- DL manuals

- Jacobsen

- Lawn Mower

- Super LF 1880 67955

- Safety, Operation And Maintenance Manual

Jacobsen Super LF 1880 67955 Safety, Operation And Maintenance Manual

Safety, Operation, & Maintenance Manual

WARNING

Warning: If incorrectly used, this machine can

cause severe injury. Those who use and maintain

this machine should be trained in its proper use,

warned of its dangers, and must read the entire

manual before attempting to set up, operate, adjust,

or service the machine.

GB

Super LF 1880™ Fairway Mower with ROPS

67955 – Kubota D1105-E3B, 2WD

67956 – Kubota D1105-E3B, 4WD

67957 – Kubota D1105-T-E3B, 4WD

68007 – Kubota D1105-E4B, 2WD

68008 – Kubota D1105-E4B, 4WD

4160165-Rev B

Summary of Super LF 1880 67955

Page 1

Safety, operation, & maintenance manual warning warning: if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers, and must read the entire manual before attempting to set up, operate, adjust, or ser...

Page 2

2 this manual contains safety and operating instructions for your new jacobsen machine. This manual should be stored with the equipment for reference during operation. Before you operate your machine, you and each operator you employ should read the manual carefully in its entirety. By following the...

Page 3

Contents 1 3 1 contents 2 safety 2.1 operating safety .................................................. 4 2.2 important safety notes .........................................5 3 specifications 3.1 product identification............................................ 6 3.2 kubota d1105-e engine ..........

Page 4: Warning

2 safety 4 2 safety 2.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern, and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manua...

Page 5: Warning

Safety 2 5 2.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6

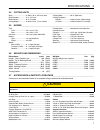

3 specifications 6 3 specifications 3.1 product identification _________________________________________________ 67955 .............................. Super lf 1880 2wd with rops 67956 .............................. Super lf 1880 4wd with rops 67957 .............................. Super lf 1880 turbo ...

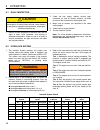

Page 7: Caution

Specifications 3 7 3.4 cutting units ___________________________________________________________ reel................................. 5 reels, 18 in. (457 mm) wide reel diameter ................. 5 in. (127 mm) blade options ................. 8 or 11 blades cutting height ................. 0.30 to ...

Page 8

3 specifications 8 3.8 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de con...

Page 9

Specifications 3 9 uk notified body for 2000/14/ec ▪ Нотифициран орган в Обединеното кралство за 2000/14/ЕО ▪ Úřad certifikovaný podle směrnice č. 2000/14/ec ▪ det britiske bemyndigede organ for 2001/14/ef ▪ engels adviesorgaan voor 2000/14/eg ▪ Ühendkuningriigi teavitatud asutus direktiivi 2000/14/...

Page 10

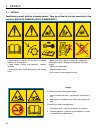

4 decals 10 4 decals 4.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181865 4181864 • read operator's manual. Do not allow untrain...

Page 11

Decals 4 11 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181862 4181861 4181860 4182520 warning radiator is under pressure. Remove cap slowly to avoid personal injury. Important do not use starting assist...

Page 12: 105

4 decals 12 . 105 db l wa 3008521 3008004 4181863 warning to prevent cuts use socket wrench or turf groomer ® knob to turn reel. Traction pedal reverse forward engaged parking brake disengaged sound power level.

Page 13: Warning

Controls 5 13 5 controls 5.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and wha...

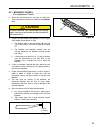

Page 14

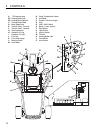

5 controls 14 10 12 14 16 a tilt steering lever b1 parking brake lock b2 parking brake release c parking brake pedal d mow speed stop e traction pedal - forward f traction pedal - reverse g seat adjustment h hydraulic oil cap i hydraulic oil light j fuel cap k fuel level gauge l backlap switch m hou...

Page 15: Caution

Controls 5 15 5.2 control descriptions __________________________________________________ a. Tilt steering lever pull lever up to release steering column. Tilt column up or down to position desired. Release lever to lock steering column in place. B. Parking brake lock / release to lock parking brake...

Page 16

5 controls 16 p. Engine oil pressure light the indicator will light if engine oil pressure drops below 7 psi (0.48 bar). Stop engine immediately, determine the cause, and correct the problem before resuming operation. Q. Horn the alarm sounds to alert the operator to conditions requiring immediate a...

Page 17

Controls 5 17 5.3 operator alerts _______________________________________________________ the machine monitors vital machine systems. It uses an audible alarm and warning lights to alert the operator of conditions requiring immediate action. When an alert occurs, follow the general guidelines listed...

Page 18: Caution

6 operation 18 6 operation 6.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses ...

Page 19: Warning

Operation 6 19 6.3 operating procedures _________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. 2. Do not operate mower or attachments with loose, damaged, or missing components. Whenever possible mow when gra...

Page 20: Notice

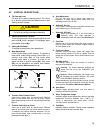

6 operation 20 6.4 starting _______________________________________________________________ important: do not use starting assist fluids. Use of such fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition and could result in serious engine damage. 1. Make ...

Page 21: Caution

Operation 6 21 6.6 to drive / transport ____________________________________________________ read and follow all safety notes contained in this manual when driving or transporting mower. Refer to section 6.3 for general operating instructions. When operating in reverse, look behind you to ensure you...

