

Page 83: Waarschuwing

Onderhoud 4 nl-19 4 onderhoud 4.1 algemeen ________________________________________________________________ 1. Afstelling en onderhoud behoren altijd te worden ver- richt door een bevoegd monteur. Als de gewenste afs- telling niet kan worden uitgevoerd, neem dan contact op met een erkende textron tu...

Page 84

4 onderhoud nl-20 4.3 motorolie ______________________________________________________________ controleer de motorolie aan het begin van iedere werkdag. Als het peil te laag is, verwijder dan de olievuldop en giet de gewenste hoeveelheid olie bij. Niet overvullen. Na de eerste 50 bedrijfsuren dient ...

Page 85: Waarschuwing

Onderhoud 4 nl-21 4.5 brandstof______________________________________________________________ hanteer brandstof voorzichtig met het oog op de grote ontvlambaarheid ervan. Gebruik een goedgekeurde brandstofhouder waarvan de schenktuit in de vulhals past. Gebruik geen blikken of trechters om brandstof...

Page 86: Voorzichtig

4 onderhoud nl-22 4.7 accu ___________________________________________________________________ u moet er absoluut zeker van zijn dat de ontstekingsschakelaar in de uit-stand staat en de contactsleutel is verwijderd voordat u de accu een onderhoudsbeurt geeft. Zet de kabels stevig aan de accuklemmen ...

Page 87: Waarschuwing

Onderhoud 4 nl-23 4.10 geluiddemper en uitlaat _______________________________________________ ter beveiliging tegen koolmonoxidevergiftiging moet het volledige uitlaatsysteem regelmatig worden geïnspecteerd. Een defecte uitlaat moet altijd worden vervangen. Als u een verandering waarneemt in de kle...

Page 88

4 onderhoud nl-24 4.12 hydrauliekolie_________________________________________________________ zie sectie 6.2 for specifieke perioden tussen onderhoudsbeurten. Na het falen van een belangrijk onderdeel dient de hydrauliekolie te worden afgetapt en ververst. Het laatste geldt ook als u de aanwezighei...

Page 89: Voorzichtig

Onderhoud 4 nl-25 4.14 elektrisch systeem ____________________________________________________ onderstaand zijn algemene voorzorgsmaatregelen vermeld om het zich voordoen van elektrische problemen te verminderen:- 1. Zorg ervoor dat alle klemmen en aansluitingen schoon zijn en stevig vastzitten. 2. ...

Page 90: Waarschuwing

4 onderhoud nl-26 4.15 radiator _______________________________________________________________ controleer het koelvloeistofpeil dagelijks. De radiateur moet vol zijn en in de overloopfles dient het max-streepje te worden bereikt. Het koelsysteem moet jaarlijks worden afgetapt en opnieuw gevuld. Ver...

Page 91: Voorzichtig

Onderhoud 4 nl-27 4.17 banden _________________________________________________________________ 1. Houd de banden op de juiste spanning om de levens- duur te optimaliseren. Controleer de spanning wanneer de banden koel zijn. Inspecteer de loopvlakslijtage. 2. Controleer de druk na iedere 50 bedrijfs...

Page 92: Waarschuwing

4 onderhoud nl-28 4.20 achteruitdraaien van kooien __________________________________________ controleer de kooimessen en het ondermes om te bepalen of de snijranden door achteruitdraaien of slijpen dienen te worden hersteld. Als de slijtage of beschadiging te ernstig is om de snijranden door leppen...

Page 93: Voorzichtig

Onderhoud 4 nl-29 4.21 stalling ________________________________________________________________ algemeen 1. De tractor dient eerst grondig te worden gewassen en gesmeerd. Repareer en lak beschadigd of blootgesteld metaal. 2. Inspecteer de tractor, draai alle bevestigingen vast en vervang versleten ...

Page 94

5 foutopsporing nl-30 5 foutopsporing 5.1 algemeen ______________________________________________________________ onderstaande foutopsporingstabel vermeldt basisproblemen die zich kunnen voordoen tijdens start-up en werking. Voor meer gedetailleerde informatie betreffende de hydraulische en elektris...

Page 95

Foutopsporing 5 nl-31 5.2 controllerlampjes ____________________________________________________ de controller is een halfgeleiderapparaat dat de elektrische functies controleert en bestuurt. De controller ontvangt ingangssignalen (inputs) van schakelaars en sensors die op diverse plaatsen in de mac...

Page 96

5 foutopsporing nl-32 5.3 elektrische circuits ___________________________________________________ tijdens foutsporing in de machine met behulp van de controller, dient altijd eerst te worden gecontroleerd of lampjes 1, 2 en 3 branden. Hiermee wordt namelijk aangegeven dat de controller voeding ontv...

Page 97: Waarschuwing

Onderhouds- en smeerschema’s 6 nl-33 6 onderhouds- en smeerschema’s 6.1 algemeen_______________________________________________________________ 1. Maak de vetsmeerpunten voor en na het smeren altijd schoon. 2. Smeer met vet dat voldoet aan de nlgi kwaliteit 2 lb specificaties of deze overtreft. Gebr...

Page 98

6 onderhouds- en smeerschema’s nl-34 6.2 onderhoudsschema ____________________________________________________ a = toevoegen of bijstellen c = reinigen i = inspecteren l = smeren r = vervangen ar = als vereist * duidt op eerste service voor nieuwe machines. ** of iedere twee jaar, indien eerder bere...

Page 99

Onderhouds- en smeerschema’s 6 nl-35 6.3 smeerschema___________________________________________________________ smeerpunten f1 - 50 bedrijfsuren (iedere week) 1 draaihuis 2 hefarm 3 hefcilinders 4 hefarmdraaipen 5 rempedaaldraaipen 6 tractiepedaaldraaipen 7 kogelscharnier 8 stuurdraaipen 9 stuurcili...

Page 100

7 notities nl-36 7 notities.

Page 101

Notities 7 nl-37.

Page 102: Bestellen Von Ersatzteilen

Copyright 1999 textron inc. "alle rechte vorbehalten, einschließlich des rechts, dieses material oder teile davon auf irgendeine weise zu reproduzieren." bestellen von ersatzteilen 1. Schreiben sie ihren vor- und zunahmen sowie ihre voll- ständige adresse auf die bestellung. 2. Erklären sie, wann un...

Page 103: Empfohlener Lagerbestand

D-3 empfohlener lagerbestand damit ihre ausrüstung jederzeit vollständig betriebsfähig und produktiv ist, ist es wichtig, daß sie einen lagerbestand der am häufigsten verwendeten wartungsteile haben. Wir geben auch die artikelnummer für zusätzliche unterstützende materialien und ausbildungshilfen an...

Page 104: Achtung

1 sicherheit d-4 1 sicherheit 1.1 betriebssicherheit ____________________________________________________ 1. Die sicherheit ist vom bewußtsein, von der aufmerk- samkeit und umsicht der personen abhängig, die die ausrüstung bedienen oder warten. Niemals zulassen, daß minderjährige diese ausrüstung be...

