Summary of 5200QDC

Page 1

Service manual mo200 model : mo200, 5200qdc.

Page 2: Contents

1 mo200 5200qdc contents service access (1) top cover, face cover .................................................... 2 service access (2) base, bed cover .................................................................. 3 service access (3) belt cover ................................................

Page 3: Service Access (1)

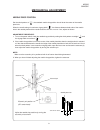

2 mo200 5200qdc service access (1) top cover to remove: 1. Remove the 2 setscrews (a) and setscrew (b), and remove the top cover. To install: 2. Follow the above procedure in reverse. Face cover to remove: 1. Remove the 2 setscrews (c) and remove the face cover. To install: 2. Follow the above proce...

Page 4: Service Access (2)

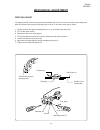

3 mo200 5200qdc service access (2) base to remove: 1. Remove the 4 setscrew (a) and the 2 setscrew (b), remove the base. To install: 2. Place the part c (concave part in the illustration) between the base and the arm boss. Install the base with the 4 setscrews (a) and the 2 setscrews (b). Bed cover ...

Page 5: Service Access (3)

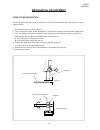

4 mo200 5200qdc service access (3) belt cover to remove: 1. Remove the setscrew (a), (b), and remove the belt cover. To install: 2. Install the belt cover with the setscrew (a) and (b). Setscrew (a) setscrew (b) belt cover.

Page 6: Service Access (4)

5 mo200 5200qdc service access (4) front cover to remove: 1. Remove the top cover and belt cover (see pages 2 and 6). 2. Loosen the setscrew (a), (b), (c), (d) and (e), remove the setscrew (f). (remove setscrews for the lump fixing plate when the setscrew (a) is hard to access.) 3. Disconnect the co...

Page 7: Service Access (5)

6 mo200 5200qdc service access (5) rear cover to remove: 1. Remove the top cover and belt cover (see pages 2 and 6). 2. Loosen the setscrews (a), (b), (c), and (d), then remove the setscrew (e). * to remove the cover, detach the presser foot lifter section first, with the presser foot lifter in the ...

Page 8: Mechanical Adjustment

7 mo200 5200qdc presser bar height and alignment when the presser foot is raised, the clearance between the presser foot and the needle plate should be 5.7- 6.3 mm. When the presser foot is lowered, the edge of the foot and the feed dog window on the needle plate should be parallel. 1. Remove the fa...

Page 9: Mechanical Adjustment

8 mo200 5200qdc mechanical adjustment needle drop position set the stitch pattern at " "; the standard needle drop position should be at the center of the needle plate hole. When the needle swings in maximum zigzag width " ", the distance between both ends of the needle hole in the needle plate and ...

Page 10: Mechanical Adjustment

9 mo200 5200qdc mechanical adjustment needle to hook timing when the machine is set the straight stitch pattern " " (left needle position), the amount of ascending travel of the needle bar from its lowest position to the position where the tip of the hook meets the right side of the needle should be...

Page 11: Mechanical Adjustment

10 mo200 5200qdc bobbin holder needle plate setscrew (a) needle setting groove tip of hook meets right side of needle needle #14 hook race 1.4-1.75 mm upper edge of needle eye hook race unit mechanical adjustment needle bar height the distance between the upper edge of needle eye and the tip of the ...

Page 12: Mechanical Adjustment

11 mo200 5200qdc test pin point of hook –0.1 to +0.05 mm hinge screw (c) setscrew (b) hook set plate setscrew (a) needle clearance to shuttle the clearance between the needle and the tip of hook should be -0.1 to +0.05 mm. Preparation: 1. Remove the needle plate, bobbin holder, and bed cover (see pa...

Page 13: Mechanical Adjustment

12 mo200 5200qdc mechanical adjustment backlash (between lower shaft gear and hook drive gear) jog the hook race back and forth to check rotary play. The standard play should be 0.8 mm (0.03") or less when the hook point is within the feed dog width. If play exceeds 0.8 mm, adjust as follows. Adjust...

Page 14: Mechanical Adjustment

13 mo200 5200qdc mechanical adjustment feed dog height the highest position of the feed dog should be between 0.8 to 0.9 mm from the surface of the needle plate when the pressure foot pressure adjusting lever is set at "3" and the presser foot is raised. 1. Set the pressure foot pressure adjusting l...

Page 15: Mechanical Adjustment

14 mo200 5200qdc mechanical adjustment zigzag synchronization the needle should start swing 8.2 mm above the surface of the needle plate when the machine is set for zigzag stitching. 1. Remove the front cover (refer to page 7). 2. Turn on the power switch, select the pattern no. 2 and set the machin...

Page 16: Mechanical Adjustment

15 mo200 5200qdc mechanical adjustment thread (polyester sewing thread (#50 white)) pull the thread at a speed of approx. 110 mm/sec. In the direction of arrow. Shaft set the thread tension dial at " a " needle thread tension the standard tension should be 80 to 95 grams when the tension dial is set...

Page 17: Mechanical Adjustment

16 mo200 5200qdc c d mechanical adjustment 1. Turn the power switch on while pressing the reverse button & auto-lock button. 2. Press the 8 button. (the standard mode shows up if you do not press the 8 button within 3 seconds.) setscrew cap 35mm stretch stitch feed balance when the number 8 is sewn ...

