- DL manuals

- Jacobsen

- Lawn Mower

- LF 550

- Technical/repair Manual

Jacobsen LF 550 Technical/repair Manual

Summary of LF 550

Page 1

Lf 550 tm and lf 570 tm lightweight fairway mowers technical/repair manual 67978, 67979, 67980, 67981, 67982, 67983.

Page 3: When Performance Matters.

Warning: if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers, and should read the entire manual before attempting to set up, operate, adjust, or service the machine. ! ©2012 jacobsen, a textron ...

Page 5: Foreword

4241262-rev b 5 litho in u.S.A. 10-2012 foreword general this manual provides detailed information and procedures to safely repair and maintain the following: jacobsen lf 550™ and lf 570™ lightweight fairway mowers and associated accessory attachments this manual is intended to introduce and guide t...

Page 6: How to Use This Manual

6 4241262-rev b foreword how to use this manual this manual is designed to provide multiple ways to locate and access repair information. Read each section in its entirety before beginning a procedure. Proper understanding of machine operation and components is the key to successful diagnostics and ...

Page 7: Table of Contents

9 2 3 4 5 6 7 8 table of contents 4241262-rev b 7 1 safety specifications and general information engine electrical hydrostatic power train hydraulics steering cutting units accessories and miscellaneous repair.

Page 9: Chapter 1

4241262-rev b 1-1 chapter 1 1 safety introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 prepare for the job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10: Introduction

1-2 4241262-rev b safety 1 introduction safety is the most important element of any repair procedure. Knowledge of the procedure to be performed and safe work habits are essential to preventing death, personal injury, or property damage. Use the following statements as a common-sense guide to proper...

Page 11

Safety 4241262-rev b 1-3 1 figure 1-1 2 6 9 10 4 3 7 8 9 1 5 8 tn3585.

Page 12: 105

1-4 4241262-rev b safety 1 105 db l wa 1 ! 4131663 4181861 4181862 3 4 5 2.

Page 13

Safety 4241262-rev b 1-5 1 4182520 8 4181863 41 8 1 8 64 6 4199140 7 9 4181865 10

Page 14: Inspect Safety Labels

1-6 4241262-rev b safety 1 inspect safety labels safety labels are critical to the safe operation of the mower. Inspect the mower for any damaged, missing, or unreadable labels. Replace labels as needed before placing the mower back in service. Keep work area clean a clean, organized, well-lit work ...

Page 15: Use Lifting Equipment Safely

Safety 4241262-rev b 1-7 1 notice 6. Remove key from key switch. Use lifting equipment safely ! Warning • always use a lifting device with a lifting capacity greater than the weight of the item being lifted. • secure the load to the lifting device using cables, chains, or slings rated to handle the ...

Page 16: Service Tires Safely

1-8 4241262-rev b safety 1 service tires safely ! Warning • always wear safety glasses or goggles. • use proper lifting methods when working with wheels and tires. • when working on an inflated tire, never position yourself directly over the work area. • when dismounting or mounting tires, use a whe...

Page 17: Handle Chemical Products

Safety 4241262-rev b 1-9 1 handle chemical products safely ! Warning routine service often requires the use of various chemical products, including lubricants and cleaning solutions. Many of these chemicals are flammable and can pose health risks if not handled properly. • never mix chemicals. Mixin...

Page 18: Safely

1-10 4241262-rev b safety 1 service electrical components safely ! Warning • disconnect the battery negative (–) cable before removing or installing electrical components. Always connect the battery negative (–) cable last. • certain test and adjustment procedures must be performed with the battery ...

Page 19: Chapter 2

2 4241262-rev b 2-1 chapter 2 specifications and general information machine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 machine serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 20: Machine Identification

2-2 4241262-rev b specifications and general information 2 machine identification machine serial number see figures 2-1 and 2-2. Figure 2-1 figure 2-2 a machine identification plate (1) listing the serial number (3) and machine weight (2) is attached to the frame of the mower and is located just ahe...

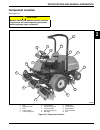

Page 21: Component Location

Specifications and general information 4241262-rev b 2-3 2 component location see figure 2-4. ! Caution figure 2-4: component location become familiar with operator controls, machine components, and correct operating procedures before beginning repair procedures. 1 ops 6 left front wheel 11 throttle...

Page 22: Specifications

2-4 4241262-rev b specifications and general information 2 specifications quick reference specifications engine general engine specifications manufacturer/models kubota ® interim tier 4/stage iiia v1505-e3b kubota ® interim tier 4/stage iiia v1505-t-e3b engine type 4-stroke, diesel fuel requirement ...

