- DL manuals

- Janome

- Sewing Machine

- 3160QDC -

- Service Manual

Janome 3160QDC - Service Manual

Summary of 3160QDC -

Page 1

Service manual 2160dc, dxl603.

Page 2

Index what to do when .............................................................................................................................. 1 - 3 changing external parts face cover .................................................................................................................

Page 3: What to Do When

1 condition cause how to fix reference 1. Skipping stitches 1. Needle is not inserted properly. 2. Needle is bent or worn. 3. Incorrectly threaded. 4.Needle or thread are inappropriate for the fabric being sewn. 5. Sewing on stretch fabric. 6. Inappropriate needle bar height. 7. Inappropriate needle...

Page 4

2 condition cause how to fix reference 3. Breaking upper thread. 1. Initial sewing speed is too fast. 2. Thread path is incorrect. 3. Needle is bent or dull. 4. Top tension is too strong. 5. Needle size is inappropriate for fabric. 6. Needle eye is worn. 7. Needle hole in needle plate is worn or bur...

Page 5

3 condition cause how to fix reference 6. Noisy operation 1. Backlash between hook gear and lower shaft gear is too great. 2. Lower shaft gear is loose. 3. Inappropriatte belt tension. 4. Not enough oil. 5. Upper shaft gear is loose. Eliminate the backlash. Eliminate the looseness. See part removal ...

Page 6: Changing External Parts

4 changing external parts face cover to remove: 1. Loosen the setscrew q and lift the face cover to disengage the rib on the inside. Remove the face cover w . To attach: 2. Follow the above procedures in reverse. Q w.

Page 7: Changing External Parts

5 free-arm cover to remove: 1. Loosen the setscrew q and w . Move the free-arm cover to the left. Remove the free-arm cover. To attach: follow the above procedures in reverse. Changing external parts q w e.

Page 8: Changing External Parts

6 changing external parts front cover (1) to remove: 1. Remove the face cover and free-arm cover (see page 4 and 5). 2. Remove the setscrews (a) q (2 pcs.). 3. Remove the setscrews (b) w (5 pcs.), back cover e . 4. Remove the setscrews (c) r (2 pcs.). 5. Disconnect all the connectors from the circui...

Page 9: Changing External Parts

7 changing external parts front cover (2) 4. Disengage the front cover and rear cover hooks. 5. Remove the front cover. To attach: follow the above procedures in reverse..

Page 10: Changing External Parts

8 changing external parts rear cover to remove: 1. Remove the face cover and free-arm cover (see page 4 and 5). 2. Remove the setscrews (a) q (4 pcs.). 3. Remove the setscrews (b) w (5 pcs.) and back cover. 4. Remove the setscrews (c) e (2 pcs.). Remove the rear cover. To attach: 5. Follow the above...

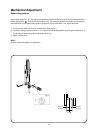

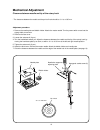

Page 11: Mechanical Adjustment

9 6.0mm mechanical adjustment presser bar height the distance between the bottom of the presser foot in up position and the needle plate should be 6.0 mm. 1. Remove the face plate and needle. 2. Lower the feed dog below the needle plate. Place a block 6 mm thick under the presser foot and lower the ...

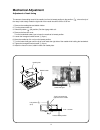

Page 12: Mechanical Adjustment

10 0.2 mm or more 0.2 mm or more A=B mechanical adjustment needle drop position set the stitch pattern to “ ”. The standard needle drop position should be at center of the needle plate hole q . Select zigzag stitch “ ”, and set the stitch width at “5.0”. The clearance between the needle and the edge...

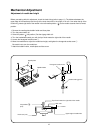

Page 13: Mechanical Adjustment

11 the amount of ascending travel of the needle bar from its lowest position to the position ( ) where the tip of the rotary hook exactly meets the right side of the needle should be 3.25 to 3.55 mm. 1. Remove the needle plate and bobbin holder. 2. Turn the power switch on. 3. Select the pattern (le...

Page 14: Mechanical Adjustment

12 before proceeding with this adjustment, check the hook timing (refer to page 11). The distance between the upper edge of the needle eye and the tip of the hook should be in the range of 1.6 to 2.0 mm when the tip of the hook timing meets right side of the needle in the left needle position ( ) as...

