- DL manuals

- Jacobsen

- Lawn Mower

- tournament cut 22

- Technical Manual

Jacobsen tournament cut 22 Technical Manual

Summary of tournament cut 22

Page 1

Technical manual gb tournament cut ™ 22 62291 - 4hp honda engine 4128650

Page 2: To Order Parts

Copyright 2003, textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” to order parts 1. Write your full name and complete address on the order. 2. Explain where and how to make shipment. 3. Give product number, name and serial number that...

Page 3: Suggested Stocking Guide

3 suggested stocking guide to keep your equipment fully operational and productive, maintain a stock of the more commonly used maintenance items. We have included part numbers for additional support materials and training aids. A more complete listing of accessories and attachments can be found in t...

Page 4: Warning

1 safety 4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equip- ment. 2. It is your responsibility to read this manu...

Page 5: Warning

Safety 1 5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6

2 specifications 6 2 specifications 2.1 product identification_________________________________________________ 62291 ............................ 22 in. (559 mm) tournament cut 22 with honda 4.0 h.P. Gasoline engine and 9 blade reel. Always provide the serial number of the unit when ordering replac...

Page 7

Specifications 2 7 2.5 dimensions _____________________________________________________________ length ..............................60 in. (1520 mm) width ................................37 in. (930 mm) height ...............................39 in. (1000 mm) weights: lbs. (kg) mower unit...............

Page 8: Danger

3 decals 8 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the decals, they are critical to the safe operation of the mower. Replace damaged decals immediately. ! Danger to avoid serious bodily injury stop engine and disengage reels bef...

Page 9: Warning

Controls 4 9 4 controls 4.1 icons ___________________________________________________________________ 4.2 controls_______________________________________________________________ a. Control lever – three position lever. Pull handle back toward operator to engage parking brake. Push handle forward to ...

Page 10: Warning

4 controls 10 e. Engine switch – the engine switch enables and disables the ignition system. The engine switch must be in the on position for the engine to run. Turning the engine switch to the off position stops the engine. F. Choke lever - the choke lever opens and closes the choke valve in the ca...

Page 11: Caution

Operation 5 11 5 operation 5.1 daily inspection ________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, missing or damaged components. Check for fuel or oil leaks. 2. Check the fuel supply and crankcase oil l...

Page 12: Caution

5 operation 12 5.3 operating procedures_________________________________________________ 1. Do not operate mower or attachments with loose, damaged or missing components. Whenever possi- ble mow when grass is dry. 2. First mow in a test area to become thoroughly familiar with the operation of the mo...

Page 13: Danger

Operation 5 13 5.4 starting/stopping engine ______________________________________________ 1. Check the fuel supply then open the fuel shut-off valve (g) . A. Move the choke lever (f) to the “close” position. B. Move throttle control (b) to 1/2 throttle. C. Set start engine switch (e) to “on”. 2. Ma...

Page 14: Warning

5 operation 14 5.6 transport wheels _____________________________________________________ 1. Push and hold the kickstand against the ground then pull the mower handle back until the mower rests on the stand. 2. To remove wheels, press retaining clip (l) away from hub and pull wheel off hub. 3. To in...

Page 15: Warning

Adjustments 6 15 6 adjustments 6.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be per- formed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, wo...

Page 16: Caution

6 adjustments 16 6.3 bedknife adjuster _____________________________________________________ 1. Threaded adjuster (a) is used to increase or decrease the spring load on the bedknife. Adjusting nuts (b) is used to move the bedknife to the reel or away from the reel. 2. Once the spring is totally coll...

Page 17

Adjustments 6 17 6.6 brake __________________________________________________________________ 1. Place control lever (j) in neutal position. 2. Adjust nuts (h) as required to remove all slack from brake cables. Figure 6e 6.7 cutting height _________________________________________________________ no...

Page 18: Caution

6 adjustments 18 6.9 torque specification __________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Caution all torque values included in these charts are approximate and...

Page 19: Warning

Maintenance 7 19 7 maintenance 7.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be per- formed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a...

Page 20: Caution

7 maintenance 20 7.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap and add oil as required. Perform initial oil change after the first 20 hours of ope...

