Summary of WREX

Page 1

Setup instructions for wrex.

Page 2: Jaeco

Jaeco wrex w ilmington r obotic ex oskeleton the jaeco wrex is a functional upper limb orthosis designed to enhance movement for individuals with neuromuscular disabilities. Its state-of- the-art construction utilizes a light weight exoskeleton that approximates normal human anatomy. Linear elastic ...

Page 3: Table of Contents

Table of contents section 1: parts description 1-1: mount parts description 1-2: arm part description section 2: mount attachment 2-1: mount base attachment 2-2: mount link attachment 2-3: mr-10 mount base attachment 2-3: preparing mount base 2-4: mount base attachment 2-6: mr-8 mount base attachmen...

Page 4: Section

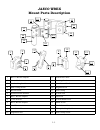

Section 1 part description.

Page 5: Jaeco

1 mr-10 mount adapter 13 attachment hole 2 moveable jaw 14 locking knob 3 jaw locking set screw 15 arm mount shaft 4 base clamp screw 16 alignment pin 5 mount screw 17 arm clamp 6 reinforcement washer 18 3 inch arm 7 mr-7 mount adapter 19 joint pin 8 t-nut screws 20 4 inch mount arm 9 mr-8 mount ada...

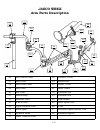

Page 6: Jaeco

Jaeco wrex arm parts description 26 pitch mount shaft 38 elevator j-link 27 pitch pivot 39 elbow pivot 28 pitch pivot cover 40 elbow j-link 29 pitch link 41 band cradle 30 roll pivot 42 forearm pivot 31 lateral stop 43 forearm link 32 shoulder link 44 slide saddle 33 wrex level 45 band spool pivot 3...

Page 7: Section

Section 2 mount attachment.

Page 8: Mount Base Attachment

2-1 mount base attachment the wrex can be attached to most common wheelchairs and mobility seating systems utilizing one of the three mount bases provided with the arm. These are the same attachment systems that are the basis of our jaeco mount relocator. It is essential that you identify the best a...

Page 9: Mount Link Attachment

Mount link attachment the mount link for the wrex is designed so that each of the three articulation; at the mount base, at the link joint and at the pitch mount shaft can pivot 360 degrees. This will allow for the ability to locate the pitch mount shaft in a large variety of locations to optimize i...

Page 10: Mr-10

Preparing mount base mr-10 mount base installation moveable jaw base clamp screws jaw locking set screws arm mount base locking knob 1. Orient the arm mount base as in illustration above. Insert the mount base screw (supplied with arm mount base) thru the attachment hole to the mr-10 mount adapter. ...

Page 11

4. Loosen but do not remove the locking knob on the arm mount base. 5. Position the mount link so that the alignment pin in the arm mount shaft is aligned with the alignment slot of the arm mount base. Insert the shaft into the base and tighten the locking knob. 6. Preposition the mount links so tha...

Page 12

7. Snug but do not tighten the six clamp screws using the large t-wrench. Add enough tension so that the joints do not move easily but can be repositioned if required to optimize the arm alignment. Note: do not tighten the clamp locking set screws at this time. 8. Hold the pitch mount shaft so that ...

Page 13: Mr-8

Preparing mount base mr-8 mount base installation for use on some invacare and motion concept seating systems note: adjustments in position may be necessary for optimal function. Mr-8 mount base adapter attachment hole t-nut locking knob arm mount base 1. Locate and mark an area 2 to 8 inches below ...

Page 14

1. Using the large t-wrench loosen, do not remove, the two t-nut screws on the mr-8 mount adapter. 2. Insert the t-nut into keyed back post channel and position the mr-8 mount adapter at the marked location (see preparing mount base #1). Tighten the two t-nut screws. Note: it may be necessary to rem...

Page 15

Optional side attachment 2-8 1. Using the large t-wrench l oosen, do not remove, the two t-nut screws on the mount adapter. 2. Insert the t-nut into keyed back post channel and position the mr-8 mount adapter at the marked location (see preparing mount base #1). Tighten the two t-nut screws. 3. Orie...

Page 16

6. Preposition the mount links so that the mount shaft base that receives the pitch mount shaft is located in the lateral 1/3 of the clients torso on the side which you intend to use the wrex arm. 7. Snug but do not tighten the six clamp screws using the large t-wrench. Add enough tension so that th...

Page 17: Mr-7

2-10 mr-7 mount base installation for use on some permobil and other seating systems preparing backrest and mount base mr-7 mount base adapter mount screw reinforcement washer 1. Remove backrest cushion. 2. Tape the template on the back of the backrest 1 ½ to 2 inches down from upper edge and as clo...