Page 15: Mechanical Adjustment

13 adjustment procedure: 1. Remove the needle plate and bobbin holder. Attach the master needle. Turn the power switch on and set the zigzag width at maximum. 2. Remove the face cover. 3. Loosen the setscrew a (2 pcs.). 4. Turn the handwheel toward you. Adjust the clearance between the needle and th...

Page 16: Mechanical Adjustment

14 the highest position of the feed dog should be between 0.80 and 0.90 mm from the surface of the needle plate. 1. Lower the presser foot and turn the power switch on. 2. Turn the handwheel toward you to set the feed dog at the highest position. 3. Remove the free-arm cover. 4. Loosen the setscrew ...

Page 17: Mechanical Adjustment

15 1. Use a hexagonal socket screw (4 x 6). Insert the screw to the hole b. Tighten the hexagonal socket screw as far as it goes. 2. Loosen the setscrew c.(left screw) 3. Turn hexagonal socket screw to adjust the feed dog (should be parallel to the surface of the needle plate). 4. Tighten the setscr...

Page 18: Mechanical Adjustment

16 mechanical adjustment top tension the top tension should be between 65 and 80g when pulling the thread up in the direction of c. * use polyester sewing thread #50 (white). * if it is not within the above limit, adjust as follows. 1. Set the tension dial “auto”. 2. Remove the cover. 3. Lower the p...

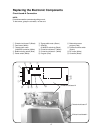

Page 19

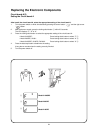

17 circuit board-a connection note: do not disconnect the connectors by pulling on cord. To disconnect, grasp the connector, not the cord. Replacing the electronic components t i o !0 !1 !2 !3 !4 printed circuit board a printed circuit board f printed circuit board l q printed circuit board p (black...

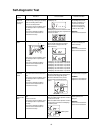

Page 20: Self-Diagnostic Test

18 to enter self-diagnostic mode: preparation: 1. Turn the power switch off. 2. Move the bobbin winder spindle to the left. 3. Raise the feed dog. 4. Set the speed control lever to the left. 5. Remove the presser foot and raise the presser foot lifter. 6. Turn the hand wheel toward you to raise the ...

Page 21: Self-Diagnostic Test

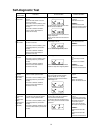

19 correct condition sewing lamp and lcd backlight lits. Lcd displays “01”. Step and items to check 01) function of lcd, buzzer and lamp procedure turn on the power switch while simultaneously pressing the start/stop button and locking stitch button. Press the start/stop button. If the result is cor...

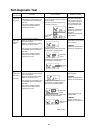

Page 22: Self-Diagnostic Test

20 correct condition lcd displays “sc 05”. Buzzer sounds when presser foot lifter is raised or lowered. The presser foot symbol appears when the foot lifter is lowered. Step and items to check 05) presser foot lifter switch procedure raise or lower the preser foot lifter. If the result is correct co...

Page 23: Self-Diagnostic Test

21 correct condition lcd displays “sc 08”. Step and items to check 08) foot control procedure attach the foot control to the sewing machine. Depress the foot control as far as it goes, then release it. If the result is correct condition, press the start/stop button to proceed the next step. If the r...

Page 24: Self-Diagnostic Test

22 self-diagnostic test buzzer sounds after few seconds when the self-diagnostic test has been finished. The test result has been determined. Correct: buzzer sounds and lcd displays “00” defective: caution buzzer sounds and lcd displays the defective part number. Refer to page 19-21 and fix the defe...

Page 25

23 circuit board-a (1) to remove: 1. Remove the front cover. (see pages 6 – 7) 2. Pull out connectors from the circuit board-a. 3. Remove the screws (6pcs.) and the circuit board-a. To attach: 1. Follow the above procedures in reverse. Note: do not disconnect the connectors by pulling on cord. To di...

Page 26

24 circuit board-a(2) setting the circuit board a replacing the electronic components after install the circuit board a, select the appropriate setting of the circuit boad a. 1. Turn the power switch on while simultaneously pressing left cursor button “ ” and the right cursor “ ” button. 2. After th...

Page 27

25 driving motor to remove: 1. Remove the front cover. 2. Remove the setscrews (2pcs.) and the driving motor and the belt. To attach: 1. Install the driving motor and the motor belt. Tighten them with setscrews (2pcs.) lightly. 2. Move the motor up or down to adjust the motor belt tension. The belt ...