Page 21

Maintenance 7 21 7.5 backlapping and grinding______________________________________________ check for damage to the bedknife and reel blades. Refer to (section 6.2). 1. Determine if backlapping or grinding will restore the proper cutting edge. 2. For optimum performance use a bedknife grinder to tou...

Page 22: Caution

7 maintenance 22 7.7 storage________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Clean the tires thoroughly an...

Page 23

Troubleshooting 8 23 8 troubleshooting 8.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information, contact your area jacobsen dealer. Symptoms possible c...

Page 24: Warning

9 maintenance & lubrication charts 24 9 maintenance & lubrication charts 9.1 general________________________________________________________________ over greasing will produce high loads on the bearings and engine; thereby reducing the performance of the machine. All maintenance intervals must be pe...

Page 25

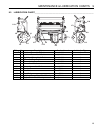

Maintenance & lubrication charts 9 25 9.3 lubrication chart______________________________________________________ l1 l2 l3 l4 l5 l6 l7 l8 l9 l9 l10 l10 l11 l12 fitting qty description service interval lubrication type l1 1 left hand frame no. 2 shaft every 8-10 hours ii l2 1 left hand frame no. 4 sh...

Page 26

10 parts catalog 26 10 parts catalog 10.1 table of contents _____________________________________________________ 1 ............Mower-traction unit connection..................... 27 2 ............Mower frame ..................................................... 28 3 ............Mower gear case .......

Page 27: Tournament Cut 22

27 > change from previous revision 13 11 10 11 11 12 11 13 4 9 8 7 6 4 9 8 7 6 1 2 3 5 tournament cut 22 1 mower-traction unit connection serial no. All item part no. Qty. Description serial numbers/notes 1-1 4127838 1 joint assembly 1-2 4127839 1 • spline sleeve with boss 1-3 4127840 1 • spline sha...

Page 28: Tournament Cut™ 22

28 2 3 5 6 7 8 9 9 10 12 11 13 14 14 16 18 19 19 20 21 22 23 24 27 27 27 27 27 27 28 29 29 29 30 31 31 33 33 4 17 15 15 15 15 25 26 34 34 37 38 39 40 35 36 32 32 1 41 43 42 44 44 tournament cut™ 22 2 mower frame serial no. All.

Page 29: Tournament Cut™ 22

29 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 2-1 4127515 1 cutting cylinder - 557 2-2 4127516 1 left-hand frame 2-3 4127624 1 right-hand frame 2-4 4127534 1 mower front stay 603.4 2-5 4127651 1 mower stay 4127581 1 bed knife comp includes ...

Page 30: Tournament Cut™ 22

30 25 26 19 2 1 20 29 28 6 9 8 21 13 12 11 10 7 3 15 27 16 15 17 18 15 15 14 16 4 5 23 24 78 22 tournament cut™ 22 3 mower gear case serial no. All.

Page 31: Tournament Cut™ 22

31 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 3-1 4127521 1 32 tooth gear 3-2 4127531 1 o-ring p18 3-3 4127625 1 no.1 shaft 3-4 4127626 1 needle bearing taf212920og 3-5 4127628 2 seal ds21294 for needle bearing 3-6 4127629 6 grease nipple 3...

Page 32: Tournament Cut™ 22

32 32 31 30 27 8 24 26 9 25 32 31 30 27 8 24 26 9 25 22 21 4 2 33 34 38 35 35 36 20 17 18 19 36 15 13 12 11 10 9 8 20 19 18 17 32 16 32 5 7 8 9 10 11 12 13 15 16 3 3 1 1 17 17 29 28 6 23 29 28 40 41 39 41 tournament cut™ 22 4 mower rollers and shield serial no. All.

Page 33: Tournament Cut™ 22

33 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 4-1 4127527 2 m8 s washer 4-2 4127536 2 adjusting screw 4-3 4127537 2 m8 nut 4-4 4127538 2 roller adjuster 4-5 4127539 1 front roller assembly includes 5~11 4-6 4127540 1 • grooved roller 4-7 41...

