Slugger ™ 2x2 ™ slugger portable magnetic drilling machine operator’s manual eye protection required hearing protection required model #17980 (120v) or #17982 (240v) serial # date of purchase warning! Before use , be sure everyone using this machine reads and understands all safety and operating ins...

Slugger ™ portable magnetic drilling machine congratulations on your purchase of a slugger™ portable magnetic drilling machine. Slugger drilling machines are designed to deliver fast, efficient hole drilling performance in portable applications. Please take a moment to complete and mail your product...

Important safety instructions warning! When using electric tools , basic safety precautions should always be followed to reduce risk of fire , electric shock and personal injury . Read and save all instructions for future reference. 1. Keep work area clean • cluttered areas and benches invite injuri...

13. Maintain tools with care • keep tools sharp and clean for better and safer performance. • follow instructions for lubricating and changing accessories. • inspect tool cords periodically and if damaged, have repaired by authorized service facility. • inspect extension cords periodically and repla...

1. If you require an additional manual, please contact jancy engineering at (563) 391-1300 for a free copy. 2. Never place hands, fingers, gloves or clothing near cutting area or rotating machine parts. 3. Always disconnect machine from power source before changing cutters, clearing chips, refilling...

Warning! Improperly connecting the grounding wire can result in electrical shock. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with tool. Never remove the grounding prong from the plug. If the cord or plug is da...

Remove all contents from packaging and inspect to ensure no damage was incurred during shipping. Your 2x2 package should include the following: operating instructions ( before you begin ) description part # qty operator’s manual lit102b 1 shunt instructions 06958 1 warranty card 0070342 1 2.5 mm hex...

1. Select correct pilot pin and place in cutter shank from the rear, align flats on cutter shank with arbor body set screws, insert cutter into arbor body. 2. Tighten set screws securely on cutter shank flats. Note: set screws should be recessed in arbor body when tight. 3. The surface you are worki...

1. Magnetic base not holding securely • material is too thin to engage magnet. • surface of material being drilled must be free of chips, debris, rust and mill scale. • does size of cutter exceed machine’s rated capacity? • check magnet face for unevenness, nicks and burrs. • is welding equipment co...

1. The motor slide may require adjustment after machine has been in service. Loosen jam nuts using provided wrench. Using feed handles, position motor/slide assembly in the full up position. Using supplied hex key, equally turn adjustment screws clockwise to increase slide tension or counterclockwis...

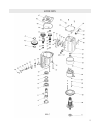

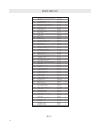

Machine parts list 11 item description part # qty 001 motor assembly 120v 07201 1 motor assembly 240v 07203 1 101 frame 07205 1 102 pressure plate 07004 1 103 d-ring strap 06796 1 104 nut, m5 0151181 5 105 sss, m5 x 25 07020 5 106 shcs, m6 x 20 0014102 3 107 washer, split m6 07016 3 108 label, gib a...

Machine parts list 12 item description part # qty 300 chip guard assembly 07026 1 301 guide plate 07213 1 302 flange plate 07214 1 303 scr,fhscs m6 x 12 054140 1 304 sfhms, m6 x 20 05mt404 1 306 shcs, m6 x 12 0070535 1 307 washer, split m6 07016 1 308 nut, m6 070308 1 611 bottle assembly 0151511 1 6...

Motor parts 13 rev.C.

14 motor parts list item description part # qty 1 retaining ring, internal 55w 07128 1 8 spindle 07129mt2 1 9 key, square 6 x 6 x 15 07127 1 10 bearing, 6006 07126 1 11 retaining ring, external 30z 07125 1 12 seal, spindle 28 x 47 x 7 07518 1 14 bearing, 6005 07122 1 15 gear case 07259 1 18 shcs, m5...

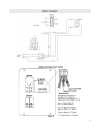

15 wiring diagrams rev. C.

Your distributor tel · 563.391.1300 or fax · 563.391.2323 2735 hickory grove road · davenport, iowa 52804 email · jancy@jancy.Com / web · jancy.Com lit102d ©10/05 description model # max diameter capacity depth usa5 120v 18066 2-3/8" 3" usa5 240v 18080 2-3/8" 3" jm101 120v 19020 1-3/8" 2" jm101 240v...