Page 28

26 switching regulator unit to remove: 1. Remove the front cover and the rear cover. 2. Remove the setscrews a (3 pcs.) and the switching regulator. 3. Remove the setscrews b (4 pcs.). To attach: 4. Follow the above procedures in reverse. Replacing the electronic components switching regulator setsc...

Page 29: Mechanical Adjustment

27 bh sensor 1.6 mm gap to enter adjusting mode mechanical adjustment adjusting buttonhole lever position to adjust the buttonhole lever guide: 1. Enter the buttonhole sensor adjusting mode. (see below. The lcd should display bh symol.) 2. Remove the face cover (see page 4) and loosen the setscrew (...

Page 31: Parts List

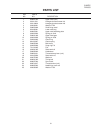

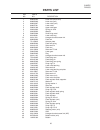

29 parts list key parts no. No. Description 2160dc dxl603 parts list model:2160dc, dxl603.

Page 32: Parts List

30 parts list 2160dc dxl603 1 2 3 4 4 5 5 6 7 8 8 9 10 10 11 12 13 14 15 16 16 18 19 20 17 21 22 16 16 25 23 24 2 25.

Page 33: Parts List

31 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 808601005 000111201 000112800 000036201 508054008 820166001 808003001 000004200 508021006 000024206 502064003 661024007 508055009 000002806 731312005 000081005 508056000 508634...

Page 34: Parts List

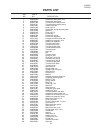

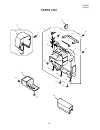

32 parts list 2160dc dxl603 1 2 3 4 5 6 7 8 9 12 13 14 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 15 33 34 35 36 37 38 39 40 41 42 44 44 45 46 48 47 49 50 43 51 52 53 54 54 56 55 57 9 10 58 9 44 11 59 61 61 62 63 66 9 65 64 60

Page 35: Parts List

33 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 808640006 808006200 808007005 503041007 502024001 000...

Page 36: Parts List

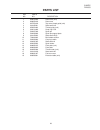

34 parts list 2160dc dxl603 1 2 3 23 24 26 27 28 28 25 36 29 30 31 32 33 34 35 37 14 14 38 40 41 39 43 44 45 14 46 42 47 48 28 25 49 50 4 5 16 19 10 15 11 7 7 6 10 8 19 17 21 12 14 9 13 18 22 20

Page 37: Parts List

35 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 808632005 808629009 808634007 808027001 508021006 000004200 000038502 508054008 820166001 000111201 8...

Page 38: Parts List

36 parts list 2160dc dxl603 6 6 6 7 2 3 5 4 7 1 20 24 21 22 23 25 26 28 29 30 31 32 33 34 27 7 35 37 38 39 36 7 42 41 43 7 44 7 40 40 8 11 9 10 12 13 14 15 16 17 18 19.

Page 39: Parts List

37 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 808618005 808077006 808078100 808079008 808080002 000002105 000081005 808626006 808067003 808068004 000163703 502015009...

Page 40: Parts List

38 parts list 2160dc dxl603 1 5 2 3 4 6 7 8 9 10 11 13 12 12 18 12 12 19 14 15 16 17 10 10 12 12.

Page 41: Parts List

39 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 808619006 808050106 827503108 000162001 650503403 000014409 502007008 502008009 000120203 739064003 502009000 000081005 822020503 808622105 808060202 840602006 000104108 808061007 808508001 rear...

Page 42: Parts List

40 parts list 2160dc dxl603 31 28 32 28 29 30 30 30 1 2 4 5 7 8 9 10 11 6 11 11 12 13 14 15 16 17 22 23 24 21 18 20 19 25 25 26 27 28 3.

Page 43: Parts List

41 parts list key parts no. No. Description 2160dc dxl603 808630106 808630405 808051200 808051705 808103002 808072104 808072403 808071103 808054100 808055008 808056102 000160700 808505008 000120203 808058104 808070102 808507000 000014306 808506009 808057000 735016307 000101828 000071013 000061205 63...

Page 44: Parts List

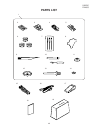

42 parts list 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 17 18 19 13 14 15 16.

Page 45: Parts List

43 parts list key parts no. No. Description 2160dc dxl603 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 808870007 822804118 829801002 825817009 822801001 102261000 639804000 653802002 802424004 647808009 822019509 829803004 625031500 102403109 753801004 856519004 830335004 830377008 c-1036 8088001...