Page 18

6. Using the large t-wrench remove the two mount screws with reinforcement washers from the mr-7 mount base. Insert the screws with reinforcement washers through the drilled holes and into the mr-7 mount base. Tighten the two mount screws 7. Loosen but do not remove the locking knob on the mount bas...

Page 19

2-12 10. Snug but do not tighten the six clamp screws using the large t-wrench. Add enough tension so that the joints do not move easily but can be repositioned if required to optimize the arm alignment. 11. Hold the pitch mount shaft so that the black pitch pivot is at the proximal end, the hole th...

Page 20

2-13 1. Lay the mount arm flat on work surface. 2. Using the large t-wrench remove the two clamp screws and the arm clamp from the 4 inch mount arm. 3. Rotate the 3 inch arm and position the 4 inch mount arm onto the joint pin as shown. Replace the arm clamp and the two clamp screws. Tighten the cla...

Page 21: Section

Section 3 wrex arm setup.

Page 22

Measuring and presetting arm components the wrex is designed for optimum functionality when all of its exoskeletal articulations can approximate the patients anatomical joints. Although this can not be exact, careful measurement and pre-fitting of the arm components will maximize the outcome. We rec...

Page 23

Select and pre-fit forearm support attach forearm support to wrex arm 1. Measure the distance from the olecranon to the ulna styloid then subtract one inch. Insure size and side is correct from the chart attached page 4-8. 2. Place the clients arm into the forearm support. When the clients arm is st...

Page 24

Measure and preset humeral elevating links 1. On the side you plan to fit the orthosis take a measurement from the head of the humerus to the lateral epicondyle. Record this measurement. 2. Lay the wrex arm flat on a work surface. 3. Using the medium t-wrench remove the four screws that connect the ...

Page 25: Section

Section 4 fitting and adjustments with client.

Page 26

Attaching the wrex arm to the wheelchair mount note: the wrex arm is designed to have as little friction as possible at all of its articulations. For client safety please be sure to control the entire device as you are attaching the arm and making adjustments. Transfer the patient into the wheelchai...

Page 27

Position wrex shoulder joint 1. Using the large t-wrench, while supporting the wrex arm, loosen the screw on the pitch pivot adjustor. 2. With the aid of the bubble level position the pitch link so that it is horizontal and parallel to the floor. 3. Tighten the pitch plate adjuster screw 4. Slide th...

Page 28

Caution: do not put the clients arm into the orthosis until all previous steps in this section have been completed. 1. Using the large t-wrench loosen the screw for the roll pivot adjustment. 2. With the aid of the bubble level roll the adjustment medially or laterally until the bubble is centered. ...

Page 29

Place the clients arm into the wrex because the wrex operates with band tension it must carefully be handled during arm placement to prevent injury check for appropriate alignment 1. Roll pivot joint should be 1½ inch above the top of the shoulder to allow full shoulder range of movement. 1. Adjust ...

Page 30

Application of elastic bands the number of bands varies depending on the weight of the clients arm and their strength the optimal number of bands allows for the client to move through their maximal range of movement. The client must be able to return to starting location to avoid the arm floating in...

Page 31

Basic adjustment for functionality ask the client to move horizontally from side to side then toward and away from the body across a tabletop. To improve reach from side to side: 1. Support the clients limb 2. Loosen the roll adjustment screw 3. Rolling the arm toward the midline to aid in reaching ...

Page 32

Desired functional outcomes of the wrex • ability to access face for – oral hygiene – feeding – washing face – shaving – wiping nose – adjusting glasses – etc. • ability to access environment for – using computer – handwriting – retrieving items from countertop, closet, etc. Removing the arm from th...

Page 33: Finalizing Setup

Finalizing setup check overall setup • again, observe clients shoulder and forearm to be sure they are at a comfortable, level, resting position. (if the client is uncomfortable, wrex wear time and use will be limited.) • make adjustments as necessary to achieve functional use. Secure the settings e...

Page 34: Forearm Support Size Chart

4-9 forearm support size chart wfs-6: ex.Small elbow to wrist crease length: minimum - 6" maximum - 7-1/2" wfs-8: small elbow to wrist crease length: minimum - 8-1/2" maximum - 9-1/2" wfs-9: medium elbow to wrist crease length: minimum - 9-1/2" maximum - 10-1/2" wfs-10: large elbow to wrist crease l...

Page 35: Jaeco

Jaeco wrex order form 1 bill to: customer name address city state zip phone ( ) fax ( ) your name 2 ship to: customer name address city state zip attention department 3 method of payment: check (payable to jaeco orthopedic) bill our account: purchase order number credit card: visa mastercard 4 shipp...

Page 36: 214 Drexel

214 drexel hot springs, ar 71901 ph: 501-623-5944 fax: 501-623-0159 email: info@jaeco-orthopedic.Com www.Jaeco-orthopedic.Com january 18, 2007.