Page 105: Achtung

Sicherheit 1 d-5 1.2 wichtige hinweise zur sicherheit _______________________________________ dieses warnsymbol wird verwendet, um sie auf potentielle gefahren aufmerksam zu machen. Gefahr - weist auf eine sofortige gefahrensituation hin, die einen todesfall oder eine ernsthafte verletzung zur folge...

Page 106

2 technische daten d-6 2 technische daten 2.1 produktidentifizierung ________________________________________________ 67866 ....................Lf 3800, 5 schneideeinheiten, zweirad- antrieb, trommel mit 7” (178 mm) durchmesser 67867 ....................Lf 3800, 5 schneideeinheiten, vier- radan-trie...

Page 107

Technische daten 2 d-7 2.3 v1505-e motor___________________________________________________________ marke ..............................Kubota modell..............................Dieselmotor v1505e, 4 zyklen, flüssigkeitsgekühlt pferdestärke ....................28 kw bei 3000 u/min verdrängung.........

Page 108

2 technische daten d-8 2.6 gewichte und masse ___________________________________________________ lf 3400 abmessungen: mm länge – mit grasfängern ...............................................3048 höhe – oberkante lenkrad ..........................................1491 breite – beim mähen..............

Page 109

Technische daten 2 d-9 2.8 zubehÖr ________________________________________________________________ beziehen sie sich auf die ersatzteilliste und fordern sie eine vollständige liste von zubehör und zusatzgeräten von ihrem vertragshändler von textron turf care and specialty products an. Traktor luftd...

Page 110: Achtung

3 einstellungen d-10 3 einstellungen 3.1 allgemeine informationen _____________________________________________ 1. Die einstellungen und wartungsarbeiten müssen immer von einem qualifizierten techniker durchgeführt werden. Wenn es nicht möglich ist, die richtige einstellung vor- zunehmen, wenden sie...

Page 111: Warnung

Einstellungen 3 d-11 3.3 einstellen des grundmessers__________________________________________ vor dem einstellen ist abschnitt 3.2 durchzulesen. Die einstellung an der vorderkante des schneidzylinders beginnen und anschließend die hinterkante einstellen. Die vorderkante der schneidzylinderklingen i...

Page 112

3 einstellungen d-12 3.4 schnitthÖhe ___________________________________________________________ hinweis: die einstellung von schneidzylinder zu grundmesser muß vor der einstellung der schnitthöhe durchgeführt werden (siehe abschnitt 3.2 und 3.3). 1. Die mähvorrichtungen zur transportposition anhebe...

Page 113

Einstellungen 3 d-13 3.5 flash attach ___________________________________________________________ einbau der schneidvorrichtungen 1. Jede schneidvorrichtung vor ihren entsprechenden hebelarm plazieren. Den hebelarm anheben und die schneidvorrichtung so positionieren, daß sich der kragen (t) mit dem ...

Page 114

3 einstellungen d-14 3.6 druckfeder ____________________________________________________________ jeder schneidzylinder ist mit einer druckfeder ausgestattet. Die druckfeder verbessert die schnittqualität, da sie einen konsistenten kontakt zwischen dem schneidzylinder und boden sicherstellt. Jedesmal...

Page 115

Einstellungen 3 d-15 3.8 riemen __________________________________________________________________ einen neuen riemen nach den ersten zehn betriebsstunden überprüfen und einstellen. Anschließend alle 100 stunden einstellen. Die riemenscheibe der lichtmaschine so einstellen, daß sich der riemen bei e...

Page 116

3 einstellungen d-16 3.10 leerlaufeinstellung __________________________________________________ die leerlaufeinstellung kann nur an der antriebspumpe vorgenommen werden. Die leerlaufeinstellung wird im werk an allen neuen traktoren und ersatzpumpen voreingestellt. Eine weitere einstellung ist nur e...

Page 117

Einstellungen 3 d-17 3.11 vorwÄrts-/rÜckwÄrtsgeschwindigkeit ________________________________ die vorwärts- und rückwärtsgeschwindigkeit werden am fahrpedal eingestellt. Zuerst die vorwärtsgeschwindigkeit einstellen, bevor die rückwärtsgeschwindigkeit eingestellt wird. Einstellen der vorwärtsgeschwi...

Page 118

3 einstellungen d-18 3.12 schneidzylinder-grenztaster _________________________________________ die hebelarme vorne links und rechts sind mit reed- schaltern ausgestattet, die dem steuergerät das signal zum ausschalten der schneidzylinder senden. Die schalter sind am rahmen des traktors direkt hinte...

Page 119: Warnung

Einstellungen 3 d-19 3.14 drehmomentdaten ______________________________________________________ textron turf care and specialty products verwendet standardmäßig plattierte schrauben der festigkeitsklasse 5, wenn nicht anders angegeben. Beim anziehen plattierter schrauben ist der wert für geschmiert...

Page 120: Achtung

4 wartung d-20 4 wartung 4.1 allgemeine informationen _____________________________________________ 1. Die einstellung und wartungsarbeiten müssen immer von einem qualifizierten techniker durchgeführt werden. Wenn keine ordnungsgemäßen einstellungen vor- genommen werden können, wenden sie sich bitte...

Page 121

Wartung 4 d-21 4.3 motorÖl ________________________________________________________________ zu beginn eines jeden tages vor dem anlassen des motors das motoröl prüfen. Wenn der Ölstand niedrig ist, den Öleinfüllverschluß entfernen und entsprechend Öl nachfüllen. Nach den ersten 50 betriebsstunden un...

Page 122: Achtung

4 wartung d-22 4.5 kraftstoff_____________________________________________________________ den kraftstoff vorsichtig handhaben, da er leicht entzündlich ist.Einen zugelassenen container verwenden, dessen schnabel in den tankeinfüllstutzen passen muß. Zum umfüllen des kraftstoffs keine dosen und tric...

Page 123: Warnung

Wartung 4 d-23 4.7 batterie ________________________________________________________________ unbedingt sicherstellen, daß der zündschalter auf „aus“ ist und der zündschlüssel abgezogen ist, bevor man an der batterie arbeitet. Die kabel sicher an den batterieklemmen anschließen und eine dünne schicht...

Page 124: Achtung

4 wartung d-24 4.10 gerÄuschdÄmpfer und auspuff ________________________________________ um eine vergiftung durch kohlenmonoxid zu verhindern, das komplette auspuffsystem regelmäßig prüfen und einen fehlerhaften geräuschdämpfer immer auswechseln. Wenn festgestellt wird, daß sich die farbe oder der t...

Page 125

Wartung 4 d-25 4.12 hydraulikÖl ____________________________________________________________ die spezifischen wartungsabstände sind in abschnitt 6.2 angegeben. Nach dem ausfall einer hauptkomponente, oder wenn das vorhandensein von wasser oder schaum im Öl, oder ein ranziger geruch festgestellt wird...

Page 126: Warnung

4 wartung d-26 4.14 elektrisches system ___________________________________________________ es folgen allgemeine vorsichtsmaßnahmen, die zum reduzieren von problemen mit dem elektrischen system getroffen werden können. 1. Sicherstellen, daß alle anschlußklemmen und verbind- ungen sauber und richtig ...

