- DL manuals

- Jacobsen

- Lawn Mower

- LF550-H-T4F

- Safety, Operation And Maintenance Manual

Jacobsen LF550-H-T4F Safety, Operation And Maintenance Manual - Notice

5 DECALS

23

NOTICE

DO NOT USE START ASSIST FLUIDS

Start assist fluids in the air intake system can be

explosive or cause an engine condition that is not

controlled and can cause engine damage.

WARNING

To prevent injury when you fold the ROPS, use caution to prevent your fingers

broken or pinched between moving and rigid parts of the ROPS.

Warning

Read the manual for instructions to backlap the cutting units.

4181861

NOTICE

Do NOT fold this ROPS

if a canopy is attached.

Damage to the mower

hood could result.

!

WARNING

This structure's

proctective capability

may be impaired by

structural damage,

over turn, or alteration.

If any of these

conditions occur, this

structure must be

replaced.

5003597

!

4131663

Summary of LF550-H-T4F

Page 1

When performance matters. ™ lf550 ™ / lf570 ™ lightweight fairway mower with folding rops 68011 – lf550-h-t4f, kubota v2403-cr-e4b, 5 gang 2wd 68012 – lf550-h-t4f, kubota v2403-cr-e4b, 5 gang 4wd 68013 – lf570-h-t4f, kubota v2403-cr-e4b, 5 gang 2wd 68014 – lf570-h-t4f, kubota v2403-cr-e4b, 5 gang 4w...

Page 2

1 contents 1 1contents contents introduction 2.1 important .............................................................................2 2.2 product identification...........................................................3 2.3 serial numbers ...........................................................

Page 3

Introduction 2 2 2introduction 2.1 important ______________________________________________________________ the jacobsen lf550 / lf570 with a diesel engine is a self propelled fairway mower. The hydraulic systems are for the traction drive, steering, lift - lower and the cutting unit drive. If you f...

Page 4

2 introduction 3 2.2 product identification_________________________________________________ mower serial number plate a product number and serial number location of mower serial number plate the serial number plate (a) is found on the right side frame rail behind the rear cutting units. Engine seri...

Page 5

Introduction 2 4 2.4 guidelines for the disposal of scrap products _______________________ 2.4.1 during service life _____________________________________________________ the used oil, oil filters and engine coolant are hazardous materials. Follow the recommended procedures for their safe removal. I...

Page 6: Warning

3 safety 5 3safety 3.1 how to operate safely ______________________________________________________ 3.1.1 safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operato...

Page 7

Safety 3 6 3.1.3 operation a never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust fumes can increase to dangerous levels. B never carry passengers. Keep other persons or animals away from the mower. C disengage all drives and engage the parki...

Page 8

3 safety 7 3.1.4 rops a the rops is a safety device. Keep the rops in the vertical and locked position. Always use the seat belt when you operate the mower. Make sure the seat belt can be released quickly in an emergency. B only operate the mower with the rops in the folded position on flat and leve...

Page 9

Safety 3 8 g disconnect the battery before you service the mower. Always disconnect the negative battery cable before the positive battery cable. Always connect the positive battery cable before the negative battery cable. H charge the battery in an area with good airflow. The battery can release hy...

Page 10: Warning

3 safety 9 3.1.8 important safety notes _______________________________________________ this safety alert symbol gives a warning of possible hazards. Danger - indicates a dangerous condition that will cause death or injury unless it is prevented. Warning - indicates a dangerous condition that can ca...

Page 11

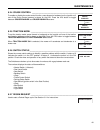

Specifications 4 10 4specifications 4.1 engine specifications __________________________________________________ lf550 / lf570 lf550-h / lf570-h make kubota kubota model d1803-dicr-e4b v2403-dicr-e4b type four cycle, liquid cooled, diesel four cycle, liquid cooled, diesel number of cylinders 3 4 bor...

Page 12

4 specifications 11 4.2 dimensions and weights ________________________________________________ lf550 / lf570 a - width of cut 100 inch (254.0 cm) b - maximum width 115 inch (292.1 cm) c - transport width 87 inch (220.9 cm) d - height rops frame in the vertical position 88 inch (223.5 cm) e - height...

Page 13

Specifications 4 12 k j c g e l a b h f d.

Page 14

4 specifications 13 4.3 mower specification ___________________________________________________ battery: 12v, 600 cca, group bci 24 service brake: dynamic braking through the traction circuit parking brake: integrated in wheel motor, hydraulic release fuel tank: 17 u.S. Gallons (65 l) hydraulic tank...