Page 34: Tournament Cut™ 22

34 31 31 32 32 2 3 5 6 7 8 9 10 12 11 13 14 14 14 14 16 36 18 19 20 21 22 23 23 23 23 24 24 24 24 27 28 28 29 30 4 17 15 25 26 26 1 33 34 35 tournament cut™ 22 5 traction unit frame serial no. All.

Page 35: Tournament Cut™ 22

35 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 5-1 4127667 1 drum assembly see illustration 6 5-2 4127803 1 transmission gear case assembly see illustration 7 5-3 4127818 1 • 2.3spcc metal washer 620 5-4 4127632 1 • m6 bolt 16s 5-5 4127797 1...

Page 36: Tournament Cut™ 22

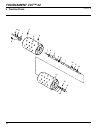

36 16 14 15 11 13 12 18 17 6 4 4 7 8 3 9 15 1 10 17 18 2 5 tournament cut™ 22 6 traction drum serial no. All.

Page 37: Tournament Cut™ 22

37 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 4127667 1 drum assembly includes 1~18 6-1 4127668 1 • drum left-hand shaft 4127669 1 • right-hand drum comp includes 2 ~ 3 6-2 4127670 1 • • right-hand drum 6-3 4127674 2 • • m25.4 bush 30.142 6...

Page 38: Tournament Cut™ 22

38 27 30 21 20 25 2 41 13 17 10 11 9 22 18 19 23 24 25 29 12 13 14 13 15 16 13 7 4 4 8 14 6 5 3 5 5 31 6 6 13 26 tournament cut™ 22 7 transmission serial no. All.

Page 39: Tournament Cut™ 22

39 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 7-1 4127803 1 transmission gear case assembly includes 2~30 7-2 4127816 1 • plate with label 7-3 4127817 1 • gear case 7-4 4127710 2 • bearing 62032nsec3 7-5 4127818 4 • 2.3spcc metal washer 620...

Page 40: Tournament Cut™ 22

40 28 20 19 4 2 1 5 3 6 9 7 10 12 11 14 16 7 6 26 26 27 27 21 25 25 24 23 22 18 17 1 8 13 11 15 9 tournament cut™ 22 8 differential serial no. All.

Page 41: Tournament Cut™ 22

41 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 8-1 4127737 2 differential housing gasket 8-2 4127738 1 left-hand differential housing 8-3 4127739 3 m6 cross-head countersunk screw 12 8-4 4127740 2 seal os18264 for needle bearing 8-5 4127741 ...

Page 42: Tournament Cut™ 22

42 11 37 36 11 10 10 14 16 15 17 18 11 6 10 13 12 10 11 30 1 29 31 28 7 7 8 8 9 9 33 32 22 19 23 24 25 27 28 26 35 34 21 25 5 4 5 3 2 20 38 43 39 40 41 42 9 tournament cut™ 22 9 left side gear case serial no. All.

Page 43: Tournament Cut™ 22

43 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 9-1 4127729 1 large gasket 9-2 4127730 1 no.1 shaft gasket 9-3 4127731 1 no.1 shaft housing 9-4 4127732 1 oil seal mhs19307 9-5 4127629 2 grease nipple 9-6 4127733 1 no.2 shaft 9-7 4127660 2 m10...

Page 44: Tournament Cut™ 22

44 18 4 7 5 5 4 6 1 2 3 19 8 10 9 11 23 24 13 22 14 12 17 21 20 16 15 tournament cut™ 22 10 right side gear case serial no. All.

Page 45: Tournament Cut™ 22

45 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 10-1 4127660 1 m10 washer minimum order of 10 10-2 4127622 1 m10 conical disk spring h 10-3 4127623 1 m10 nut 3p10h1 10-4 4127734 4 1c5191p metal washer 1322 10-5 4127735 2 0.8nbs55 metal washer...

Page 46: Tournament Cut™ 22

46 34 19 3 41 43 40 42 39 19 11 5 4 8 9 10 6 7 1 2 12 21 21 20 15 16 18 21 26 17 23 25 24 38 37 29 35 36 28 30 31 32 32 1. Read operators manual before operating machine. 2. Keep all shields in place and hardware securely tightened. 3. Before you clean, adjust or repair this equipment, disengage all...

