Jacto XP-16 Operator's Manual

XP

JACTO INC.

19217 SW 119

th

Ave.

Tualatin, Oregon 97062

Tel: (503) 885-8723

Fax: (800) 511-3671

Toll free: (800) 522-8610

E-mail: info@jacto.com

Home page: www.jacto.com

Operator's manual

∙

Manual de instrucciones

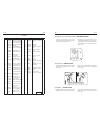

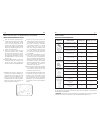

Tank / Depósito

Lever / Palanca

Lance / Lanza

Trigger valve / Válvula

Diaphragm / Diafragma

Chamber / Cámara

Nozzle / Boquilla

Lid / Tapa

SPRAYER VIEW ∙ PRESENTACIÓN

XP312, XP416, XP12

& XP-16

INTRODUCTION∙ INTRODUCCIÓN

04/2014 - 1211834 - 0547 - MIC_USA

This manual contains information for the

proper assembly, operation and care of

your sprayer.Carefully read and follow the

instructions contained in this manual befo-

re using your sprayer.

Este manual contiene todas las informaciones

necesarias sobre el montaje y funcionamiento

de su equipo. Léalo con atención y siga

rigurosamente sus instrucciones de uso.

Hose / Manguera