Page 127: Achtung

Wartung 4 d-27 4.15 kÜhler _________________________________________________________________ den kühlmittelstand täglich prüfen. Der kühler muß voll sein und die auffangflasche muß bis zur markierung 'max.' voll sein. Jährlich ablassen und wieder auffüllen. Den kühlerdeckel entfernen, den motorblock...

Page 128: Warnung

4 wartung d-28 4.17 reifen ___________________________________________________________________ 1. Reifen müssen jederzeit richtig mit luft gefüllt sein, um ihre nutzlebensdauer zu verlängern. Den reifendruck prüfen, während die reifen kühl sind. Das profil auf ver- schleiß überprüfen. 2. Den druck a...

Page 129: Warnung

Wartung 4 d-29 4.19 pflege und reinigung __________________________________________________ den traktor und die vorrichtungen nach jedem gebrauch abwaschen. Die ausrüstung sauber halten. Hinweis: keinen teil der ausrüstung abwaschen, wenn sie heiß ist. Keine hochdruckspritzvorrichtung oder dampf ver...

Page 130: Achtung

4 wartung d-30 4.20 rÜcklÄppen der schneidzylinder ______________________________________ den schneidzylinder und das grundmesser prüfen, um festzustellen, ob die schneidkante durch rückläppen oder schleifen wiederhergestellt werden kann. Wenn der verschleiß oder die beschädigung so stark ist, daß d...

Page 131: Warnung

Wartung 4 d-31 4.21 lagerung_______________________________________________________________ allgemeine informationen 1. Den traktor gründlich waschen und schmieren. Beschä- digtes und freigelegtes metall reparieren und lackieren. 2. Den traktor überprüfen, alle schrauben anziehen, verschlissene oder...

Page 132

5 fehlersuche d-32 5 fehlersuche 5.1 allgemeine informationen _____________________________________________ die folgende fehlersuchtabelle listet die grundsätzlichen probleme auf, die beim anlassen und betrieb entstehen können. Ausführlichere informationen über das hydraulik- und elektrische system ...

Page 133

Fehlersuche 5 d-33 die schneidzylinder schneiden ungleichmäßig. 1. Das grundmesser zum schneidzylin- der ist nicht richtig eingestellt. Die einstellung vom grundmesser zum schneidzylinder prüfen 2. Die motordrehzahl ist zu niedrig. Die motordrehzahl prüfen. Den motor mit vollgas betreiben. 3. Die mä...

Page 134

5 fehlersuche d-34 5.2 steuergerÄtlampen ___________________________________________________ das steuergerät ist ein festkörperbauteil, das die elektrischen funktionen überwacht und steuert. Das steuergerät enthält eingangssignale von verschiedenen schaltern und sensoren in der ganzen maschine und ü...

Page 135

Fehlersuche 5 d-35 5.3 stromkreise____________________________________________________________ bei der fehlersuche an der maschine mit hilfe des steuergeräts immer prüfen, ob die lampen 1, 2 und 3 erleuchtet sind. Das bedeutet, daß das steuergerät strom hat und das programm aktiv ist. Hinweis: das s...

Page 136: Achtung

6 wartungs- und schmierplÄne d-36 6 wartungs- und schmierplÄne 6.1 allgemeine informationen _____________________________________________ 1. Die schmierstellen immer vor und nach dem schmieren reinigen. 2. Zum schmieren eine nlgi-schmiere verwenden, die der lb-spezifikation von klasse 2 gerecht wird...

Page 137

Wartungs- und schmierplÄne 6 d-37 6.2 wartungsplan _________________________________________________________ a - hinzufügen oder einstellen c - reinigen i - prüfen l - schmieren r - auswechseln ar - soweit erforderlich * zeigt den ersten kundendienst für neue maschinen an. ** oder alle zwei jahre (f...

Page 138

6 wartungs- und schmierplÄne d-38 6.3 schmierplan ___________________________________________________________ schmierstellen f1: alle 50 stunden (wöchentlich) 1 drehgehäuse 2 hebelarm 3 hubzylinder 4 hebelarm-drehgelenk 5 bremspedal-drehgelenk 6 fahrpedal-drehgelenk 7 kugelgelenk 8 lenkzapfen 9 lenk...

Page 139

Anmerkungen 7 d-39 7 anmerkungen.

Page 140: Ordinazione Dei Ricambi

Copyright 1999 textron inc. “tutti i diritti riservati, compreso quello di riproduzione totale o parziale in qualunque forma”. Ordinazione dei ricambi 1. Riportare il proprio nome e indirizzo completi sull'ordine. 2. Spiegare dove e come effettuare la spedizione. 3. Fornire il numero del prodotto, i...

Page 141: Come Usare Questo Manuale

I-3 guida alle scorte consigliate per mantenere l’apparecchiatura pienamente funzionante ed efficiente, conservare una scorta delle parti di ricambio più comunemente utilizzate. Di seguito sono elencati i ricambi per il materiale aggiuntivo con il relativo numero e i supporti per l’addestramento. Un...

Page 142: Avviso

1 sicurezza i-4 1 sicurezza 1.1 sicurezza del funzionamento __________________________________________ 1. La sicurezza dipende dalla consapevolezza, attenzione e prudenza del personale addetto all’operazione o alla manutenzione dell’apparecchiatura. Non consentire mai ai minori di 18 anni di azionar...

Page 143: Avviso

Sicurezza 1 i-5 1.2 note importanti di sicurezza ___________________________________________ questo simbolo di allarme di sicurezza viene utilizzato per indicare pericoli potenziali. Pericolo - indica una situazione imminentemente pericolosa che, se non evitata, provocherÀ la morte o gravi lesioni. ...

Page 144

2 caratteristiche i-6 2 caratteristiche 2.1 identificazione del prodotto __________________________________________ 67866 .........Lf 3800, 5 unità di taglio, 2 ruote motrici, usa bobina di 178 mm di diametro 67867 .........Lf 3800, 5 unità di taglio, 4 ruote motrici, usa bobina di 178 mm di diametr...

Page 145

Caratteristiche 2 i-7 2.4 motore v1505-te fabbricante......................Kubota modello............................V1505te diesel, 4 tempi, raffreddato a liquido potenza ...........................33 kw @ 3000 giri/min cilindrata .........................1498 cc coppia ...............................

Page 146

2 caratteristiche i-8 2.7 gruppo di falciatura __________________________________________________ lf 3400, lf3400 turbo, lf 4675 larghezza complessiva: 5 unità di taglio............. 2,54 m 7 unità di taglio................3,53 m numero di bobine: 5 unità di taglio............. Cinque - tre anterior...

Page 147: Avviso

Regolazioni 3 i-9 3 regolazioni 3.1 dati generali ___________________________________________________________ 1. Le regolazioni e la manutenzione devono essere sem- pre effettuate da un tecnico qualificato. Se non è possi- bile effettuare la corretta regolazione, contattare un concessionario textron...

Page 148: Attenzione

3 regolazioni i-10 3.3 regolazione della lama fissa__________________________________________ leggere la sezione 3.2 prima di apportare qualsiasi modific a. Iniziare la regolazione al bordo d’attacco della bobina, seguito dal bordo d’uscita. Il bordo d’attacco delle lame della bobina. (b-fig. 3b). 1...