Page 15

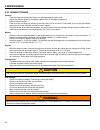

Specifications 4 14 4.5 vibration level_________________________________________________________ the mower was tested for hand and arm vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The engine was in operation and the cutting...

Page 16: Notice

4 specifications 15 4.6 slopes _________________________________________________________________ do not use on slopes greater than 18.4°. The 18.4° slope was calculated with static stability measurements according to the requirements of bs en iso 5395-3. 4.7 cutting unit specification ______________...

Page 17

Specifications 4 16 4.9 accessories____________________________________________________________ 4.9.1 lf550 cutting units _____________________________________________________ lf550 left hand 7 blade reel 62839 (3 required) lf550 right hand 7 blade reel 62840 (2 required) lf550 left hand vertical mo...

Page 18

4 specifications 17 4.9.7 canopy / sun shade_____________________________________________________ product number 68127 4.9.8 hood locking latch____________________________________________________ kit number 1004049 4.9.9 premium seat___________________________________________________________ premium...

Page 19

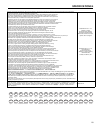

Specifications 4 18 4.11 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de c...

Page 20

4 specifications 19 conformity assessment procedure (noise) ▪ Оценка за съответствие на процедурата (Шум) ▪ postup hodnocení plnění podmínek (hluk) ▪ procedure for overensstemmelsesvurdering (støj) ▪ procedure van de conformiteitsbeoordeling (geluid) ▪ vastavushindamismenetlus (müra) ▪ vaatimustenmu...

Page 21

Specifications 4 20 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. Подпис на човека, упълномощен да състави декларацията от името н...

Page 22

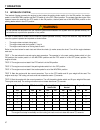

5 decals 21 5decals 5.1 safety decals _________________________________________________________ understand the purpose of these decals. The decals are important to the safe operation of the mower. Replace the damaged decals immediately. Danger to prevent injury while you do work on the battery: 1. C...

Page 23

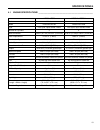

Decals 5 22 read the manual.Warning always use the seat belt with the rops frame in the vertical and locked position. Warning • read the manual. Do not allow persons without training to use the mower. • keep the shields in position and hardware fastened. • keep your hands, feet and clothing away fro...

Page 24: Notice

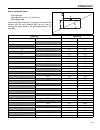

5 decals 23 notice do not use start assist fluids start assist fluids in the air intake system can be explosive or cause an engine condition that is not controlled and can cause engine damage. Warning to prevent injury when you fold the rops, use caution to prevent your fingers broken or pinched bet...

Page 25

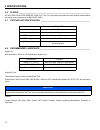

Decals 5 24 5.2 instruction decals ____________________________________________________ traction pedal operation backlap decal rotate knob to set backlap speed. Tow valve operation 3008521 3008683 3008682.

Page 26

6 controls 25 6controls 6.1 operator compartment________________________________________________ 6.2 6.3 6.4 6.5 6.7 6.8 6.6.

Page 27

Controls 6 26 6.2 armrest ________________________________________________________________ ! Jacobsen ldu-a mcu-a 6.2.1 6.2.2 6.2.3 6.2.4 6.2.5 6.2.6 6.2.7 6.2.8 6.2.9 6.3.

Page 28

6 controls 27 6.2.1 ignition switch _________________________________________________________ the ignition switch has three positions, off, run and start. In the run position, the controller program is active and input and output circuits are monitored. 6.2.2 parking brake switch____________________...

Page 29

Controls 6 28 6.2.4 pto switch _____________________________________________________________ the pto switch is a 2-position knob type switch to engage and to disengage the cutting units. The pto switch must be in the off (down) position to start the engine. Pull on the red knob to move the switch to...

Page 30: Caution

6 controls 29 6.2.7 joystick _______________________________________________________________ the joystick controls the cutting units lift and lower. The joystick operates in automatic or manual mode. Push the joystick to lower the cutting units or pull the joystick to lift the cutting units. Manual ...

Page 31: Warning

Controls 6 30 6.3 ldu _____________________________________________________________________ the lcd display unit (ldu) shows the current values for the operation of the mower, has indicator lights and sounds audible warnings. The ldu operates in one of two modes, operator mode (normal operation) and...

