- DL manuals

- Jacobsen

- Lawn Mower

- Tri King 67069

- Parts & Maintenance Manual

Jacobsen Tri King 67069 Parts & Maintenance Manual

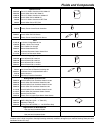

19

17

18

13

6

5

9

15

16

7

8

10

4

3

11

1 - INCLUDES ITEMS 3 - 16

Parts & Maintenance Manual

Instrukcja cz

ęś

ci zamiennych i konserwacji

Tri King

®

Triplex Mower with ROPS

Kosiarka Tri King

®

z trzema b

ę

bnami i pa

łą

kiem ROPS

67069 – Kubota D722-E3B Engine

67069 – Silnik Kubota D722-E3B

WARNING

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

OSTRZE

Ż

ENIE

OSTRZE

Ż

ENIE: Przy niew

ł

a

ś

ciwym u

ż

ytkowaniu opisywana

maszyna mo

ż

e by

ć

przyczyn

ą

wielu powa

ż

nych zagro

ż

e

ń

.

Osoby korzystaj

ą

ce z maszyny i przeprowadzaj

ą

ce prace

konserwacyjne powinny by

ć

przeszkolone pod wzgl

ę

dem jej

prawid

ł

owego u

ż

ycia, zapozna

ć

si

ę

z mo

ż

liwymi zagro

ż

eniami

oraz przeczyta

ć

ca

łą

instrukcj

ę

przed jej rozruchem,

uruchomieniem, regulacj

ą

lub konserwacj

ą

.

When Performance Matters.

™

GB

United

Kingdom

PL

Poland

4189623-Rev.A-PL

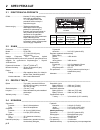

Summary of Tri King 67069

Page 1

19 17 18 13 6 5 9 15 16 7 8 10 4 3 11 1 - includes items 3 - 16 parts & maintenance manual instrukcja cz ęś ci zamiennych i konserwacji tri king ® triplex mower with rops kosiarka tri king ® z trzema b ę bnami i pa łą kiem rops 67069 – kubota d722-e3b engine 67069 – silnik kubota d722-e3b warning wa...

Page 2

© copyright 2009, jacobsen a textron company. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” this manual contains adjustment, maintenance, troubleshooting instructions and parts list for your new jacobsen machine. This manual should be stored w...

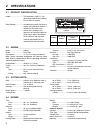

Page 3: Table of Contents

3 table of contents 1 safety 1.1 operating safety ........................................... 4 1.2 important safety notes ................................. 5 2 specifications 2.1 product identification .................................... 6 2.2 engine ..................................................

Page 4: 1 Safety

1 safety 4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern, and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manua...

Page 5: Safety 1

Safety 1 5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6: 2 Specifications

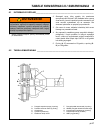

2 specifications 6 2 specifications 2.1 product identification _________________________________________________ 67069 .............................. Tri-king mower, 3-wd, 17.7 hp diesel engine with rops. Without front lift arms or mowers. Serial number ................ An identification plate, like...

Page 7: Specifications 2

Specifications 2 7 2.5 weights and dimensions ________________________________________________ dimensions: inches (mm) length ............................................................. 99 (2519) height........................................................... 51.5 (1308) width - wheel .............

Page 8: 3 Adjustments

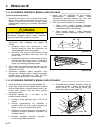

3 adjustments 8 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn ...

Page 9: Adjustments 3

Adjustments 3 9 3.4 neutral and 3wd switches _____________________________________________ 1. Check traction pedal adjustment. 2. Use a volt/ohm meter to determine when switch opens or closes. A. Adjust switch (g) so “finger” of actuating arm (f) is centered over sensing portion of switch. Switch co...

Page 10: 3 Adjustments

3 adjustments 10 3.7 traction pedal neutral ________________________________________________ 1. If the mower “creeps” in either direction when the engine is running, but the traction pedal is not depressed, adjust spring tension so that the pedal always returns to neutral when released. Note: the mo...

Page 11: Adjustments 3

Adjustments 3 11 3.10 parking brake__________________________________________________________ 1. Check linkage cables and pivots to ensure they are operating smoothly. 2. Park the mower on a 30% slope (16.7°) near the bottom of the hill, with the front of the mower facing downhill. Engage the parkin...

Page 12: 3 Adjustments

3 adjustments 12 3.13 reel to bedknife _______________________________________________________ (pre-adjustment check) 1. Check the reel bearings for end play or radial play. If there is any abnormal movement of the reel, up and down or side to side, adjust or replace components as needed. 2. Inspect...

Page 13

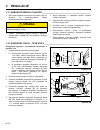

A d j u s t m e n t s 3 13 3.15 cutting modes __________________________________________________________ 1. The mower may be operated in the fixed mode or the floating mode. 2. Fixed mode is generally used for cutting heights greater than 1 in. (25 mm) and the mower does not require a front roller u...

Page 14: 3 Adjustments

3 adjustments 14 3.17 removing the cutting unit _____________________________________________ 1. To prevent contamination of the hydraulic system, as well as loss of oil, do not disconnect the hoses from the motor. 2. Raise and lock the lift arms in transport mode (section 3.4) and disconnect the do...

Page 15: Adjustments 3

Adjustments 3 15 3.19 cutting height - floating mode _________________________________________ follow the procedures outlined in section 3.16. 1. Assemble the front roller adjuster (b) to holes num- ber 2 and 4 only of the mower frame. Do not use hole numbers 1 and 3. Refer to the chart below for co...

Page 16: 3 Adjustments

3 adjustments 16 3.20 torque specification___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. 3.21 specific torque ________________________________________________...

Page 17: Maintenance 4

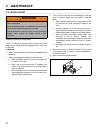

Maintenance 4 17 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 18: 4 Maintenance

4 maintenance 18 4.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap, and add oil as required. Perform initial oil change after first 50 hours of operat...

Page 19: Maintenance 4

Maintenance 4 19 4.5 fuel ____________________________________________________________________ handle fuel with care - it is highly flammable. Use an approved container, the spout must fit inside the fuel filler neck. Avoid using cans and funnels to transfer fuel. • fill the fuel tank to within 1 in...