Page 18: Mechanical Adjustment

17 mo200 5200qdc x threader plate supporter (a) fig. 2 pin (b) adjustment of left or right direction threader plate nut setscrew (c) view from "x" setscrew (d) vertical adjustment fig. 3 mechanical adjustment replacement and adjustment of the needle threader plate if the hook of the threader plate i...

Page 19

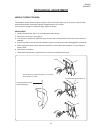

18 mo200 5200qdc buttonhole lever guide setscrew (a) bh lever adjusting screw buttonhole sensor clearance 1.6 mm setscrew (b) adjusting buttonhole lever position 1. Turn the power switch on while pressing the reverse button & auto-lock button. 2. Press the 4 button. (the standard mode shows up if yo...

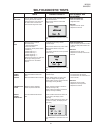

Page 20: Connector Diagram

19 mo200 5200qdc flexible cable connector diagram refer to the diagram for locating the connector post on the circuit board a : buttonhole sensor (blk) b : sewing light (wht) c : upper shaft sensor (blk) d : feed motor (blk) e : zigzag width motor (wht) f : dc motor (wht) g: power transformer (prima...

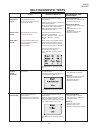

Page 21: Self Diagnostic Tests

20 mo200 5200qdc self diagnostic tests preparation: • turn off the power switch. • shift the bobbin winder spindle to the left. • raise the feed dog. • shift the speed control lever to the left. • remove the presser foot and raise the presser foot lifter. • turn the handwheel toward you to raise the...

Page 22: Self Diagnostic Tests

21 mo200 5200qdc correct results • the display shows "self check start". Lcd and led blinks. • beeps when enter the lcd & led check mode. Press clr button to proceed to the next step. The display shows "key" and the machine beeps. • beeps when enter the key check mode. • beeps when buttons or keys a...

Page 23: Self Diagnostic Tests

22 mo200 5200qdc correct results the display shows "sensor" and the machine beeps. • when the buttonhole lever is pulled, the screen displays "bh:h". • when the buttonhole lever is positioned in center, the screen displays "bh:l". • when the buttonhole lever is pushed, the screen displays "bh:h". Ea...

Page 24: Self Diagnostic Tests

23 mo200 5200qdc correct results the display shows "foot controller" and the machine beeps. • when the foot control is not depressed, the screen should display "000" to "016". • when the foot control is depressed fully, the screen should display "208" to "250". • when the plug is removed, the screen...

Page 25

24 mo200 5200qdc f1: ac125v 3.15a f2: ac125v 2.5a f3: ac125v 2.5a replacing printed circuit board a and fuses replacing printed circuit board "a" to remove: 1. Remove the front cover (see page 5). 2. Unplug the connectors from the printed circuit board "a". 3. Remove the 3 setscrews and remove print...

Page 26: And Slide Volume

25 mo200 5200qdc replacing printed circuit board "k" to remove: 1. Remove the front cover unit (see page 5). 2. Unplug the printed circuit board "l" connector and slide volume connector. 3. Remove the 9 setscrews and remove the printed circuit board "k". To install: 4. To install the printed circuit...

Page 27: And Printed Circuit Board L

26 mo200 5200qdc replacing printed circuit board "f" to remove: 1. Remove the front cover unit (see page 5). 2. Unplug the printed circuit board "f" connector and remove the cs ring. 3. Remove the two setscrews (a) and remove the printed circuit board "f". To install: 4. To install the printed circu...

Page 28: Motor Belt Tension

27 mo200 5200qdc replacing dc motor and adjusting motor belt tension to remove: 1. Remove the belt cover (see page 4). 2. Unplug the dc motor connector. 3. Remove the two setscrews, then remove the dc motor and belt. To install: 4. Lightly tighten the two screws. 5. Put the motor belt on the pulley ...

Page 29

28 mo200 5200qdc replacing machine socket (unit) replacing the machine socket to remove: 1. Remove the front and rear cover (see page 5 and 6). 2. Remove the two screws and remove the machine socket. To install: 3. To install the machine socket, follow the above procedure in reverse. Note pull out t...

Page 30: Replacing The Transformer

29 mo200 5200qdc replacing the transformer to remove: 1. Remove the board "a" (see page 24). 2. Remove the two setscrews and remove the transformer. To install: 3. To install the transformer, follow the above procedure in reverse. Note place the rear end of the transformer on the transformer support...

Page 31

30 mo200 5200qdc replacing the zigzag width motor to remove: 1. Remove the board "a" (see page 24). 2. Remove the two zigzag rod setscrews (a). Disconnect the connector from the board "a". 3. Remove the two setscrews (b) and remove the zigzag width motor. To install: 4. To install the zigzag width m...

Page 32

31 mo200 5200qdc replacing the feed motor to remove: 1. Remove the base cover (see page 3). 2. Remove the front cover (see page 5). 3. Disconnect the connector from the board "a". 4. Remove the snap ring (e-3). 5. Remove the two setscrews (a), (b) and remove the feed motor. To install: 6. To install...

Page 33

32 mo200 5200qdc replacing the needle plate motor to remove: 1. Remove the base cover (see page 3). 2. Remove the front cover (see page 5). 3. Disconnect the connector from the board "a". 4. Remove the two setscrews (a) and remove the needle plate motor. To install: 5. To install the needle plate mo...