Page 149

Regolazioni 3 i-11 3.5 flash attach ___________________________________________________________ installazione gruppi di falciatura 1. Porre ciascun gruppo di falciatura di fronte al rispettivo braccio di sollevamento. Sollevare il braccio di solleva- mento e posizionare il gruppo di falciatura così ...

Page 150

3 regolazioni i-12 3.6 molle di tenuta ________________________________________________________ ciascuna bobina è dotata di una molla di tenuta che esercita una pressione verso il basso per migliorare la qualità del taglio e assicurare un contatto consistente tra la bobina e il terreno. Controllare ...

Page 151

Regolazioni 3 i-13 3.9 freni ___________________________________________________________________ registrare i freni dopo aver sostituito o riparato il gruppo frenante, oppure se la corsa del pedale diventa eccessiva. 1. Allentare i dadi di regolazione (c). 2. Regolare il tirante in modo che il pedal...

Page 152

3 regolazioni i-14 3.11 marce avanti/retromarcia _____________________________________________ le marce in avanti e la retromarcia sono regolate sul pedale della trazione. Innestare la marcia avanti prima di regolare la retromarcia. Regolazione della marcia in avanti: 1. Accertarsi che la pompa dell...

Page 153

Regolazioni 3 i-15 3.12 fine corsa della bobina________________________________________________ i bracci di sollevamento anteriori sinistro e destro sono forniti di interruttori a lamelle che segnalano alla centralina di fermare le bobine. Gli interruttori sono montati sul telaio del trattore dirett...

Page 154: Attenzione

3 regolazioni i-16 3.14 specifica della coppia _________________________________________________ textron turf care and specialty products usa bulloni placcati grade 5 di serie, salvo indicazione al contrario. Per il serraggio di bulloni placcati utilizzare il valore riportato per bulloni lubrificati...

Page 155: Avviso

Manutenzione 4 i-17 4 manutenzione 4.1 dati generali ___________________________________________________________ 1. La regolazione e la manutenzione devono essere effet- tuate in tutti i casi da un tecnico qualificato. Se non è possibile apportare le corrette modifiche, contattare un concessionario ...

Page 156

4 manutenzione i-18 4.3 olio del motore ________________________________________________________ controllare l’olio del motore all’inizio di ciascuna giornata, prima di mettere in moto il motore. Se il livello dell’olio è basso, rimuovere il tappo del serbatoio dell’olio e rabboccare con olio second...

Page 157: Avviso

Manutenzione 4 i-19 4.5 carburante ____________________________________________________________ manipolare il carburante con attenzione perché è altamente infiammabile. Usare un contenitore autorizzato provvisto di becco inseribile all’interno del bocchettone del serbatoio. Non usare lattine né imbu...

Page 158: Attenzione

4 manutenzione i-20 4.7 batteria________________________________________________________________ accertarsi che l’interruttore d’accensione sia effettivamente spento e che la chiave sia stata rimossa prima di effettuare la manutenzione sulla batteria. Serrare bene i cavi ai morsetti della batteria e...

Page 159: Avviso

Manutenzione 4 i-21 4.10 silenziatore e tubo di scarico _________________________________________ serrare tutti i componenti del collettore di scarico ad una coppia uniforme. Serrare o sostituire i fermi dello scarico. Per proteggere dall’avvelenamento dell’ossido di carbonio, esaminare regolarmente...

Page 160

4 manutenzione i-22 4.12 olio idraulico __________________________________________________________ vedere gli intervalli specifici della manutenzione nella sezione 6.2. Spurgare e sostituire l’olio idraulico dopo un guasto importante del componente o se si nota la presenza d’acqua o schiuma nell’oli...

Page 161: Attenzione

Manutenzione 4 i-23 4.14 sistema elettrico ______________________________________________________ le precauzioni generali che possono essere adottate per ridurre i problemi elettrici sono elencate di seguito. 1. Accertarsi che tutti i morsetti e i raccordi siano puliti e correttamente fissati. 2. Es...

Page 162: Avviso

4 manutenzione i-24 4.15 radiatore ______________________________________________________________ controllare quotidianamente il livello del refrigerante. Il radiatore dev'essere pieno e la bottiglia di recupero dev'essere al livello indicato con max. Svuotare e riempire una volta l'anno. Togliere i...

Page 163: Attenzione

Manutenzione 4 i-25 4.17 pneumatici ______________________________________________________________ 1. Tenere i pneumatici correttamente gonfi per prolun- garne la durata. Controllare la pressione di gonfiaggio mentre i pneumatici sono freddi. Controllare il bat- tistrada. 2. Controllare la pressione...

Page 164: Attenzione

4 manutenzione i-26 4.19 cura e pulizia __________________________________________________________ lavare il trattorino e gli attrezzi dopo ciascun uso. Tenere le apparecchiature pulite. Nota: non lavare qualsiasi parte dell’apparecchiatura mentre è calda. Non usare spruzzi o vapore ad alta pression...

Page 165: Avviso

Manutenzione 4 i-27 4.20 rotazione inversa delle bobine ________________________________________ controllare la bobina e la lama fissa per determinare se sia possibile ripristinare il filo arrotandola o molandola. Se l'usura o il danno sono tali da rendere impossibile la rettifica del filo con l’arr...

Page 166: Attenzione

4 manutenzione i-28 4.21 conservazione _________________________________________________________ dati generali 1. Lavare bene e lubrificare il trattorino. Riparare e verniciare il metallo danneggiato o esposto. 2. Esaminare il trattorino, serrare tutti i componenti, sostituire i componenti logori o ...

Page 167

Soluzione dei problemi 5 i-29 5 soluzione dei problemi 5.1 dati generali ___________________________________________________________ la tabella della soluzione dei problemi sotto elenca i problemi fondamentali che possono verificarsi durante l’avviamento e il funzion- amento. Richiedere informazioni...

Page 168

5 soluzione dei problemi i-30 5.2 spie della centralina __________________________________________________ la centralina è un dispositivo elettronico a stato solido che controlla e gestisce le funzioni elettriche. La centralina riceve i segnali di ingresso da vari interruttori e sensori sparsi per l...

Page 169

Soluzione dei problemi 5 i-31 5.3 circuiti elettrici _______________________________________________________ quando si cercano guasti sulla macchina tramite la centralina, controllare che le spie 1, 2 e 3 siano accese. Queste spie indicano che la centralina è sotto tensione e il programma di control...

Page 170: Avviso

6 tabelle della manutenzione e lubrificazione i-32 6 tabelle della manutenzione e lubrificazione 6.1 dati generali ___________________________________________________________ 1. Pulire sempre gli accessori della lubrificazione prima e dopo la lubrificazione. 2. Lubrificare con grasso di specifica co...

Page 171

Tabelle della manutenzione e lubrificazione 6 i-33 6.3 tabella della lubrificazione __________________________________________ 1 2 3 3 4 11 11 12 12 13 13 14 14 14 5 6 15 7 7 8 8 9 10 9 lf023 punti di ingrassaggio f1 - ogni 50 ore (ogni settimana) 1 alloggiamento del perno 2 braccio di sollevamento ...

Page 172

7 note i-34 7 note.

Page 173

Parts catalog 8 8 parts catalog 8.1 table of contents______________________________________________________ 1.1 .........Decals ..................................................................... 32 2.1 .........Hood ....................................................................... 34 3.1 .....

