Instruction read these instructions carefully before use. Please keep these instruction after assembling. Spacewalker ord. No. 00 6137 gb safety precautions this radio control model is not a toy! Not suitable for persons under 14 years! * first-time builders should seek advice people having building...

2 sicherheitshinweise contents safety information 2 general information 2 technical data 2 highlights 2 box contents 3 building the model 3 - 15 control throws and centre of gravity 15 recommended accessories 16 plans 17 / 18 safety information flying models are not toys, and should only be operated...

3 kit contents: • cnc laser cut formers and ribs, strip wood, selected light weight balsa sheet and aircraft grade plywood. • fitting kit including wheels, undercarriage, horns and hinges. • clear canopy. • instructions. 1. For the drive-in nut to have more support, the holes are doubled with a ply ...

4 5. Wing support, rib and screw holder are mounted. 6. Turn the frame. 7. The battery board and motor support are vertical to each other and mounted to the frame. 9. Insert the both left over fuselage pieces. Every part should be aligned, fixed and glued. The top fuselage piece is glued in place fo...

5 11. 3 x 4 mm borders (brown edge facing up) are glued.. Tip: the borders are 1 mm further up compared to the frame. They are sanded slightly. 12. A border is glued to the centre of the underside. Looking at part f4, it is sanded from the border to the outside. 13. The side borders are fitted and g...

6 17. The fuselage nose is sanded. 18. Lay the lid frame in the fuselage and placed the balsa pieces on top. To prevent lid frame being stuck to the fuselage, a sheet of paper or plastic wrap is placed in between. 3 x 4 mm strips are drawn (note position). 19. The cover is laid flat on the building ...

7 23. To bend the undercarriage wire, use the cut-out from the support as reference. 24. It is recommended to apply a dummy empennage made of 4 mm balsa rest. It is applied and removed later. This will help you to align the empennage. 25. Small pieces of 6 mm balsa are cut, placed on the fuselage an...

8 zusammenbau 29. The bowden wire (not incl.) is installed. 30. Assembly elevator and rudder servo. 31. Carve 1,5mm into the ribs the covering foil will lay on later. This will avoid edges in the foil later on. 33. Both elevator pieces are connected with 1,5mm spring wire. 32. Mount the rear wheel w...

9 35. Template for cockpit window. 36. The cockpit window is folded along the diagonal edge. 37. The undercarriage covering is made of 3 layers of balsa. The first piece is made of 1,5 mm balsa with a little overlay. For filling, use 3 mm balsa. 39. “cylinder head” 38. Last step is to apply a 1,5 mm...

10 zusammenbau 41. Sanded wheel pants. 42. The rudders are sanded either on one side for paper hinges or both sides for plastic hinges.. 43. Supports for the wing spar are glued into place. 45. Insert the last wing spar. Tip: the wing can also be built on the plan. However, a line in right angle on ...

11 47. The servo frame is 1,5 mm higher than the wing spar. The planking later one will even it out. 48. Rib no. 1 in a right angle to the wing spar. 49. Some ribs are higher than the wing spar. Also this part is evened out later on by planking.. 51. The top planking is fixed with tape. 50. Start wi...

12 zusammenbau 53. If all is dried, start with the inner/ lower planking. 54. The final edge is filled approx 25 mm upwards so the wing screws do not push through. 55. Final edge and ribs are supported with small balsa triangles. 57. Now the leading edge can be applied and sanded. Before doing so, m...

13 59. Sand the final edge. 60. The tip is made of 4 layers with 6 mm wood each layer. 61. Sand the curved edge. 63. Now the curved edge is sanded right to its original shape. 62. Curved edge 64. Cut out the aileron and sand it..

14 zusammenbau 65. Now the wings can be put together. 66. If the main wings do not fit the fuselage… 67. … a 4 mm piece of wood is applied until… 69. To avoid creases in the covering foil around the rudder horn, a frame is build from 1,5mm balsa. Once the model is covered this gap can be cut out for...

15 71. Assemble the elevator and rudder servo as shown. 72 the finished build shell. Set-up: aileron: +/- 10 mm deflection elevator: +/- 10 mm deflection rudder: +/- 25 mm deflection cg: 40 mm from the nose down thrust ~ 2° down (already installed) traction ~ 2 - 2,5° to the right (depending on moto...

16 plane - the original sized plan can be found on the dvd.

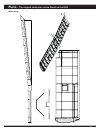

17 plane - the original sized plan can be found on the dvd 48 +3mm unterlegen 0mm 0mm 0mm main wings.

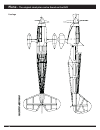

40 2° cg 2° spacewalker i 18 plane - the original sized plan can be found on the dvd fuselage.

19.

All rights reserved. Copyright jamara e.K. 2011 copying or reproduction in whole or part, only with the expressed permission of jamara e.K. Jamara e.K. Inh. Erich natterer am lauerbühl 5 - de-88317 aichstetten tel. +49 (0) 75 65/94 12-0 - fax +49 (0) 75 65/94 12-23 info@jamara.Com www.Jamara.Com ord...