Page 47: Tournament Cut™ 22

47 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 11-1 446136 5 lockwasher, 5/16 heavy 11-2 443108 2 nut, 5/16-24 hex 11-3 460052 1 cotter pin, 3/16 x 1-1/2” 11-4 366800 1 spring clutch 11-5 366799 1 spring clutch 11-6 400228 3 screw, 5/16-24 x...

Page 48: Tournament Cut™ 22

48 ignition coil spark plug ignition switch 50 watt charge coil honda engine ac ac + _ rectifier opc switch magnet bk bk bk bk wh wh wh rd a b e e c d b c d 2 3 3 3 3 5 6 6 7 8 9 10 12 11 14 16 18 21 19 20 22 23 24 12 30 29 28 30 31 33 4 4 17 15 25 13 34 37 38 39 40 35 36 32 32 1 40 a to clutch to l...

Page 49: Tournament Cut™ 22

49 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 12-1 366708 2 flanged bearing 12-2 4125847 1 prawl 12-3 443110 4 nut, 3/8-16 hex 12-4 400268 2 screw, 3/8-16 x 1-3/4” hex head 12-5 4127065 1 lever, brake 12-6 446142 2 lockwasher, 3/8 heavy 12-...

Page 50: Tournament Cut™ 22

50 > change from previous revision 3 4 5 2 6 7 8 9 10 3 4 5 1 tournament cut™ 22 13 handle mount serial no. All item part no. Qty. Description serial numbers/notes 13-1 4127848 1 left-hand handle adjuster 13-2 4127849 1 right-hand handle adjuster 13-3 4127850 2 m10 adjustment bolt 25 13-4 4127851 2 ...

Page 51: Tournament Cut™ 22

51 > change from previous revision 1 5 6 7 10 8 9 11 2 3 12 4 tournament cut™ 22 14 tools serial no. All item part no. Qty. Description serial numbers/notes 14-1 4127889 1 tool bag 14-2 4127890 1 bladed screwdriver n200 14-3 4127891 1 spanner 8x10 14-4 4127892 1 box spanner 7 14-5 4127893 1 cylinder...

Page 52: Tournament Cut™ 22

52 18 9 11 10 8 5 4 3 6 7 1 2 11 10 9 5 4 8 3 1 2 25 24 22 23 20 19 25 24 23 22 20 19 21 26 27 30 30 28 29 28 29 tournament cut™ 22 15 drum wheel parts serial no. All.

Page 53: Tournament Cut™ 22

53 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 15-1 4127693 2 brake drum 15-2 4127694 4 m8 hollow set screw 10 15-3 4127696 2 wheel clamping seat 15-4 4127697 2 tyre 4.10/3.50-6 assembly 4127704 2 • tyre 4.10/3.50-6 4127705 2 • wheel 3sp-6 4...

Page 54: Tournament Cut™ 22

54 7 2 31 3 19 28 30 32 18 17 4 5 16 17 4 21 22 27 26 25 24 23 20 23 8 6 9 10 14 15 12 13 29 29 8 6 1 9 11 14 15 12 13 24 25 26 27 28 22 3 tournament cut™ 22 16 grass catcher serial no. All.

Page 55: Tournament Cut™ 22

55 > change from previous revision tournament cut™ 22 item part no. Qty. Description serial numbers/notes 16-1 4127868 1 grass catcher 54 comp 16-2 4127869 1 grass catcher attachment piece 16-3 4127870 2 stopped cap 12.7 16-4 4127871 2 1c5191p metal washer 1728 16-5 4127872 1 m6 clip pin 16-6 412787...

Page 56: Index

56 index 2811102.......................35 3000053.......................33 3001235.......................33 3006127.......................49 340830.........................47 366708.........................49 4117467.......................35 4124759.......................50 4125501.....................

Page 57: Index

57 index 4127766................ 43 , 45 4127767...................... 43 4127768...................... 43 4127769................ 43 , 45 4127770................ 43 , 45 4127771...................... 43 4127773................ 43 , 45 4127775...................... 43 4127777...................... 4...

Page 58

Textron golf, turf & specialty products po box 7708, charlotte, nc 28241-7708 www.Ttcsp.Com equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and factory trained technicians backed b...