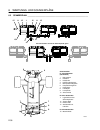

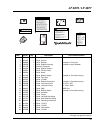

Page 174: Lf 3400 / Lf 3800

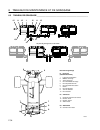

32 1 2 15 20 13 1 2 3 4 5 6 7 8 9 10 12 11 13 15 23 3 14 16 17 20 21 22 18/19 lf 4675 lf 4677 turbo turbo lf 3400 lf 3800 1 . Read operators manual before operating machine. 2. Keep shields in place and hardware securely fastened. 3. Before you clean, adjust or repair this equiptment, disengage all ...

Page 175: Lf 4675 / Lf 4677

33 > change from previous revision to avoid injury when working with battery 1. Always connect the black ground (–) cable last and remove it first. 2. Keep sparks and flames away, and avoid contatc with acid. To avoid injury when jumping battery 1. Connect positive (+) terminal to positive (+) termi...

Page 176: Lf 3400 / Lf 3800

34 lf 3400 / lf 3800 2.1 hood serial no. All lf34-1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 16 13 14 18 20 26 22 19 25 27 27 6.

Page 177: Lf 4675 / Lf 4677

35 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1003527 1 hood assembly, lf 3400/3800 includes items 16 ~ 20 on illustration 1.1 1 1004981 1 hood assembly, lf 4675/4677 includes items 16 ~ 20 on illustration 1.1 2 3007549 1 • foam, front 3 3...

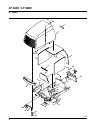

Page 178: Lf 3400 / Lf 3800

36 lf 3400 / lf 3800 3.1 seat pan serial no. All 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 15 17 21 22 23 24 25 20 18 8 9 9 19 7 7 10 10 25 26 27 / 28 29 30 32 33 34 35 20 20 29 9 31 36.

Page 179: Lf 4675 / Lf 4677

37 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1004279 1 floorpan 2 3009292 1 seat pan 3 3006909 1 support, right seat 4 3006910 1 support, left seat 5 3009995 1 adjuster, latching 6 3006988 1 adjuster, slave 7 400258 9 screw, 3/8-16 x 3/4”...

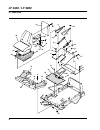

Page 180: Lf 3400 / Lf 3800

38 lf 3400 / lf 3800 4.1 instrument panel 5 gang units (lf 3400, lf 3800 and lf 3400 turbo) serial no. All lf34-3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 19 10 11 14 23 8 8 7 32.

Page 181: Lf 3400 / Lf 3800

39 > change from previous revision lf 3400 / lf 3800 item part no. Qty. Description serial numbers/notes 1 2811487 1 instrument panel 2 162723 1 hour meter 447006 1 • lockwasher, #10 444310 1 • nut, #10 3 365943 1 fuel gauge 4 3005121 1 water temperature gauge 447002 3 • lockwasher, #6 external toot...

Page 182

40 1 6 7 8 24 25 26 28 29 30 31 32 23 6 29 13 14 15 16 17 18 19 20 21 22 27 19 8 9 11 9 12 10 10 34 4 5 3 2 33 33 35 5.1 instrument panel lf 4675 and 4677 models serial no. All lf34-3.

Page 183: Lf 4675 / Lf 4677

41 > change from previous revision item part no. Qty. Description serial numbers/notes 1 2811991 1 instrument panel lf 4675 and 4677 only 2 162723 1 hour meter 447006 1 • lockwasher, #10 444310 1 • nut, #10 3 365943 1 fuel gauge 4 3005121 1 water temperature gauge 447002 3 • lockwasher, #6 external ...

Page 184: Lf 3400 / Lf 3800

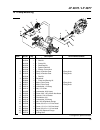

42 lf 3400 / lf 3800 6.1 traction pedal linkage serial no. All lf34-4 1 2 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 27 26 6 14 28 20 21 22 27 27 27 27 23 27 28 26 26 29 30

Page 185: Lf 4675 / Lf 4677

43 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1003288 1 treadle pivot 2 352726 2 • bushing 3 3007230 1 stop, mow speed 4 3003474 1 grip, pedal 5 3003475 1 grip, pedal 6 366974 2 rod end 7 3007392 1 switch, proximity 8 3006327 1 shaft, turn...

Page 186: Lf 3400 / Lf 3800

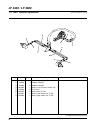

44 lf 3400 / lf 3800 7.1 brake pedal linkage serial no. All lf34-5 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 22 23 21 7 9 14 15 16 18 13 20 24.

Page 187: Lf 4675 / Lf 4677

45 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 3006838 1 bracket, brake 2 3007392 1 switch, proximity 3 3006327 2 shaft, turn assist 4 3007606 1 lever, parking brake 5 3006997 1 mount, brake 6 1003616 1 brake arm 7 352726 2 • bushing 8 4712...

Page 188: Lf 3400 / Lf 3800

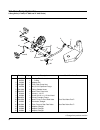

46 4 5 6 7 8 9 10 13 14 15 16 17 19 20 21 22 23 27 28 29 30 31 33 1 2 3 18 10 11/12 25/26 32 10 23 23 20 16 17 24 34 35 35 reverse view 36 37 38 39 40 41 42 34 lf 3400 / lf 3800 8.1 frame and front axle serial no. All.

Page 189: Lf 4675 / Lf 4677

47 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 5002573 2 tire 2 5002574 2 rim 3 360111 2 valve, inflation 4 1001757 2 wheel motor see 49.1 5 557623 2 • key 6 557624 2 • nut, hex 7 2812246 1 frame includes four (4) of item 10 8 366871 2 • bu...

Page 190: Lf 3400 / Lf 3800

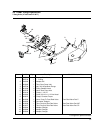

48 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 9 9 9 4 16 15 17 15 20 15 25 29 31 31 26 32 lf 3400 / lf 3800 9.1 2wd steering 2wd units only serial no. 67866,67868.

Page 191: Lf 4675 / Lf 4677

49 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 3006981 2 tire 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 117139 1 steering axl...

Page 192: Lf 3400 / Lf 3800

50 lf 3400 / lf 3800 10.1 4wd steering 4wd units only serial no. 67915, 67916-1601 and up serial no. 67867 -1601 and up serial no. 67869-1601 and up serial no. 67889-1601 and up lf34-8 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 18 20 21 22 23 4 4 9 9 9 11 16 17 20 15 15 15 24 25 26 27 28 29 30 31 32 33 ...

Page 193: Lf 4675 / Lf 4677

51 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 3006981 2 tire 2 1003638 2 rim 3 360111 2 inflation valve 4 361648 6 washer, thrust 5 361647 2 bearing, thrust 6 471214 2 fitting, grease 7 461393 2 pin, spring 1/4 x 2” 8 117139 1 steering axl...

Page 194: Lf 3400 / Lf 3800

52 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 11 11 lf 3400 / lf 3800 11.1 tilt steering serial no. All.

Page 195: Lf 46756 / Lf 4677

53 > change from previous revision lf 46756 / lf 4677 item part no. Qty. Description serial numbers/notes 1 5002918 1 actuator, gas spring 2 5002919 1 cable, actuator 3 2811346 1 tower, steering 4 1003458 1 valve, steering see 39.1 339979 3 • adapter, straight 339974 2 • adapter, straight 5 443828 1...

