- DL manuals

- Jacuzzi

- Kitchen & Bath Fixtures

- SUMMER RAIN

- Installation And Operating Instructions Manual

Jacuzzi SUMMER RAIN Installation And Operating Instructions Manual

Summary of SUMMER RAIN

Page 1

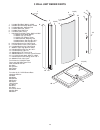

Summer rain ™ 2 wall & 3 wall walk-in shower systems installation and operating instructions.

Page 2

Note: this is a professional grade product. A knowledge of construction techniques, plumbing and electrical installation according to codes are required for proper installation and user satisfaction. We recommend that a licensed contractor perform the installation of all jacuzzi whirlpool bath produ...

Page 3: Owner'S Record

Owner's record save these instructions for future use. Date purchased ____________________________________________________________ purchased from ____________________________________________________________ installed by ________________________________________________________________ serial number _...

Page 4

Important: read complete instructions before beginning installation. Each unit arrives ready for installation, equipped with base, glass and associated hardware. Remove the unit from the carton. Retain the shipping carton until satisfactory inspection of the product has been made. Immediately upon r...

Page 5

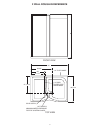

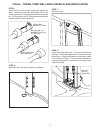

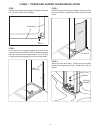

3 2 wall rough-in reference 60" 42-5/16" 33-3/4" 27-15/16" 84" 23" 21-1/2" front view top view 1/2" rigid copper pipe under base cold supply 1-1/2" tile flange hot supply minimum water pressure for the system is 40psi.

Page 6

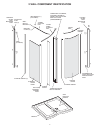

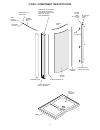

2 wall component identification 4 hex wrench (1) (provided) straight glass wall mounting post straight glass panel mounting post cap (2) 3 screws and 3 wall anchors per mounting post curved glass wall mounting post tower with plumbing, fixtures, magnetic gasket, bottom plate and top cover (preassemb...

Page 7

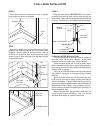

5 preliminary rough-in spread mortar or leveling compound etc. Evenly over entire area strainer drain assembly silicone sealant shower base rubber washer fiber washer nut apply lubricant the floor structure beneath the unit must be able to support a total weight of the unit and bather. Refer to the ...

Page 8

6 tighten sealing nut tool (included) gap tile flange incorrect shim stud correct tile flange stud use screws (provided) use screws (provided) step 5 with a large screwdriver and the tool included with the drain, tighten the inside compression nut to seal the drain pipe connection. After drain is fu...

Page 9

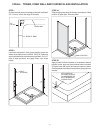

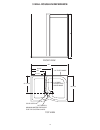

7 2 wall base installation stud cement board 1/4" minimum gap silicone sealant tile tile adhesive 1/4" minimum gap silicone sealant stud cement board 1/8" gap grout stud shim if necessary do not fill cement board tile silicone sealant 1-1/8" maximum no minimum step 7 apply tile (or other finishing m...

Page 10

8 step 1 position the wall posts so the edge of the post is set back 3/4" (19 mm) in from the edge of the base step 2 level both wall posts in their proper position and mark where screw holes are to be drilled. Drill 3/16" holes and secure with wall anchors and screws provided. Cut a 12" strip of ta...

Page 11

Step 5 place the tower onto base. Ensure the curved glass locates into the glazing channel. Install bolt but do not tighten. Step 6 insert tower support rail into glass panel rail but do not tighten at this time. 9 step 4 slide the glass panel into the wall post. Make sure that the corner notch is p...

Page 12

Step 11 secure the rails. 10 attach rail bracket to wall secure rail to bracket (turn cw to tighten) move cover cap over bracket step 9 place the front rail and tower support rail against the walls. Check level and mark the position for the rail mounting bracket. The screw position will be above the...

Page 13

11 2 wall: tower, fixed wall and curved glass installation step 13a insert fixed glass support rail into panel post and tighten set screw. Glass panel support rail drill 1/8" pilot hole and screw m3.5x9.5 mm screw into hole step 13b drill a 1/8" pilot hole into tower support rail using the hole in t...

Page 14

2 wall: tower, fixed wall and curved glass installation tower cover insert this side first tower cover tower top plate 12 step 16 turn on water supply and check for leaks. Correct any leaks before installing tower cover. Step 17 install tower cover as shown. Insert cover at top first. Step 18 seal a...

Page 15

13 important: read complete instructions before beginning installation. Each unit arrives ready for installation, equipped with base, glass and associated hardware. Remove the unit from the carton. Retain the shipping carton until satisfactory inspection of the product has been made. Immediately upo...

Page 16

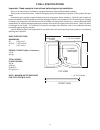

3 wall rough-in reference 60" 42-5/16" 33-3/4" 27-15/16" 84" 23" 21-1/2" front view top view 1/2" rigid copper pipe under base cold supply 1-1/2" tile flange hot supply minimum water pressure for the system is 40psi 14.