Page 32: Warning

6 controls 31 the red hydraulic-level light indicates a low-fluid level in the hydraulic tank. Immediately stop the engine. Visually inspect the mower for indications of leaks around connections, hoses and hydraulic components. Return the mower to the service area for maintenance. The red hydraulic ...

Page 33

Controls 6 32 6.3.2 alarm screens _________________________________________________________ there are six alarm screen displays to tell the operator or technician of a problem that must be corrected. When the engine oil pressure is less than 7 psi (0.48 bar), the low oil pressure screen is shown on ...

Page 34: Notice

6 controls 33 6.3.4 operator mode ________________________________________________________ the operator mode is used by the operator to see the engine hours of operation, and inhibit the active dpf regen cycle. The cruise active or backlap mode screens are shown when the conditions are met. When the...

Page 35: Caution

Controls 6 34 6.4 traction pedal _________________________________________________________ the traction pedal controls the movement of the mower. Press the front of the pedal to move in the forward direction. Press the rear part of the pedal to move in the reverse direction. When traction pedal is n...

Page 36

6 controls 35 6.7 backlap switch ________________________________________________________ the backlap switch is found on the fan shroud and is used to switch the reels to backlap mode. For normal operation, the backlap switch must be in the off position. To backlap, press the top of the switch to th...

Page 37: Caution

Operation 7 36 7operation 7.1 daily inspection ________________________________________________________ do a visual inspection of the mower. Look for indications of wear or loose hardware. Look for any components that are not included on the mower or damaged components. Check for fuel and oil leaks ...

Page 38: Warning

7 operation 37 7.2 interlock system ______________________________________________________ the interlock system prevents the engine to start unless the parking brake switch is in the on position, the traction pedal is in the neutral position and the pto switch is in the off (down) position. The syst...

Page 39: Warning

Operation 7 38 7.3 operating procedure __________________________________________________ 1. Always start the engine with the operator in the seat, never while next to the mower. Never start the engine with persons near the mower. 2. Never operate the engine without enough ventilation or in an enclo...

Page 40: Notice

7 operation 39 7.4 starting the engine ____________________________________________________ start the engine with the operator in the seat, the pto switch in the off position and the parking brake switch in the on position. Remove your foot from the traction pedal. Always wear the seat belt with the...

Page 41: Warning

Operation 7 40 7.6 driving _________________________________________________________________ read and follow all safety instructions contained in this manual when you drive the mower. When you operate in the reverse direction, look behind you to make sure you have a clear path. Important: equipment ...

Page 42: Warning

7 operation 41 7.9 mowing on slopes______________________________________________________ the mower is made to have good traction and to have good balance. Operate the mower with caution when you drive on a gradient. If you drive on wet grass, the traction and steering control of the mower is decrea...

Page 43

Operation 7 42 how to calculate a slope: tools required: level (a), either 1 yard, or 1 meter long. Tape measure (b). Use the level (a) and position it horizontally to measure the distance (c) with tape measure (b). Use the chart to calculate the slope angle or the percentage grade of the slope (d)....

Page 44: Notice

7 operation 43 7.10 towing the mower _____________________________________________________ if the mower has a problem and can not drive to the service area, open the bypass valve and load the mower on a trailer. If a trailer is not available, tow the mower at a slow speed for short distances. Be car...

Page 45

Maintenance and lubrication charts 8 44 8maintenance and lubrication charts 8.1 maintenance chart mower service interval chart interval item section first 50 hours • replace engine oil • replace engine oil filter • replace hydraulic oil filter • check steering system • check electrical wiring • chec...

Page 46

8 maintenance and lubrication charts 45 8.2 lubrication chart _____________________________________________________ 8.3 fluid requirements ____________________________________________________ fluid requirements quantity type engine oil with filter v2403 7.5 quart (7.1 liter) 10w-30 api classificatio...

Page 47: Warning

Maintenance 9 46 9maintenance 9.1 general precautions ________________________________________________________ a qualified technician must always do adjustments and maintenance. If the correct adjustments can not be made, contact your jacobsen dealer. Inspect the equipment according to the maintenan...

Page 48: Notice

9 maintenance 47 9.2.1 calibrate pedal _______________________________________________________ to calibrate the traction pedal, press forward or backward on the joystick until the calibrate pedal? Screen is on the ldu. With traction pedal in the neutral position, press the ldu button to enter the se...

Page 49

Maintenance 9 48 9.2.4 cruise control ________________________________________________________ to enable or disable the cruise control function, press forward or backward on the joystickuntil one of the cruise control screens is shown on the ldu. Press the ldu buttonto toggle between cruise enabled ...