Page 20: 4 Maintenance

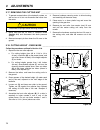

4 maintenance 20 4.8 jump starting __________________________________________________________ before attempting to “jump start” the mower, check the condition of the discharged battery. Section 4.7 when connecting jumper cables: 1. Stop the engine on the vehicle with a good battery. 2. Connect red j...

Page 21: Maintenance 4

Maintenance 4 21 4.11 hydraulic oil___________________________________________________________ refer to section 6.3 for specific maintenance intervals. The hydraulic reservoir on this machine is filled with jacobsen greens care 68 biodegradable fluid. Drain and replace the hydraulic oil after a majo...

Page 22: 4 Maintenance

4 maintenance 22 4.14 muffler and exhaust __________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine i...

Page 23: Maintenance 4

Maintenance 4 23 4.17 care and cleaning _____________________________________________________ wash the mower and implements after each use. Keep the equipment clean. 1. Use compressed air to clean engine and radiator fins. A special blow gun is available through jacobsen dealer. 2. Use only fresh wa...

Page 24: 4 Maintenance

4 maintenance 24 4.19 backlapping ___________________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, they...

Page 25: Maintenance 4

Maintenance 4 25 4.20 storage ________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, replace worn or damaged components. 3. Drain and refill radiator. ...

Page 26: 5 Troubleshooting

5 troubleshooting 26 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact ...

Page 27: Warning

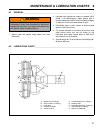

Maintenance & lubrication charts 6 27 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

Page 28

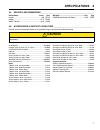

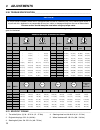

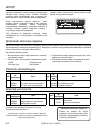

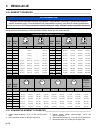

6 maintenance & lubrication charts 28 6.3 maintenance charts ___________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** every 250 hours, or yearly whichever comes first. *** in...

Page 30

Niniejsza instrukcja zawiera informacje dotycz ą ce regulacji, konserwacji i usuwania usterek oraz list ę cz ęś ci pa ń stwa nowej maszyny firmy jacobsen. Niniejsz ą instrukcj ę nale ż y przechowywa ć wraz z maszyn ą , aby mo ż na si ę by ł o z ni ą konsultowa ć podczas eksploatacji. Przed uruchomie...

Page 31: Spis Tre

Pl-3 spis tre ś ci 1 bezpiecze Ń stwo 1.1 bezpiecze ń stwo podczas eksploatacji . . . . . 4 1.2 wa ż ne informacje dotycz ą ce bezpiecze ń stwa . . . . . . . . . . . . . . . . . . . . . . 5 2 specyfikacje 2.1 identyfikacja produktu . . . . . . . . . . . . . . . . . . 6 2.2 silnik . . . . . . . . . ....

Page 32: 1 Bezpiecze

1 bezpiecze Ń stwo pl-4 1 bezpiecze Ń stwo 1.1 bezpiecze Ń stwo podczas eksploatacji ________________________________ 1. Bezpiecze ń stwo zale ż y od koncentracji, uwagi i ostro ż no ś ci osób obs ł uguj ą cych lub konserwuj ą cych sprz ę t. Maszyna nie mo ż e by ć obs ł ugiwana przez osoby niepe ł ...

Page 33: Bezpiecze

Bezpiecze Ń stwo 1 pl-5 1.2 wa Ż ne informacje dotycz Ą ce bezpiecze Ń stwa _________________________ pokazany symbol ostrzegawczy informuje o potencjalnym zagro ż eniu. Baczno ŚĆ – wskazuje sytuacj ę stanowi ą c ą bezpo ś rednie zagro ż enie; je ś li si ę jej nie zapobiegnie, b Ę dzie ona skutkowa ...

Page 34: 2 Specyfikacje

2 specyfikacje pl-6 2 specyfikacje 2.1 identyfikacja produktu _______________________________________________ 67069.............................. Kosiarka tri-king, nap ę d na trzy ko ł a, silnik wysokopr ęż ny 17,7 km, pa łą k rops. Bez przednich ramion no ś nych i zespo ł ów tn ą cych. Numer seryj...

Page 35: Specyfikacje 2

Specyfikacje 2 pl-7 2.5 masa i wymiary _________________________________________________________ wymiary: mm (cale) d ł ugo ść ........................................................... 2519 (99) wysoko ść ........................................................ 1308 (51,5) szeroko ść – ko ł a........

Page 36: 3 Regulacje

3 regulacje pl-8 3 regulacje 3.1 informacje ogÓlne ____________________________________________________ 1. Regulacje i prace konserwacyjne powinien przeprowadza ć zawsze wykwalifikowany technik. Je ś li nie mo ż na dokona ć odpowiedniej regulacji, nale ż y skontaktowa ć si ę z autoryzowanym sprzedaw...

Page 37: Regulacje 3

Regulacje 3 pl-9 3.4 prze ŁĄ czniki biegu ja Ł owego i nap Ę du na trzy ko Ł a ___________________ 1. Sprawdzi ć regulacj ę peda ł u jazdy. 2. U ż y ć woltomierza/omomierza, aby ustali ć , kiedy prze łą cznik otwiera si ę i zamyka. A. Ustawi ć prze łą cznik (g) tak, aby palec ramienia uruchamiaj ą c...

Page 38: 3 Regulacje

3 regulacje pl-10 3.7 po Ł o Ż enie neutralne peda Ł u jazdy ____________________________________ 1. Je ś li kosiarka wykonuje minimalny ruch (pe ł zanie) przy w łą czonym silniku, a peda ł jazdy jest zwolniony, nale ż y wyregulowa ć napr ęż enie spr ęż yny, aby zwolniony peda ł zawsze wraca ł w po ...

Page 39: Regulacje 3

Regulacje 3 pl-11 3.10 hamulec postojowy____________________________________________________ 1. Nale ż y sprawdzi ć linki i przeguby, aby mie ć pewno ść , ż e dzia ł aj ą bez problemów. 2. Ustawi ć kosiark ę na zboczu o nachyleniu 30% (16,7°) w pobli ż u jego podnó ż a tak, aby przód kosiarki by ł s...