Page 23

Specifications and general information 4241262-rev b 2-5 2 electrical test specifications resistance across solenoid coil— front mow solenoid coil at 68° f ohms 5.3 ± 10% resistance across solenoid coil— front backlap coil at 68° f ohms 5.3 ± 10% resistance across solenoid coil— rear mow solenoid co...

Page 24

2-6 4241262-rev b specifications and general information 2 hydrostatic power train test specification traction pump flow gpm (lpm) 38.3 (145) at 3150 rpm forward system relief pressure— machine serial numbers ending 1651 through 2499 psi (bar) 3625 ± 10% (250 ± 10%) at 3150 rpm forward system relief...

Page 25

Specifications and general information 4241262-rev b 2-7 2 brake release valve—check valve torque lb-ft (n·m) 20–25 (27.1–33.9) 4wd valve—ports “lrf,” “lrr,” “rrf,” and “rrr” fitting torque lb-ft (n·m) 110 (149) 4wd valve—ports “lf” and “rf” fitting torque lb-ft (n·m) 110 (149) 4wd valve—drn port fi...

Page 26

2-8 4241262-rev b specifications and general information 2 hydraulics test specifications front cutting units pump flow gpm (lpm) 6.8 (25.7) at 3150 rpm rear cutting units pump flow gpm (lpm) 6.8 (25.7) at 3150 rpm lift/steer pump flow gpm (lpm) 6.8 (25.7) at 3150 rpm hydraulic leakage percentage ra...

Page 27

Specifications and general information 4241262-rev b 2-9 2 steering test and adjustment specifications rear axle alignment toe-in measurement in. (mm) 0.030–0.090 (0.8–2.3) rear axle steering arm-to-steering stop measurement in. (mm) 0.030–0.090 (0.8–2.3) rear axle assembly end play in. (mm) 0.010–0...

Page 28

2-10 4241262-rev b specifications and general information 2 cutting units checks and adjustments reel bearing pre-load in. (mm) 0.040 (1.0) bedknife front face height in. (mm) 0.060 (1.5) bedknife front face angle degrees 5 bedknife top face angle (rear relief) degrees 8–10 reel blade relief angle d...

Page 29

Specifications and general information 4241262-rev b 2-11 2 accessories and miscellaneous ops mounting hardware mounting hardware torque lb-ft (n·m) 80–90 (108–122) fuel tank capacity gal (l) 17 (64.4) work light work light adjustment bolt lb-in. (n·m) 60–75 (6.8–8.5) front tires size 26.5 x 14-12 t...

Page 30

2-12 4241262-rev b specifications and general information 2 weights and dimensions overall weight lb (kg) 67978 (lf 550, 2wd): 2837 (1287) 67979 (lf 550, 4wd): 2960 (1343) 67981 (lf 570, 2wd): 3135 (1422) 67982 (lf 570, 4wd): 3274 (1485) 67980 (lf 550 turbo, 4wd): 2974 (1349) 67983 (lf 570 turbo, 4w...

Page 31: Standard Torque Values

Specifications and general information 4241262-rev b 2-13 2 standard torque values inch fastener torque values metric fastener torque values notice note jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. When tightening plated bolts, use the value given for lubricated. All torqu...

Page 32: Hydraulic Hose, Tube, and

2-14 4241262-rev b specifications and general information 2 hydraulic hose, tube, and fitting general instructions o-ring installation • always install new o-rings. • on hoses with o-ring fittings, make sure o-rings are properly seated before tightening. • o-rings should be lubricated with the fluid...

Page 33: Chapter 3

3 4241262-rev b 3-1 chapter 3 engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 general engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 34: Specifications

3-2 4241262-rev b engine 3 specifications general engine specifications repair specifications engine manufacturer/models kubota ® interim tier 4/stage iiia v1505-e3b kubota ® interim tier 4/stage iiia v1505-t-e3b engine type 4-stroke, diesel fuel requirement no. 2-d diesel fuel (cetane rating 45) nu...

Page 35: Component Location

Engine 4241262-rev b 3-3 3 component location kubota v1505 see figures 3-1 and 3-2. Figure 3-1: component location—right side 1 radiator/hydraulic oil cooler 7 engine coolant drain valve 2 thermostat 8 engine oil pressure switch 3 engine oil fill cap 9 alternator 4 muffler 10 fan belt 5 exhaust mani...

Page 36

3-4 4241262-rev b engine 3 figure 3-2: component location—left side 1 air cleaner indicator 7 throttle cable 2 air cleaner assembly 8 air vent screw 3 engine coolant filler/pressure cap 9 fuel shutoff solenoid 4 radiator/hydraulic oil cooler 10 fuel filter 5 engine temperature sensor 11 battery 6 ai...