Page 50: Notice

9 maintenance 49 9.2.8 display units ___________________________________________________________ to set the units shown on the ldu, press forward or backward on the joystickuntil the units setting screen is shown on the ldu. Press the ldu buttonto toggle between english units or metric units screens...

Page 51: Caution

Maintenance 9 50 9.4 engine oil ______________________________________________________________ check engine oil level check the engine oil level before you start the engine or at least five minutes after you stop the engine. A park the mower on a level surface. B remove the dipstick, clean the dipst...

Page 52: Warning

9 maintenance 51 9.5 engine air filter _______________________________________________________ check the service indicator each day. If the red band become visible in the window, replace the filter elements. Do not remove the elements to inspect or clean. Removal of the filter that is not necessary ...

Page 53: Caution

Maintenance 9 52 9.7 fuel system ____________________________________________________________ water separator if the water is not removed from the fuel, damage to the fuel-injection system can occur. When the water in fuel screen is shown on the ldu or every 100 hours, drain the water from the water...

Page 54: Caution

9 maintenance 53 9.8 battery ________________________________________________________________ before you service the battery, make sure the ignition switch is in the off position and the key is removed. Tighten the battery cables on the battery terminals, to prevent corrosion, apply a layer of silic...

Page 55: Warning

Maintenance 9 54 9.9 charge the battery __________________________________________________________ read the battery charger manual for specified instructions on the operation of the charger. When possible, remove the battery from the mower before you charge the battery. If the battery is not sealed,...

Page 56: Warning

9 maintenance 55 9.11 diesel particulate filter ______________________________________________ during the operation of the mower, the level of particle material will increase in the diesel particulate filter (dpf) system. The periodic regen of the dpf system is needed to remove particle material. Du...

Page 57

Maintenance 9 56 parked regen state - when a parked regen is needed, the regen request light will flash and the tier 4 service message screen is shown on the ldu. Park the mower on concrete or gravel to prevent damage to the turf. If the regen inhibited is selected on the ldu, turn the ignition swit...

Page 58

9 maintenance 57 a regen cycle that is not completed will move the engine through six different levels of control. Level 0 - normal operation of mower with passive regen. When particles reach the active regen level, the engine controller will change to level 1. When the engine controller is at level...

Page 59: Warning

Maintenance 9 58 9.12 hydraulic hoses ______________________________________________________________ always lower the cutting units to the ground, disengage all drives, engage parking brake, stop the engine and remove the key before you inspect or disconnect hydraulic lines or hoses. Check visible h...

Page 60: Notice

9 maintenance 59 9.13 hydraulic fluid ________________________________________________________ drain and replace the hydraulic oil if one of the following occur. • component failure • water or foam is in the hydraulic fluid • the hydraulic fluid has a rancid odor (indication of high heat) • every 50...

Page 61: Warning

Maintenance 9 60 9.16 wheel mounting procedure ____________________________________________ remove dirt, grease and oil from the stud threads. Do not lubricate threads. Put the wheel on the hub. Inspect the wheel to make sure of full contact between surface of wheel and hub. Tighten all hardware wit...

Page 62: Caution

9 maintenance 61 9.18 folding rops ___________________________________________________________ a folding roll over protective structure (rops) is included with this mower. Inspect the rops periodically for loose hardware or damage. Every 400 hours, inspect the seat, seat belt, rops mounting hardware...

Page 63: Warning

Maintenance 9 62 9.19 to backlap the reels __________________________________________________ check the reel and the bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, ...

Page 64: Caution

9 maintenance 63 9.20 electrical system ____________________________________________________________ general precautions to decrease electrical problems are - • make sure that all the connections are clean and correctly fastened. • check the interlock system, fuses and circuit breakers at normal int...

Page 65: Notice

Maintenance 9 64 9.21 care and cleaning _____________________________________________________ clean the mower and cutting units after each use. To prevent damage to the engine, do not wash the mower with the engine in operation. When possible, clean the mower with compressed air. Use compressed air ...

Page 66: Caution

9 maintenance 65 9.22 mower storage ________________________________________________________ general • clean the mower and lubricate. Repair and paint damaged or open metal. • inspect the mower, tighten all hardware, replace worn or damaged components. • drain and fill the radiator. • clean the tire...