Page 40: 3 Regulacje

3 regulacje pl-12 3.13 ustawienie prze Ś witu b Ę bna i no Ż a dolnego ___________________________ (kontrola przed regulacj ą ) 1. Sprawdzi ć lub osiowy oraz luz promieniowy ł o ż ysk b ę bna. Je ś li wyst ę puj ą nietypowe ruchy b ę bna, na przyk ł ad w gór ę lub w dó ł czy te ż na boki, nale ż y p...

Page 41: Regulacje 3

Regulacje 3 pl-13 3.15 tryby ci Ę cia ____________________________________________________________ 1. Kosiark ę mo ż na u ż ytkowa ć w trybie sta ł ym lub w trybie swobodnym. 2. Tryb sta ł y wykorzystywany jest przy wysoko ś ci ci ę cia wi ę kszej ni ż 25 mm (1 cal), a kosiarka nie wymaga przedniego...

Page 42: 3 Regulacje

3 regulacje pl-14 3.17 demonta Ż zespo Ł u tn Ą cego ____________________________________________ 1. Nie nale ż y od łą cza ć przewodów od silnika, aby nie dopu ś ci ć do zanieczyszczenia uk ł adu hydraulicznego oraz utraty oleju. 2. Unie ść i zablokowa ć ramiona no ś ne w po ł o ż eniu transportowy...

Page 43: Regulacje 3

Regulacje 3 pl-15 3.19 wysoko ŚĆ ci Ę cia – tryb swobodny _____________________________________ post ę powa ć zgodnie z procedurami opisanymi w punkcie 3.16. 1. Zamontowa ć element reguluj ą cy przedniego wa ł ka ( b ) w otworach 2 i 4 tylko na ramie kosiarki. Nie wykorzystywa ć otworów 1 i 3. Nale ...

Page 44: 3 Regulacje

3 regulacje pl-16 3.20 momenty dokr Ę ce Ń ____________________________________________________ firma jacobsen standardowo wykorzystuje ś ruby platerowane klasy 5, o ile nie podano inaczej. W przypadku dokr ę cenia ś rub platerowanych nale ż y stosowa ć warto ś ci dotycz ą ce ś rub smarowanych. 3.21...

Page 45: Konserwacja 4

Konserwacja 4 pl-17 4 konserwacja 4.1 informacje ogÓlne_____________________________________________________ 1. Regulacje i prace konserwacyjne powinien przeprowadza ć zawsze wykwalifikowany technik. Je ś li nie mo ż na dokona ć odpowiedniej regulacji, nale ż y skontaktowa ć si ę z autoryzowanym spr...

Page 46: 4 Konserwacja

4 konserwacja pl-18 4.3 olej silnikowy _________________________________________________________ sprawdza ć poziom oleju silnikowego na pocz ą tek ka ż dego dnia, przed uruchomieniem silnika. Je ś li poziom oleju jest niski, nale ż y zdj ąć korek wlewu oleju i doda ć odpowiedni ą ilo ść oleju. Pierw...

Page 47: Konserwacja 4

Konserwacja 4 pl-19 4.5 paliwo__________________________________________________________________ z paliwem nale ż y post ę powa ć bardzo ostro ż nie – jest wysoce ł atwopalne. Nale ż y stosowa ć odpowiedni pojemnik, dziobek musi mie ś ci ć si ę wewn ą trz szyjki wlewu paliwa. Nale ż y unika ć wlewan...

Page 48: 4 Konserwacja

4 konserwacja pl-20 4.8 rozruch z innego akumulatora________________________________________ przed prób ą uruchomienia kosiarki z akumulatora innego pojazdu, nale ż y sprawdzi ć stan wy ł adowanego akumulatora. P punkt 4.7 . Podczas pod łą czania przewodów rozruchowych: 1. Zatrzyma ć silnik pojazdu ...

Page 49: Konserwacja 4

Konserwacja 4 pl-21 4.11 olej hydrauliczny _____________________________________________________ szczegó ł owe okresy konserwacji podane s ą w punkcie punkt 6.3 . Zbiornik uk ł adu hydraulicznego w tej kosiarce nape ł niony jest biodegradowalnym p ł ynem jacobsen greens care 68. Olej hydrauliczny na...

Page 50: 4 Konserwacja

4 konserwacja pl-22 4.14 t Ł umik i uk Ł ad wydechowy _____________________________________________ aby chroni ć si ę przed zatruciem tlenkiem w ę gla, nale ż y regularnie sprawdza ć ca ł y uk ł ad wydechowy i zawsze wymienia ć t ł umik, je ś li jest wadliwy. W przypadku zauwa ż enia zmiany w kolorz...

Page 51: Konserwacja 4

Konserwacja 4 pl-23 4.17 czyszczenie i piel Ę gnacja ______________________________________________ po ka ż dym u ż yciu kosiark ę i jej narz ę dzia nale ż y umy ć . Utrzymywa ć maszyn ę w czysto ś ci. 1. Do czyszczenia silnika i ż eberek ch ł odnicy nale ż y stosowa ć spr ęż one powietrze. U sprzed...

Page 52: 4 Konserwacja

4 konserwacja pl-24 4.19 docieranie przez cofanie b Ę bna _______________________________________ sprawdzi ć b ę ben i nó ż dolny, aby stwierdzi ć , czy docieranie lub szlifowanie przywróci ostro ść no ż a. Je ś li zu ż ycie lub uszkodzenia s ą tak du ż e, ż e no ż y b ę bna i no ż a dolnego nie da ...

Page 53: Konserwacja 4

Konserwacja 4 pl-25 4.20 przechowywanie _______________________________________________________ informacje ogólne 1. Dok ł adnie umy ć i przesmarowa ć kosiark ę . Naprawi ć i pomalowa ć uszkodzone lub ods ł oni ę te elementy metalowe. 2. Dokona ć przegl ą du kosiarki, dokr ę ci ć wszystkie elementy ...