Page 22: Warning

6 operation 22 6.8 mowing _________________________________________________________________ to mow: 1. Start the engine and lower the mowers to the ground. 2. Turn reel switch to on and disengage parking brake. 3. Move throttle lever to fast then slowly depress traction pedal to the desired mowing s...

Page 23: Notice

Operation 6 23 6.10 daily maintenance______________________________________________________ important: for more detailed maintenance information, adjustments, and maintenance/lubrication charts, see the parts & maintenance manual. 1. Park the mower on a flat, level surface. Fully lower the implement...

Page 24: Warning

7 maintenance & lubrication charts 24 7 maintenance & lubrication charts 7.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

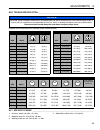

Page 25

Maintenance & lubrication charts 7 25 7.3 maintenance charts ___________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** or every two years whichever comes first. *** inspect vi...

Page 26: Warning

8 maintenance 26 8 maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 27: Warning

Maintenance 8 27 8.4 air filter _______________________________________________________________ check the service indicator daily. If red band appears in the window (a) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk of ...

Page 28: Caution

8 maintenance 28 8.7 battery ________________________________________________________________ make absolutely certain the ignition switch is off and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric greas...

Page 29: Warning

Maintenance 8 29 8.10 hydraulic hoses _______________________________________________________ 1. Always lower implements to ground, disengage all drives, engage parking brake, stop engine, and remove key before inspecting or disconnecting hydraulic lines or hoses. 2. Check visible hoses and tubes da...

Page 30: Caution

8 maintenance 30 8.12 electrical system _____________________________________________________ general precautions that can be taken to reduce electrical problems are listed below. 1. Make certain all terminals and connections are clean and properly secured. 2. Check the interlock system and fuses re...

Page 31: Warning

Maintenance 8 31 8.13 muffler and exhaust ___________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine ...

Page 32: Caution

8 maintenance 32 8.17 care and cleaning _____________________________________________________ wash the mower and implements after each use. Keep the equipment clean. Note: do not wash any portion of the mower while mower is hot. Do not use high pressure spray or steam. Use cold water and automotive ...

Page 33: Warning

Maintenance 8 33 8.19 backlapping____________________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, they...

Page 34: Caution

8 maintenance 34 8.20 storage________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Drain and refill radiator. 4...

Page 35: Warning

Adjustments 9 35 9 adjustments 9.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 36

9 adjustments 36 9.4 neutral switch and 4wd cut-out switch _______________________________ the traction pedal is designed to return to neutral whenever the forward or reverse foot pedals are released. If the mower continues to creep after the traction pedal is released, check neutral adjustment and ...

Page 37

Adjustments 9 37 9.6 traction pedal speed limiter ___________________________________________ cutting quality is better at speeds well below the transport speed of the mower. An initial mow speed of 6 mph is set at the factory and should be satisfactory for most cutting conditions. Local turf condit...

Page 38

9 adjustments 38 9.9 steering adjustments _________________________________________________ 1. Turn wheels to straight ahead position. 2. Loosen jam nuts (q) on both sides of tie rod (r). 3. Turn tie rod (r) to provide proper toe-in. Toe-in must not exceed +1/16 in. (1.5 mm) (s). Align ball joints a...

Page 39: Caution

Adjustments 9 39 9.11 bedknife-to-reel _______________________________________________________ (pre-adjustment check) 1. Check the reel bearings for end play or radial play. There should be no end play or radial play. See section 9.14. 2. Inspect the reel blades and bedknife to insure good sharp edg...

Page 40: Notice

9 adjustments 40 9.12 bedknife adjustment __________________________________________________ 1. Read section 9.11 before making the adjustment. 7. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blades is that end which passes over the bedkn...

Page 41: Notice

Adjustments 9 41 9.14 reel bearing ___________________________________________________________ any end play or radial play indicates bad bearings, a weak tension spring, or a backed-off nut. 1. Check bearing housing mounting hardware. Tighten or replace components as required. Carefully clean thread...

Page 42

9 adjustments 42 9.18 flash attach___________________________________________________________ installing cutting units 1. Place each cutting unit in front of its respective lift arm. Raise lift arm and position cutting unit so that yoke (r) is in line with swivel housing (q). Carefully lower arm ont...

Page 43: Notice

Adjustments 9 43 9.20 torque specification ___________________________________________________ jacobsen uses grade 5 bolts as standard, unless otherwise noted. 9.21 specific torque ________________________________________________________ 1. Ball joints: 30-35 ft-lb (40.5 - 47.2 nm). 2. Bedknife shoe...

Page 44

10 problem solving 44 10 problem solving 10.1 general problem solving______________________________________________ the problem solving chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact ...

Page 45

Quality of cut 11 45 11 quality of cut 11.1 quality of cut problem solving________________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area shoul...

Page 46

11 quality of cut 46 11.3 marcelling_____________________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip di...

Page 47

Quality of cut 11 47 11.4 step cutting____________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to another. This is usually caused by mechanical wear or...

Page 48

11 quality of cut 48 11.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is...

Page 49

Quality of cut 11 49 11.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or...

Page 50

11 quality of cut 50 11.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or u...

Page 51

Quality of cut 11 51 11.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Prob...

Page 52

11 quality of cut 52 11.9 rifling or tramlining __________________________________________________ 11.10mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wav...

Page 53

Notes 12 53 12 notes.

Page 54

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and f...