Installation and operation manual hhplus series pumps (models php & phpu) for your safety: this product must be installed and serviced by a professional service technician, qualified in pool/spa installation. The procedures in this manual must be followed exactly. Improper installation and/or operat...

Table of contents section 1. Safety information 1.1 safety instructions................................ 4 section 2. General information 2.1 introduction...........................................5 2.2 description........................................... 5 section 3. Preparation and location 3.1 p...

Page 4 1. Read and follow all instructions danger 2. Do not block pump suction, as this will cause severe or fatal injury if blocked with the body. Warning 3. To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times. 4. Do not attempt t...

Page 5 jandy® pumps section 2. General information 2.1 introduction this manual contains information for the proper installation, operation and maintenance of jandy ® hhplus pumps. Procedures in this manual must be followed exactly. To obtain additional copies of this manual contact us at 707-776-82...

Page 6 4.3 installation tips 4.3.1 if the pump is located below water level, it may produce higher pressure compared to an above water installation. Isolation valves must be installed before and after the pump to prevent back flow of pool water during any routine servicing that may be required. 4.3....

Page 7 jandy® pumps 5.3 electrical wiring 5.3.1 the pump motor must be securely and adequately grounded using the green screw provided. Ground before attempting to connect to an electrical power supply. Do not ground to a gas supply line. 5.3.2 wire size must be adequate to minimize voltage drop dur...

Page 8 section 7. Use and maintenance 7.1 general maintenance 1. The pump will collect any large debris present in the water at the pump basket. As debris accumulates it will begin to block the flow of water through the pump, and must be removed. The cleaner the basket is kept, the more effective an...

Page 9 jandy® pumps section 8. Troubleshooting 8.1 troubleshooting 8.1.1 jandy strongly recommends that you call a qualified service technician to perform any repairs on the filter/pump system. To locate a qualified technician, chack your local yellow pages or visit www.Jandy.Com and click on "produ...

Page 10 section 9. Specialty service jandy strongly recommends that you call a qualified service technician to perform any repairs on the filter/pump system. 9.1 blocked impeller 1. Turn off the pump. Switch off the circuit breaker to the pump motor. 4. Pull the motor and mounting bracket out of the...

Page 11 jandy® pumps 6. Remove the shaft cover on the back of the motor by prying it off with a flat head screwdriver. This will allow a wrench to be placed on the motor shaft and prevent it from rotating while the impeller is removed. 7. Turn the impeller counterclockwise, while holding the motor s...

Page 12 mounting bracket side of the mechanical seal apply silicone sealant around outside edge figure 6. Mechanical seal replacement figure 7. Mechanical seal replacement 9.4 mechanical seal replacement 1. Follow steps 1-7 of section 9.2, "removing the impeller." 2. Remove the ceramic seal from the...

Page 13 jandy® pumps 9.5 motor replacement 1. Have a qualified service technician or electrician properly disconnect the electrical wiring at the pump motor. 2. Follow steps 1-7 of section 9.2, "removing the impeller." 3. Remove the four (4) bolts holding the mounting bracket to the motor. Before re...

Page 14 key size order no. Description (hp) part no: 1 motor, single-speed jhp/php .75 r0556101 1 motor, single-speed jhp/php 1.0 r0556102 1 motor, single-speed jhp/php 1.5 r0556103 1 motor, single-speed jhp/php 2.0 r0556104 1 motor, single-speed jhpu/phpu 1.0 r0556101 1 motor, single-speed jhpu/php...

Page 15 jandy® pumps figure 9. Php & phpu exploded view 1 16 (qty 6) 12 8 9 19 (qty 2) 18 6 14 15 7 17 (qty 4) 5 10 3 4 11 13 (qty 2) 20 18 2.

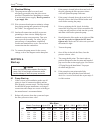

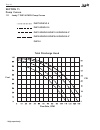

Page 16 section 11. Pump curves 11.1 jandy™ php & phpu pump curves flow rate, gpm psi feet total discharge head php.75/phpu1.0 php1.0/phpu1.5 php1.5/phpu2.0/php1.5-2/phpu2.0-2* php2.0/phpu2.5/php2.0-2/phpu2.5-2* php3.0 * high-speed only.

Page 17 jandy® pumps section 12. Pump dimensions 12.1 jandy ® php & phpu pump dimensions model hp voltage pipe carton overall length (a) no. Size weight franklin century php.75 .75 115/230 2" 44lbs. 26 " 26½" php1.0 1.0 115/230 2" 49lbs. 26½" 27" php1.5 1.5 115/230 2" 56lbs. 27¼" 28¼" php2.0 2.0 230...

Page 18 notes:.

H0558800- * ul 1081 csa c22.2 no 108-m89 *6000 condor drive, moorpark, ca, usa 93021 • 707.776.8200 fax 707.763.7785 480 s. Service road west, oakville, ontario, canada l6k 2h4 • 905.844.8233 fax 905.844.2635 litho in u.S.A. © water pik technologies, inc. 0802 for technical support call 707.776.8200...