Page 54: 5 Usuwanie Problemów

5 usuwanie problemÓw pl-26 5 usuwanie problemÓw 5.1 informacje ogÓlne ____________________________________________________ tabela usuwania problemów opisuje podstawowe problemy, które mog ą wyst ą pi ć podczas rozruchu i eksploatacji. Wi ę cej informacji na temat uk ł adu hydraulicznego i uk ł adu e...

Page 55: Ostrze

Tabele konserwacji i smarowania 6 pl-27 6 tabele konserwacji i smarowania 6.1 informacje ogÓlne_____________________________________________________ 1. Nale ż y zawsze oczy ś ci ć punkty smarowania przed i po smarowaniu. 2. Stosowa ć smar, który spe ł nia lub przekracza specyfikacje nlgi klasa 2 lb....

Page 56

6 tabele konserwacji i smarowania pl-28 6.3 tabele konserwacji ____________________________________________________ u - uzupe ł nienie lub ustawienie c - czyszczenie o - ogl ę dziny s - smarowanie w - wymiana wp - wed ł ug potrzeby * oznacza okres pocz ą tkowy w przypadku nowych maszyn. ** co 250 go...

Page 57: Parts Catalog 7

Parts catalog 7 31 7 parts catalog 7.1 table of contents______________________________________________________ 1.1 .................................................................................Decals.....................................................................................................

Page 58: Tri-King

32 with green s care tri-kin g ® important t h i s m a c h i n e u s e s g r e e n s c a r e 6 8 , a b i o d e g r a d a b l e h y d r a u l i c f l u i d . ( o r d e r 5 0 0 3 1 0 3 f o r 5 g a l . P a i l ) . 2 8 120 3 2 b io d e g radable flu id 4141266 2 8 11597 4199140 41 8 1 8 62 41 8 1 8 6 3 ...

Page 59: Tri-King

33 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4181864 1 decal, battery warning 2 4141266 1 decal, oil 3 2812032 1 decal, hydraulic fluids 4 4181863 1 decal, see manual for service 5 4124357 1 decal, left side stripe 6 4124358 1 decal, right side st...

Page 60: Tri-King

34 1 2 3 4 5 5 5 6 6 7 8 8 9 9 9 9 10 10 11 11 12 1 3 14 14 15 15 16 16 17 17 1 8 1 8 19 19 20 20 20 20 21 22 22 2 3 2 3 24 25 tri-king 2.1 hood serial no. All.

Page 61: Tri-King

35 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 2810064 1 pivot bracket 2 2811139 ar shim, hood 3 441676 2 carriage bolt, 3/8-16 x 1-1/4” 4 453011 2 flat washer, 3/8 5 446142 6 lockwasher, 3/8 heavy 6 443110 6 nut, 3/8-16 hex 7 2811495 2 pivot link 8...

Page 62: Tri-King

36 1 2 3 3 4 4 5 5 6 7 7 7 7 8 8 8 8 8 9 9 9 10 11 12 13 14 14 15 15 16 16 17 18 18 19 19 20 20 20 21 20 20 21 21 21 21 22 22 23 24 25 25 26 26 27 28 29 30 31 32 33 34 35 36 37 39 37 40 tri-king 3.1 seat pan and foot rest serial no. All.

Page 63: Tri-King

37 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 5001665 1 seat pan includes decals 2 3003301 1 seat base 3 440134 2 carriage bolt, 3/8-16 x 3” 4 446142 2 lockwasher, 3/8 heavy 5 443110 2 nut, 3/8-16 hex 6 400188 4 screw, 5/16-18 x 1” hex head 7 45200...

Page 64: Tri-King

38 1 2 3 4 4 5 6 7 8 9 10 11 12 1 3 1 3 14 15 15 16 16 17 17 17 17 1 8 1 8 1 8 1 8 19 19 19 19 20 20 21 22 22 2 3 24 25 tri-king 4.1 panel mounting serial no. All.

Page 65: Tri-King

39 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 ref 1 instrument panel assembly see 5.1 2 3003540.7 1 mounting bracket 3 441602 2 carriage bolt, 5/16-18 x 3/4” 4 444718 4 locknut, 5/16-18 hex center 5 403770 2 screw, 5/16-18 x 3/4” hex flange 6 10022...

Page 66: Tri-King

40 1 2 3 4 5 6 7 8 9 10 11 12 1 3 14 14 15 16 17 1 8 19 20 21 22 2 3 24 25 26 26 27 2 8 29 3 0 3 1 3 2 33 3 4 3 5 3 6 3 6 3 7 38 38 3 9 tri-king 5.1 instrument panel serial no. All.

Page 67: Tri-King

41 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 2811437 1 instrument panel 2 3003350 1 • decal, panel overlay 3 2811597 1 • decal, parking brake 4 3002053 1 • decal, backlap switch 5 1001958 1 ignition switch reference sw9, see 42.1 6 5002101 1 • bez...

Page 68: Tri-King

42 1 2 2 3 3 3 3 4 4 5 6 7 8 9 10 10 11 12 1 3 14 14 15 16 16 17 1 8 19 20 21 21 22 22 2 3 2 3 24 25 25 26 26 27 27 2 8 2 8 29 3 0 3 1 3 2 33 3 4 3 4 3 5 3 5 3 5 3 5 3 6 3 7 38 3 9 ● ● ● 41 42 40 40 tri-king 6.1 traction pedal linkage serial no. All.

Page 69: Tri-King

43 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 2811387 1 traction pedal 2 328133 2 bushing included with frame 3 453017 6 flat washer, 1/2 4 460028 1 cotter pin, 1/8 x 1” 5 2811390 1 spring, torsion 6 2811654 1 arm, switch actuating 7 352936 1 • bus...

Page 70: Tri-King

44 1 2 2 3 4 5 6 7 8 9 10 11 12 1 3 1 3 25 1 3 14 15 16 16 17 17 1 8 19 20 21 22 22 2 3 24 tri-king 7.1 lift pedal and spring bracket serial no. All.

Page 71: Tri-King

45 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 1002606.7 1 lift pedal 2 328133 2 bushing, pedal included with frame 3 453017 1 flat washer, 1/2 4 460028 1 cotter pin, 1/8 x 1” 5 3003474 1 grip, pedal 6 4240904 1 lift valve 4240905 1 • seal kit 7 400...