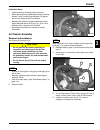

Page 37: Checks and Adjustments

Engine 4241262-rev b 3-5 3 checks and adjustments purging the fuel system adjustment see figures 3-3 through 3-5. ! Caution note fuel system will need to be purged of air whenever fuel filter or fuel lines are removed, fuel tank is completely emptied, or engine has not been used for an extended time...

Page 38: Repair

3-6 4241262-rev b engine 3 ! Warning 8. Crank engine over for approximately 10 seconds. 9. When bubbles no longer appear in fuel coming out of air vent plug hole, tighten air vent plug. 10. Turn ignition switch to off position. Repair fan belt removal and installation see figures 3-6 and 3-7. 1. Par...

Page 39

Engine 4241262-rev b 3-7 3 installation notes • install fan belt by reversing order of removal. • adjust belt tension by loosening alternator mounting screws (1 and 3) and pulling alternator (2) against belt (4) until proper tension is achieved. • measure belt tension at midpoint between pulleys. Ad...

Page 40

3-8 4241262-rev b engine 3 installation notes • install air cleaner assembly by reversing order of removal. • install dust cap with air inlet (3) located at bottom of assembly. Figure 3-10 • reset air filter indicator by pressing button (8) on end of indicator (9). Muffler and exhaust assembly remov...

Page 41

Engine 4241262-rev b 3-9 3 6. Install insulating sleeve (5), tailpipe (6), and u-bolt (3), and install, but do not tighten, two nuts (4). 7. Install two screws (7) and two lock washers (8). Tighten screws (7) to 35–40 lb-ft (47.5–54.2 n·m). 8. Tighten two nuts (4). Exhaust manifold—naturally aspirat...

Page 42

3-10 4241262-rev b engine 3 radiator/hydraulic oil cooler removal see figures 3-14 through 3-19. ! Warning 1. Park the mower safely. (see “park mower safely” on page 1-6.) 2. Allow engine to cool completely. 3. Raise the hood. Notes • the engine coolant capacity (engine only) for non-turbo models is...

Page 43

Engine 4241262-rev b 3-11 3 figure 3-17 note plug hoses after disconnecting to prevent loss of hydraulic oil. 10. Disconnect upper hydraulic hose (8) from radiator/hydraulic oil cooler. 11. Remove screws (9). Figure 3-18 12. Disconnect lower hydraulic hose (10) from bottom of radiator/hydraulic oil ...

Page 44

3-12 4241262-rev b engine 3 engine oil cooler (turbocharger engine only) removal and installation see figure 3-20. 1. Park the mower safely. (see “park mower safely” on page 1-6.) 2. Allow engine to cool completely. Figure 3-20 notes • label all hoses before disconnecting to ensure correct installat...

Page 45

Engine 4241262-rev b 3-13 3 fuel filter removal and installation see figures 3-22 through 3-24. ! Caution 1. Park the mower safely. (see “park mower safely” on page 1-6.) 2. Allow engine to cool completely. 3. Disconnect battery negative (–) cable at battery. Figure 3-22 4. Turn fuel outlet shutoff ...

Page 46

3-14 4241262-rev b engine 3 fuel pump removal and installation see figures 3-25 through 3-27. ! Caution note naturally aspirated engine shown; turbocharged engine is similar. 1. Park the mower safely. (see “park mower safely” on page 1-6.) 2. Allow engine to cool completely. 3. Disconnect battery ne...

Page 47

Engine 4241262-rev b 3-15 3 engine removal and installation see figures 3-28 through 3-36. Note naturally aspirated engine shown; turbocharged engine is similar. 1. Park the mower safely. (see “park mower safely” on page 1-6.) 2. Allow engine to cool completely. 3. Disconnect battery negative (–) ca...

Page 48

3-16 4241262-rev b engine 3 figure 3-31 14. Unscrew hose clamp (10). 15. Disconnect fuel return line (9). 16. Remove nut (12). Disconnect glow plug wire (11). Figure 3-32 17. Remove nut (13) and disconnect battery cable (14) at alternator. 18. Disconnect wire connector (15). 19. Remove screw (16) an...

Page 49

Engine 4241262-rev b 3-17 3 figure 3-35 23. Unlatch wire harness clamps (24). 24. Remove bolt (25). ! Warning figure 3-36 25. Using an engine hoist, support engine (26) and remove three engine mounting bolts (27). 26. Check for any connected wires and components. 27. Carefully remove engine from mac...

Page 50

3-18 4241262-rev b engine 3 installation notes • inspect engine mounts, and replace if necessary. • install engine by reversing order of removal. • if necessary, remove components from engine and install components on new engine. • apply dielectric grease (jacobsen pn 365422) to any wire connectors ...