Page 196: Lf 4675 / Lf 4677

54 lf 4675 / lf 4677 12.1 radiator and air cleaner serial no. All lf34-10 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 34 35 36 37 38 39 37 35 35 35 35 34 34 34 34 34 34 34 33 33 25 25 25 25 24 23 23 23 22 21 21 21 40 41 16 16.

Page 197: Lf 4675 / Lf 4677

55 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 3001965 1 air filter 5000919 1 • air cleaner element 5000920 1 • cover 5000921 1 • valve 2 3001388 1 bracket, air filter 3 3006094 1 shroud, rear frame 4 3006583 1 bracket, air cleaner mounting...

Page 198: Lf 3400/ Lf 3800

56 ref. Negative battery cable 1 2 3 14 15 18 19 20 21 22 23 24 25 26 27 28 29 30 31 24 24 6 7 10 12 13 21 16 17 4/5 16 17 8 9 11 22 30 2 20 a a 32 33 34 lf 3400/ lf 3800 13.1 engine assembly and mounting serial no. All.

Page 199: Lf 4675 / Lf 4677

57 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1002855 1 engine, kubota v1305-e lf 3400 1 1002856 1 engine, kubota v1505-e lf 3800 1 1002857 1 engine, kubota v1505-te lf 3400 turbo, lf 4675 & lf 4677 2 366879 3 isolator, engine 3 1003239 1 ...

Page 200: Lf 3400 / Lf 3800

58 > change from previous revision 1 2 3 4 5 6 7 8 9 10 3 7 lf 3400 / lf 3800 14.1 engine exhaust serial no. All item part no. Qty. Description serial numbers/notes 1 1004653 1 muffler lf 3400 & 3800 only 1 1002931 1 muffler lf 3400 turbo, lf 4675, lf 4677 2 1004598 1 tailpipe 3 363586 6 screw, m8-1...

Page 201: Lf 4675 / Lf 4677

59 > change from previous revision 1 2 4 10 12 11 14 15 16 17 10 3 5 6 7 8 9 13 lf 4675 / lf 4677 15.1 pump mounting serial no. All item part no. Qty. Description serial numbers/notes 1 2810006 1 pump, traction 5003034 1 • seal kit 5003432 1 • control kit 5003433 1 • shaft seal kit 5003434 1 • syste...

Page 202: Lf 3400 / Lf 3800

60 a a b b connect to engine fuel injector overflow. Connect to engine fuel pump 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 22 23 19 18 18 18 13 15 17 18 lf 3400 / lf 3800 16.1 fuel and hydraulic tanks serial no. All.

Page 203: Lf 4675 / Lf 4677

61 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 132647 1 valve, shut off 2 3001279 1 switch, float 3 3002397 1 plug, magnetic 339899 1 • o-ring 4 3009204 1 fuel tank 5 3005871 1 hydraulic tank 6 3005872 1 shell, tank cover 7 3006243 2 plate,...

Page 204: Lf 3400 / Lf 3800

62 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 3 6 lf 3400 / lf 3800 17.1 2wd traction hydraulics serial no. 67915-1601 and up serial no. 67868-1601 and up item part no. Qty. Description serial numbers/notes 1 1003462 1 hose, pump to upper traction tee 2 339994 4 adaptor, straight 3 339999...

Page 205: Lf 4675 / Lf 4677

63 > change from previous revision lf 4675 / lf 4677 18.1 4wd traction hydraulics serial no. 67916-1601 and up serial no. 67869-1601 and up item part no. Qty. Description serial numbers/notes 1 1003440 1 hose, pump to reverse 4wd tee 2 339994 6 adapter, straight 3 339999 2 adapter, straight 4 100345...

Page 206: Lf 3400 / Lf 3800

64 > change from previous revision a b a b p t g 10 9 8 1 2 3 front lift valve rear reel valve 1 2 3 4 5 5 6 7 8 9 10 12 11 14 16 16 18 17 1 15 15 13 17 9 to lift valve p port to lift valve t port from gear pump to steering cylinder aux in out lt rt charge (inner) filter lf 3400 / lf 3800 19.1 charg...

Page 207: Lf 4675 / Lf 4677

65 > change from previous revision a b a b p t2 10 9 8 1 2 3 front lift valve rear reel valve charge (inner) filter 1 2 3 4 5 5 6 7 8 9 10 12 11 14 16 16 18 17 1 15 15 13 17 9 to lift valve p port to lift valve t port from gear pump to steering cylinder aux in out lt rt lf 4675 / lf 4677 20.1 charge...

Page 208

66 > change from previous revision 1 2 3 4 5 6 7 8 9 10 13 15 12 11 14 6 9 5 21.1 gear pump hydraulics 5 gang units (lf 3400, lf 3800 and lf 3400 turbo) item part no. Qty. Description serial numbers/notes 1 365959 1 strainer, tank mounted 362743 1 • o-ring 2 340090 1 adapter, 90° 3 1003992 1 tube, g...

Page 209

67 > change from previous revision 22.1 gear pump hydraulics 7 gang units (lf 4675 and lf 4677) item part no. Qty. Description serial numbers/notes 1 365959 1 strainer, tank mounted 362743 1 • o-ring 2 340090 1 adapter, 90° 3 1003992 1 tube, gear pump inlet 4 445796 1 nut, 3/8-16 spiralock flange 5 ...

Page 210: Lf 3400 / Lf 3800

68 > change from previous revision 1 2 3 4 5 6 7 8 9 10 11 8 4 12 14 13 15 16 lf 3400 / lf 3800 23.1 return hydraulics 5 gang units (lf 3400, lf 3800 and lf 3400 turbo) serial no. All item part no. Qty. Description serial numbers/notes 1 1003453 1 hose, oil cooler 2 2812271 1 tube, drain 3 1004312 1...

Page 211: Lf 4675 / Lf 4677

69 > change from previous revision 1 2 3 4 5 6 7 8 9 10 11 12 13 15 16 17 8 4 12 14 lf 4675 / lf 4677 24.1 return hydraulics 7 gang units (lf 4675 and lf 4677) serial no. All item part no. Qty. Description serial numbers/notes 1 1003453 1 hose, oil cooler 2 2812271 1 tube, drain 3 1004312 1 tube, ri...

Page 212: Lf 3400 / Lf 3800

70 > change from previous revision 6 7 10 12 11 7 1 2 3 4 5 7 6 6 7 8 11 10 6 12 9 10 11 lf 3400 / lf 3800 25.1 hydraulic valve & filter mounting 5 gang units (lf 3400, 3800 and lf 3400 turbo) item part no. Qty. Description serial numbers/notes 1 123015 1 charge filter 556417 1 • head 2811255 1 • oi...

Page 213: Lf 4675 / Lf 4677

71 > change from previous revision 6 7 9 10 12 11 7 13 1 2 3 4 5 7 6 6 7 8 6 10 11 lf 4675 / lf 4677 26.1 hydraulic valve and filter mounting 7 gang units (lf 4675 and lf 4677) item part no. Qty. Description serial numbers/notes 1 123015 1 charge filter 556417 1 • head 2811255 1 • oil filter cartrid...