Page 72: Tri-King

46 1 2 2 3 4 5 6 7 8 9 10 10 10 11 12 1 3 14 15 16 17 1 8 19 20 20 20 20 21 21 21 21 22 22 22 22 2 3 2 3 24 24 25 25 26 27 tri-king 8.1 parking brake serial no. All.

Page 73: Tri-King

47 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 2500127 1 parking brake lever 2 n/s 2 • stabilizer plate 3 545237 2 • spacer 4 545234 2 • clevis pin 5 460002 2 • cotter pin, 1/16 x 1/2” 6 400216 2 screw, 5/16-18 x 2-3/4” hex head 7 2812215 1 plate, s...

Page 74: Tri-King

48 1 2 2 2 2 3 4 4 5 6 7 8 8 9 9 10 10 11 11 12 12 1 3 1 3 14 15 16 16 17 17 1 8 1 8 19 19 20 20 21 22 22 2 3 3 9 40 41 2 3 24 24 25 25 26 27 2 8 29 3 0 3 1 3 2 33 3 4 3 5 3 6 3 7 38 42 tri-king 9.1 frame and steering column serial no. All.

Page 75: Tri-King

49 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 n/s 1 frame assembly 2 328133 4 • bushing, pedal pivot 3 3002170 4 • bushing, lift arm pivot 4 365106 2 • bushing, lift crank 5 471216 1 • grease fitting, 1/4-28 6 4182425 1 wheel motor, 11.9 in 3 front...

Page 76: Tri-King

50 ! Warning thi s s tructure' s proctective capability may be impaired by s tructural dama g e, over turn, or alteration. If any of the s e condition s occur, thi s s tructure mu s t be replaced. 500 3 597 ! Warning 500 3 59 8 u s e s eat belt 1 2 3 4 5 5 6 7 7 8 9 10 10 10 11 11 11 12 1 3 1 3 14 1...

Page 77: Tri-King

51 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 69157 1 rops assembly 2 n/s 1 • base, rops 3 5003595 1 • plate, rear backing 4 5003596 1 • bracket, seat belt 5 5000629 1 • seat belt, 60” 6 400370 2 • screw, 7/16-20 x 1” hex head 7 452010 2 • flat was...

Page 78: Tri-King

52 1 2 2 3 3 4 5 6 7 7 7 8 8 9 9 10 11 12 1 3 14 15 16 17 1 8 1 8 19 20 20 21 21 22 2 3 24 tri-king 11.1 rear steering serial no. All.

Page 79: Tri-King

53 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4138501 1 steering cylinder 4137139 1 • seal kit 2 443820 2 nut, 1/2-20 hex 3 3010485 2 ball joint 4 353914 4 wheel bolt, 1/2-20 x 3/4” 5 1001129.7 1 steering fork includes cup portion of item 9 6 47123...

Page 80: Tri-King

54 1 2 3 4 4 5 6 7 8 8 9 9 10 11 12 1 3 14 15 16 17 1 8 19 20 21 22 2 3 24 tri-king 12.1 air filter serial no. All.

Page 81: Tri-King

55 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 1001354 1 air cleaner 5000913 1 • element, air cleaner 5000912 1 • cover 5000914 1 • valve, vactuator 2 3002862 1 foam ring 3 3002863 1 hose, engine air intake 4 326112 2 clamp, hose 5 361005 2 screw, m...

Page 82: Tri-King

56 1 2 3 4 4 4 4 4 5 5 5 5 5 6 6 6 6 7 7 7 7 8 8 9 10 10 20 20 11 12 12 12 12 1 3 1 3 14 14 15 15 16 17 17 17 17 1 8 19 tri-king 13.1 radiator serial no. All.

Page 83: Tri-King

57 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4141036 1 radiator 2 4150717 1 bracket, front radiator mount 3 4140846 1 shroud, fan 4 362535 9 screw, m6-1 x 16 mm hex head 5 446128 9 lockwasher, 1/4 6 452004 9 flat washer, 1/4 7 452008 6 flat washer...

Page 84: Tri-King

58 1 2 2 2 2 3 3 3 3 4 4 4 4 4 4 4 5 6 6 7 8 9 9 10 10 10 11 11 11 11 12 12 12 12 1 3 1 3 1 3 1 3 14 tri-king 14.1 engine mount serial no. All.

Page 85: Tri-King

59 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 ref 1 engine and pump assembly see 15.1 2 3004523 4 mount, isolation 3 400186 8 screw, 5/16-18 x 7/8” hex head 4 446136 12 lockwasher, 5/16 heavy 5 400190 1 screw, 5/16-18 x 1-1/4” hex head 6 452006 2 f...

Page 86: Tri-King

60 1 2 3 4 5 5 6 6 7 7 8 9 9 9 9 9 10 11 12 1 3 14 15 16 17 1 8 19 20 21 22 2 3 24 25 26 26 27 27 2 8 2 8 2 8 29 3 0 tri-king 15.1 engine and pump serial no. All.

Page 87: Tri-King

61 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4189580 1 engine, kubota d722-e3b 2 5002644 1 • cartridge, engine oil filter 3 4127309.7 1 bracket, front engine mount 4 2811637.7 1 bracket, rear engine mount 5 452008 8 flat washer, 3/8 6 363485 8 loc...

Page 88: Tri-King

62 1 2 3 4 4 5 6 6 7 8 9 10 11 11 11 12 1 3 14 15 16 17 1 8 19 19 19 19 20 21 21 22 22 2 3 24 25 26 26 27 27 38 3 9 27 2 8 2 8 29 3 0 3 1 3 2 33 3 4 3 4 3 4 3 5 3 5 3 6 3 6 3 6 3 7 tri-king 16.1 engine exhaust serial no. All.

Page 89: Tri-King

63 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4121920 1 muffler ● 2 553020 1 gasket, muffler ● 3 594331 4 bolt, muffler 4 452006 6 flat washer, 5/16 5 400264 1 screw, 3/8-16 x 1-1/4” hex head 6 452008 2 flat washer, 3/8 7 4121007.7 1 bracket, muffl...