Page 67: Warning

Adjustments 10 66 10adjustments 10.1 general precautions ________________________________________________________ a qualified technician must always do adjustments and maintenance. If the correct adjustments can not be made, contact your jacobsen dealer. Inspect the equipment according to the mainte...

Page 68: Notice

10 adjustments 67 10.3 steering adjustment __________________________________________________ steering toe-in adjustment a turn the rear wheels to the straight position. B loosen the jam nuts on both ends of the tie rod. C rotate the tie rod to get the correct toe-in. The toe- in must not be more th...

Page 69

Adjustments 10 68 10.5 armrest height adjustment ____________________________________________ the armrest has four available height settings for the operator. To adjust armrest height: 1. Stop the engine and remove the key. 2. Remove the armrest hardware from the bracket on the right side of the sea...

Page 70: Notice

10 adjustments 69 10.7 bedknife-to-reel _______________________________________________________ 1. Check the reel bearings for end play or radial play. 2. Inspect the reel blades and the bedknife to make sure of good sharp edges without bends or surface damage. A the leading edge of the reel blades ...

Page 71

Adjustments 10 70 10.9 cutting height _________________________________________________________ note: always make the reel-to-bedknife adjustment before you adjust the height of cut. See sections 10.7 and 10.8. 1. Lift the cutting units to the transport position. Set the parking brake switch in the ...

Page 72

10 adjustments 71 10.11 flash attach ™ _________________________________________________________ installing cutting units 1. Put each cutting unit in front of the lift arm. Lift the lift arm and put the cutting unit so that the yoke is aligned to the swivel housing. Carefully lower the lift arm on t...

Page 73: Notice

Adjustments 10 72 10.12 bedknife adjuster spring ______________________________________________ for correct operation, the bedknife adjuster spring must be compressed to 1-7/16 to 1-1/2 in. (3.65 to 3.8 cm). To adjust the spring compression, loosen or tighten the locknut to get a distance of 1-7/16 ...

Page 74: Notice

10 adjustments 73 10.15 torque specification __________________________________________________ jacobsen uses grade 5 (inch) and grade 8.8 (metric) plated bolts, unless a note is given. Always check the marks on the head of the bolts for the bolt grade. For tightening plated bolts, use the value giv...

Page 75

Problem solving 11 74 11problem solving 11.1 general ________________________________________________________________ the problem solution chart lists basic problems that can occur during start and operation of the mower. For complete information about the hydraulic and electrical systems, contact y...

Page 76: Notice

11 problem solving 75 11.2 controller ____________________________________________________________ the mower controller is a solid state device that monitors and controls the electrical functions of the mower. The controller receives the input signals from switches and sensors in the mower. The cont...

Page 77

Quality of cut 12 76 12quality of cut 12.1 quality of cut problem solving________________________________________ make a “test cut” to check the performance of the mower before you start the repairs. This area must have turf conditions that are known and do not change across the area. This type of a...

Page 78

12 quality of cut 77 12.3 marcelling ____________________________________________________________ note: arrow indicates direction of travel. Marcelling is a repeated pattern of different cutting heights, that causes an appearance that is like a wave. In most cases, the wave tip-to-tip distance is 2 ...

Page 79

Quality of cut 12 78 12.4 step cutting____________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut higher on one side of a cutting unit than the other side. Step cutting can occur when one cutting unit is higher than an...

Page 80

12 quality of cut 79 12.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut shorter than the adjacent areas. The area can be light green or brown. A low hoc setting or turf that ...

Page 81

Quality of cut 12 80 12.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are separated blades of grass that are not cut, or are cut incorrectly. Probable cause remedy edge of the cutting blade(s) are not sharp. Sharpen th...

Page 82

12 quality of cut 81 12.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of grass that is not cut. The cause of a streak can be a damaged blade. Probable cause remedy the bedknife is damaged. Replace the bedknife...

Page 83

Quality of cut 12 82 12.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings increased at one end of cutting unit(s) or between cutting units. Windrowing can make a line in the direction of travel....

Page 84

12 quality of cut 83 12.9 rifling or tramlining __________________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of different cutting heights that gives the grass an appearance like a wave. This appearance is normally because of heavy c...

Page 85

Quality of cut 12 84 12.10 mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Mismatched cutting units is a pattern of different cutting heights, that gives the grass a stepped cut appearance. This appearance is normally because of a mi...

Page 86

13 notes 85 13notes.

Page 87

Notes 13 86.

Page 88

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...