Page 214: Lf 3400 / Lf 3800

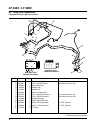

72 lift cylinder hoses steering hoses reel motor hoses reel motor hoses fuel hoses steering hoses center reel drain wing reel tubes wing reel motor hoses lf 4675 / 4677 inner frame support bracket for hydraulic tubing 6 7 4 9 3 5 6 4 5 22 7 11 9 10 28 1 22 6 26 6 26 18 3 19 1 2 3 4 5 18 19 20 16 17 ...

Page 215: Lf 4675 / Lf 4677

73 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 445795 ar nut, 5/16-18 spiralock flange 2 441614 1 carriage bolt, 5/16-18 x1” 3 3007558 ar clamp, double tube 4 345666 ar clamp, 1/2” i.D. 5 409811 ar screw, 5/16-18 x 5/8” thread cutting 6 445...

Page 216: Lf 3400 / Lf 3800

74 > change from previous revision 1 2 3 4 5 6 9 7 8 10 10 10 10 10 2 7 9 7 9 7 4 7 9 9 right front cylinder center front cylinder left front cylinder p t1 g 10 9 8 1 2 3 10 9 8 1 2 3 lift valve 5 gang units lift valve 7 gang units lf 3400 / lf 3800 28.1 front lift hydraulics serial no. All item par...

Page 217: Lf 4675 / Lf 4677

75 > change from previous revision 1 2 3 4 6 6 7 6 6 8 8 8 8 5 5 5 5 7 lf 4675 / lf 4677 29.1 wing lift hydraulics 7 gang units (lf 4675 and lf 4677) serial no. All item part no. Qty. Description serial numbers/notes 1 1004227 1 hose, lift valve to left wing lift valve port 6 2 1004228 1 hose, left ...

Page 218: Lf 3400 / Lf 3800

76 > change from previous revision 9 8 1 2 13 9 8 5 3 3 4 10 11 12 6 7 9 9 4 9 lf 3400 / lf 3800 30.1 rear lift hydraulics 5 gang units (lf 3400, lf 3800 and lf 3400 turbo) serial no. All item part no. Qty. Description serial numbers/notes 1 1003352 1 hose, left rear to right rear base ports 2 10033...

Page 219: Lf 4675 / Lf 4677

77 > change from previous revision 9 8 1 2 9 8 5 3 5 10 6 7 4 9 lf 4675 / lf 4677 31.1 rear lift hydraulics 7 gang units (lf 4675 and lf 4677) serial no. All item part no. Qty. Description serial numbers/notes 1 1003352 1 hose, left rear to right rear base ports 2 1003351 1 hose, left rear to right ...

Page 220: Lf 3400 / Lf 3800

78 > change from previous revision ra rb ca cb lb la lf 3400 / lf 3800 32.1 wing reel hydraulics 7 gang units only (lf 4675 and lf 4677) serial no. All item part no. Qty. Description serial numbers/notes 1 1004430 1 tube, left wing pressure rear reel valve port la 2 1004431 1 tube, left wing return ...

Page 221: Lf 4675 / Lf 4677

79 > change from previous revision lf 4675 / lf 4677 33.1 front reel hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 1003337 1 hose, valve to right front motor front reel valve port a 2 1003444 1 hose, right front to bulkhead 3 1003445 1 hose, bulkhead to center motor...

Page 222: Lf 3400 / Lf 3800

80 > change from previous revision lf 3400 / lf 3800 34.1 rear reel hydraulics 5 gang units (lf 3400, lf 3800 and lf 3400 turbo) serial no. All item part no. Qty. Description serial numbers/notes 1 1003336 1 hose, valve to right rear motor 2 1003443 1 hose, right rear to left rear motor 3 1003335 1 ...

Page 223: Lf 4675 / Lf 4677

81 > change from previous revision ra rb ca cb lf 4675 / lf 4677 35.1 rear reel hydraulics 7 gang units (lf 4675 and lf 4677) serial no. All item part no. Qty. Description serial numbers/notes 1 1004432 1 tube, rear pressure rear valve port ca 2 1004284 1 hose, tube to right rear motor 3 1004285 1 h...

Page 224: Lf 3400 / Lf 3800

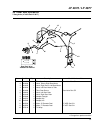

82 30 outside yokes only. 31 32 32 33 1 2 5 6 7 8 9 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 18 11 11 6 6 17 19 7 7 8 8 10 17 19 28 17 19 9 19 32 19 19 32 32 3 4 10 11 11 8 8 7 7 19 19 6 6 32 17 19 6 32 17 31 30 lf 3400 / lf 3800 36.1 lift arms serial no. All.

Page 225: Lf 4675 / Lf 4677

83 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1002483 1 left front lift arm 2 1002484 1 right front lift arm 3 1002485 1 left rear lift arm 4 1002486 1 right rear lift arm 5 1002487 1 center lift arm 6 3006539 10 • bushing 2 per lift arm 7...

Page 226: Lf 3400/ Lf 3800

84 lf 3400/ lf 3800 37.1 outrigger lift arms 7 gang units only (lf 4675 and lf 4677) serial no. All from proximity switch proximity switch hook-up 1 2 3 4 5 6 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 9 14 19 19 20 21 1 outside yokes only. 31 32 32 33.

Page 227: Lf 4675 / Lf 4677

85 lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1004391 1 wing, l.H. Mounting assembly 2 1004392 1 wing, r.H. Mounting assembly 3 1004393 1 arm, l.H. Mounting assembly 4 3006539 4 • bushing 2 per lift arm 5 1004394 1 arm, r.H. Mounting assembly 6 1004492 2 pin, cylinder 7 ...

Page 228: Lf 3400 / Lf 3800

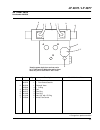

86 a b c d e f g h j k l m a - headlight b - lift arm limit switch c - fuel level sender/ instrument panel d - seat switch e - oil float switch f - glow plugs g - fuel solenoid h - charge filter switch j - engine oil pressure switch k - temperature sender l - 4wd valve (4wd only) m - reel valve 3 am...

Page 229: Lf 4675 / Lf 4677

87 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 ------------ 1 tray, battery see 8.1 2 1004776 2 headlight 5000527 1 • bulb 5003623 1 • bracket 3 2812301 1 controller 4 400104 1 screw, 1/4-20 x 1/2” hex head 5 446134 4 lockwasher, 5/16 6 366...

Page 230: Lf 3400/ Lf 3800

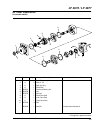

88 to prevent cuts use socket wrench or turf groomer knob to turn reel. ! Warning to prevent injury, disengage all drives, engage parking brake and stop engine before working in machine or emptying grass catchers. ! Danger lf 3400/ lf 3800 39.1 five inch reel assembly lf 3400, lf 3400 turbo and lf 4...

Page 231: Lf 4675 / Lf 4677

89 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 5003087 1 frame, reel 2 361877 2 • decal, danger 3 1000997 1 • decal, warning 4 5003053 1 7 blade left hand reel 4 5003054 1 7 blade right hand reel 5 1004786 1 bearing housing 6 500534 1 • bea...