Page 90: Tri-King

64 > change from previous revision 1 2 3 4 4 5 6 7 7 7 7 7 8 8 8 8 9 10 11 12 1 3 14 15 16 tri-king 17.1 fuel control serial no. All item part no. Qty. Description serial numbers/notes 1 2810134 1 bracket, throttle cable 2 361898 1 screw, m8-1.25 x 16 mm hex head 3 446136 1 lockwasher, 5/16 heavy 4 ...

Page 91: Tri-King

65 > change from previous revision a b a b view rotated 1 8 0° for clarity 1 1 1 1 2 3 4 5 6 7 7 8 9 10 10 tri-king item part no. Qty. Description serial numbers/notes 1 366526 4 clamp, hose 2 554748 ar hose, 5/16 i.D. Tank to fuel filter 10 foot length, cut to 37” 3 550553 1 filter, fuel 550489 1 e...

Page 92: Tri-King

66 1 2 2 3 3 4 4 5 5 6 7 8 22 2 3 24 9 10 11 12 1 3 14 15 16 17 1 8 1 8 19 20 21 tri-king 19.1 fuel and hydraulic tanks serial no. All.

Page 93: Tri-King

67 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 1002019.6 1 tank, hydraulic oil approximately 4.5 gallons 2 400424 4 screw, 1/2-13 x 4-1/2” hex head 3 344132 4 washer 4 446154 4 lockwasher, 1/2 heavy 5 443118 4 nut, 1/2-13 hex 6 1000973 1 bracket, ba...

Page 94: Tri-King

68 1 2 3 3 3 4 5 6 6 7 7 8 9 10 11 12 1 3 21 22 22 14 15 16 16 16 16 17 1 8 19 20 20 tri-king 20.1 traction pump and charge filter serial no. All.

Page 95: Tri-King

69 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4129590 1 pump, hydraulic traction see 37.1 2 400272 2 screw, 3/8-16 x 2-1/4” hex head 3 446142 4 lockwasher, 3/8 heavy 4 400276 1 screw, 3/8-16 x 3” hex head 5 400274 1 screw, 3/8-16 x 2-1/2” hex head ...

Page 96: Tri-King

70 1 2 2 3 4 5 7 8 9 9 10 11 12 12 1 3 14 15 16 17 17 17 17 6 tri-king 21.1 traction pump hydraulics serial no. All.

Page 97: Tri-King

71 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 3003219 1 hose, charge pump suction 2 108094-02 2 clamp, hose 3 4129590 1 pump, hydraulic traction see 20.1 for pump mounting 4 340070 1 fitting, -10 orfs x -10 orb 90° 339911 1 • o-ring, -10 orfs 33989...

Page 98: Tri-King

72 port a port b 1 2 2 2 2 2 2 (port b) 2 (port b) 2 (port b) 2 (port a) 2 (port a) 3 4 (port a) 5 6 7 8 9 10 11 12 17 17 17 17 1 3 14 15 16 port a port b port a port b motor (10) viewed from re a r motor (6) viewed from re a r motor (15) viewed from re a r tri-king 22.1 traction hydraulics serial n...

Page 99: Tri-King

73 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4129590 1 pump, hydraulic traction see 20.1 for pump mounting 2 339989 11 fitting, -10 orfs x -10 orb straight 339911 1 • o-ring, -10 orfs 339899 1 • o-ring, -10 orb 3 2810603 1 tube, pump to upper moto...

Page 100: Tri-King

74 r l p t e 1 2 2 2 2 3 4 5 6 7 8 9 10 11 12 12 1 3 14 22 22 22 22 15 16 17 1 8 19 20 21 item 5 item 3 item 6 item 11 item 14 part of frame 2 3 24 25 26 27 tri-king 23.1 steering and lift hydraulics serial no. All.

Page 101: Tri-King

75 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4129590 1 pump, hydraulic traction see 20.1 for pump mounting 2 340061 5 fitting, -6 orfs x -6 orb 90° 339909 1 • o-ring, -6 orfs 339897 1 • o-ring, -6 orb 3 4223520 1 tube, pump to steering valve steer...

Page 102: Tri-King

76 1 1 1 1 2 3 4 5 6 part of frame 7 8 9 9 10 11 12 1 3 14 15 16 17 tri-king 24.1 gear pump hydraulics serial no. All.

Page 103: Tri-King

77 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 367458 4 clamp, hose 2 3003113 1 hose, suction 3 3003115 1 tube, gear pump suction 4 354080 1 clamp, hose see 9.1 5 3003114 1 hose, formed suction 6 4174020 1 pump, 3 section gear see 15.1 7 1001147 1 t...

Page 104: Tri-King

78 1 2 3 3 4 4 5 5 6 6 6 6 6 6 6 6 7 7 8 8 8 9 10 10 11 12 12 1 3 1 3 14 15 tri-king 25.1 reel hydraulics serial no. All.

Page 105: Tri-King

79 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4174020 1 pump, 3 section gear see 15.1 2 339979 3 fitting, -6 orfs x -6 orb straight 339909 1 • o-ring, -6 orfs 339897 1 • o-ring, -6 orb 3 1001492 1 hose, pump to left motor pump section 1 4 1001493 1...

Page 106: Tri-King

80 > change from previous revision 1 2 3 4 4 4 4 4 4 4 5 5 5 5 5 5 6 6 4 10 11 12 12 1 3 1 3 1 3 center reel 14 14 16 15 7 7 8 9 tri-king 26.1 hydraulic tube clamps serial no. All item part no. Qty. Description serial numbers/notes 1 3003242 1 bracket, tube clamp 2 441668 2 carriage bolt, 1/4-20 x 1...

Page 107: Tri-King

81 > change from previous revision 1 2 3 4 5 6 7 7 12 16 17 1 3 14 15 6 8 9 10 11 tri-king item part no. Qty. Description serial numbers/notes 1 2810264 1 cable, positive battery 2 3003523 1 cable, negative battery 3 3004539 1 convoluted conduit 4 400112 1 screw, 1/4-20 x 1” hex head 5 447010 1 lock...