Page 17

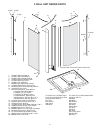

3 wall component identification hex wrench (1) (provided) mounting post cap 3 screws and 3 wall anchors curved glass wall mounting post tower with plumbing, fixtures, magnetic gasket, bottom plate and top cover (preassembled) tower mounting bolt & washer curved glass glazing gasket (2) front rail br...

Page 18

3 wall base installation the floor structure beneath the unit must be able to support a total weight of the unit and bather. Refer to the table under total weight. Step 1 provide an opening in the subfloor no less than 5" x 5" square. This opening should be located on the center lines of the shower ...

Page 19

3 wall base installation step 5 with a large screwdriver and the tool included with the drain, tighten the inside compression nut to seal the drain pipe connection. After drain is fully installed, test for proper drainage. If the shower base does not drain properly, rectify this condition before pro...

Page 20

Step 7 with a large screwdriver and the tool included with the drain, tighten the inside compression nut to seal the drain pipe connection. After drain is fully installed, test for proper drainage. If the shower base does not drain properly, rectify this condition before proceeding with the installa...

Page 21

3 wall: tower and curved glass installation step 1 position the wall post so the edge of the post is set back 3/4" (19 mm) in from the finish wall. Step 2 level the post in its proper position and mark where screw holes are to be drilled. Drill 3/16" holes and secure with wall anchors and screws pro...

Page 22

3 wall: tower and curved glass installation step 5 insert support rails into brackets in top moulding of tower but do not tighten at this time. Step 6 slide mounting bracket covers and mounting brackets onto front rail and tower support rail. Tower support rail front rail rail wall mounting bracket ...

Page 23

3 wall: tower and curved glass installation step 9 secure the rails. Step 10 tighten the tower base bolt. Two shut-off valves are provided. To hook up supply lines, unscrew valves from braided line. Using thread sealant, screw valve to stub outs at bottom of tower. Then reconnect braided line using ...

Page 24

Step 13 turn on water supply and check for leaks. Correct any leaks before installing tower cover. Step 14 install tower cover as shown. Insert cover at top first. 3 wall: tower and curved glass installation tower cover insert this side first tower cover tower top plate step 15 seal all around the b...

Page 25

2 & 3 wall operation 23 stop release temperature valve the temperature of the mixed water is adjusted by means of the graduated handle. This handle has a safety stop set at 100 ° f (38 ° c). To increase the temperature, press the red button to release the stop and keep turning the handle. Shower hea...

Page 26

24 2 & 3 wall maintenance to remove any lime scale from the shower head and body sprays , rub with your finger the outer ring of nozzles on the shower head and all nozzles on the body spray. To clean the foot temperature tester, unscrew the nozzle and back flush the wire mesh filter. Do not use meta...

Page 27

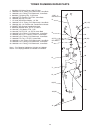

Tower fixtures repair parts 1. C546000 lock nut, 1/2" npt wp (5x) 2. G559000 ring compression ss (5x) 3. G560000 washer rubber (5x) 4. U546000 (part of u547000) nut transfer valve, chrome 5. U566000 gasket, 1.41 id x .063 thick 6. U547000 valve, mixer/transfer assembly 7. U550827 (part of u547000) 5...

Page 28

Tower plumbing repair parts 1. A944000 (9x) spring clamp, .625 od hose 2. U405000 l=31.0" tubing, pvc reinforced, 10mm barb 3. U405000 l=5.5" tubing, pvc reinforced, 10mm barb 4. A945000 (7x) spring clip, .75 od hose 5. U400000 ftg, straight, 1/2" fts x 10mm barb 6. U403000 (2x) cap, 1/2" fst 7. U71...

Page 29

1 2 3 4 5 (2x) 6 (2x) 7 (6x) 8 9 10 11 12 13 (6x) 15 17 16 18 20 21 14 (6x) 1. U134827 rail back walk-in 2. U133827 rail 2 wall walk-in 3. U245827 rail assembly walk-in 4. U149000 bracket, mounting rail 5. U119827 wall post, panel 6. U138827 cap, wall post 7. J686000 tape high bond, 2 sided 8. U1590...

Page 30

3 wall unit repair parts 1. U134827 rail back walk-in 3 wall 2. U245827 rail assembly walk-in 3 wall 3. U149000 bracket, mounting rail 4. U119827 wall post, panel 5. U138827 cap, wall post 6. U124xxx tower cover 7. U257xxx final shell, tower, walk-in 3-wall u126xxx tower body walk-in u136xxx cap, to...

Page 31

Jacuzzi whirlpool bath p.O. Box 702168 dallas, tx 75370-2168 warranty coverage jacuzzi whirlpool bath (the “company”) offers the following express limited warranty to the original purchaser of any jacuzzi whirlpool bath designer collection bath product (“unit”) who purchases the product for personal...

Page 32

Responsibilities of others inspecting the unit prior to installation is the responsibility of the installer or building contractor who acts on behalf of the user. They are responsible for ensuring the unit is free of defect or damage. Notices are placed on and in the unit and on the shipping carton ...