Page 232: Lf 3400 / Lf 3800

90 lf 3400 / lf 3800 40.1 five inch reel assembly lf 3400, lf 3400 turbo and lf 4675 models serial no. All 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 22 / 21 8 12 20 25 24 23 26 / 27 19 28 18 13 29.

Page 233: Lf 4675 / Lf 4677

91 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1000770 1 rear roller see 31.1 2 1002224 2 zerk bolt 3 446142 2 lockwasher, 3/8 heavy 4 400264 2 screw, 3/8-16 x 1-1/4” hex head 5 453011 2 flat washer, 3/8 6 345510 2 spacer 7 2000065 1 castin...

Page 234: Lf 3400 / Lf 3800

92 lf 3400 / lf 3800 41.1 seven inch reel assembly lf 3800 and 4677 models serial no. All lf34-29 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 14 18 18 26 35 34 33 35 36 37 27 36 38 38 39 39.

Page 235: Lf 4675 / Lf 4677

93 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 2810472 1 reel, 11 blade used on 67848 1 2810471 1 reel, 9 blade used on 67858 2 5002609 1 frame, 7” reel 3 361877 2 • decal, danger 4 2811399 1 bedknife backing assembly 5 503460 1 • bedknife ...

Page 236: Lf 3400 / Lf 3800

94 lf 3400 / lf 3800 42.1 seven inch reel assembly lf 3800 and lf 4677 models serial no. All lf34-30 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 22 21 23 24 25 13 26 14 27 28 29.

Page 237: Lf 4675 / Lf 4677

95 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 123268 1 front roller see 30.1 2 1002446 1 rear roller, 24” serial no. 67848-1601 ~ 1899, see 32.1 2 1003728 1 rear roller, 22” serial no. 67848-1900 and up, see 32.1 2 1003728 1 rear roller, 2...

Page 238: Lf 3400 / Lf 3800

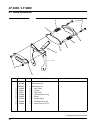

96 > change from previous revision lf 3400 / lf 3800 43.1 down pressure spring serial no. All item part no. Qty. Description serial numbers/notes 1 461397 1 roll pin, 1/4 x 1-1/4” 2 453017 1 flat washer, 1/2 3 400268 1 screw, 3/8-16 x 1-3/4” hex head 4 3008593 1 tube, down pressure 5 460312 1 hairpi...

Page 239: Lf 4675 / Lf 4677

97 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 3003416 1 shaft 2 3000115 1 tube ◆ 3 500534 2 bearing, cup and cone 4 471214 2 grease fitting ◆ 5 338647 2 grease seal ◆ 6 n/s 16 spacer ◆ 7 3004882 2 grease seal 8 3005156 2 sleeve,wear ◆ 9 36...

Page 240: Lf 3400 / Lf 3800

98 > change from previous revision lf 3400 / lf 3800 45.1 rear roller part number 1000770 serial no. All item part no. Qty. Description serial numbers/notes 1 3001654 1 shaft, roller 2 3001655 1 tube, roller 3 3001656 2 seal, grease 4 5000625 2 bearing, cup and cone 5 3000983 2 seal, grease 6 300176...

Page 241: Lf 4675 / Lf 4677

99 > change from previous revision lf 4675 / lf 4677 item part no. Qty. Description serial numbers/notes 1 1002445 1 tube, 24” roller 1 1003727 1 tube, 22” roller 2 3005318 1 shaft, 24” roller 2 3008027 1 shaft, 22” roller 3 3005156 2 sleeve, wear 4 3004882 2 seal, grease 5 500534 2 bearing, cup and...

Page 242: Lf 3400 / Lf 3800

100 > change from previous revision 1 2 3 4 5 6 7 8 9 7 6 lf 3400 / lf 3800 47.1 brake assemblies serial no. All item part no. Qty. Description serial numbers/notes 1 340603 2 bracket, brake mounting 503308 1 disk brake, r.H. 2500722 1 disk brake, l.H. 2 590259 4 • nut, 3/8-24 3 549441 2 • v-plate 4...

Page 243: Lf 4675 / Lf 4677

101 > change from previous revision 1 / 7 2 3 4 5 3 a b g *used to power both front and rear reels for lf 3400 and lf 3800 units and for front reels only on lf 4675 and lf 4677 units. 6 lf 4675 / lf 4677 48.1 reel valve part number 2822502 serial no. All item part no. Qty. Description serial numbers...

Page 244: Lf 3400 / Lf 3800

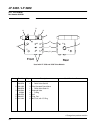

102 > change from previous revision 7 8 9 10 12 11 13 14 15 16 17 18 19 20 21 1 2 3 4 5 6 lf 3400 / lf 3800 49.1 front wheel motor part number 1001757 serial no. All item part no. Qty. Description serial numbers/notes 1 558066 8 screw, torx 2 5002110 1 front retainer 3 558063 1 shaft and bearing kit...

Page 245: Lf 4675 / Lf 4677

103 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 lf 4675 / lf 4677 50.1 rear wheel motor part number 390859 serial no. All item part no. Qty. Description serial numbers/notes 1 a 1 seal exclusion 2 a 4 seal, 3” i.D. 3 a 1 back up ring 4 a 1 shaft seal 5 554781 1 shaft and bearing ki...

Page 246: Front

104 > change from previous revision 1 2 3 4 5 8 9 10 g p t 5 1 t 6 4 front rear 2 3 2 2 2 used with lf 3400 and 3400 turbo models. 6 lf 3400 / lf 3800 51.1 lift valve part number 2822501 serial no. All item part no. Qty. Description serial numbers/notes 1 5003144 1 relief valve 5003579 1 • relief va...

Page 247: Lf 4675 / Lf 4677

105 > change from previous revision 1 2 3 4 4 5 6 6 7 8 9 9 9 10 11 12 13 13 2 used with lf 4675 and 4677 models. Front rear lf 4675 / lf 4677 52.1 lift valve part number 1004096 serial no. All item part no. Qty. Description serial numbers/notes 1 5003144 1 relief valve 5003579 1 • seal kit 2 500135...

Page 248: Lf 3400 / Lf 3800

106 > change from previous revision lf 3400 / lf 3800 53.1 reel motor part number 2822503 serial no. All item part no. Qty. Description serial numbers/notes 1 5001068 1 o-ring 2 5003140 2 relief valve 3 5003688 1 face plate 5003589 1 seal kit 1 2 3.

Page 249: Lf 4675 / Lf 4677

107 > change from previous revision lf 4675 / lf 4677 54.1 reel motor part number 1002620 serial no. All item part no. Qty. Description serial numbers/notes 1 3006021 1 o-ring 2 5003140 2 relief valve 3 5003485 1 face plate 4 5003031 1 seal kit not shown 5 4102440 1 shaft, output 1 2 3 used on lf 38...

Page 250: Lf 3400 / Lf 3800

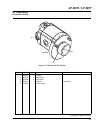

108 lf 3400 / lf 3800 55.1 steering valve part number 1003458 serial no. All 1 2 3 4 5 6 7 8 10 9 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 31 32 33 34 35 36 37 4 4 4 11 11 38 30

Page 251: Lf 4675 / Lf 4677