Page 108: Tri-King

82 1 2 3 4 4 5 6 7 8 9 9 10 11 12 1 3 14 15 16 17 17 1 8 19 20 21 22 2 3 24 25 26 27 2 8 29 29 3 0 3 1 3 1 3 2 33 3 4 3 5 3 6 3 7 38 tri-king 28.1 lift cylinder linkage serial no. All.

Page 109: Tri-King

83 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 122759 1 cylinder, hydraulic lift 554331 1 • seal kit 2 554330 1 • bushing, bronze 3 364238 1 pin, cylinder 4 345700 6 washer, shim 5 460052 1 cotter pin, 3/16 x 1-1/2 6 1001258.7 1 crank bottom 7 30737...

Page 110: Tri-King

84 1 1 2 2 3 2 2 3 3 3 4 4 4 5 5 5 6 7 7 8 8 9 10 11 11 12 1 3 14 15 16 17 17 1 8 1 8 19 20 21 21 22 2 3 24 25 26 27 2 8 29 3 0 3 1 3 2 33 / 3 4 3 5 3 6 3 7 38 3 9 40 40 3 0” reel lift arm s tri-king 29.1 reel assembly serial no. All.

Page 111: Tri-King

85 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 3002430 2 pin, lift arm 2 400272 ar screw, 3/8-16 x 2-1/4” hex head 3 444762 ar locknut, 3/8-16 hex center 4 1002603 3 motor, reel see 36.1 5 2810171 3 snap ring 6 67114 1 26” 7 blade left reel assembly...

Page 112: Tri-King

86 5 bl a de reel (option a l) 7 bl a de reel ( s t a nd a rd) 10 bl a de reel (option a l) 26 in. (660 mm) reel s 3 0 in. (762 mm) reel s 67114 67116 67115 6712 3 67126 67125 2500712 50020 8 7 2500714 left center right left center right 2500712 50020 8 7 2500714 250071 3 50020 88 2500715 50 33 59 5...

Page 113: Tri-King

87 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 1001643 1 26” reel mower frame used on 67114, 67115, and 67116 1 1001642 1 30” reel mower frame used on 67123, 67124, and 67125 2 5001607 1 bearing housing, reel motor 3 3001152 1 • washer 4 3000983 1 •...

Page 114: Tri-King

88 41 8 2520 1 2 2 3 3 3 4 5 6 7 8 9 10 11 12 1 3 14 15 16 17 1 8 19 20 21 22 22 22 22 22 2 3 2 3 2 3 24 25 67114 67115 67116 6712 3 67124 67125 tri-king 31.1 outer reel serial no. 67114 - all serial no. 67115 - all serial no. 67116 - all serial no. 67123 - all serial no. 67124 - all serial no. 6712...

Page 115: Tri-King

89 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 ref 1 inner reel see 30.1 2 400258 6 screw, 3/8-16 x 3/4” hex head 3 446142 8 lockwasher, 3/8 heavy 4 364282 1 plate, support 5 3005890 4 wheel bolt, 3/8-16 6 5000616 1 bedkinfe backing, 26” used on 671...

Page 116: Tri-King

90 1 2 2 3 4 4 5 6 7 7 8 8 8 8 9 9 10 10 10 10 11 11 12 12 1 3 1 3 1 3 1 3 14 14 15 15 16 22 17 17 1 8 1 8 19 19 20 20 21 21 21 2 3 21 2 3 tri-king 32.1 pivot arms serial no. 67114 - all serial no. 67115 - all serial no. 67116 - all serial no. 67123 - all serial no. 67124 - all serial no. 67125 - al...

Page 117: Tri-King

91 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 4113759 1 26” center pivot arm used on 67116 1 4113756 1 30” center pivot arm used on 67125 2 364140 2 • bushing 3 4113758 1 26” left pivot arm used on 67114 3 4113757 1 26” right pivot arm used on 6711...

Page 118: Tri-King

92 1 / 2 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 10 10 11 11 12 12 1 3 1 3 1 3 1 3 14 14 14 14 15 15 15 15 15 15 16 16 16 16 16 17 1 8 19 19 20 21 21 21 21 22 22 22 22 2 3 24 25 24 tri-king 33.1 roller brackets and skids serial no. 67114 - all serial no. 67115 - all serial no. 67116 - all serial no. 67123 -...

Page 119: Tri-King

93 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 132639 1 roller, 26” reel rear used on 67114, 67115, and 67116 1 132640 1 roller, 30” reel rear used on 67123, 67124, and 67125 2 5002831 1 • tube, 26” reel roller used on 67114, 67115, and 67116 2 5002...

Page 120: Tri-King

94 1 1 2 2 3 3 3 3 4 4 4 4 4 4 4 4 5 5 5 5 6 6 6 6 7 7 7 7 8 8 8 8 9 9 3 0” reel 26” reel 9 9 9 9 9 9 10 10 10 10 10 10 10 10 11 11 11 11 16 16 16 16 17 17 17 17 12 12 12 12 12 12 12 12 1 3 1 3 1 3 1 3 1 3 1 3 1 3 1 3 14 14 14 14 14 14 15 16 16 tri-king 34.1 down pressure springs serial no. 67114 - ...

Page 121: Tri-King

95 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 2811281 1 lift arm, left side 26” reel used with 67114, see 29.1 1 2811279 1 lift arm, left side 30” reel used with 67123, see 29.1 2 2811280 1 lift arm, right side 26” reel used with 67115, see 29.1 2 ...

Page 122: Tri-King

96 1 2 3 3 3 4 4 4 4 5 6 7 8 8 8 8 8 8 9 9 9 10 10 10 10 10 10 10 10 10 10 10 10 11 12 1 3 14 14 14 15 16 16 16 17 17 17 1 8 19 tri-king 35.1 reel pump part no. 4174020 serial no. All.

Page 123: Tri-King

97 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 n/s 1 gear housing, section 3 2 n/s 1 ball, steel ● 3 n/s 3 shear pin ● 4 5001442 4 snap ring ● 5 n/s 1 oil seal 6 5001435 1 driveshaft 7 5001444 1 plug, lee 8 n/s 6 gear, 7/16” wide 0.226 in 3 /rev ● 9...

Page 124: Tri-King

98 1 2 3 4 5 5 5 5 6 7 8 9 10 10 10 10 11 11 12 1 3 14 15 16 17 1 8 19 20 21 22 2 3 3 2 24 25 26 27 2 8 29 3 0 3 1 tri-king 36.1 reel motor part no. 1002603 serial no. All.

Page 125: Tri-King

99 > change from previous revision tri-king item part no. Qty. Description serial numbers/notes 1 5001448 1 stator 2 5001443 1 drive shaft ● 3 n/s 1 oil seal ● 4 n/s 1 retaining ring 5 5001446 4 sleeve, bearing ● 6 n/s 1 gasket, 0.00050 (silver) use gasket same color as original gasket. ● 6 n/s 1 ga...

Page 126: Tri-King

100 1 2 3 3 4 5 6 7 8 9 10 10 11 12 1 3 1 3 14 15 16 16 17 1 8 19 20 21 22 2 3 24 25 26 27 2 8 2 8 29 3 0 3 1 3 2 33 3 4 3 5 3 6 3 7 38 3 9 40 41 42 4 3 44 45 tri-king 37.1 traction pump part no. 4129590 serial no. All.

Page 127: Tri-King

101 tri-king item part no. Qty. Description serial numbers/notes 1 4132078 1 charge pump kit 2 4120216 1 • carrier 3 n/s 6 • roller 4 n/s 4 • screw, 5/16-18 x 1-1/4” hex socket 5 n/s 1 • screw, 5/16-18 x 1-3/4” hex socket 6 4120217 1 • pin, drive ● 7 549354 1 • seal, square cut ring ● 8 549380 1 • s...

Page 128: Tri-King

102 > change from previous revision 1 1 2 / 3 4 4 4 4 5 5 5 5 6 tri-king 38.1 3wd valve part no. 4111942 serial no. All item part no. Qty. Description serial numbers/notes 1 4113025 2 check valve 5003578 1 • seal kit, check valve 2 4113026 1 spool valve 5003579 1 • seal kit, spool valve 3 4113027 1 ...

Page 129: Tri-King

103 > change from previous revision 1 2 3 4 5 7 6 tri-king item part no. Qty. Description serial numbers/notes 1 n/s 1 cam left side 1 n/s 1 cam right side 2 557823 1 pivot pin 3 503660 1 carrier, side pad 4 557824 1 pad, support 5 557825 1 lever retainer spring 6 557826 1 pad, support 7 503660 1 ca...

Page 130: Tri-King

104 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 tri-king 40.1 wheel motor, 11.9 in 3 part no. 4182425 serial no. All item part no. Qty. Description serial numbers/notes ◆ 1 n/s 1 seal guard ● 2 n/s 4 seal, 3” i.D. ● 3 n/s 1 back up ring ● 4 n/s 1 shaft seal 5 5003384 1 shaft and be...

Page 131: Tri-King

105 > change from previous revision 1 2 3 4 5 6 7 8 2 2 2 9 10 11 tri-king item part no. Qty. Description serial numbers/notes ◆ 1 n/s 1 seal guard ● 2 n/s 4 seal, 3” i.D. ● 3 n/s 1 back up ring ● 4 n/s 1 shaft seal 5 5003384 1 shaft and bearing kit 6 554780 1 key 7 554779 1 hex nut ◆ 8 n/s 1 shaft ...

Page 132: Tri-King

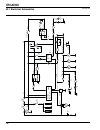

106 sa i b bg ml bn off-none r un - b+i+a; x+y off-g+m r un - b+l optional light kit st ar t - b+i+s rd rd y x rd bk + - b1 m1 g g k1 bs p p cb1 1 2 rd bn bn/bk bn/ye bn/gy bn/rd bn/rd rd/wh rd/wh rd/ye rd/gn rd/gn or/gn or/bn or/bn or/ye or/b u or/ye or/wh ye/gy rd/ye rd/bk gy bk bk bk bk rd/wh rd/...

Page 133: Tri-King

107 > change from previous revision tri-king item reference illustration part number description serial numbers/notes b1 see 19.1 ns battery cb1 see 16.1 3000359 50 amp circuit breaker cb2 see 5.1 338601 10 amp circuit breaker d1 not shown 555846 clutch diode included in wire harness d2 not shown 55...

Page 134: Tri-King

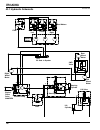

108 rear wheel motor left wheel motor right wheel motor traction pump engine direct drive 3400 rpm reel motors right center left electric clutch filter tank 5.5 gals. In system steering cylinder steering valve filter lift cylinder lift valve 3wd valve a t b p pb t p l r 1 2 a1 a b1 b a b tri-king 43...

Page 135: Fluids and Compounds

Fluids and compounds * refer to the operator’s manual or the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Jacobsen offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See your local jacobsen dealer for a co...

Page 136: Index

110 index 1000956.7....................83 1000973.......................67 1001010.......................41 1001129.7....................53 1001134.......................67 1001147.................77 , 79 1001148.... 67 , 69 , 71 , 75 1001176.7....................45 1001258.7....................83 1...

Page 137: Index

111 index 326112 ........................ 55 328133 ............ 43 , 45 , 49 338289 ........................ 64 338383 ........................ 47 338561 ........................ 91 338562 ........................ 91 338585 ........................ 89 338601 ........................ 41 338647 ........

Page 138: Index

112 index 4211400.......................49 4218141.......................75 4223520.......................75 4236021.......................53 4236061.......................53 4240904.................45 , 75 4240905.................45 , 75 4242563.......................49 4242564........................

Page 139: Index

113 index 557580 ........................ 55 557823 ...................... 103 557824 ...................... 103 557825 ...................... 103 557826 ...................... 103 558012 ........................ 37 558036 ........................ 41 594331 ........................ 63 64205-054........

Page 141

When performance matters. ™ Światowej klasy jakość, wydajność i pomoc techniczna world class quality, performance and support equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all our manufacturing locations. A worldwide dealer network and facto...